CKD series FSM-H small flow sensor - BIBUS France

CKD series FSM-H small flow sensor - BIBUS France CKD series FSM-H small flow sensor - BIBUS France

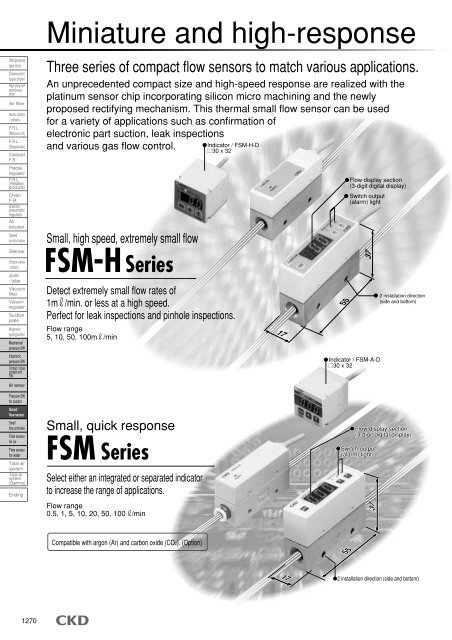

- Page 3: Small size flow sensor applications

- Page 7 and 8: FSM-H/FSM/FSM-V SeriesRefrigerating

- Page 10 and 11: FSM-VFM SeriesEven if the flow rang

- Page 12 and 13: Analog output type specifications (

- Page 14: Internal structure and parts listFS

- Page 17 and 18: Refrigeratingtype dryerDesiccanttyp

- Page 19 and 20: FSM SeriesRefrigeratingtype dryerDe

- Page 22 and 23: For argon, carbon dioxideHow to ord

- Page 24 and 25: FSM SeriesRefrigeratingtype dryerDe

- Page 26 and 27: FSM SeriesRefrigeratingtype dryerDi

- Page 28 and 29: FSM SeriesRefrigeratingtype dryerDi

- Page 30 and 31: FSM SeriesRefrigeratingtype dryerPr

- Page 32 and 33: FSM-H/FSM SeriesRefrigeratingtype d

- Page 34 and 35: FSM-H/FSM SeriesRefrigeratingtype d

- Page 36 and 37: Refrigeratingtype dryerDesiccanttyp

- Page 38 and 39: FSM-V SeriesRefrigeratingtype dryer

- Page 40 and 41: FSM-V SeriesRefrigeratingtype dryer

- Page 42 and 43: FSM-V SeriesRefrigeratingtype dryer

- Page 44 and 45: Refrigeratingtype dryerDesiccanttyp

- Page 46 and 47: FSM all series commonRefrigeratingt

- Page 48 and 49: FSM all series commonRefrigeratingt

- Page 50 and 51: FSM all series commonRefrigeratingt

Small size <strong>flow</strong> <strong>sensor</strong> applicationsRefrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filterActive in a wide variety of fieldsSmall size <strong>flow</strong> <strong>sensor</strong> is used for machines, automobiles, measuring instruments and precision devices, etc., inadvanced fields such as semiconductors and biomechanics, and in applications for medical materials and foods.Working fluidAuto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)EndingAmenityIndustrySensor applicationsLeakage inspectionPinhole inspectionConfirmation of ionizer purge gasWelding gas controlPurge gas <strong>flow</strong> controlContact confirmationVacuum confirmationAutomobile, etc.Liquid crystal Confirmation of ionizer purge gasCompatible with a variety of <strong>flow</strong> ranges.The inline speed controller (special order)can be used as a simple<strong>flow</strong> controller.Semiconductor Purge gas <strong>flow</strong> controlControl of purge gas is vital inmaintaining system performance.Miniature size makes this ideal forassembly into the device.Food/Medical Leakage inspectionThe inspection cycle time can be shortened.(Measurements can be made immediately after filling container.)Even when the pressure is extremely low, the output is made in proportion to thepinhole, so the acceptability can be judged and the status can be confirmed.Electric part Vacuum confirmation(1) High-speed response comparable to pressure <strong>sensor</strong> -- response is determined by the inner volume of piping and pressure. etc.(2) Flow detection eliminates adjustment and incorrect detections resulting from fluctuating pressure.(3) Nozzle and filter clogging is detected.(4) Control suction errors, such as inclined suction, by detection <strong>flow</strong>.Comparison with pressure <strong>sensor</strong> (Nozzle diameter:Small size <strong>flow</strong> <strong>sensor</strong> (using <strong>FSM</strong>-N-010) Pressure <strong>sensor</strong>(m /min)Flow difference : 830m /minPressure difference : 2kPa83070Very clear!0Suction0SuctionWelding argon and carbon gas <strong>flow</strong> controlCompatible with a variety of <strong>flow</strong> ranges.Machinery manufacturing Contact confirmationEven <strong>flow</strong>s that cannot be determined with apressure <strong>sensor</strong> because differential pressureis low are determined precisely.0.3, vacuum pressure: -70 kPa)Control of N2 gas for laser oscillator andsemiconductor manufacturing equipment1272

Refrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filterAuto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)Ending1274Safety precautionsPneumatic components: Warning and CautionsAlways read this section before starting use.Refer to Intro 67 for general precautions.Small size <strong>flow</strong> <strong>sensor</strong> <strong>FSM</strong>-H/<strong>FSM</strong>/<strong>FSM</strong>-V Series1. Working fluidDANGERDo not use this product with flammable fluids.When this product is used for liquefied gas, evaporategas. This product could fail if processing liquefiedgas.WARNINGThis product cannot be used as a business meter.This product does not conform to Measuring Laws, andthus cannot be used for commercial purposes. Use this<strong>sensor</strong> for factory applications.Do not use fluids other than the applicable fluid becauseaccuracy cannot be guaranteed.Compressed air from the compressor contains drainage- water, oil oxide, foreign substances, etc. - soinstall a filter, air dryer, and oil mist filter on the primaryside (upper stream side) of the <strong>sensor</strong>. The<strong>sensor</strong>'s meshing rectifies <strong>flow</strong> in the pipe. It doesnot filter out foreign substances, so provide a filter.Sourcepressure(Recommended circuit)AirdryerWhen using a valve on the primary side of this product,use only an oil-prohibit specification valve. This<strong>sensor</strong> could malfunction or fail if exposed to splatteringgrease, oil, etc.2. Working EnvironmentDANGERFilterRegulator Oil mist Flow <strong>sensor</strong>filter <strong>FSM</strong> Series(Micro alescer)Flammable environmentDo not use this product in an explosive gas environment.The structure is not explosion-proof, and explosionsor fires could occur.WARNINGCorrosive environmentDo not use this product in an environment containingcorrosive gases such as sulfurous acid.Design & SelectionAmbient temperature, fluid temperatureUse ambient temperature/fluid temperature in 0 theto 50°C within specified range.Do not use this product where temperature suddenly changes, even ifambient temperature is within specifications. Otherwise, dew could form.Maximum working pressure and specified <strong>flow</strong> rate rangeApplications exceeding the maximum working pressureand specified <strong>flow</strong> rate range may result in faults.Use this product only within the specified range.Drip-proof environmentThis product's protective structure is IP40 or equivalent. Donot install it where it could be exposed to water, salt, dust,or cutting chips, or a compressed or decompressed environment.This product cannot be used where the temperaturechanges sharply or in a highly humid environment whereinternal damage could be caused by dew condensation.3. Flow unitCAUTIONThis product's <strong>flow</strong> rate is measured at a mass <strong>flow</strong> unaffectedby temperature or pressure. The unit is /min., butthis is the display when the mass <strong>flow</strong> is converted to volumetric<strong>flow</strong> at 20°C 1 barometric pressure (101 kPa).4. Withstand pressureCAUTIONWithstanding pressure differs by each <strong>series</strong>. Selectiontime care must be taken.5. Over<strong>flow</strong>CAUTIONWith each <strong>series</strong>, no problem will occur in the <strong>sensor</strong>,even in an over<strong>flow</strong> double the measurement range.If dynamic pressure is applied near the maximumworking pressure (when a pressure difference exceedingthe maximum working pressure is applied betweenprimary and secondary sides), a problem could occurwith the <strong>sensor</strong>. If dynamic pressure is applied,such as when a workpiece is filled for leakage inspection,provide a bypass circuit or restrictor so that dynamicpressure is not applied to the <strong>sensor</strong>.

<strong>FSM</strong>-H/<strong>FSM</strong>/<strong>FSM</strong>-V SeriesRefrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filterAuto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)EndingCAUTIONFor metal body (stainless steel, aluminum) power supplies,use DC-stabilized power separated from the ACprimary side. Connect either the plus or minus side ofthe power supply to the F.G. A varistor (limit voltage 40V) is connected between the metal body internal powercircuit and metal body to prevent dielectric breakdownof the <strong>sensor</strong>. Do not conduct a withstand voltage testor insulation resistance test between the internal powercircuit and metal body. Disconnect wiring if this testingis required. An excessive potential difference betweenpower and metal body will burn internal parts.After installation, connecting and wiring the metal body,electrical welding of the device or frame, or short-circuitaccidents, etc., could cause welding current, excessivehigh voltage caused by welding, or surge voltage, etc.,to run through wiring or ground line connected betweensuch devices, damaging lines or devices. Do any worksuch as electrical wiring after removing this device anddisconnecting all electric wires connected to the F.G.PipingCAUTIONWhen piping <strong>FSM</strong>-H/<strong>FSM</strong>, check that the fluid's directionmatches the direction indicated on the component.With the <strong>FSM</strong>-V, check the direction of the arrow andpipe and install based on the fluid <strong>flow</strong> direction andswitch operation.(Example of piping) Switch typeSuctionBlowSuction nozzleVacuum filterWhen installing the <strong>sensor</strong> on piping, see the torquebelow so that excessive screw-in torque or load torqueis not applied to the connection port.(Reference value)Port threadM5Rc1/8 (G1/8)Rc1/4- +Suction side: + sideBlow side: -side(Example of piping) Analog typeSuctionBlowSuction nozzleVacuum filter1V5VSuction side: 3 to 5VBlow side: 3 to 1 VSwitch valveSwitch valveInstallation & AdjustmentFlow directionFlow directionFlow directionFlow directionTightening torque N·m0.5 to 1.03 to 56 to 8Vacuum sourceAir sourceVacuum sourceAir sourceAttach a wrench to metal sections when tightening pipesso that pressure is not applied to the resin section.Check that sealing tape or adhesive does not get insideduring piping.When winding fluorine resin sealing tape around threads, windsealing tape once or twice, leaving two to three threads openat the end of the screw. Press tape with a nail tip to stick it ontothreads.When using liquid sealing agent, leave one to twothreads open from the end, and avoid applying too much. Checkthat the sealing agent does not get on device threads.(Well)Seal tapeSolid/liquid sealantSolidliquidsealant(Poor) (Well) (Poor)SolidliquidsealantConnect a joint even when using the metal body typewith the out side opened. The port filter could comeoff.When using a push in joint, accurately insert tubeand confirm that it does not become dislocated evenwhen pulled. Cut tube at a right angle with a dedicatedcutter before use.Connect fiber tubing as follows (steps (1) to (5)).(1) Set the collar to the very back.(2) Cut the end of fiber tubingat a right angle.Collar(4) Insert fiber tubingat the last position.(5) Pull the collar forward tolock it in place.Clean out pipe with air blow to remove foreign substances,swarf, etc., before piping. The rectifier or <strong>sensor</strong>chip could be damaged if a large amount of foreignmatter, swarf, etc., occurs.(3) Pass the collar through, andconfirm that fiber tubing is correctlyinserted during work.1276

<strong>FSM</strong>-H/<strong>FSM</strong>/<strong>FSM</strong>-V SeriesAdjustmentCAUTIONIf switches are operated when <strong>flow</strong> is not stable, suchas pulsating, operation may be unstable. In this case,provide sufficient margin between the two setting valuesand avoid setting switches in an unstable area.Confirm that switch operation is stable before use.When setting the <strong>FSM</strong>-V Series switch output, use aflat-tip screwdriver fitting the trimmer groove (0.5 wide,1.9 long, and 0.45 deep) or a Phillips screwdriver for0 bits. The trimmer rotates 240 degrees and couldbreak if turned more or forced when turned.InstallationCAUTIONThis product can be installed in any direction; top,bottom, left, or right.<strong>FSM</strong>-H/<strong>FSM</strong> SeriesHorizontal installation (through hole used)Bracket installation (*bracket used)Vertical installation (bottom side female thread used)* A dedicated bracket(option) is available.(Model no.: <strong>FSM</strong>-LB1)(Refer to page 1298)<strong>FSM</strong>-V SeriesFor discrete miniature <strong>flow</strong> <strong>sensor</strong>Install using the two penetration holes (side.3.2) on theSeparate indicator <strong>FSM</strong>-H-D *, <strong>FSM</strong>-A-D * or <strong>FSM</strong>-V-D * commonA mounting bracket and kit (option) are available forinstalling the separated display.Bracket model no.: PPD3-KL-DBracket model no.: PPD3-KD-D2-nominal 3P tight: One side installation foot (radial)2-nominal 3P tightInstallation hole machining dimensions502-M318*33.50.318: Both sides installation foot (parallel)Installation hole machining dimensions4-M3Bracket model no.: PPD3-KHS-D : With panel mount bracket set and panel guardInstallation hole machining dimensionsBracket model no.: PPD3-KC : Operation protective coverProtective coverRefrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filterAuto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)EndingFour M3 (length 6mm) setscrews forfixing includedProtective cover holderSmallFlow <strong>sensor</strong>1277

<strong>FSM</strong>-VFM SeriesEven if the <strong>flow</strong> range is exceeded, analog output willcontinue."Hi" is displayed.Note that this is outside guaranteed precision.Analog output is also made when fluid <strong>flow</strong>s in reverse.(This exceeds the guaranteed accuracy. Excludingthe <strong>FSM</strong>-V Series.) If the signal could be confusedwith the forward direction signal, check thatthere is no problem with the PLC sequence program.Miniature inline filter <strong>FSM</strong>-VFM SeriesDo not use this product for vacuum circuits that couldcome in contact with acids, alkaline, carboxylic acid,other organic compounds, screw-lock agent, solvent,or alcohol solutions, or air containing these substances.The body could be damaged, and cause a hazardoussituation.Use designated tubing and plastic plugs.Tube outer diameter precision· Polyamide tube: Within 0.1mm· Polyurethane tube(Up to 6): Within 0.1mm( 8 and over): Within+0.1- 0.15 mm<strong>CKD</strong> recommended modelPlastic plugSoft nylon tubePolyurethane rubber tubeUrethane tubeGWP*-B SeriesF15** SeriesU95** SeriesNU-04/06 SeriesRead "Safety precaution on joint tube" for push-in joint.Regularly inspect the polyamide case for cracks, damage,and other deterioration. Clean and replace asnecessary.Filter element clogging will decrease vacuum sourceconductance. Regularly inspect, clean, and replacethe element.During Use & MaintenanceCAUTION Use a household-grade neutral detergent to clean thebody, then rinse with water.If <strong>small</strong> particles such as dust during suction enterthe <strong>flow</strong> path, foreign matter will not be filtered andmay <strong>flow</strong> to the secondary side.Select a filter suiting the purpose.Replacing the elementJointJoint fixing pin12Element(1) Pull out the joint fixing pin using a blunt jig, etc.The joint fixing pin must reused, so do not lose it.(2) Pull out the joint.(3) Replace the element, and insert the joint.(4) Insert the joint fixing pin, and fix the joint.43Refrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filterAuto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)EndingReturn the container to atmospheric pressure beforeremoving the body to clean or replace, etc., the filterelement.The <strong>flow</strong> direction is oriented. Check the arrow onthe body during reassembly.Check that the required vacuum degree is attained inthe circuit after reassembly.SmallFlow <strong>sensor</strong>1279

Refrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filterSmall <strong>flow</strong> <strong>sensor</strong>Small <strong>flow</strong> <strong>sensor</strong> extremely <strong>small</strong> <strong>flow</strong> typeIndicator type/analog output type<strong>FSM</strong>-H Series (air/nitrogen gas)Flow rate range: 0.25 to 5, 0.5 to 10, 2.5 to 50, 50 to 100m/min.Auto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)Indicator type specificationsIndicator typeDescriptions<strong>FSM</strong>-H-N/P-005ML <strong>FSM</strong>-H-N/P-010ML <strong>FSM</strong>-H-N/P-050ML <strong>FSM</strong>-H-N/P-100MLFlow rate range m /min. Note 1Precision Working conditionsIndicatorInstallationWorking fluidMax. working pressure MPaMin. working pressure MPaWithstanding pressure MPaAmbient temperature/humidityWorking fluid temperatureLinearity (display/analog output)Pressure characteristicsTemperature characteristicsRepeatabilityResponsivenessType of displayDisplay min. unit Note 6Output typePower voltageCurrent consumptionLead wireFunctionsInstallation attitudeStrait piping sectionProtective structureProtective circuit Note 4EMC directiveIndicator type weight0.25 to 5 0.5 to 10 2.5 to 50 5 to 100Clean air (JIS B 8392-1. 1. 1 to 5. 6. 2), compressed air (JIS B 8392-1. 1. 1 to 1. 6. 2) Note 2 , N2 gas Note 31.0-0.091.50 to 50 , 90%RH or less0 to 50 (with no dew condensation)3% F.S. or less (0.1MPa, 25 , <strong>flow</strong> rate range 5 to 100%F.S.)3% F.S. or less (-0.09 to 1.0MPa, where 0.1MPa is reference)0.2%F.S./ or less (15 to 35 , where 25 is reference)0.5%F.S. or less50ms or less Note 5Flow display (3.5-digit 7-segment display, orange), run and switch output display (orange)0.01mL/min. Note 1 0.1mL/min. Note 1Switch output 2 points(NPN or PNP open collector output, 30 VDC and 50 mA or less, voltage drop of 2.4 V or less, PLC- and relay-compatible)Analog output 1 point(1 to 5V voltage output, connected load impedance 50K and over)12/24 VDC (10.8 to 26.4V)60mA or less3.7 0.2mm 2 x 5 conductor 1mFlow display, <strong>flow</strong> display peak hold, switch output, analog outputHorizontal or verticalNot requiredIEC standards IP40Power supply reverse connection protection, switch output reverse connection protection, switch output load short-circuit protectionEN55011, EN61000-6-2, EN1000-4-2/3/4/6/8Unit: gModel no.Port size (body material)<strong>FSM</strong>-N/P-005 <strong>FSM</strong>-N/P-010 <strong>FSM</strong>-N/P-050 <strong>FSM</strong>-N/P-1006A Rc1/8 (stainless steel)6G G1/8 (stainless steel)150 150 150 150EndingAnalog output type weightModel no.Port size (body material)6A Rc1/8 (stainless steel)6G G1/8 (stainless steel)<strong>FSM</strong>-A-005 <strong>FSM</strong>-A-010 <strong>FSM</strong>-A-050 <strong>FSM</strong>-A-100140 140 140 140Unit: g1280

Analog output type specifications (without display)DescriptionsFlow rate range m /min. Note 1Precision Working conditionsInstallationWorking fluidMax. working pressureMin. working pressureWithstanding pressureMPaMPaMPaAmbient temperature/humidityWorking fluid temperatureLinearity (analog output)Pressure characteristicsTemperature characteristicsRepeatabilityResponsivenessType of displayOutput typePower voltageCurrent consumptionLead wireFunctionsProtective circuit Note 4Installation attitudeStrait piping sectionProtective structureEMC directiveAnalog output type<strong>FSM</strong>-H SeriesSpecifications<strong>FSM</strong>-H-A-005ML <strong>FSM</strong>-H-A-010ML <strong>FSM</strong>-H-A-050ML <strong>FSM</strong>-H-A-100ML0.25 to 5 0.5 to 10 2.5 to 50 5 to 100Clean air (JIS B 8392-1. 1. 1 to 5. 6. 2), compressed air (JIS B 8392-1. 1. 1 to 1. 6. 2) Note 2 , N2 gas Note 31.0-0.091.50 to 50 and 90%RH or less0 to 50 (with no dew condensation)3% F.S. or less (0.1MPa, 25 , <strong>flow</strong> rate range 5 to 100%F.S.)3% F.S. or less (-0.09 to 1.0MPa, where 0.1MPa is reference)0.2%F.S./ or less (15 to 35 , where 25 is reference)0.5%F.S. or less50ms or less Note 5Power display (green)Analog output 1 point (1 to 5V voltage output, connected load impedance 50K12/24 VDC (10.8 to 26.4V)50mA or less3.7 0.2mm 2 x 3 conductor 1mAnalog outputPower supply reverse connection protectionHorizontal or verticalNot requiredIEC standards IP40EN55011, EN61000-6-2, EN1000-4-2/3/4/6/8and over)Note 1: Converted to volumetric <strong>flow</strong> at 20 1 barometric pressure (101kPa)Note 2: When using compressed air, use clean air that complies to JIS B 8392-1:2003 Class 1.1.1 to 1.6.2. Compressed air from the compressorcontains drainage (water, oxidized oil, foreign matter, etc.). Install a filter (filtration: 5 m), air dryer (minimum pressure dew point: 10 orless), and oil mist filter (maximum oil concentration: 0.1 mg/m 3 ) on the primary side of this product to maintain product functions.PneumaticspressuresourceAir dryerFilterRegulatorOil mist filter(Micro alescer)<strong>FSM</strong> SeriesAir filter: F SeriesOil mist filter: M SeriesNote 3: Consult with <strong>CKD</strong> when using gas other than air or N2.Note 4: This product's protection circuit is effective only for specific misconnections and load short-circuits. It does not provide protection for all misconnections.Note 5: Response time varies depending on the piping conditions.Note 6: This indicates the minimum display for the <strong>flow</strong>, and does not guarantee display accuracy.Separate indicator specifications (analog output type dedicated)Model no.DescriptionsAvailableanalog output type model no.Type of displayDisplay min. unit Note 6IndicatorOutputPower voltageCurrent consumptionLead wireFunctionsAmbient temperature/humidityProtective structureEMC directiveWeightg<strong>FSM</strong>-H-D N/P-005MLSeparate indicator<strong>FSM</strong>-H-D N/P-010ML <strong>FSM</strong>-H-D N/P-050ML <strong>FSM</strong>-H-D N/P-100ML<strong>FSM</strong>-H-A-005ML <strong>FSM</strong>-H-A-010ML <strong>FSM</strong>-H-A-050ML <strong>FSM</strong>-H-A-100MLFlow display (3.5-digit 7-segment display, orange), run and switch output display (orange)0.01mL/min. Note 1 0.1mL/min. Note 1Switch output 2 points(NPN or PNP open collector output, 30 VDC and 50 mA or less, voltage drop of 2.4 V or less, PLC- and relay-compatible)Analog output 1 point(1-5V voltage output, connected load impedance 50K and over)12/24 VDC (10.8 to 26.4V)50mA or less (only indicator)3.7 0.2mm 2 x 5 conductor (1m)Flow display, <strong>flow</strong> display peak hold, switch output, analog output0 to 50 , 85%RH or less (no dew)IEC standards IP40EN55011, EN61000-6-2, EN1000-4-2/3/4/6/8Approx. 70 (including lead wire 1m)Refrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filterAuto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)EndingSmall Extremely <strong>small</strong> <strong>flow</strong> typeFlow <strong>sensor</strong>1281

<strong>FSM</strong>-H SeriesRefrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filterAuto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)How to order<strong>FSM</strong>-HN005MLA Output type6AB Flow rate range<strong>FSM</strong>-H-N-005ML-6A-KModel: <strong>FSM</strong> indicator typeA Switch output type : NPN outputB Flow rate range : 0.25 to 5m /min.C Port size: Rc1/8 (stainless steel body)D Option: With company certification<strong>FSM</strong>H D N010MLKC Port sizeSeparate indicator (analog output type dedicated)Model no.A Switch output typeD OptionB Flow rate rangeSymbolA Output typeNPSymbolA Output typeDescriptionsA Analog output 1 pointN NPN output 2 points, analog output 1 pointP PNP output 2 points, analog output 1 pointB Flow rate range005ML 0.25 to 5m /min.010ML 0.5 to 10m /min.050ML 2.5 to 50m /min.100ML 5 to 100m /min.C Port size6A Rc1/8 (stainless steel body)6G G1/8 (stainless steel body)* Refer to page 1285 for model No. and dimensions ofbracket (optional).D OptionBlankKT (Note 1)NoneWith company certificationWith traceability certificateNote 1) Proof of traceability, inspection results, andtraceability system diagram are included.DescriptionsNPN output 2 points, analog output 1 pointPNP output 2 points, analog output 1 pointB Flow rate range005ML 0.25 to 5m /min.010ML 0.5 to 10m /min.050ML 2.5 to 50m /min.100ML 5 to 100m /min.* Refer to pages 1314 to 1321 for the operation and dimensions, etc.,EndingBracket for separate indicatorPPD3KL-DA Bracket kitSymbolDescriptionsA Bracket kitKL-D Single foot bracket (L type)KD-D Both sides foot bracket (parallel)KHS-D Panel mount bracket set with coverKC Operation protective cover* Refer to pages 1314 to 1315 for dimensions and size of bracket.1282

Internal structure and parts list<strong>FSM</strong>-H-N/P-*-*Indicator type stainless steel body1 2<strong>FSM</strong>-H SeriesHow to order / internal structure and parts list3Refrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filter11Auto. drain/ othersF.R.L.(Module unit)104F.R.L.(Separate)CompactF.R.5PreciseregulatorF.R.L.(Relatedproducts)No.123456Parts nameFront seatCaseLead wire with holder (5 - conductor)Module holderSensor circuit boardStainless steel body98MaterialPolyester filmABS resinABS resin/polyvinyl chloridePolyamide resinAluminaStainless steelNo.789101176Parts nameSensor chipRectifierPort filterSensor gasketElectron circuit boardMaterialSiliconeStainless steelStainless steelFluoro rubberCleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilter<strong>FSM</strong>-H-A-*-*Analog type stainless steel bodyVacuumregulatorSuctionplate1 2 3Magneticspring bufferMechanicalpressure SW11Electronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>104Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>98765Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterNo.123456Parts nameFront seatCaseLead wire with holder (3 - conductor)Module holderSensor circuit boardStainless steel bodyMaterialPolyester filmABS resinABS resin/polyvinyl chloridePolyamide resinAluminaStainless steelNo.7891011Parts nameSensor chipRectifierPort filterSensor gasketElectron circuit boardSeparate indicator <strong>FSM</strong>-H-D*-*Refer to Page 1314 for internal structure of a separate indicator.MaterialSiliconeStainless steelStainless steelFluoro rubberTotal airsystemTotal airsystem(Gamma)EndingSmall Extremely <strong>small</strong> <strong>flow</strong> typeFlow <strong>sensor</strong>1283

Dimensions (bracket)<strong>FSM</strong>-H SeriesDimensionsRefrigeratingtype dryerModel no.: <strong>FSM</strong>-LB155304-R1.751Desiccanttype dryerHigh polymermembranedryerAnalog output characteristicsAnalog output (V)<strong>FSM</strong>-H-*-*278.44Pressure loss characteristicsPressure loss (Pa)Pressure loss (Pa)510 F. S. <strong>flow</strong>Flow ( /min)<strong>FSM</strong>-H-*-005ML-*43.532.521.510.500 1 2 3 4<strong>FSM</strong>-H-*-050ML-*10987654321Flow (m /min)00 10 20 30 40Flow (m /min)63.5Enclosed four M3 (length 6mm) setscrews for fixing(Note) If <strong>flow</strong> range is exceeded, maximum of 8V will be output.5500.1MPa0.3MPa0.1MPa0.3MPaFor details on the display and operation section names,functions and operation methods, refer to page 1306 for integrated display and page 1318 for separated display.Pressure loss (Pa)Pressure loss (Pa)1614121086425<strong>FSM</strong>-H-*-010ML-*765432100 2 4 6 8<strong>FSM</strong>-H-*-100ML-*Flow (m /min)00 20 40 60 80Flow (m /min)101000.1MPa0.3MPa0.1MPa0.3MPa1285Air filterAuto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)EndingSmall Extremely <strong>small</strong> <strong>flow</strong> typeFlow <strong>sensor</strong>

Refrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerSmall <strong>flow</strong> <strong>sensor</strong>Indicator type/analog output type<strong>FSM</strong> SeriesAir, nitrogen gas (<strong>flow</strong> rate range: 0.05 to 100 /min)Argon, carbon dioxide (<strong>flow</strong> rate range: 0.05 to 50 /min)Air filterAuto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)Ending<strong>FSM</strong> for air or N2 gas <strong>series</strong>Indicator type specificationsDescriptionsFlow rate range /min. Note 1Working fluidMax. working pressure MPaMin. working pressure MPaWithstanding pressure MPaAmbient temperature/humidityWorking fluid temperatureIndicator Precision Working conditionsInstallationLinearity (display/analog output)Pressure characteristicsTemperature characteristicsRepeatabilityResponsivenessType of displayDisplay min. unit Note 5Output typePower voltageCurrent consumptionLead wireFunctionsInstallation attitudeStrait piping sectionProtective structureProtective circuit Note 3EMC directiveIndicator type weight (air, N2 gas)DiscontinuedProduction of the <strong>FSM</strong> Series is scheduled to bediscontinued on the end of March, 2009.Indicator typeThe <strong>FSM</strong>2 Series is available as an alternative mode.<strong>FSM</strong>-N/P-005 <strong>FSM</strong>-N/P-010 <strong>FSM</strong>-N/P-050 <strong>FSM</strong>-N/P-100 Contact <strong>FSM</strong>-N/P-200 the <strong>CKD</strong> Sales <strong>FSM</strong>-N/P-500 Office for details. <strong>FSM</strong>-N/P-1010.05 to 0.5 0.1 to 1 0.5 to 5 1 to 10 2 to 20 5 to 50 10 to 100Clean air (JIS B 8392-1. 1. 1 to 5. 6. 2), compressed air (JIS B 8392-1. 1. 1 to 1. 6. 2) Note 2 , N2 gas0.7-0.071.00 to 50 , 90%RH or less0 to 50 (with no dew condensation)5%F.S. or less (0.1MPa, 25 , <strong>flow</strong> rate range 10 to 100%F.S.)5%F.S. or less (-0.07 to 0.7MPa, 0.1MPa reference)0.2%F.S./ or less (15 to 35 , where 25 is reference)Unit: gModel no.Port size (body material)<strong>FSM</strong>-N/P-005 <strong>FSM</strong>-N/P-010 <strong>FSM</strong>-N/P-050 <strong>FSM</strong>-N/P-100 <strong>FSM</strong>-N/P-200 <strong>FSM</strong>-N/P-500 <strong>FSM</strong>-N/P-101H4H66A6AAM58A8AA4 push-in (nylon)6 push-in (nylon)Rc1/8 (stainless steel)Rc1/8 (aluminum)M5 (stainless steel)Rc1/4 (stainless steel)Rc1/4 (aluminum)7067150-160--7067150-160--7067150-160--7067150-160--7067150-160----17090--------205105Analog output type weight (air, N2 gas)Model no.Port size (body material)H4 4 push-in (nylon)H6 6 push-in (nylon)6A Rc1/8 (stainless steel)6AA Rc1/8 (aluminum)M5 M5 (stainless steel)8A Rc1/4 (stainless steel)8AA Rc1/4 (aluminum)<strong>FSM</strong>-A-0056360140-150--50ms or less Note 4Flow display (3.5-digit 7-segment display, orange), run and switch output display (orange)1mL/min. Note 1 0.01L/min. Note 1 0.1L/min. Note 1<strong>FSM</strong>-A-010 <strong>FSM</strong>-A-050 <strong>FSM</strong>-A-100 <strong>FSM</strong>-A-200 <strong>FSM</strong>-A-500 <strong>FSM</strong>-A-1016360140-150--6360140-150--1%F.S. or less6360140-150--6360140-150--Switch output 2 points--16080---Unit: g-----195953%F.S. or less( 2%F.S. or less in <strong>flow</strong> 50%F.S. or less)(NPN or PNP open collector output, 30 VDC and 50 mA or less, voltage drop of 2.4 V or less, PLC- and relay-compatible)Analog output 1 point(1 to 5V voltage output and connected load impedance 50K and over)12/24 VDC (10.8 to 26.4V)60mA or less3.7 0.2mm 2 x 5 conductor 1mFlow display, <strong>flow</strong> display peak hold, switch output, analog outputHorizontal or verticalNot requiredIEC standards IP40Power supply reverse connection protection, switch output reverse connection protection, switch output load short-circuit protectionEN55011, EN61000-6-2, EN1000-4-2/3/4/6/8Clean room specifications (catalog No. CB-033SA)Dust generation preventing structure for use in cleanrooms<strong>FSM</strong><strong>FSM</strong>P70P801286

Analog output type specifications (air, N2 gas, without display)DescriptionsFlow rate range /min. Note 1Working fluidMax. working pressure MPaMin. working pressure MPaWithstanding pressure MPaAmbient temperature/humidityWorking fluid temperaturePrecision Working conditionsInstallationLinearity (analog output)Pressure characteristicsTemperature characteristicsRepeatabilityResponsivenessType of displayOutput typePower voltageCurrent consumptionLead wireFunctionsProtective circuit Note 3Installation attitudeStrait piping sectionProtective structureEMC directivePneumaticspressuresourceAir dryerAnalog output type<strong>FSM</strong>-A-005 <strong>FSM</strong>-A-010 <strong>FSM</strong>-A-050 <strong>FSM</strong>-A-100 <strong>FSM</strong>-A-200 <strong>FSM</strong>-A-500Filter0.05 to 0.5 0.1 to 1 0.5 to 5 1 to 10 2 to 20 5 to 50Clean air (JIS B 8392-1. 1. 1 to 5. 6. 2), compressed air (JIS B 8392-1. 1. 1 to 1. 6. 2) Note 2 , N2 gas0.7-0.071.00 to 50 , 90%RH or less0 to 50 (with no dew condensation)5%F.S. or less (0.1MPa, 25 , <strong>flow</strong> rate range 10 to 100%F.S.)5%F.S. or less (-0.07 to 0.7MPa, 0.1MPa reference)0.2%F.S./ or less (15 to 35 , where 25 is reference)Regulator1%F.S. or less50ms or less Note 4Power display (green)Analog output 1 point (1 to 5V voltage output, connected load impedance 50K12/24 VDC (10.8 to 26.4V)50mA or less3.7 0.2mm 2 x 3 conductor 1mAnalog outputPower supply reverse connection protectionHorizontal or verticalNot requiredIEC standards IP40EN55011, EN61000-6-2, EN1000-4-2/3/4/6/8Oil mist filter(Micro alescer)<strong>FSM</strong> SeriesAir filter: F SeriesOil mist filter: M Series<strong>FSM</strong> SeriesSpecifications<strong>FSM</strong>-A-10110 to 1003%F.S. or less( 2%F.S. or less in <strong>flow</strong> 50%F.S. or less)and over)Note 1: Converted to volumetric <strong>flow</strong> at 20 1 barometric pressure (101kPa)Note 2: When using compressed air, use clean air that complies to JIS B 8392-1:2003 Class 1.1.1 to 1.6.2. Compressed air from the compressorcontains drainage (water, oxidized oil, foreign matter, etc.). Install a filter (filtration: 5 m), air dryer (minimum pressure dew point: 10 orless), and oil mist filter (maximum oil concentration: 0.1 mg/m 3 ) on the primary side of this product to maintain product functions.Note 3: This product's protection circuit is effective only for specific misconnections and load short-circuits. It does not provide protection for all misconnections.Note 4: Response time varies depending on the piping conditions.Note 5: This indicates the minimum display for the <strong>flow</strong>, and does not guarantee display accuracy.Separate indicator specifications (analog output type dedicated)Model no.Separate indicatorDescriptions<strong>FSM</strong>-A-D N/P-005 <strong>FSM</strong>-A-D N/P-010 <strong>FSM</strong>-A-D N/P-050 <strong>FSM</strong>-A-D N/P-100 <strong>FSM</strong>-A-D N/P-200 <strong>FSM</strong>-A-D N/P-500 <strong>FSM</strong>-A-D N/P-101Availableanalog output type model no.<strong>FSM</strong>-A-005 <strong>FSM</strong>-A-010 <strong>FSM</strong>-A-050 <strong>FSM</strong>-A-100 <strong>FSM</strong>-A-200 <strong>FSM</strong>-A-500 <strong>FSM</strong>-A-101Type of displayFlow display (3.5-digit 7-segment display, orange), run and switch output display (orange)Display min. unit Note 5 1mL/min. Note 1 0.01L/min. Note 1Switch output 2 points0.1L/min. Note 1Output(NPN or PNP open collector output, 30 VDC and 50 mA or less, voltage drop of 2.4 V or less, PLC- and relay-compatible)Analog output 1 point(1-5V voltage output, connected load impedance 50K and over)Power voltageCurrent consumptionLead wireFunctions12/24 VDC (10.8 to 26.4V)50mA or less (only indicator)3.7 0.2mm 2 x 5 conductor (1m)Flow display, <strong>flow</strong> display peak hold, switch output, analog outputAmbient temperature/humidityProtective structure0 to 50 , 85%RH or less (no dew)IEC standards IP40EMC directiveWeightgEN55011, EN61000-6-2, EN1000-4-2/3/4/6/8Approx. 70 (including lead wire 1m)IndicatorRefrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filterAuto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)EndingSmallFlow <strong>sensor</strong>1287

<strong>FSM</strong> SeriesRefrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filterAuto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)Ending<strong>FSM</strong> for argon or carbon dioxide <strong>series</strong>Indicator type specificationsDescriptionsFlow rate range /min. Note 1Indicator Precision Working conditionsInstallationWorking fluidWorking pressureWithstanding pressureMPaMPaAmbient temperature / humidityWorking fluid temperatureLinearity (display/analog output)Pressure characteristicsTemperature characteristicsRepeatabilityResponsivenessType of displayDisplay min. unit Note 6Output typePower voltageCurrent consumptionLead wireFunctionsInstallation attitudeStrait piping sectionProtective structureProtective circuit Note 5EMC directiveModel no.Port size (body material)6A Rc1/8 (stainless steel)6AA Rc1/8 (aluminum)M5 M5 (stainless steel)M5A M5 (aluminum)Indicator type (argon, carbon dioxide)<strong>FSM</strong>-N/P-005 <strong>FSM</strong>-N/P-010 <strong>FSM</strong>-N/P-050 <strong>FSM</strong>-N/P-100 <strong>FSM</strong>-N/P-200 <strong>FSM</strong>-N/P-5000.05 to 0.5 0.1 to 1 0.5 to 5 1 to 10 2 to 20 5 to 50Argon, carbon dioxide Note 20 to 0.5 Note 30.750 to 50 , 90%RH or less0 to 50 (with no dew condensation)5%F.S. or less (0.1MPa, 25 , <strong>flow</strong> rate range 10 to 100%F.S.)5% F.S. or less (0 to 0.5MPa, where 0.1MPa is reference)0.2%F.S./ or less (15 to 35 , where 25 is reference)Indicator type weight (argon, carbon dioxide)Model no.Port size (body material)6A Rc1/8 (stainless steel)6AA Rc1/8 (aluminum)M5 M5 (stainless steel)M5A M5 (aluminum)50ms or less Note 4Flow display (3.5-digit 7-segment display, orange), run and switch output display (orange)1mL/min. Note 1 0.01L/min. Note 10.1L/min. Note 1Switch output 2 points(NPN or PNP open collector output, 30 VDC and 50 mA or less, voltage drop of 2.4 V or less, PLC- and relay-compatible)Analog output 1 point(1 to 5V voltage output, connected load impedance 50K and over)12/24 VDC (10.8 to 26.4V)60mA or less3.7 0.2mm 2 x 5 conductor 1mFlow display, <strong>flow</strong> display peak hold, switch output, analog outputHorizontal or verticalNot requiredIEC standards IP40Power supply reverse connection protection, switch output reverse connection protection, switch output load short-circuit protection<strong>FSM</strong>-N/P-005 <strong>FSM</strong>-N/P-010 <strong>FSM</strong>-N/P-050 <strong>FSM</strong>-N/P-100 <strong>FSM</strong>-N/P-200 <strong>FSM</strong>-N/P-50015080160851508016085Analog output type weight (argon, carbon dioxide)15080160851508016085* All the pressure is gauge pressure.<strong>FSM</strong>-A-005 <strong>FSM</strong>-A-010 <strong>FSM</strong>-A-050 <strong>FSM</strong>-A-100 <strong>FSM</strong>-A-200 <strong>FSM</strong>-A-50014070150751%F.S. or less1407015075EN55011, EN61000-6-2, EN1000-4-2/3/4/6/8140701507514070150753%F.S. or less( 2%F.S. or less in <strong>flow</strong> 50%F.S. or less)17090--16080--17090--16080--Unit: gUnit: g1288

Analog output type specifications (argon, carbon dioxide, without display)DescriptionsFlow rate range /min. Note 1Precision Working conditionsInstallationWorking fluidWorking pressureWithstanding pressure<strong>FSM</strong> SeriesSpecificationsRefrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filterAuto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)EndingSmallFlow <strong>sensor</strong>MPaMPaAmbient temperature/humidityWorking fluid temperatureLinearity (analog output)Pressure characteristicsTemperature characteristicsRepeatabilityResponsivenessType of displayOutput typePower voltageCurrent consumptionLead wireFunctionsProtective circuit Note 5Installation attitudeStrait piping sectionProtective structureEMC directiveAnalog output type (argon and carbon dioxide)<strong>FSM</strong>-A-005 <strong>FSM</strong>-A-010 <strong>FSM</strong>-A-050 <strong>FSM</strong>-A-100 <strong>FSM</strong>-A-200 <strong>FSM</strong>-A-5000.05 to 0.5 0.1 to 1 0.5 to 5 1 to 10 2 to 20 5 to 50Argon, carbon dioxide Note 20 to 0.5 Note 30.750 to 50 , 90%RH or less0 to 50 (with no dew condensation)5%F.S. or less (0.1MPa, 25 , <strong>flow</strong> rate range 10 to 100%F.S.)5% F.S. or less (0 to 0.5MPa, where 0.1MPa is reference)0.2%F.S./ or less (15 to 35 , where 25 is reference)1%F.S. or less50ms or less Note 4Power display (green)Analog output 1 point (1 to 5V voltage output, connected load impedance 50K12/24 VDC (10.8 to 26.4V)50mA or less3.7 0.2mm 2 x 3 conductor 1mAnalog outputPower supply reverse connection protectionHorizontal or verticalNot requiredIEC standards IP40EN55011, EN61000-6-2, EN1000-4-2/3/4/6/8* Refer to page 1287 for the specifications of the separate indicator.3%F.S. or less( 2%F.S. or less in <strong>flow</strong> 50%F.S. or less)and over)* All the pressure is gauge pressure.Note 1: Converted to volumetric <strong>flow</strong> at 20 1 barometric pressure (101kPa)Note 2: Dry gas (minimum pressure dew point -40 or less) free of corrosive elements such as chlorine, sulfur, or acids.Clean gas (solid particles 0.1 m or less, oil 0.1 mg/m 3 or less) free of dust or oil mist.Note 3: Argon and carbon gas models are used with positive pressure. If used with negative pressure (vacuum), accuracy may not satisfyspecifications. When installing on a vacuum system, be sure to restrict the secondary side of the product, or take other means so thatthe product does not achieve negative pressure.Note 4: Response time varies depending on the piping conditions.Note 5: This product's protection circuit is effective only for specific misconnections and load short-circuits. It does not provide protection for allmisconnections.Note 6: This indicates the minimum display for the <strong>flow</strong>, and does not guarantee display accuracy.1289

For argon, carbon dioxideHow to order<strong>FSM</strong>NA100Output typeB6AFlow rate rangeCARPort size6A6AARc1/8 (stainless steel body)Rc1/8 (aluminum body)<strong>FSM</strong> SeriesHow to orderSymbolDescriptionsA Output typeANPAnalog output 1 pointNPN output 2 points, analog output 1 pointPNP output 2 points, analog output 1 pointB Flow rate range005 0.05 to 0.5 /min.010 0.1 to 1 /min.050 0.5 to 5 /min.100 1 to 10 /min.200 2 to 20 /min.500 5 to 50 /min.C Port sizeRefrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filterAuto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencer<strong>FSM</strong>-N-100-6A-ARModel: <strong>FSM</strong> indicator typeA Switch output type : NPN outputB Flow rate range : 1 to 10 /min.C Port size: Rc1/8 (stainless steel body)D Working fluid : ArgonDWorking fluidM5 (stainless steel body)M5* Excluding <strong>flow</strong> rate range 100 (CO2), 200, 500M5 (aluminum body)M5A* Excluding <strong>flow</strong> rate range 100 (CO2), 200, 500D Working fluidAR ArgonCO2 Carbon dioxide* Refer to page 1298 for model No. and dimensions ofbracket (optional).Check valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Bracket for separate indicatorPPD3 KL-DA Bracket kitSymbolDescriptionsA Bracket kitKL-D Single foot bracket (L type)KD-D Both sides foot bracket (parallel)KHS-D Panel mount bracket set with coverKC Operation protective cover* Refer to pages 1314 to 1315 for dimensions and size of bracket.Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)EndingSmallFlow <strong>sensor</strong>1291

<strong>FSM</strong> SeriesRefrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filterInternal structure and parts list<strong>FSM</strong>-N/P-*-6A-*Indicator type stainless steel body1 23Auto. drain/ othersF.R.L.(Module unit)11F.R.L.(Separate)CompactF.R.104PreciseregulatorF.R.L.(Relatedproducts)5CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeNo.123456Parts nameFront seatCaseLead wire with holder (5 - conductor)Module holderSensor circuit boardStainless steel body98MaterialPolyester filmABS resinABS resin/polyvinyl chloridePolyamide resinAluminaStainless steelNo.789101176Parts nameSensor chipRectifierPort filterSensor gasketElectron circuit boardMaterialSiliconeStainless steelStainless steelFluoro rubberVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SW<strong>FSM</strong>-A-*-H6Analog type resin body1 23Electronicpressure SWContact / closecontact conf.SW12Air <strong>sensor</strong>Pressure SWfor coolant114Small<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controller5Flow <strong>sensor</strong>for airFlow <strong>sensor</strong>for water109876Total airsystemTotal airsystem(Gamma)EndingNo.123456Parts nameFront seatCaseLead wire with holder (3 - conductor)Module holderPush-in cartridge joint 6Sensor circuit boardMaterialPolyester filmABS resinABS resin/polyvinyl chloridePolyamide resinAluminaNo.789101112Parts nameResin bodySensor chipRectifierPort filterSensor gasketElectron circuit boardMaterialPolyamide resinSiliconeStainless steelStainless steelFluoro rubberSeparate indicator <strong>FSM</strong>-A-D*-*Refer to Page 1314 for internal structure.1292

<strong>FSM</strong> SeriesRefrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filterDimensions (indicator type)Body material: Polyamide resin, port size: 4<strong>FSM</strong>-*-*-H43.7Auto. drain/ othersF.R.L.(Module unit)55Lead wire length 1mF.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirbooster37174.6279272- 3.4 penetrating4 push-in jointSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>9.5Body material: Polyamide resin, port size: 6<strong>FSM</strong>-*-*-H62-M3 depth 515.53.7Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controller554.69Lead wire length 1mFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for water6 push-in jointTotal airsystemTotal airsystem(Gamma)3727Ending17272- 3.4 penetrating9.52-M3 depth 515.51294

Dimensions (indicator type)Body material: Stainless steel, aluminum<strong>FSM</strong>-*-*-*3.7<strong>FSM</strong> SeriesDimensionsRefrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filterAuto. drain/ othersF.R.L.(Module unit)55Lead wire length 1mF.R.L.(Separate)CompactF.R.EPreciseregulatorF.R.L.(Relatedproducts)A17C27B2- 3.4 penetratingDCleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencer9.52-M3 depth 5Check valve/ othersJoint/ tubeVacuumfilterVacuumregulator15.5SuctionplateMagneticspring bufferAir, nitrogen gasArgon, carbon dioxideModel no.<strong>FSM</strong>-N/P-005-6A<strong>FSM</strong>-N/P-005-M5<strong>FSM</strong>-N/P-010-6A<strong>FSM</strong>-N/P-010-M5<strong>FSM</strong>-N/P-050-6A<strong>FSM</strong>-N/P-050-M5<strong>FSM</strong>-N/P-100-6A<strong>FSM</strong>-N/P-100-M5<strong>FSM</strong>-N/P-200-6A<strong>FSM</strong>-N/P-200-M5<strong>FSM</strong>-N/P-500-6A/6AA<strong>FSM</strong>-N/P-101-8A/8AA<strong>FSM</strong>-N/P-005-6A/6AA-AR/CO2<strong>FSM</strong>-N/P-005-M5/M5A-AR/CO2<strong>FSM</strong>-N/P-010-6A/6AA-AR/CO2<strong>FSM</strong>-N/P-010-M5/M5A-AR/CO2<strong>FSM</strong>-N/P-050-6A/6AA-AR/CO2<strong>FSM</strong>-N/P-050-M5/M5A-AR/CO2<strong>FSM</strong>-N/P-100-6A/6AA-AR<strong>FSM</strong>-N/P-100-M5/M5A-AR<strong>FSM</strong>-N/P-100-6A/6AA-CO2<strong>FSM</strong>-N/P-200-6A/6AA-AR/CO2<strong>FSM</strong>-N/P-500-6A/6AA-AR/CO2Flow rate range/min0.05 to 0.50.1 to 10.5 to 51 to 102 to 205 to 5010 to 1000.05 to 0.50.1 to 10.5 to 51 to 101 to 102 to 205 to 50A373737373739.5473737373739.539.539.5B272727272729.5372727272729.529.529.5C4.64.64.64.64.64.64.64.64.64.64.64.64.64.6D999999149999999ERc1/8M5Rc1/8M5Rc1/8M5Rc1/8M5Rc1/8M5Rc1/8Rc1/4Rc1/8M5Rc1/8M5Rc1/8M5Rc1/8M5Rc1/8Rc1/8Rc1/8Mechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)EndingSmallFlow <strong>sensor</strong>1295

<strong>FSM</strong> SeriesRefrigeratingtype dryerDimensions (analog output type)Desiccanttype dryerHigh polymermembranedryerBody material: Polyamide resin, port size: 4<strong>FSM</strong>-A-*-H43.7Air filterAuto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)5532 32179.54.6Body material: Polyamide resin, port size: 6<strong>FSM</strong>-A-*-H64.627559272- 3.4 penetrating2-M3 depth 515.53.717272-M3 depth 59.59Lead wire length 1mCompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)Lead wire length 1m274 push-in joint6 push-in jointEnding2- 3.4 penetrating15.51296

Dimensions (analog output type)Body material: Stainless steel, aluminum<strong>FSM</strong>-A-*-*3.7<strong>FSM</strong> SeriesDimensionsRefrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filterAuto. drain/ others55Lead wire length 1mF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.CPreciseregulatorF.R.L.(Relatedproducts)A1727B2- 3.4 penetratingDECleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencer9.52-M3 depth 5Check valve/ othersJoint/ tubeVacuumfilterVacuumregulator15.5SuctionplateArgon, carbon dioxideAir, nitrogen gasModel no.<strong>FSM</strong>-A-005-6A<strong>FSM</strong>-A-005-M5<strong>FSM</strong>-A-010-6A<strong>FSM</strong>-A-010-M5<strong>FSM</strong>-A-050-6A<strong>FSM</strong>-A-050-M5<strong>FSM</strong>-A-100-6A<strong>FSM</strong>-A-100-M5<strong>FSM</strong>-A-200-6A<strong>FSM</strong>-A-200-M5<strong>FSM</strong>-A-500-6A/6AA<strong>FSM</strong>-A-101-8A/8AA<strong>FSM</strong>-A-005-6A/6AA-AR/CO2<strong>FSM</strong>-A-005-M5/M5A-AR/CO2<strong>FSM</strong>-A-010-6A/6AA-AR/CO2<strong>FSM</strong>-A-010-M5/M5A-AR/CO2<strong>FSM</strong>-A-050-6A/6AA-AR/CO2<strong>FSM</strong>-A-050-M5/M5A-AR/CO2<strong>FSM</strong>-A-100-6A/6AA-AR<strong>FSM</strong>-A-100-M5/M5A-AR<strong>FSM</strong>-A-100-6A/6AA-CO2<strong>FSM</strong>-A-200-6A/6AA-AR/CO2<strong>FSM</strong>-A-500-6A/6AA-AR/CO2Flow rate range/min0.05 to 0.50.1 to 10.5 to 51 to 102 to 205 to 5010 to 1000.05 to 0.50.1 to 10.5 to 51 to 101 to 102 to 205 to 50A323232323234.5423232323234.534.534.5B272727272729.5372727272729.529.529.5C4.64.64.64.64.64.64.64.64.64.64.64.64.64.6D999999149999999ERc1/8M5Rc1/8M5Rc1/8M5Rc1/8M5Rc1/8M5Rc1/8Rc1/4Rc1/8M5Rc1/8M5Rc1/8M5Rc1/8M5Rc1/8Rc1/8Rc1/8Magneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)EndingSmallFlow <strong>sensor</strong>* Dimensions of separate indicator <strong>FSM</strong>-A-D*-* are same as <strong>FSM</strong>-V-D*-*. Refer to Page 1314.1297

<strong>FSM</strong> SeriesRefrigeratingtype dryerDimensions (bracket)Desiccanttype dryerHigh polymermembranedryerAir filterModel no.: <strong>FSM</strong>-LB155304-R1.751Auto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAnalog output characteristicsAnalog output (V)<strong>FSM</strong>-*-*-*510 F.S. <strong>flow</strong>Flow ( /min)278.4463.5Enclosed four M3 (length 6mm) setscrews for fixing(Note) If <strong>flow</strong> range is exceeded, maximum of 8V will be output.For details on display and operation section names, functions, and operation methods, refer to page 1306 for the integrated display andpage 1314 for the separated display.5Air <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)Ending1298

Pressure loss characteristics (air, N2 gas)Pressure loss (kPa)Pressure loss (kPa)Pressure loss (kPa)Pressure loss (kPa)<strong>FSM</strong>-*-005-*0.70.60.50.40.30.20.100 0.1 0.2 0.3 0.4<strong>FSM</strong>-*-050-*54.543.532.521.510.500 1 2 3 4<strong>FSM</strong>-*-200-*54.543.532.521.510.500 4 8 12 16<strong>FSM</strong>-*-101-*25201510Flow ( /min)Flow ( /min)Flow ( /min)0.5520-0.07MPa0.1MPa0.3MPa-0.07MPa0.1MPa0.3MPa0.1MPa0.3MPa0.1MPa0.3MPaPressure loss (kPa)Pressure loss (kPa)Pressure loss (kPa)<strong>FSM</strong>-*-010-*1.61.41.210.80.60.40.200 0.2 0.4 0.6 0.8<strong>FSM</strong>-*-100-*54.543.532.521.510.5<strong>FSM</strong>-*-500-*-0.07MPa00 2 4 6 818161412108642Flow ( /min)Flow ( /min)00 10 20 30 40Flow ( /min)11050<strong>FSM</strong> SeriesTechnical data-0.07MPa0.1MPa0.3MPa0.1MPa0.3MPa0.1MPa0.3MPaRefrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filterAuto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)EndingSmallFlow <strong>sensor</strong>500 20 40 60 80Flow ( /min)1001299

<strong>FSM</strong> SeriesRefrigeratingtype dryerPressure loss characteristics (argon)Desiccanttype dryerHigh polymermembranedryerAir filterAuto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorPressure loss (kPa)Pressure loss (kPa)<strong>FSM</strong>-*-005-*-AR0.040.0350.030.0250.020.0150.010.00500 0.1 0.2 0.3 0.4<strong>FSM</strong>-*-050-*-AR0.80.70.60.50.40.30.20.1Flow ( /min)0.50.1MPa0.3MPa0.1MPa0.3MPaPressure loss (kPa)Pressure loss (kPa)<strong>FSM</strong>-*-010-*-AR0.090.080.070.060.050.040.030.020.0100 0.2 0.4 0.6 0.8<strong>FSM</strong>-*-100-*-AR2.521.510.5Flow ( /min)0.1MPa0.3MPa10.1MPa0.3MPaSuctionplateMagneticspring buffer00 1 2 3 4Flow ( /min)500 2 4 6 8Flow ( /min)10Mechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerPressure loss (kPa)<strong>FSM</strong>-*-200-*-AR87654320.1MPa0.3MPaPressure loss (kPa)<strong>FSM</strong>-*-500-*-AR60504030200.1MPa0.3MPaFlow <strong>sensor</strong>for air110Flow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)00 4 8 12 16Flow ( /min)2000 10 20 30 40Flow ( /min)50Ending1300

Pressure loss characteristics (carbon dioxide)Pressure loss (kPa)Pressure loss (kPa)Pressure loss (kPa)<strong>FSM</strong>-*-005-*-CO20.0250.020.0150.010.00500 0.1 0.2 0.3 0.4<strong>FSM</strong>-*-050-*-CO20.70.60.50.40.30.20.100 1 2 3 4<strong>FSM</strong>-*-200-*-CO210987654321Flow ( /min)Flow ( /min)00 4 8 12 16Flow ( /min)0.55200.1MPa0.3MPa0.1MPa0.3MPa0.1MPa0.3MPaPressure loss (kPa)Pressure loss (kPa)Pressure loss (kPa)<strong>FSM</strong>-*-010-*-CO20.0450.040.0350.030.0250.020.0150.010.00500 0.2 0.4 0.6 0.8<strong>FSM</strong>-*-100-*-CO22.521.510.500 2 4 6 8<strong>FSM</strong>-*-500-*-CO2605040302010Flow ( /min)<strong>FSM</strong> SeriesTechnical dataRefrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filterAuto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)EndingSmallFlow <strong>sensor</strong>Flow ( /min)00 10 20 30 40Flow ( /min)110500.1MPa0.3MPa0.1MPa0.3MPa0.1MPa0.3MPa1301

<strong>FSM</strong>-H/<strong>FSM</strong> SeriesRefrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filterAuto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerNames and functions of display and operating sectionsDisplay integrated type (<strong>FSM</strong>-H/<strong>FSM</strong> Series common)Over<strong>flow</strong> display· Lights and displays when the 3-digitdisplay is exceeded.(At 10.00 /min, this turns on, and 0.00 isdisplayed on the 3-digit LED.)MODE key· Use to enter setting mode.· Use to return to the <strong>flow</strong> display.· Use to release the peak hold operation.Minus display (Excluding <strong>FSM</strong> (air, nitrogen use))· Lights when gas <strong>flow</strong>s in reverse.3-digit LED display· Displays the <strong>flow</strong> rate and switch settings, etc.RUN display· Turns on when displaying <strong>flow</strong>.· Blinks during peak hold operation.· Turns off during various setting modes.Output (OUT1) display· Turns on when CH1 output is on.· Blinks when overcurrent is detected.Output (OUT2) display· Turns on when CH2 output is on.· Blinks when overcurrent is detected.Check valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)· is displayed for an over<strong>flow</strong>.· is displayed for overcurrent in reverse.(Excluding <strong>FSM</strong> (air, nitrogen use))1 (UP) key· Sequentially displays CH1 data when the <strong>flow</strong> rate is displayed.· Displays maximum during peak hold operation.· Sets the mode when the mode is selected.· Used to increment values, etc., when data is set.2 (DOWN) key· Sequentially displays CH2 data when the <strong>flow</strong> rate is displayed.· Displays the minimum during peak hold operation.· Used to decrement the value, etc., when data is set.* The design of the front sheet differs for the <strong>FSM</strong>-H Series, but display and operation section names and functions are the same.Separate indicator typeRefer to pages 1318 to 1321 for details on the display and operation section names, functions, and operation methods.Ending1302

OperationSwitch output functionSwitch operation mode<strong>FSM</strong>-H/<strong>FSM</strong> SeriesOperationRefrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filterOperation pattern name LED display Operation waveformWindow operation 1(ON within specified range)Window operation 2(ON out of specified range)Hysteresis operation 1(Flow <strong>small</strong> side ON)Hysteresis operation 2(Flow large side ON)Switch output OFFSet point confirmation methodCH1 data displayPressCH2 data displayWhen a key is pressed while the <strong>flow</strong> is displayed, the switch data ON setting, OFF setting,operation waveform, zero adjustment, and model are displayed and confirmed.Switch operation is not affected during the following operations:ON sideblinkingONOFFON-ON set pointOFF-OFF set pointONOFF-ON set pointON3%F.S. and overOperation waveform displayFlow+OFF set point3%F.S. and over1%F.S.1%F.S. and overOFF-OFF set pointONOFF-1%F.S. and over1%F.S.Flow+ON set pointFlow+OFF set pointFlow+ON set pointOutput is turned off regardlessof ON or OFF setting.Flow+Note 1.Note 2.Note 3.Note 4.Note 5.ON set point displayWhen used for a winding operation, leave an intervalof 3% F.S. or more between the two settings.1%F.S. hysteresis is automatically added to the onand off sides.When used for hysteresis operation, leave aninterval of 1% F.S. or more between the two settings.If there is no difference between the two settings,operation may not take place or may be unstable.If switches are operated when <strong>flow</strong> is not stable,such as pulsating, operation may be unstable.In this case, provide sufficient margin between thetwo setting values. Confirm that switch operation isstable before use.The left side of the operation waveform indicatesnegative pressure, and the right side indicatespositive pressure.The magnitude relationship of the ON and OFFsettings is determined when the waveform is set, anda reverse magnitude relationship cannot be attained.With this product, however, operation of thedesignated operation pattern is the priority.When the two settings are input, the magnituderelationship is automatically determined, and each isjudged and processed at the appropriate ON andOFF settings.In other words, even if ON and OFF settings areinput reversed, input is recognized correctly as ONand OFF and operation occurs with the designatedoperation mode.OFF sideblinkingAuto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)PressOFF set point displayOperation waveform displayEnding0 point adjustment value, model number display(<strong>FSM</strong> (air and nitrogen) is excluded.)0 point adjustment value and model number display are alternately shown.Switch operation is not affected during this operation.SmallFlow <strong>sensor</strong>"AdJ" display 0 point adjustment value display Model number displayPress at the same time1303

<strong>FSM</strong>-H/<strong>FSM</strong> SeriesRefrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filterAuto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWUsing each functionPeak hold functionMaximum and minimum values for the <strong>flow</strong> rate within a set interval is displayed.Use for such as are the instantaneous <strong>flow</strong> change confirmation.The peak hold operation does not affect this product's basic functions such as switch operations or pressure display.Flow display state"460" is displayed.Press at the same timeSwitch output functionPeak hold operation start(RUN light blinking)Peak value displayPressBottom value displayPressRefer to page 1305 for operation methods.This product has 2-point switch output, and uses four operation modes and stopping.The switch function is started by setting the required operation pattern and by setting two settings (ON and OFF) that specify the operation point.Determine the required operation mode and on and off before setting.Select and set the following data to operate the switch:CH1: operation pattern CH1: ON set point CH1: OFF set pointCH2: operation pattern CH2: ON set point CH2: OFF set pointBlinkingBlinkingPeak value "475"Bottom value "453"Air <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)Forced outputRefer to page 1305 for operation methods.Use this function to forcibly turn switch output on and confirm wiring connection or initial operation of the input device.(Note) Use this test for operation checking of wiring and input unit.Do not use this function instead of actual signals when executing the sequence program while the machine or device is operating.0 point adjustment Refer to page 1305 for operation methods (excluding <strong>FSM</strong> [air, nitrogen use]).Deviation of the display from zero is compensated for in the state with no <strong>flow</strong> rate.If set incorrectly, readjust when no gas is <strong>flow</strong>ing.Ending(Note) The above settings and testing greatly affect the output signal and display.Be sure to stop the machine and devices using this product, and confirm that safety can be ensured even ifproblems or an incorrect display occurs before operating.Using this function while the machine or device is operating could cause unforeseen problems or incorrect displays."Operation"To return to the <strong>flow</strong> display during operations in any setting mode, turn power off and on. The <strong>flow</strong> display isredisplayed.1304

Switch output, forced output, 0 point adjustment operation(Flow display)For safety, if the key is notoperated for two secondsor more before the mode isset, the pressure display isredisplayed.<strong>FSM</strong>-H/<strong>FSM</strong> SeriesBasic key operationOperationThese key operations are valid in the switch operation pattern setting, on/off setting and zero point adjustment mode.Refrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerAir filterPressBlinkingBlinkingReleaseBlinkingPress onceWhen the keyis held down, thepressure display isredisplayed.DeterminationPress onceChange the mode withthe UP/DOWN keysSwitch CH1Operation mode changeChannel 1 displayAlternatedisplayON point waveform displayOFF point waveform displayOperation mode display Set point display Set point displaySwitch CH2Operation mode changeData returnPress at the same timePress onceSetting data of switch outputPress onceCountUpAlternatedisplayCountDownSwitch CH2Setting ON and OFF dataData readingPress at the same timeSwitch CH1Setting ON and OFF dataPress onceChange the mode withthe UP/DOWN keysAlternatedisplayTo <strong>flow</strong> displayAuto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Press onceSet in the same manneras switch CH1.Press oncePressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerPress onceFlow <strong>sensor</strong>for airBlinkingDeterminationCH1 output ONSwitch output forced ON modeCH2 output ONTo <strong>flow</strong> displayFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)EndingPress onceBlinkingCAUTIONPress once<strong>FSM</strong>(Air/nitrogen)To <strong>flow</strong> displayDeterminationPress oncePressAlternatedisplayPressPress once0 point adjustment mode (<strong>FSM</strong> (air, nitrogen) is excluded.)"AdJ" display0 point adjustmentvalue displayBe sure no gas is <strong>flow</strong>ing when adjusting zero.Adjusted value readingPress at the same timeTo <strong>flow</strong> displayPress once1305SmallFlow <strong>sensor</strong>

Refrigeratingtype dryerDesiccanttype dryerHigh polymermembranedryerMiniature <strong>flow</strong> <strong>sensor</strong>Small size <strong>flow</strong> <strong>sensor</strong>Analog output type/switch output type<strong>FSM</strong>-V Series (air/nitrogen gas)Flow rate range: 0.05, 0.1, 0.5, 1, 5, 10 /min.Air filterAuto. drain/ othersF.R.L.(Module unit)F.R.L.(Separate)CompactF.R.PreciseregulatorF.R.L.(Relatedproducts)CleanF.R.ElectropneumaticregulatorAirboosterSpeedcontrol valveSilencerCheck valve/ othersJoint/ tubeVacuumfilterVacuumregulatorSuctionplateMagneticspring bufferMechanicalpressure SWElectronicpressure SWContact / closecontact conf.SWAir <strong>sensor</strong>Pressure SWfor coolantSmall<strong>flow</strong> <strong>sensor</strong>Small<strong>flow</strong> controllerFlow <strong>sensor</strong>for airFlow <strong>sensor</strong>for waterTotal airsystemTotal airsystem(Gamma)Sensor specificationsModel no.DescriptionsFlow rate range ( /min) Note 7 -0.05 to + 0.05 -0.1 to + 0.1 -0.5 to + 0.5 -1 to + 1 -5 to + 5 -10 to + 10 -0.05 to + 0.05 -0.1 to + 0.1 -0.5 to + 0.5 -1 to + 1 -5 to + 5 -10 to + 10Ref.: Applicable nozzle for suction/release applications 0.1 nozzle 0.2 nozzle 0.3 nozzle Collet nozzle 0.1 nozzle 0.2 nozzle 0.3 nozzle Collet nozzleWorking fluidMax. working pressure MPaMin. working pressure MPaClean air (JIS B 8392-1. 1. 1 to 5. 6. 2), compressed air (JIS B 8392-1. 1. 1 to 1. 6. 2) Note 1 , nitrogen gas0.2-0.1Withstanding pressure MPa0.3Ambient temperature/humidityWorking fluid temperature0 to 50, 90%RH or less (with no dew condensation)0 to 50DisplayPower display (green)Power display (green), switch output display (yellow)OutputAnalog output 1 point Note 2Switch output 2 points Note 3(1-5V voltage output, connected load impedance 50K and over) (NPN or PNP open collector output, 30 VDC 50mA or less, PLC/reraly compatible)Linearity5%F.S. or less (0.1MPa, 25 , <strong>flow</strong> rate range 100%F.S.)Pressure characteristics 5%F.S. or less (-0.09 to 0.2MPa, where 0.1MPa is reference)Temperature characteristics 0.2%F.S./ or less (15 to 35 , where 25 is reference)Repeatability (repeatability)1%F.S. or less 2%F.S. or less2%F.S. or lessWorking conditionsInstallation Analog output precision *4ResponsivenessPower voltageCurrent consumptionLead wireInstallation attitudeStrait piping sectionProtective structureVibration resistanceEMC directiveWeight g<strong>FSM</strong>-V-A-R0005<strong>FSM</strong>-V-A-R0010Analog output type<strong>FSM</strong>-V-A-R0050<strong>FSM</strong>-V-A-R0100<strong>FSM</strong>-V-A-R0500<strong>FSM</strong>-V-A-R1000<strong>FSM</strong>-V-N/P-R00055ms or less (when discrete <strong>sensor</strong> is reaching 90% of ultimate output voltage) Note 512/24 VDC (10.8 to 26.4V)30mA or less<strong>FSM</strong>-V-N/P-R0010Switch output type<strong>FSM</strong>-V-N/P-R0050<strong>FSM</strong>-V-N/P-R01002.6 0.15mm 2 x 3-conductor (3m) 2.6 0.15mm 2 x 4-conductor (3m)FreeNot requiredIEC standards IP4010 to 150 Hz, double amplitude 1.5 mm, maximum 10 G, two hours each in X, Y, Z directionsEN55011, EN61000-6-2, EN1000-4-2/3/4/6/8Approx. 8 (excluding leads, joints)<strong>FSM</strong>-V-N/P <strong>FSM</strong>-V-N/P-R0500 -R1000Note 1: Refer to the Compressed air quality classes according to JIS B 8392-1:2003 on page 1281.Note 2: Analog output indicate 3 V when the <strong>flow</strong> is 0, and changes to the 5 V side when the lead when gas <strong>flow</strong>s to the right looking at the unit with leads on the right.Analog output changes to the 1 V side when the <strong>flow</strong> is reversed.Note 3: The Fixed hysteresis 1 boundary value judgment type switch output is used. The Output can be set within the full <strong>flow</strong> range by turning the trimmer. OUT1 andOUT2 operation modes are opposite.Note 4: F.S. (full scale) in these specifications indicates the <strong>flow</strong> range. For example, F.S. for <strong>flow</strong> rate -10 to +10 /min is 20 /min.Note 5: Response time varies depending on the piping conditions.Note 6: When using this product to confirm suction, be sure to insert an air filter (filtration rate 30 m or less) between the suction nozzle and this product to preventforeign matter from being sucked in.A filter for drainage removal must be inserted on the primary (upstream) side when compressed air is used.Note 7: Converted to volumetric <strong>flow</strong> at 20 1 barometric pressure (101 kPa).Ending1306