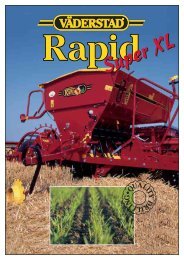

Vaderstad Carrier Effective Soil Cultivation Brochure - LiveUpdater

Vaderstad Carrier Effective Soil Cultivation Brochure - LiveUpdater

Vaderstad Carrier Effective Soil Cultivation Brochure - LiveUpdater

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Effective</strong> soil cultivation

CARRIERFaster dryingThere are also biological advantages for the soil if<strong>Carrier</strong> is used for shallow cultivation instead ofploughing. Minimal cultivation increases thehumus content in the upper soil layer, which meansthat silty soil does not crust over as easily after rainand that any crust formed on the soil surface iseasier for germinating seedlings to penetrate.Minimal cultivation also leads to more worms inthe soil and more large pores to carry water away.Many farmers who convert to minimal cultivationcan confirm that after a few years there is less standingwater in the field and that the soil dries outfaster.An implement for the future<strong>Carrier</strong> is a powerful implement that brings a rangeof economic and biological advantages. In otherwords, <strong>Carrier</strong> makes cropping more rational andthe soil easier to cultivate. <strong>Carrier</strong> releases time,saves money and increases soil fertility. That is thereason why so many proactive farmers have taken<strong>Carrier</strong> to their hearts in such a short time. <strong>Carrier</strong>is the tillage machine of tomorrow, here today!5

FLEXIBILITY, CAPACITY, QUALITY, ECONOMYFlexible <strong>Carrier</strong> for all occasions<strong>Carrier</strong> is a multi-tasker. It is used throughout Europe as an all-purpose implement bygrowers who place high demands on flexibility in crop production. It is available in workingwidths from 3 - 12 metres and meets most needs. Versatility acquires a whole new meaningwhen one and the same <strong>Carrier</strong> can be used for ……stubble cultivationThe most common area of work for<strong>Carrier</strong> is incorporating harvesttrash into the soil. After only oneor two passes, the upper 5 - 7 cmsoil layer is completely homogenised.The secret is to maintain ahigh speed >12 km/h, so that thetwo rows of notched discs throwthe soil to the side. At the sametime, harvest trash is pulverisedand mixed in and the soil is levelledand left ready for drilling or furthertillage operations.…straw harrowing and stubblecultivationBlockages occasionally arise in thecombine harvester, causing thechopper to eject uneven heaps ofstraw, which have to be re-distributed.With the roomy straw harrowin place, even thick heaps of straware gradually fed into the discs.This prevents straw pans developingin patches in the field andcausing nitrogen deficiency andyield decreases in the followingcrop. The straw harrow is animportant prerequisite forsuccessful ploughless cropping.… furrow levellingFrom the very first day <strong>Carrier</strong> arrivedon the market, it took up aprominent position due to its abilityto level plough furrows. <strong>Carrier</strong>System Disc with Crossboard isnow available, making the machinean even better implement onplough furrows. The Crossboardslices off the tops of the furrowswhile at the same time crushingclods. Next come the roller rings,which level the soil surface andreconsolidate the soil.6

FLEXIBILITY, CAPACITY, QUALITY, ECONOMY…reconsolidation androllingThe heavy steel roller rings and therubber roller are equally efficientat reconsolidating, to create anoptimal degree of consolidation inthe topsoil. Through their weight,they contribute to creating optimalcontact between seed and soil, andthe crop can germinate successfully.With the toolbar raised, <strong>Carrier</strong>can be used as a conventionalroller. The entire weight of themachine is then carried by the rearroller rings, making <strong>Carrier</strong> apowerful weapon against crusts orpans.…soil cultivation and seedbedpreparation<strong>Cultivation</strong> depth can be set preciselyon <strong>Carrier</strong>. This property incombination with the efficientslicing action of the discs acrossthe entire working width meansthat <strong>Carrier</strong> is also very suitablefor soil cultivation and seedbedpreparation. The mode of action ofthe discs allows for high speeds, sothe capacity is great. The rotatingmovement of the discs also producesa fine tilth, which acts as agood evaporation barrier for theseed.…sowing small-seededcropsWith BioDrill in place, <strong>Carrier</strong> istransformed into a drill for smallseededcrops. The seed is placedat the discs and covered with soilby the roller.7

FLEXIBILITY, CAPACITY, QUALITY, ECONOMYha/h76543Capacity - <strong>Carrier</strong> 5 metrehp2201901601302108 km/h 12 km/h 16 km/h<strong>Carrier</strong> capacity determined by horsepower …Time is a limiting factor,but also the key to successfulcrop production.<strong>Carrier</strong> slashes the numberof hours spent in the field,provided that there is sufficienthorsepower in front ofthe <strong>Carrier</strong> machine to utiliseits full potential.<strong>Carrier</strong> on the farm provides enormouspotential to rationalise cropproduction. The shallow cultivationincreases the capacity of soiltillage many times over comparedwith ploughing. However, a lot ofavailable horsepower is needed infront of <strong>Carrier</strong> to allow highspeeds in the field. The increase inwork rate is then most apparent.A question of timingShallow cultivation with <strong>Carrier</strong> isvery much a question of timing.The secret is to hit the right timefor the different operations.Sometimes only one opportunityarises and it has to be exploited.One such sensitive operation is thefirst cultivation after harvest. Thefirst thing to do once the combineleaves the field is to immediatelyallow the <strong>Carrier</strong> machine to mix8harvest trash into the surface,preferably within the first 24 hoursafter harvest. For this reason, thecapacity of <strong>Carrier</strong> must be equalto, or greater than, the capacity ofthe combine harvester. Drive thecombine during the day while thesun is shining and the <strong>Carrier</strong> in theevening when the dew has fallen.Within 24 hoursThe rule of thumb of within 24hours is based on the fact that thesoil surface is still damp duringthat period. This moisture stimulatesvolunteer seeds to germinateand harvest trash to decompose. Itis important that the first cultivationis shallow, 5 - 6 cm, so thatseeds are encouraged to germinate.When they have emerged, theyare able to grow properly beforebeing killed by the next cultivation.If an autumn crop is to follow, thewindow of opportunity can be slim.It must therefore be possible toquickly cultivate any areas to beautumn-sown. This possibility isprovided by <strong>Carrier</strong>.Robust constructionThe robust construction of <strong>Carrier</strong>machines allows very high speedsin the field. There are no problemswith driving at 12 - 15 km/h. On thecontrary, the machine does abetter job at high speeds comparedwith lower. Aggregates are brokenup more finely and harvest trash isincorporated more thoroughly.High speeds not only improve workcapacity, but also produce bettersoil tillage results.Save a week’s work…The diagram above shows thepotential time savings associatedwith higher speeds. If thespeed can be increased from 8 to12 km/h, this increases the capacityof a <strong>Carrier</strong> with 5 m workingwidth from 3 ha/h to around 4.5ha/h. Using this <strong>Carrier</strong> to cultivate180 ha in two passes involves120 hours in the tractor at 8km/h. However at 12 km/h, only80 hours are needed in the tractor.The difference is a fullworking week! This time can beused for other things.

FLEXIBILITY, CAPACITY, QUALITY, ECONOMYha/h15Capacity within different modelsCR 1225129CR 65063CR 300010 km/h15 km/h…and also by working widthAnother way to increase capacityis to choose a <strong>Carrier</strong> witha greater working width. Awider machine costs a littlemore and is thus suitable forco-ownership, so that thefixed costs can be distributedover more hectares. A widermachine gives both increasedcapacity and lower cropproduction costs, sinceworking time in the field iscut.The work rate of <strong>Carrier</strong> is impressivelyhigh. It is extremely rare for<strong>Carrier</strong> capacity to act as a bottleneckin the process of fitting in harvest, tillageand seed drilling. High speed isthe key to a high work rate – but anotheroption is simply to move up to a<strong>Carrier</strong> with a greater width.Perfect machineIncreased working width meansincreased capital costs. These fixedcosts have to be spread out acrossmore hectares. This can be achievedby farm expansion, but also by severalfarms co-owning a larger machine.<strong>Carrier</strong> is the perfect machine for coownership.The machine is robustand has low maintenance requirements.In addition, co-ownership of alarger <strong>Carrier</strong> than demanded by thefarm acreage provides a fantasticopportunity to exploit the highercapacity of such a machine. An incredibleamount can be achieved in ashort time. This makes it easier tocultivate at the right time and toavoid driving in the field under lessthan favourable conditions. Thisaspect is an important factor in thesuccess of ploughless tillage.From 2 to 7 ha/hThe diagram above clearly shows theeffects of greater working width andhigher speed on capacity. If twoneighbours who each have a <strong>Carrier</strong>with 3 metre working width co-operateinstead to buy one with 6.5 metresworking width, their work rate ismore than doubled from just over 2 tojust under 5 ha/h at the same drivingspeed of 10 km/h. A more powerfultractor would allow even greaterspeeds. At 15 km/h, a 6.5 metre<strong>Carrier</strong> has a capacity of over 7 ha/h.A larger tractor is more expensive,but can also be co-owned.Freed timeThe chase after hours and minutescan appear unnecessary in a shorttermperspective. However, productivityis the cornerstone in maintainingcompetitive ability. All the hoursadded together soon make up daysand weeks of freed time that can beused more constructively. Many whohave grasped the importance ofsaving time in the field have quitesimply expanded their area, sincethey have time to cultivate morehectares.Lower production costsThe driving force in reducing thehours spent in the field is to reduceproduction costs. All thoseaiming to be involved in the agricultureof tomorrow will have towork each hectare a little morecheaply. Achieving this calls for apowerful, reliable and economicalsoil tillage implement with ahigh capacity to work the soil.<strong>Carrier</strong> is such an implement.9

Tough testingTo ensure long lifetime, our machinesare driven hard under extremeconditions in parallel with R&Dwork. A <strong>Carrier</strong> disc gets a taste ofboth rough sandy soils and heavyclay soils before it reaches themarket. In addition to test-driving inthe field, our machines are alsotested for lap after lap in gravel pitsand stone quarries, where they areexposed to more merciless treatmentthan they would ever experiencein normal operations on afarm. This paves the way for longlifetime and thus good overalleconomy.FLEXIBILITY, CAPACITY, QUALITY, ECONOMYEfficient discs<strong>Carrier</strong> is equipped with hardenedconical discs, manufactured fromSwedish quality steel for maximumdurability and lifetime. These resistantdiscs can therefore withstandtough conditions. Maintenance islow due to the high quality of thesteel. Although the discs eventuallyshow some signs of wear after atime, their conical shape meansthat their angle of attack alwaysremains the same and the soil tillageoutcome is always equally good,regardless of whether the discs arenew or old.Maintenance-free rollerpackageThe steel rings in the roller packageare tightened with many tonnes ofpressure in the factory duringmanufacturing. This pre-tighteningremoves the need to tighten theroller package manually and meansthat in practice, the roller packageis completely maintenance-free.The pressure is maintained at analmost constant level during theentire lifetime of the machine.11

FLEXIBILITY, CAPACITY, QUALITY, ECONOMYl/ha605052,1 lHalved diesel consumption on heavy claysClay content 40% Clay content 20%403024,7 l27,4 l22,8 l2010Shallow cultivation with<strong>Carrier</strong> lowers dieselconsumption in soil tillage.This increases profitabilityand decreases emissions ofgreenhouse gases, benefitingboth the grower andthe environment.Shallow cultivation with <strong>Carrier</strong> isthe sensible option when theamounts of harvest trash present, orthe structure of the soil, do not createa need for deeper loosening byploughing. Consumption of diesel isconsiderably reduced. This decreasesthe costs of soil tillage and savesthe farmer money. However theenvironment also benefits whendiesel consumption decreases.Half the amount of dieselCalculations of diesel consumptionin field trials show that it can behalved when <strong>Carrier</strong> replaces the120Drilling 14,7 lCultivator 8,6 lDrilling 10,8 l<strong>Carrier</strong> x 2 13,9 lDrilling 12 lPlough 15,4 lPlough 28,8 lPloughing – seedbed preparation –drilling. 2 x <strong>Carrier</strong> – seedbed preparation –drilling. Estimated diesel consumption in systems with a plough or<strong>Carrier</strong>, 2003 - 2004. Seedbed preparation with combinations of Rexius roller and <strong>Carrier</strong> according to need to prepare the soil for drilling with a Rapiddrill. Source: Dr. Johan Arvidsson, Swedish University of Agricultural Sciences, Uppsala.<strong>Carrier</strong> saves dieselplough on a heavy soil with approx.40% clay. Ploughing, seedbed preparationand drilling use up 54 litres ofdiesel per hectare to establishwinter wheat. However, two passesby <strong>Carrier</strong> plus seedbed preparationand Rapid drilling reduce dieselconsumption radically to 24 litresper hectare.Inexpensive seedbed preparationwith <strong>Carrier</strong>One reason for this is of course theactual ploughing. It takes moreenergy to plough the soil to 20 cmdepth than to only cultivate the top5 - 7 cm, as is the case with <strong>Carrier</strong>.However another contributingfactor is the amount of seedbedpreparation necessary when thesoil is ploughed. More tillageoperations are required to levelfurrows and create a sufficientlyfine tilth for acceptable establishmentof the following crop. Thedeeper an implement is operated,Drilling 10,1 l<strong>Carrier</strong> x 2 12,7 lthe more power required to reconsolidateand fine-till the soil and allthis power demands more energyin the form of diesel. With shallow<strong>Carrier</strong> cultivation, seedbed preparationis cheaper.Better net resultsEven on a lighter soil with around20% clay, less energy is required fortwo passes with <strong>Carrier</strong> comparedwith ploughing. The differences arenot as dramatic here, but opting forshallow cultivation with <strong>Carrier</strong>instead of ploughing reduces dieselconsumption by 25%. A cost savingof 25% means that productioncosts are lowered, crop productionis more efficient and net profits areimproved.

FLEXIBILITY, CAPACITY, QUALITY, ECONOMY‘Maintenance costs incredibly low’Far down in the most southernpart of Sweden, thethree farms Ellinge,Hviderup and Skarhulthave a machinery co-operativeand co-own a <strong>Carrier</strong>820. After four seasons andalmost 4000 hectaresworked, they know that themaintenance costs amountto exactly 1,39 € perhectare.These three large arable farmstogether crop 2150 neighbouringhectares. Before the 2003 season,the three farms decided to invest ina <strong>Carrier</strong>.Only 1.39 € per hectareDuring the growing seasons2003 – 2006, the farms worked atotal of 3785 hectares, i.e. approx.950 hectares per year. All the spareparts costs including workshopbills were carefully logged, so thefarmers know the maintenancecosts to the exact decimal. Spreadacross the hectares worked, thetotal is low.‘Maintenance costs were 1,39 € perhectare’, reports Hans Törnlycke,who is manager of one of the threefarms. He knew that the machinewas cheap to run but still could nothelp being impressed by the finalfigures.‘It’s fantastic. Many believe that amachine like this is expensive tomaintain, but 1.39 € per hectare isnothing. The maintenance costsare incredibly low’.Frictionless co-operationOver 80% of the maintenance costsare for replacement discs. Themanagers take the opportunity tohave this done during the lowseason in the winter, so each farmsends a man to one of the farmworkshops. It takes one day forthese three to replace all the discs.‘Working together is a pleasant wayto lay the foundations for good cooperation’,says Hans Törnlycke.None of the farms could havebought a <strong>Carrier</strong> with 8.20 metresworking width, but placing theinvestment in proportion to thearea cultivated brings it down to areasonable level. The advantage isthat all gain access to a machinewith an enormously high capacityon the days they require it. The cooperationhas been problem-free.The farms use the machine fordifferent purposes because theyhave different enterprises andcultivation systems.The <strong>Carrier</strong> machine cultivatesstubble, levels plough furrows,incorporates farmyard manure andprepares the seedbed for sugarbeet,to list its main activities.‘Actually, we never clash with eachother’.Robust constructionThe limitation on <strong>Carrier</strong> capacityis the horsepower of the tractorengine. It is possible to drive at12 - 13 km/h with <strong>Carrier</strong>. Despitedriving as fast as possible, themachine stays in one piece. A discor so might be sacrificed when ithits a really big stone, but it is easyto replace and at no great cost.‘Our <strong>Carrier</strong> practically neverbreaks down. The reason is thehigh quality of the materials andthe simple and robust construction’,believes Hans Törnlycke. Themachine is stored in the machineryshed when it is not working in thefield, so apart from disc replacementat regular intervals, he thinksthat their <strong>Carrier</strong> has a lot more togive.‘It can easily last for another fiveyears’.13

THE CARRIER PRINCIPLEZone 1Zone 2The <strong>Carrier</strong> principle– effective cultivation and reconsolidationTwo rows of 430 mm conical discs efficientlyslice across the entire working width inthe interval 3 - 10 cm depth. The soil is leftwell reconsolidated by a 550/600 mmroller with hardened steel or rubber rings.Zone 1 – Straw distributionUniform distribution of straw is a precondition in shallowtillage, in order to create equal germination conditionsfor all seeds. A straw harrow in front of <strong>Carrier</strong>helps to distribute the straw over a greater area, particularlyif this operation is carried out at a slight angleto the driving direction of the combine.Zone 2 A – Disc cultivationTwo rows of 430 mm conical discs aggressively slicethe soil and harvest trash down to max. 10 cm depth.Working with small discs allows a considerably higherrotation speed, which means that <strong>Carrier</strong> takes manysmall bites, whereas a larger disc would have freedlarger chunks. The effect is easy to see in the fine tilthstructure, the thorough mixing and the level soil surfacethat the machine leaves in its wake.Because of the conical shape of the discs, the optimalangle of attack is maintained, in contrast to a curveddisc, which gradually becomes less effective as itwears down.14

THE CARRIER PRINCIPLEZone 3Zone 2 B – Crossboard cultivationCertain <strong>Carrier</strong> models also have Crossboard (insteadof the straw harrow). Crossboard as the toolbarequips the machine to perform efficient stubble cultivationand in the next instant crush, pulverise andlevel a large, heavy plough furrow.Zone 3 – ReconsolidationIn shallow cultivation it is important to leave the soilsurface well reconsolidated, in order to create optimalconditions for germination of volunteer and weedseeds and decomposition of straw. <strong>Carrier</strong> is equippedwith 550/600 mm steel rings that efficiently reconsolidatethe soil and set the seal on tillage.Crossboard is available for many of the trailed <strong>Carrier</strong>models.For the smallest <strong>Carrier</strong> models, the rubber roller isavailable as an option.15

System Disc creates a finetilthSystem Disc consists of two rowsof intensively working and slicingdiscs (430 mm). For full cultivation,the two rows of System Disc can beadjusted in relation to each other.The relatively small discs spacedat 12.5 cm intervals along the rowsensure a higher rotation speed andthereby a more intensive cultivationof the soil surface. A small discalso takes out smaller bites, whichcreates a finer tilth. The fine soilparticles ensure good soil/seedcontact, promoting germination ofweed and volunteer seeds, whichcan then be tilled under in asecond pass.Powerful soil cultivationField levelled with adjustableside discsThe outer disc arms can be adjustedin the vertical direction to producegood levelling of the field and toavoid furrows being left betweenbouts. <strong>Cultivation</strong> is strikinglyuniform after <strong>Carrier</strong>.Forged disc armThe new disc arm is 20 mm higherthan previously and also gives a 20mm wider space between the sideof the disc and the coulter arm.This increases the ability to feedharvest trash and straw throughand allows for a higher drivingspeed.Conical discs<strong>Carrier</strong> is equipped with hardenedconical discs for optimal slicing andincorporation of straw. A conicaldisc always maintains the correctworking angle, regardless of wear,while a concave disc loses itsslicing ability as it becomes worndown. In practice, this means thatthe conical discs do not have to bereplaced as frequently.Conical discsSameangleSameangleConcave discsSmallangleLargeangle16

SOIL CULTIVATIONFull slicing with lateraladjustmentAchieving efficient control of rootpropagatedweeds requires allroots to be thoroughly sliced up inthe first pass. To ensure optimalslicing and thereby uniform tillage,the front row of discs can easily beadjusted laterally with the help of aturnbuckle.Hydraulic depth control<strong>Cultivation</strong> depth is easily set withthe help of clips that limit therange of movement of the hydrauliccylinder. Extra clips are storedbeside the hydraulic cylinder. Onthe <strong>Carrier</strong> 1225-model, depth isset by electric depth controlwithout clips.High weight on discsA <strong>Carrier</strong> with System Disc has aweight of 750 - 1100 kg/m. Thisweight can be used to force thediscs down into the soil in hard ordry conditions or simply to reconsolidatethe soil surface. Our experienceis that every kg is needed!The heavy <strong>Carrier</strong> machine keepsthe discs at the pre-set depth andgives full slicing within the cultivationinterval of 3 - 10 cm.17

Powerful steel rollerThe steel roller of pressure-hardenedsteel has enormous durabilityand acts with all its weight andstrength to press down stones andbreak up and pulverise clods andlumps. In contrast to cast-ironrings, the steel roller runs cleanand makes it possible to work evenin very wet conditions.<strong>Effective</strong> reconsolidationNo draggingEach roller ring consists of twohalves pressed against each other,which creates an internal tensionthat causes the rings to continuallypress tightly together and driveeach other. This minimises the riskof soil being dragged and walledup. The shape of the roller ringsmeans that they not only work onthe surface, but also aggressivelywork to press straw down into thesoil.Rubber dampener prolongslifetimeThe ball bearings on which theroller package is mounted on theaxle are surrounded by a rubberdampener. This ingenious solutionabsorbs shocks and impacts,protecting the rings and the axlesand prolonging their lifetime.<strong>Effective</strong> scrapersTo allow work to be carried out inwet conditions, a scraper bar efficientlycleans between the steelrings. Adjustable arms with similarlyadjustable wearing parts thatare shaped to match the contoursof the rings efficiently clean off anysoil and harvest trash that picksupon the roller.18

RECONSOLIDATIONReconsolidation and fine soil decide the resultsIn reduced tillage, a falseseedbed is a centralconcept in inducing weedand volunteer seeds togerminate. The false seedbedsucceeds if the soil isreconsolidated after cultivationand if the soil issufficiently finely tilled.As soon as the combine leaves thefield, the <strong>Carrier</strong> should be put towork. The first cultivation shouldtake place within 24 hours.Shallow cultivateThen there is still moisture left inthe upper layer that makes volunteersand weed seeds germinate -an essential factor in the success ofshallow cultivation. Encouragingweed seeds to germinate is calledcreating a false seedbed. The firstcultivation should be shallow, to 5 -6 cm depth. This causes any seedspresent to germinate and emergerapidly. Each day’s delay in theemergence of weed seeds meansthat time is lost. This is especiallyimportant if the next crop is to be awinter cereal.Reconsolidation importantReconsolidation of the soil at thetime of the first cultivation iscompletely decisive in achievingfast and uniform germination. Thisis why a harrow or cultivator doesnot give the same results in creatinga false seedbed as <strong>Carrier</strong> withroller. In a loose, airy, coarse anddry seedbed, the germinationprocess does not begin until afterrain. In a reconsolidated soil wherethe roller has recreated the contact,the weed seeds can begin togerminate at once.More fine soil with <strong>Carrier</strong>The more finely tilled the soil, themore contact areas there arebetween damp soil and weed andvolunteer seeds. Small disc diameteris important in creating a lot offine soil. <strong>Carrier</strong> has strength here,since its 430 mm diameter discsproduce a more finely-worked soilthan discs with a greater diameter.Furthermore, the relatively small<strong>Carrier</strong> discs have the advantagethat it is easier for them to forcetheir way into dry soil. This is animportant argument at harvesttime, when the soil is often desiccatedand difficult to penetrate.19

CARRIER MODEL OVERVIEW20

CARRIER MODEL OVERVIEW<strong>Carrier</strong>with or without straw harrow for everything from stubbleto ploughedSizes: 420, 500, 650, 820, 1225Capacity at 10 km/h:• Ca 0.9 ha/h per metre working width• 3 - 11 ha/h• 30 - 110 ha/dayCapacity at 14 km/h:• Ca 1.2 ha/h per metre working width• 5 - 15 ha/h• 50 - 150 ha/day<strong>Carrier</strong> Crossboardwith Crossboard for stubble to heavy plough furrowsSizes: 420, 500, 650Capacity at 10 km/h:• Ca 0.9 ha/h per metre working width• 3 - 6 ha/h• 30 - 60 ha/dayCapacity at 14 km/h:• Ca 1.2 ha/h per metre working width• 5 - 8 ha/h• 50 - 80 ha/daySee pp. 22 - 25See pp. 26 - 27<strong>Carrier</strong> Trailedwith or without Crossboard in flexible and powerfulformatSizes: 300, 350, 400Capacity at 10 km/h:• Ca 0.9 ha/h per metre working width• 3 - 4 ha/h• 30 - 40 ha/dayCapacity at 14 km/h:• Ca 1.2 ha/h per metre working width• 4 - 5 ha/h• 40 - 50 ha/day<strong>Carrier</strong> Mountedperfect format for small, irregular fieldsSizes: 300, 350, 400Capacity at 10 km/h:• Ca 0.9 ha/h per metre working width• 3 - 4 ha/h• 30 - 40 ha/dayCapacity at 14 km/h:• Ca 1.2 ha/h per metre working width• 4 - 5 ha/h• 40 - 50 ha/daySee pp. 28 - 29See pp. 30 - 3121

CARRIER<strong>Carrier</strong> performs miracles on both stubble and furrows<strong>Carrier</strong> machines inworking widths 4.2 to 12.25m are available with orwithout a straw harrow.The straw harrow isperfect when workingdirectly after the combinefor encouraging weed andvolunteer seeds to germinateand for mixing soil intothe straw so that decompositioncan begin.The 2007 model has been fittedwith raised rigging screws and istherefore more spacious and givesvery good throughflow throughthe entire machine. This allowsboth driving speed and efficiencyof work to be increased.Straw harrowWith the spacious straw harrow in position even thick heaps of straw canbe gradually fed through into the discs. This helps to avoid the yielddecreases that can arise in the following crop as a result of straw clumping.With a straw harrow as part of the toolbar, the straw is evenly distributed,thus decreasing the risk of nitrogen deficiency and of roots havingto force their way through a thick layer of straw. The straw harrow is aprecondition for successful ploughless cropping.22

CARRIEREasy to adjustOne of the main changes on the 2007 model is theraising of rigging screws. This construction optionallows for easy, quick and comfortable setting of thetoolbar.Roomy constructionRaising the rigging screws has created more space inthe machine and given good throughflow across theentire width. Large amounts of straw, clay clods andsoil pass through <strong>Carrier</strong> at high speed without therisk of blockages.23

CARRIERWhen capacity is decisive<strong>Carrier</strong> 1225 has an impressivecapacity and canmatch the pace of severalof the larger combines.A shallow cultivation immediatelyafter the combine brings greatadvantages since the soil moisturehas not yet been lost from thesurface layer. <strong>Cultivation</strong> is easier,the moisture gives good germinationof weed and volunteer seedsand decomposition of straw andharvest trash is faster. The reconsolidatedsurface also provides agood barrier to evaporation.24No time to lose<strong>Carrier</strong> System Disc 1225 has animpressive work rate of approx. 15 haper hour. On a daily basis, this is equivalentup to 200 ha cultivated area,which means that <strong>Carrier</strong> is able tomatch the pace of a number of thelarger combines. An appropriate tractorsize is in excess of 400 hp, to copewith cultivation at around 14 km/h.Built for toughnessThe framework of <strong>Carrier</strong> SystemDisc 1225 is considerably differentfrom that of the smaller siblings inthe <strong>Carrier</strong> family. The centre frameconsists of a welded steel profilemanufactured from highly durablematerial in order to withstand thestresses to which a machine of thissize is exposed. On the wheelsections, the roller axles are dividedto distribute the load overmore bearings. Sturdy bogie wheelsensure stable transport. Hydraulicor pneumatic brakes are standard.Optional straw harrow<strong>Carrier</strong> System Disc 1225 can beequipped with a straw harrow infront of the discs. Optimal resultsare achieved by working at a slightangle to the combine direction sothat the straw is distributed over agreater area.

CARRIER3 metre25

CARRIER CROSSBOARDWith integral Crossboard inthe System Disc toolbar,<strong>Carrier</strong> is equipped to performefficient stubble cultivationand in the next instant crush,pulverise and level a large,heavy plough furrow. Thisprovides completely new andunique possibilities for fullflexibility without the performanceor quality of work beingcompromised.26Choose <strong>Carrier</strong> with Crossboardwhen combining ploughless tillagewith ploughing of certain areas,depending on crop rotation, theweather, soil conditions, etc. Thismachine can get the job done in anycircumstances - it is an implementfor all conceivable situations.All operated from the cabBoth the working depth of the discsand the angle of attack of Crossboardcan be adjusted hydraulically fromthe tractor cab during work.System CrossboardSystem Disc Crossboard (SDCB) isavailable for <strong>Carrier</strong> 420, 500 and650. Crossboard consists of sprungtines made from special steel,which aggressively crush a coarseplough furrow. The working plateson the end of these tines can easilybe replaced if required.

CARRIER CROSSBOARDAngle of attack can be adjustedCrossboard can be mounted in anupper or lower position to achievea more aggressive or a more obliqueangle of attack.Stabiliser bar for powerfulcultivationThe Crossboard tines are linkedtogether with a stabiliser bar ofvery high quality spring-steel witha fracture point of over 1100N/mm 2 . This stabiliser bar gives avery thorough levelling effect oneven the heaviest and most difficultclays. On lighter soils or wheregentler levelling is desired, the barcan be removed.Folded up in stubbleThe Crossboard is attached to thetoolbar and is raised up duringturning. When driving in stubble,the Crossboard can be folded upcompletely.27

CARRIER TRAILEDTrailedA trailed <strong>Carrier</strong> withrubber roller is now availablein 3, 3.5 and 4 m widths.With its strong construction,it has been designedfrom first principles towithstand a considerableweight increase whenrequired.Extra ballast weights of up to 800kg give the machine an impressiveworking weight of approx. 750kg/working metre.Responsive on headlandsThe ingenious drawbar, which is linked to the hydraulic arms of the tractor,gives the machine its speed and agility in work, on the road and, not least,during turning on headlands. During turning, the machine is raised up onthe rubber roller by the depth control cylinder. The machine then hangslightly on the tractor lift arms and has a fantastic turning ability – it can turn‘on a sixpence’. The drawbar is telescopic and can be extended if the tractoris equipped with twin tyres or if the <strong>Carrier</strong> machine is fitted withCrossboard.28

CARRIER TRAILEDEasy transportThis machine is very easy to transporton the road. Thanks to theingenious drawbar, the machinefollows the tractor very well, evenat high transport speeds, on poorroad surfaces or very sloping roads.Optional CrossboardAn aggressive Crossboard is available as an option. The Crossboard isplaced in front of the discs and can carry out an intensive crushing andlevelling operation on heavy furrows. The sprung Crossboard tines arelinked together by a strong stabiliser bar, for even better cultivation acrossthe entire working width.Rubber roller reconsolidatesevenlyThe rubber roller reconsolidatesthe soil evenly and has a low dragresistance, which reduces thedraught requirement. It works verywell on lighter soils, since it doesnot drag the soil along the surface.29

CARRIER MOUNTEDMounted<strong>Carrier</strong> is available in ahydraulically mountedversion in working widthsof 3, 3.5 and 4 metres. Thismodel is particularly suitableon small irregularfields since it is easy toreverse and turn.Ballast weightsExtra ballast weights are available as an option for adjusting the penetrationand reconsolidation ability. These are easily fitted on the powerfulcentre beam. The machine weighs 550 kg/m in its basic form, but can beloaded up to 800 kg/m. The machine is easy to adjust and a rubber roller isavailable as an option.30

CARRIER MOUNTEDHydraulic depth control<strong>Cultivation</strong> depth is easily set withthe help of clips that limit therange of movement of the hydrauliccylinder. During work, themachine can be ‘lightened’ withthe help of the hydraulic cylinderand the hydraulic arms of the tractor.Easy transportA hydraulically mounted <strong>Carrier</strong> 300 - 400 is easy to transport, simply liftup the machine and drive to the next field. The machine is designed to beas compact as possible without compromising throughflow in the field.This compactness brings the advantage that the centre of gravity of themachine is as close to the tractor as possible, resulting in less load on thehydraulic system and safer transport. The lighting is well protected.Optional rubber rollerEquipping <strong>Carrier</strong> with a rubberroller creates a machine that isparticularly suitable for lightersoils, since the rubber roller haslow friction and very little tendencyto drag the soil.31

BIODRILLWith BioDrill, <strong>Carrier</strong> canbe transformed into a seeddrill for small-seededcrops.With BioDrill on <strong>Carrier</strong>, ley seed,catch crops and other smallseededspecies can be drilled withprecision in a combined operationwith soil cultivation. This savespasses, time and money. The seedsare metered out by Väderstad’sown tried and tested Fenix system,which allows very small amountsof seed to be drilled with highprecision. The seed nozzles placeseeds beside the notched <strong>Carrier</strong>discs and they are then covered bythe roller. The hydraulic fan ensuresa uniform distribution of seedto all seed nozzles. BioDrill issuitable for the CR 500, 650, 820models. The Rexius roller and thelarge Rapid seed drills can also beequipped with BioDrill.For more information,order our BioDrillbrochure now.32

CARRIER DRILLWhen a 3 metre <strong>Carrier</strong> thatcan also drill seed isrequired, then <strong>Carrier</strong> Drillis the right choice.With <strong>Carrier</strong> Drill, all soil cultivationand drilling can be performedby a single machine. Few othersystems on the market can match itin terms of capital binding andversatility. On small or mediumsizedfarms, Väderstad <strong>Carrier</strong> Drillcan carry out all the soil cultivationand seed drilling necessary to establisha new crop. This machine isprimarily intended for ploughlesstillage, since it has no Crossboardand thus does not have the sameability to level off soil after ploughing.The seed is placed in a band in thewake of each disc, covered with soiland packed down by the roller. Theacknowledged ability of Väderstad<strong>Carrier</strong> to cultivate to a shallow,precise working depth providesgood conditions for uniform emergence.The feed system is the welltestedsystem in use on Rapiddrills. However, seed placement isnot quite as exact as with Rapid.For more information,order our <strong>Carrier</strong> Drillbrochure now.33

FARMERS’ EXPERIENCESStraw is incorporated, thefield is level and volunteerseeds germinate at once.After a number of experimentsin soil tillage, SvenRingdahl is satisfied atlast.Various possibilities for soil tillagewere created on Berg Farm with thearrival of the Väderstad <strong>Carrier</strong>.Sven Ringdahl combines arable andfattening pigs on Berg Farm onVärmlandsnäs – a peninsula extendingout into Lake Vänern, Sweden’slargest and Europe’s third largestlake. Sven has been experimentingwith soil tillage during all hisworking life as a farmer. New ideashave appeared and been tested,before being approved or rejected.Triumphs and setbacks have followedeach other in rapid succession.However for the past three years atleast, he is happy with soil tillage onBerg Farm.‘<strong>Carrier</strong> has revolutionised soil tillagehere’, he says without hesitation.34‘<strong>Carrier</strong> has revolutionised tillage’Covers and levels<strong>Carrier</strong> works on all his soils. Mostof these consist of light sandyloams, but there are also silty andclayey loams for <strong>Carrier</strong> to workwith. The greatest advantage with<strong>Carrier</strong> is its ability to incorporateharvest trash into the soil.‘It covers enough straw unless it isvery plentiful. The other advantageis that the soil is so level after thismachine’.Before investing in <strong>Carrier</strong>, SvenRingdahl experimented with discimplements, rotary spade harrowsand cultivators of different makes.‘But a disc implement leaves wallsand a cultivator finds it difficult toproduce a level surface. That’swhere <strong>Carrier</strong> has the advantage’.Quality of tillageThe third argument for <strong>Carrier</strong> is theuniform reconsolidation, accordingto Sven Ringdahl.‘Reconsolidation is almost overexaggerated’,he laughs, referring tothe fast germination of volunteerseeds. It is the weight of the machineand in particular the packer rollerthat creates this effect. However,Sven believes that the weight of themachine can also lead to one disadvantage.‘You have to be careful when the soilis too wet, because <strong>Carrier</strong> can thenpush the soil in front of it. But at thesame time, this weight is an advantagein seedbed tillage on clays’.Last autumn, Sven Ringdahl experimentedwith just one pass beforespring sowing. Otherwise he normallycarries out two passes to preparefor both winter and spring crops –<strong>Carrier</strong>, slurry spreading, then<strong>Carrier</strong> again and finally seed drillingwith Rapid. This was also the basicpattern followed before <strong>Carrier</strong> arrivedon Berg Farm.Now Sven Ringdahl saves on averagea half pass per field with <strong>Carrier</strong>.However, it is not the number ofpasses that are at the root of hiswarm feelings for the machine.‘No, the main thing is the quality, theresults are so much better in tillagebefore sowing. The disc implementfluffed up the soil and threw the

FARMERS’ EXPERIENCESstraw on top. Now the soil is fullyconsolidated and the straw buried’.Low maintenanceAfter 2000 hectares of work homeand away with his <strong>Carrier</strong>, he hasonly needed to replace a few discsand a bolt on a scraper. That’s all. Somaintenance costs per hectare arelow, and that is important becausethe machine works many hectaresand in fact replaces the ploughcompletely. Sven Ringdahl stoppedploughing as far back as 1987.‘I sometimes ask myself why’, hesmiles. But he knows exactly why.‘It took too long. As the animalnumbers increased and the farmarea expanded, every hour of theday became more valuable’. Small,irregular fields take an extremelylong time to plough properly.Another reason was that SvenRingdahl wanted to include moreautumn-sown crops in order toincrease his yields. That is no easytask in a region where there are onlytwo weeks to play with betweenharvest and autumn sowing.However, without ploughing thereare good chances of fitting in thework. Last autumn he even managedto sow winter rape for the firsttime. As with all the other crops, heenjoys looking at the rape crop andwalking through it.‘I gain a lot of strength from growingcrops and tilling the soil’.Cropping, Berg Farm 2007:• 30 ha winter wheat• 54 ha triticale• 16 ha winter rape• 15 ha spring rape• 80 ha spring barley• 45 ha oatsAt Berg, <strong>Carrier</strong> gives:• Better straw incorporation• Optimal reconsolidation• Level fields• Fast germination of volunteerseeds• Faster soil cultivation• A longer time for autumn drilling• Freed time for pig production35

SERVICEVäderstad <strong>Carrier</strong> – a reliable investmentInvesting in a Väderstad<strong>Carrier</strong> means acquiring avery reliable and flexibletillage partner.Väderstad <strong>Carrier</strong> has been on themarket since 1999 and is a triedand tested machine. To date wehave supplied more than 5,500<strong>Carrier</strong>s, many of which haveworked more than 10,000 – 20,000ha and are still going strong.Robust constructionFew moving parts and a robustconstruction mean that <strong>Carrier</strong> haslow maintenance costs. Väderstad<strong>Carrier</strong> is sought after on thesecond-hand market and has ahigh resale value.Service nearbyVäderstad has representatives inaround 30 countries and we have awell-established network of subsidiarycompanies, importers andsales agents. Highly skilled servicetechnicians with many years ofexperience guarantee top classservice.Let your machine stay aVäderstad machineIn our distribution networkcomprises well-stocked spareparts depots for fast support, anddeliveries are made via the leadinglogistics experts on the market. Wesupply spare parts for all ourmachines, providing owners withsecurity throughout the lifetime oftheir machines. All our spare partscatalogues are available via theinternet and are continually updatedfor fast and easy identificationof any parts required. Always useVäderstad quality spare parts toensure problem-free operation andto maintain the value of yourVäderstad machine.36

MACHINE SUMMARYRapid RDMechanical, with or without Combi. The Rapid drill isa flexible universal implement for drilling in manydifferent kinds of conditions - ploughed, ploughless ordirect drilled.RD 300, 400SRD 300, 400CRapid RDAPneumatic, with or without Combi. Very high drillingcapacity combined with extraordinary soil cultivatingability. Despite its imposing dimensions, this drill isvery responsive on headlands and in transport.RDA 400, 450, 600, 800SRDA 600, 800C<strong>Carrier</strong><strong>Carrier</strong> is a very versatile soil cultivating machine thatis suitable in both ploughless and ploughed cultivationsystems. Folding.CR 420, 500, 650, 820, 1225<strong>Carrier</strong> 300 - 400 (mounted)Same versatility as the trailed <strong>Carrier</strong> but with 3-pointlift. Excellent for medium-sized farms with a demandfor capacity and quality in soil tillage.CR 300, 350, 400<strong>Carrier</strong> 300 - 400 (trailed)Same machine as <strong>Carrier</strong> 3-point lift, but with towbarand rubber roller. Great flexibility and capacity in aresponsive machineCR 300, 350, 400RexiusRexius is a cultivating roller with high ability forsuperb soil cultivation. It is an excellent followingimplement after the cultivator or harrow where thereis an extra high requirement for soil consolidation.RS 500, 650, 820, 940, 1020, 123037

MACHINE SUMMARY<strong>Carrier</strong> Drill<strong>Carrier</strong>'s acknowledged soil cultivation abilitycombined with a seed hopper. The one machine isused to first cultivate the soil, then drill - a very costeffective alternative in good cropping conditions.CRD 300BioDrillBioDrill is a flexible little drill for small-seeded species,which are sown in the same pass as cultivation ordrilling with Rapid RDA. BioDrill can be fitted onRollex, Rexius, <strong>Carrier</strong>, Rapid RDANZ Aggressive och NZ MiniPowerful harrows with a work result characterised byfully worked soil, a level seed base and a fine-texturedseedbed.NZA 500, 600, 700, 800, 900, 1000NZM 400, 500 (hydraulically carried)TopDownAbsolutely the most flexible solution on the market forshallow to deep cultivation in a single machine.TD 300, 400, 500, 600, 700CultusA powerful cultivator with a range of different tooloptions, depending on soil texture, for example arubber roller for lighter soils, steel roller for heaviersoils.CS 300 (rigid), CS 420, 500, 620 (folding)RollexThe Rollex ring roller after drilling ensures goodcontact between soil and seed, while at the same timereducing the risk of stones entering harvesting equipment.RX 62038

VÄDERSTADYour cropping profits– our driving forceOur driving force is to create flexiblemachines for soil cultivationand seed drilling that do an excellentjob regardless of the croppingsystem used. All our machinesperform several operations in asingle pass and have a high workcapacity – all of which saves time,energy and money. The long lifetimeof the machines and theirhigh re-sale value make them verycost-effective and allow owners tolower overall machinery costs.Our concept of fewer passes andshallower tillage promotes goodsoil structure and increases earthwormnumbers – both centralfactors in maintaining and improvingsoil fertility and yield capacity.Väderstad has supplied highquality machinery and methodsto farmers all over the worldsince 1962. Väderstad is a familyownedSwedish company withrepresentatives in around 30countries world-wide.www.vaderstad.comVÄDERSTAD LTDVÄDERSTAD SARLVÄDERSTAD GmbHVÄDERSTADVÄDERSTAD OÜVÄDERSTAD SIAVÄDERSTAD UABVÄDERSTAD Sp.z o.oVÄDERSTAD LLCVÄDERSTAD KftMain officeSubsidiariesImporter39

<strong>Carrier</strong> shows the way<strong>Carrier</strong> is a multi-tasker. It is used throughout Europe as an all-purpose implement bygrowers who place high demands on flexibility in crop production. The main area ofwork for <strong>Carrier</strong> is a quick pass after the combine, which accelerates the decompositionof the straw. However <strong>Carrier</strong> is also an excellent implement for seedbed preparation,while the simple but functional straw harrow at the front of the machine is veryeffective at spreading straw and chaff.The smallest <strong>Carrier</strong> model is 3 m and is available in hydraulically mounted and trailedversions. The largest <strong>Carrier</strong> model is trailed, and has a working width of 12.25 m.Regardless of width; the machines do the same job and help growers to simplify theircropping, save money and increase profitability.VÄDERSTAD-VERKEN ABSE-590 21 VÄDERSTAD • SwedenTel. +46 142 820 00 • Fax +46 142 820 10www.vaderstad.comVäderstad-Verken AB is the holder of a number of immaterial rights such as patents, brand names and trademark protection.The product/s described in this document may be covered by one or several of these rights.990515-ENVV Ver. 00 Mjölby Tryckeri AB/Desktopteknik AB 2007.02