SmartStruct Brochure copy - Tilling Timber

SmartStruct Brochure copy - Tilling Timber

SmartStruct Brochure copy - Tilling Timber

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Building for Today and Tomorrow<strong>SmartStruct</strong>Collaborative <strong>Timber</strong> Building Solutions31-45 Orchard Street,Kilsyth, Victoria 3137New South Wales109 Kurrajong Avenue,Mt Druitt, NSW 2770Queensland20-24 Nealdon Drive,Meadowbrook, QLD, 4131Western Australia10 Cartwright Drive,Forrestdale, WA 6112Large-Scale Engineered<strong>Timber</strong> ConstructionSystemsemail: sales@tilling.com.auemail: nswsales@tilling.com.auemail: qldsales@tilling.com.auemail: wasales@tilling.com.auPhone +61 3 9725 0222Fax +61 3 9725 3045illingPhone +61 2 9677 2600Fax +61 2 9677 2500www.tilling.com.auPhone +61 7 3440 5400Fax +61 7 3440 5444Proudly Australian OwnedPhone +61 8 9399 1609Fax +61 8 9399 1065<strong>SmartStruct</strong>Collaborative <strong>Timber</strong> Building Solutions© Copyright <strong>Tilling</strong> <strong>Timber</strong> Pty Ltd ABN 92 004 621 121 SmarStruct is a registered Trademark of <strong>Tilling</strong> <strong>Timber</strong> June 2012

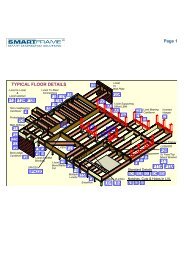

<strong>SmartStruct</strong>Collaborative <strong>Timber</strong> Building Solutionsillingwww.tilling.com.auLarge-Scale Engineered <strong>Timber</strong> ConstructionSystemsPresently there is considerable interest in theconstruction of large-scale projects utilising timber.<strong>Timber</strong> is an ideal alternative to current constructionmethods with considerable environmentaladvantages, such as the storage of Carbon andRecyclability.A primary reason for building in timber is the speed ofassembly. <strong>Timber</strong> has been found to be quicker toconstruct and easier to work with, not to mentionconsiderable advantages in weight reduction withcomparable strength alternative materials.Considerable interest is focusing on Cross Laminated<strong>Timber</strong>(CLT). CLT is increasingly growing in popularitywith extensive media attention on the viability andmarket acceptance of timber as an alternativecommercial construction material. However, thereexists a number of complementary products thataccompany CLT. These include, Commercial I-Joist[500mm and 600mm], Cassette Modular FlooringSystems, Glue Laminated Beams and Post-tensionLaminated Veneer Lumber (LVL) or Glulam Box Beams.Designing with <strong>Timber</strong> – The Significant DifferenceThose wishing to produce a structure in timber willfind that construction methods shall be different. Firstand foremost it is imperative that Project Developerscollaborate at the onset of projects with Architects,competent <strong>Timber</strong> Structural Engineers, experiencedin Mass Wood Systems and Services Engineers toensure a process of education occurs. This educationalprocess shall eliminate considerable problemsoccurring down the track. This is where the <strong>Tilling</strong><strong>SmartStruct</strong> system comes in.Large-Scale Engineered<strong>Timber</strong> ConstructionSystemsTrusting Your Project to <strong>Tilling</strong><strong>Tilling</strong> has formed a Worldwide consortium to ensurea tailored Design, Engineering, Supply, Delivery andInstallation service to the Australian Market.Employing a consultative approach, solutions aredesigned in accordance with the scope of works in acollaborative process ensuring the most viable andcost effective solution is found and implemented.Cross Laminated <strong>Timber</strong>Cross Laminated <strong>Timber</strong> is a new and innovativebuilding material that permits fast and efficientconstruction of single or multi-residential typebuildings. CLT was first developed in Austria, andwithin the last 20 years, production has spread toother parts of Europe and into parts of North America.It is used mainly for wall, ceiling and roofconstruction.DesignServiceOn-siteLabourSavingChain ofCustodyCertifiedThermalAcousticCLT is fabricated by bonding together timber boardswith structural adhesives to produce a solid timberpanel with each layer of the panel alternatingbetween longitudinal and transverse lamellae.Alternating the grain directions of each layer oftimber reduces many of the weaknesses that previoustimber products had. Specifically:The effects of shrinkage and swelling are vastlyreduced. Load may be transferred in more than onedirection.Performance-wise, Cross Laminated <strong>Timber</strong> hasproved itself to be superior in comparison to othertimber products in terms of:Fire resistance - CLT has a considerable fire resistanceand is complemented by the use of traditional fireresistant material, such as fire resistant plasterboard.Building with CLT means that fire must travel throughlarge area of solid timber surface with little cavityavailable for fire to burn and travel through.Noise Insulation - CLT possesses inherent noiseabsorbing propertiesHeat Insulation - CLT walls are able to absorb a largeamount of energy before releasing it into the atmosphereon the other side of the wall.Technical DetailsCross Laminated <strong>Timber</strong> comes in 3, 5 or 7 layers. Thewidth, length and thickness, however, vary betweenCLT production companies.Constructing buildings with CLT is not an overlycomplicated process. The connection details are fairlystraightforward and use a combination of nail platesand varying length self-tapping screws. The followingare some examples of CLT connections used incommercial construction applications.