Window Center Glass Performance - Pella.com

Window Center Glass Performance - Pella.com

Window Center Glass Performance - Pella.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

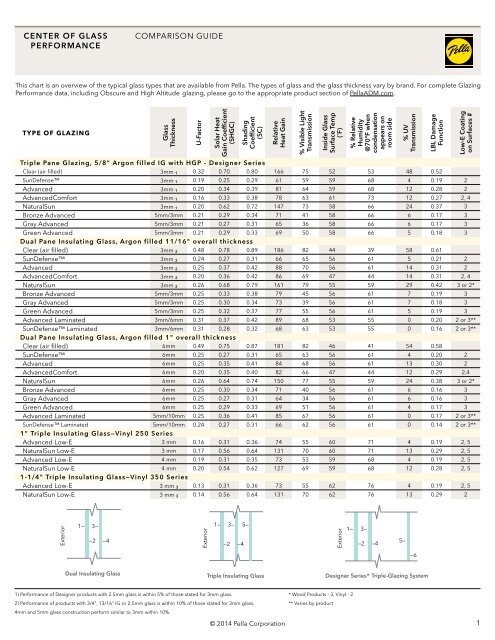

CENTER OF GLASSPERFORMANCECOMPARISON GUIDEThis chart is an overview of the typical glass types that are available from <strong>Pella</strong>. The types of glass and the glass thickness vary by brand. For <strong>com</strong>plete Glazing<strong>Performance</strong> data, including Obscure and High Altitude glazing, please go to the appropriate product section of <strong>Pella</strong>ADM.<strong>com</strong>.TYPE OF GLAZING<strong>Glass</strong>ThicknessU-FactorSolar HeatGain Coefficient(SHGC)ShadingCoefficient(SC)RelativeHeat Gain% Visible LightTransmissionInside <strong>Glass</strong>Surface Temp(˚F)% RelativeHumidity@70°F whencondensationappears onroom side% UVTransmissionLBL DamageFunctionLow-E Coatingon Surfaces #Triple Pane Glazing, 5/8" Argon filled IG with HGP - Designer SeriesClear (air filled) 3mm 1 0.32 0.70 0.80 166 75 52 53 48 0.52SunDefense 3mm 1 0.19 0.25 0.29 61 59 59 68 4 0.19 2Advanced 3mm 1 0.20 0.34 0.39 81 64 59 68 12 0.28 2AdvancedComfort 3mm 1 0.16 0.33 0.38 78 63 61 73 12 0.27 2, 4NaturalSun 3mm 1 0.20 0.62 0.72 147 73 58 66 24 0.37 3Bronze Advanced 5mm/3mm 0.21 0.29 0.34 71 41 58 66 6 0.17 3Gray Advanced 5mm/3mm 0.21 0.27 0.31 65 36 58 66 6 0.17 3Green Advanced 5mm/3mm 0.21 0.29 0.33 69 50 58 66 5 0.18 3Dual Pane Insulating <strong>Glass</strong>, Argon filled 11/16" overall thicknessClear (air filled) 3mm 2 0.48 0.78 0.89 186 82 44 39 58 0.61SunDefense 3mm 2 0.24 0.27 0.31 66 65 56 61 5 0.21 2Advanced 3mm 2 0.25 0.37 0.42 88 70 56 61 14 0.31 2AdvancedComfort 3mm 2 0.20 0.36 0.42 86 69 47 44 14 0.31 2, 4NaturalSun 3mm 2 0.26 0.68 0.79 161 79 55 59 29 0.42 3 or 2*Bronze Advanced 5mm/3mm 0.25 0.33 0.38 79 45 56 61 7 0.19 3Gray Advanced 5mm/3mm 0.25 0.30 0.34 73 39 56 61 7 0.18 3Green Advanced 5mm/3mm 0.25 0.32 0.37 77 55 56 61 5 0.19 3Advanced Laminated 3mm/6mm 0.31 0.37 0.42 89 68 53 55 0 0.20 2 or 3**SunDefense Laminated 3mm/6mm 0.31 0.28 0.32 68 63 53 55 0 0.16 2 or 3**Dual Pane Insulating <strong>Glass</strong>, Argon filled 1" overall thicknessClear (air filled) 6mm 0.49 0.75 0.87 181 82 46 41 54 0.58SunDefense 6mm 0.25 0.27 0.31 65 63 56 61 4 0.20 2Advanced 6mm 0.25 0.35 0.41 84 68 56 61 13 0.30 2AdvancedComfort 6mm 0.20 0.35 0.40 82 66 47 44 12 0.29 2,4NaturalSun 6mm 0.26 0.64 0.74 150 77 55 59 24 0.38 3 or 2*Bronze Advanced 6mm 0.25 0.30 0.34 71 40 56 61 6 0.16 3Gray Advanced 6mm 0.25 0.27 0.31 64 34 56 61 6 0.16 3Green Advanced 6mm 0.25 0.29 0.33 69 51 56 61 4 0.17 3Advanced Laminated 5mm/10mm 0.25 0.36 0.41 85 67 56 61 0 0.17 2 or 3**SunDefense Laminated 5mm/10mm 0.24 0.27 0.31 66 62 56 61 0 0.14 2 or 3**1" Triple Insulating <strong>Glass</strong>—Vinyl 250 SeriesAdvanced Low-E 3 mm 0.16 0.31 0.36 74 55 60 71 4 0.19 2, 5NaturalSun Low-E 3 mm 0.17 0.56 0.64 131 70 60 71 13 0.29 2, 5Advanced Low-E 4 mm 0.19 0.31 0.35 73 53 59 68 4 0.19 2, 5NaturalSun Low-E 4 mm 0.20 0.54 0.62 127 69 59 68 12 0.28 2, 51-1/4" Triple Insulating <strong>Glass</strong>—Vinyl 350 SeriesAdvanced Low-E 3 mm 3 0.13 0.31 0.36 73 55 62 76 4 0.19 2, 5NaturalSun Low-E 3 mm 3 0.14 0.56 0.64 131 70 62 76 13 0.29 2Exterior1—3——2 —4Exterior1—3— 5——2 —4Exterior1—3——2 —45——6Dual Insulating <strong>Glass</strong>Triple Insulating <strong>Glass</strong>Designer Series® Triple-Glazing System1) <strong>Performance</strong> of Designer products with 2.5mm glass is within 5% of those stated for 3mm glass.* Wood Products - 3, Vinyl - 22) <strong>Performance</strong> of products with 3/4", 13/16" IG or 2.5mm glass is within 10% of those stated for 3mm glass.** Varies by product4mm and 5mm glass construction perform similar to 3mm within 10%.© 2014 <strong>Pella</strong> Corporation1

CENTER OF GLASSPERFORMANCEELEMENTS OF GLAZING PERFORMANCEThere are several elements of glazing performance, including U-Factor, Visible Light Transmission and Solar Heat Gain Coefficient. Definitions of the glazingperformance elements are below.Glazing performance data is based on the WINDOW 5.2 and THERM 5.2 <strong>com</strong>puter programs for analyzing energy performance. WINDOW and THERMsoftware are the latest technology in simulating energy performance. When <strong>com</strong>paring performance with other manufacturers, it is important to verify howthe values were determined.GLAZING PERFORMANCE TERMSINSIDE GLASSSURFACETEMPERATURERELATIVE HEAT GAINSHADINGCOEFFICIENTSOLAR HEAT GAINCOEFFICIENTU-FACTORUV TRANSMISSIONLBL DAMAGEFUNCTIONVISIBLE LIGHTTRANSMISSIONCONDENSATIONRESISTANCEThe temperature on the inside surface of the glass at the center of the glass. It is based on an outside temperature of 0°F, inside temperature of 70° F, and an approximate 15 mph outside wind. Room side barriers to interior air flow (blinds,shades, drapes, screens) tend to lower inside glass surface temperature and humidity levels at which condensationoccurs. Outside screens tend to raise inside glass surface temperature and level of humidity at which condensationoccurs.The actual amount of heat energy (BTU per hour-sq.ft.) that enters a room through a glazing system (Assumes typicaldaytime summer conditions of 89° F outside and 75° F inside). The lower the value, the better the unit keeps out heatenergy.The amount of solar heat that passes through a particular glazing system divided by the amount that passes through asingle piece of 1/8" thick clear glass (Assumes 89° F outside and 75° F. inside). The lower the value, the better the glasskeeps out solar heat.The amount of solar heat that enters a room through a window or door (total unit) or glazing system (center-glass),divided by the amount that is actually contacting the exterior of the unit (Assumes 89° F outside and 75° F inside). Thelower the value, the better the unit or glazing keeps out solar heat.The rate of heat transfer (BTU per hour-sq. ft.) through a window or door (total-unit) or glazing system (center-glass)(Assumes 0° F outside at night with an approximate 15 mph wind and 70° F inside). The lower the U-Factor, the betterthe insulating properties of the unit or glazing system.The percentage of ultra violet rays that enter a room through the glazing system. It is a predictor of potential fadingdamage. Lower percentages indicate less fading potential (UV rays are those with a wavelength ranging from 0.30 to0.38 microns).This function, developed by Lawrence Berkeley Laboratories, is another way of expressing UV Transmission. It is abetter predictor of potential fading damage than UV Transmission. Lower values indicate less fading potential.The LBL Damage Function is a weighted value, which takes into account that as the wavelength of the UV rays getsshorter, the fading damage potential increases. Therefore, two glazing systems with the same UV Transmission mayhave different LBL Damage Function values because one allows more shorter wavelength rays to pass through than theother.The percentage of visible light that is transmitted through the window or door (total-unit) or glazing system(center-glass).A relative indicator of a fenestration product’s ability to resist the formation of condensation at a specific set ofenvironmental conditions. The higher the Condensation Resistance value the greater the resistance to the formation ofcondensation. Actual condensation performance is a function of temperature, humidity and air movement. For moreinformation see NFRC 501-2010, “User Guide to the Procedure for Determining Fenestration Product CondensationResistance Rating Values”Total-unit values can be found in the individual product sections.© 2014 <strong>Pella</strong> Corporation2