Syntron® Electromagnetic Feeders - FMC Technologies

Syntron® Electromagnetic Feeders - FMC Technologies

Syntron® Electromagnetic Feeders - FMC Technologies

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

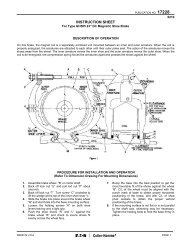

Sub-resonant Tuning for Electromechanical <strong>Feeders</strong>Stroke consistency and speed stability for high-capacity feeding.Low sub-resonant tuning is the key characteristicof Syntron ® electromechanicalfeeders, making them the most stable andconsistent feeders available on the market.Feeder tuning involves adjustment of thenatural frequency of the feeder in relationshipto its operating frequency. If theoperating frequency is greater than thenatural frequency, the feeder is superresonanttuned, making it very unstableunder headload. Conversely, if the naturalfrequency is greater than the operatingfrequency, the feeder is sub-resonant tuned,making it more consistent and stable underheadload.Regardless of manufacturer, all heavy-duty,two-mass electromechanical vibratingfeeders are sub-resonant tuned. For subresonanttuned feeders, the distance fromresonance is critical to feeder performance.Most manufacturers tune their feederscloser to resonance, while Syntron feedersare tuned further from resonance.Material damping and other variations inheadload cause fluctuations in capacityand feed rates of all sub-resonant tunedfeeders. Because Syntron electromechanicalfeeders are tuned further from resonance,capacity and feed rates remain more stableand consistent even when the feeder issubjected to material damping and othervariations in headload. In addition, Syntronelectromechanical feeder design incorporatesinternal damping, which contributesto their stability and consistency.On the comparison chart (Figure 1), curve 1represents a typical competitive feeder ina no-load state without internal damping.Curve 2 represents a Syntron feeder in ano-load state with internal damping.Curve 3 represents a feeder with materialheadload and associated damping.Because Syntron feeders are tuned furtherfrom resonance and are designed withSub-Resonant Tuning forElectromechanical <strong>Feeders</strong>Figure 1. Comparison of Tuning Ratiosinternal damping, it is evident that theloss in relative trough stroke under headloadfor a Syntron feeder (Y) is negligibleas compared to a substantial loss in relativetrough stroke for competitive feeders (X).This is why Syntron electromechanicalfeeders are more consistent and stable thanany other feeder, even when subjected tomaterial damping and other variations inheadload.Material Handling Solutions15www.fmctechnologies.com/materialhandling