Syntron® Electromagnetic Feeders - FMC Technologies

Syntron® Electromagnetic Feeders - FMC Technologies

Syntron® Electromagnetic Feeders - FMC Technologies

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

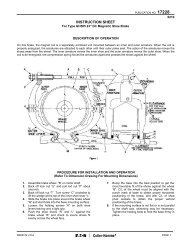

Syntron ® <strong>Electromagnetic</strong> <strong>Feeders</strong> (cont’d.)<strong>Electromagnetic</strong> Feeder TroughsSyntron ® <strong>Electromagnetic</strong> Feeder models FH-22 through F-88 can be furnishedwith standard flat-bottom troughs, special flat-bottom troughs or belt-centeringdischarge troughs.Drive units can be positioned either above or below the trough. A below-deckdrive unit is most commonly used, but above-deck drive units can be suppliedfor installations where there is insufficient space below the trough. However,an above-deck drive unit may reduce feeder capacity slightly.Capacities for feeder models with standard troughs are based on sandweighing 100 pounds per cubic foot. Capacities vary depending on drive unitlocation, material characteristics, material density, trough length and width,trough liner type, feeder installation, skirt boards and hopper transitions.Several trough options are available for special applications. Syntron ® extralongfeeder troughs can be supplied with either below-deck or above-deckmultiple electromagnetic drive units. Extra-long feeder troughs provide manyadvantages in conveying materials over long distances; unlike belt conveyors,there are no idlers or pulley drive units to wear, lubricate, or replace. Longtubular troughs can convey pure, clean materials without atmospheric contaminationand safely convey dusty, poisonous materials without endangeringprocessing personnel.Other trough options include:• Syntron vibrating inspection tables feed material forward at a smooth,controlled rate of flow. This enables an operator to remove materialthat does not meet specification.• Syntron “spreader” feeders spread a wide, even layer of material witha diagonal discharge trough or diagonal-slotted trough.• Electrically heated trough liner plates minimize accumulation of damp orwet materials in feeder troughs. Available only on specially designed feeders,heated liner plates increase feeder efficiency by eliminating the downtimerequired to clean troughs. They are especially effective for materials withmoisture contents ranging from five to fifteen percent. The electric heatingelement is insulated and sandwiched between two steel plates.Diagonal discharge spreader feeder.Standard flat-bottom trough,below-deck drive unit.Tubular trough, below-deck driveunit.Flat bottom trough, above-deckdrive unit.Other Trough Options Include:■ Covered Trough with Dust Seals■■■■Open Trough with Dust SealsScreening <strong>Feeders</strong>Diagonal Discharge TroughBelt-Centering Discharge TroughTrough Liner Options Include:■ T-1A■■AR-400AR-500■ Stainless Steel■■■■UHMW PlasticRubberCeramicCarbide Overlay12