HUBER ROTAMAT(R) Ro 5

HUBER ROTAMAT(R) Ro 5

HUBER ROTAMAT(R) Ro 5

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

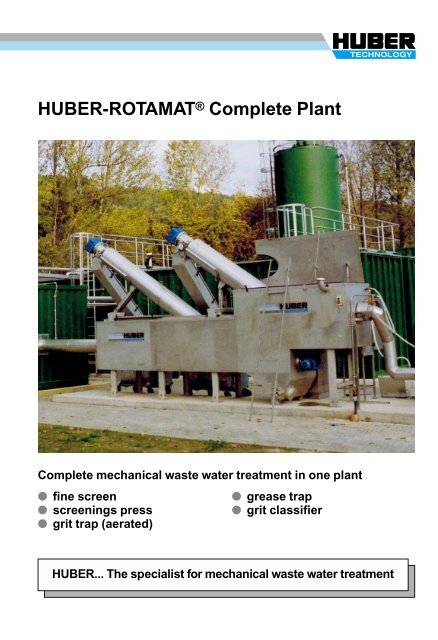

<strong>HUBER</strong>-<strong>ROTAMAT</strong> ® Complete PlantComplete mechanical waste water treatment in one plant● fine screen● grease trap● screenings press● grit classifier● grit trap (aerated)<strong>HUBER</strong>... The specialist for mechanical waste water treatment

Process description ®The waste water flows through thechannel towards the Complete Plant(subterraneously installation) or it istransported there via a pump (above<strong>ROTAMAT</strong> ® Complete Plant subterraneouslyinstallation, STW Steinbergground). Regarding the CompletePlant several process steps areintegrated in one container made ofstainless steel. The waste water firstof all streams through a Fine Screen(bar spacing 6/10mm) or through aScreen (bar spacing 3mm and/or5mm). Function and mode ofoperation see separate descriptions<strong>Ro</strong> 1, <strong>Ro</strong> 2, <strong>Ro</strong> 9). Thereby it iscleaned from all floating andsuspended materials. The screeningsare discharged from the container bymeans of an integrated ScreeningsPress, dehydrated and compacted toa solids content of up to 40 %. Thedehydrated and compactedscreenings are thrown into astanardized container. The presswater is returned to the waste waterstream which avoids a BOD change.By means of the integrated press thevolume of the screenings is reducedby 60% which saves disposal costs.The Grit Trap follows which is laid outaccording to the ATV regulations(regulations issued by the sewageengineering organisation). Here thesettling material is transported inopposite direction to the flow andwashed out by organic substances. Atthe end of the horizontal settlingmaterial screw conveyor the settlingmaterial falls in a sump at the side.From this sump the settling material isdischarged via a Grit Classifier. Thegrit is dehydrated and finally throwninto a grit container. Screenings andgrit can be disposed separately. TheComplete plant can be equipped withDehydrated screeningsseparated discharge withsimultaneous dehydration of gritand screeningsan additional Grit Trap Aeration.Furthermore it can be completed by aGrease Trap Aeration and greasetrap are additional equipmentimproving the entire function. Ifnecessary the plant can beadditionally equiped with anintegrated screenings and gritwashing.The electrical control of the plantworks fully automatically dependingon the water level, the grit trap worksdepending on the time. In order toguarantee an emergency bypass incase of power failure a safety bypasscan be added on the channel. Theentire construction is very robust. Thiscannot only be proved by the fact thatall parts are made of stainless steeland therefore maintanance-free butalso by the entire constructionregarding motor, bearing and gear.Thereby our ten-year experience withthis plants shows to advantage.View into the ROTMAT ® Fine Screen bagging unit view into the channel, the aeration(left side) is clearly visible

The <strong>ROTAMAT</strong> ® -Principle3 systems possible in the inlet area of the<strong>HUBER</strong>-<strong>ROTAMAT</strong> ® Complete Plant● Fine Screen <strong>Ro</strong> 1bar spacing 5-12 mm● Wedge Screen <strong>Ro</strong> 2,bar spacing 0,5 - 5 mm● Micro Strainer <strong>Ro</strong> 9bar spacing 0,5 - 5 mmScreenings Washing:Screening, washing, pressing – all in one system!if necessary with:● integrated screeningswashing● integrated grit washingThe Screenings Washing can be integratedinto every <strong>HUBER</strong> cleaning system:<strong>ROTAMAT</strong> ® Fine Screen<strong>Ro</strong> 1<strong>ROTAMAT</strong> ® Wedge SectionScreen <strong>Ro</strong> 2<strong>ROTAMAT</strong> ® Micro Strainer<strong>Ro</strong> 9preliminary washing washing with pressure fine washing● less odour annoyance● reduction in volume and weight by washingout 95% of the faeces. Therefore thedisposal costs are much lower.● increased dehydration, therefore a rise incolorific value concerning an incinerationwhich may follow● return of the step of biodegradation of thetreatment process● functional construction as the screeningspress● retrospective equipment possible withoutproblems● best quality for low price● service water can be used i.e. no freshwater consumption