EC20B - Volvo Construction Equipment

EC20B - Volvo Construction Equipment

EC20B - Volvo Construction Equipment

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

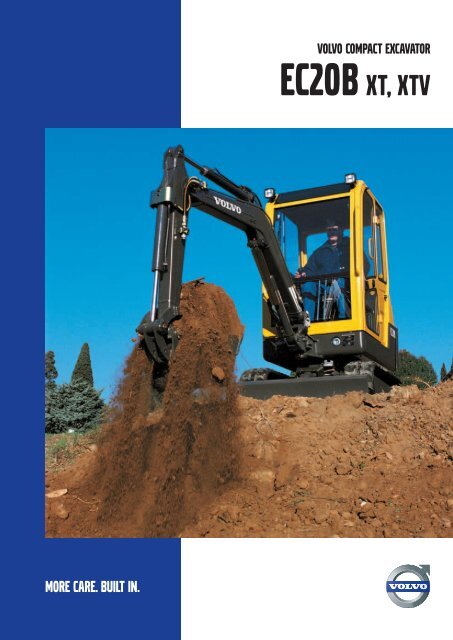

More care. Built in.VOLVO COMPACT EXCAVATOR<strong>EC20B</strong> XT, XTV

DIG IN TO SOLID PERFORMANCE.When you want a strong and reliable compactexcavator to meet your toughest demands - lookto the <strong>Volvo</strong> <strong>EC20B</strong>. Its compact design is big onversatility, comfort and performance. Built for easyoperation and maintenance, it’s the most costeffectivebusiness investment you’ll ever make.Move with precisionThe <strong>Volvo</strong> <strong>EC20B</strong> is also built forprecision work. Utilizing the besttechnology available, the closedcentreload-sensing hydraulic systemdelivers precise control under anycondition. Hydraulic speed relies onlyon the position of the control lever,regardless of the load or number ofmovements. This quality allows you tocombine all machine movements forfine precision and more productivework.Increase your speed andproductivityThe units also feature two travelspeeds for fast cycle times that saveboth time and money. The exclusivequick coupling system lets you easilyconnect an attachment or bucketright from the cab for increasedspeed and efficiency.Compact by designThe hydraulic offset of the boomreduces the overall excavatordimensions, helping you work in tightspaces and alongside walls. Inaddition, the wrap-around shape ofthe counterweight providesprotection against rear impact.Built strongThe <strong>EC20B</strong> features a double-yokepivot that doubles the bearing surfaceon the chassis. There is also a longpin that distributes the stress, forreduced wear and longer life. Theboom and dipper structuresincorporate cast steel parts on heavilystressed areas. Sturdy steel platesprotect all hydraulic connectors. Forreduced operating costs, a hydraulicmotor drives the crown gear directly,without a reduction gear, offering nowear or play. Heavy-duty towing andanchor points make craning jobseasier. An optional anti-theft keypadlocks the machine’s starting andhydraulic function for added safety.Jobsite flexibilityThe variable-width chassis offers thechoice of two cost-effectiveproduction options. Choose theexceptional stability of an extra-widechassis or the versatility of a machinethat can fit through small spaces, withan overall width reduced to less than1 m. The 250 mm wide tracks offerexcellent stability, traction and longlife. For increased flexibility, the bladesystem offers two side extensions.Each blade can be fitted or removedwithout tools to save time and money.• Extendible track and blade.• Two-speed travel for greater mobility.2• Quick coupler for fast, easy changes.

• Comfortable ergonomic armrests.• Optimum load-sensing efficiency.• Versatile and powerful performance.3

EXPECT THE BEST FROM VOLVO.At <strong>Volvo</strong>, we know that safety and comfort areimportant to your productivity. That’s why the <strong>EC20B</strong>offers you all of the above and more: a productive,reliable machine that’s easy to keep running. Get themost out of each day in the machine designed for youand your work.Comfort built inQuiet operation is key to operatorcomfort and environmental control.That’s why the <strong>Volvo</strong> <strong>EC20B</strong> has aquiet, low emission engine with plentyof power. Superior soundproofinghelps reduce operator fatigue. Short,responsive drive controls avoidexcessive movements for easieroperation. Gauges are in front of theoperator to keep track of keyfunctions. Well-positioned armrestsmake long shifts more comfortablewhile ensuring precision control. Thevinyl covered adjustable suspensionseat offers comfortable all dayoperation.More room insideWhile the <strong>Volvo</strong> <strong>EC20B</strong> is compact,the cab is large and roomy for a moreefficient work environment. The largeflat floor provides plenty of legroomand storage space. Even tall operatorswill feel at ease in the ergonomic cab.In addition, the hydraulic attachmentcontrol pedal folds away when not inuse and can be positioned to the rightfor easy access and optimal operatingspace.A new view on safetyYou’ll have 360° of visibility forexcellent jobsite command. Theround, compact engine cover hasimproved rear visibility for bettersafety on narrow or congested sites.Non-slip steps and floor provide safe,easy entry and exit. The cab dooropens wide and the console swingsup and out of the way for a safer exit.The gas strut assisted window openseasily and the right side window slideopen wide for greater visibility andcomfort. There’s a standard seatbeltfor added safety and FOPS 1, ROPSand TOPS certified cabs andcanopies for maximum protection.Maintenance made easyThe <strong>EC20B</strong> is easy to maintain formaximum uptime. Unlike many othercompact excavators, its unique tiltingcounterweight and wrap-aroundshape provide total engine accessand optimum rear protection. Thehydraulic oil cooler is mounted on asliding support allowing better accessto cleaning cooler fins.The fuel supply circuit has atransparent at-a-glance pre-filter andfeatures a self-priming electric pump.When working in confined areas, thetwo consoles on the canopy versionlift for access from the right or left. Allboom supply hoses are loose fittedand connect on the outside of themachine for less wear and damage.• Perfect accessibility of the hydraulics compartment.4• Spacious and comfortable cab.

SPECIFICATIONSEngineWater-cooled low emissions Tier 4 <strong>Volvo</strong> D1D diesel engine.Displacement, total952 ccGross power, ratedPower, installed (ISO 9249)Maximum torque (ISO 9249)Bore x strokeGas emissionElectrical systemRated voltageBattery capacityAlternator ratingStarter motor output12.0 kW (16.1 hp) at 2200 r/min11.7 kW (15.7 hp) at 2200 r/min53 Nm at 1800 rpm76 mm x 70 mmPM: 0.4 g/kwhNOx + HC : 7.5 g/kwhCO: 6.6 g/kwh12 V12 V - 45 Ah12 V - 40 A12 V - 1.6 kWHydraulic systemClosed-centre Load-Sensing hydraulic system providing totalindependence of each movement.Controlpower-assisted hydraulic controlsVariable displacement pump for all the equipment, travel andpower-assisted circuits:Maximum delivery44 l/min.Maximum operating pressure21 MPa (210 bars)Double-acting hydraulic circuit for accessories:Maximum deliveryMaximum operating pressureCushions:On the boom ramBucket performanceBreakout forceTearout force40 l/min21 MPa (210 bars)at the rod end1850 daN1250 daNSlewing systemTurntable slewing is provided by an Ortitrol hydraulic motor whichdrives directly (without a reduction gear) a ball internal crownwheel with remote lubrication:Slewing speed9 r/minUndercarriage<strong>EC20B</strong> XTVTrack widthTrack tensionBlade heightWidth of the blade250 mmby grease piston240 mm980 mm and 1350 mmDrivetrainEach track is driven by an axial piston hydraulic motor equippedwith two speeds and an epicyclic reduction gear.Max. speed (low/high speed)2.7 - 4.7 km/hMax. tractive forceService fill capacitiesFuel tankHydraulic system, totalEngine oilCooling systemWeight<strong>EC20B</strong> XT1770 daN21 l33 l3.6 l4.5 lGround pressure Rubber Tracks Steel TracksCab version 0.29 kg/cm 2 0.30 kg/cm 2Canopy version 0.27 kg/cm 2 0.28 kg/cm 2Operating mass Rubber Tracks Steel TracksCab version 1809 kg 1865 kgCanopy version 1685 kg 1741 kgTransport mass Rubber Tracks Steel TracksCab version 1666 kg 1722 kgCanopy version 1542 kg 1598 kg<strong>EC20B</strong> XTVGround pressure Rubber Tracks Steel TracksCab version 0.30 kg/cm 2 0.31 kg/cm 2Canopy version 0.28 kg/cm 2 0.29 kg/cm 2Operating mass Rubber Tracks Steel TracksCab version 1901 kg 1957 kgCanopy version 1777 kg 1833 kgTransport mass Rubber Tracks Steel TracksCab version 1758 kg 1814 kgCanopy version 1634 kg 1690 kgUndercarriage<strong>EC20B</strong> XTTrack widthTrack tensionBlade heightWidth of the blade250 mmby grease piston240 mm1200 mmNoise levelsThe <strong>EC20B</strong> conforms to the 2006 European Machine DirectiveNoise Level (2000/14/CE) of 93 dB(A) for this class ofmachine.6

Buckets<strong>EC20B</strong>XT/XTVExcavatorbucketWidth Weight Capacity250 mm 33 kg 30 l300 mm 36 kg 32 l400 mm 42 kg 47 l450 mm 46 kg 55 lDipper A B C* C D E F1050 mm 3750 2670 2570 2350 2350 4010 41001300 mm 3900 2820 2810 2600 2600 4250 4250* Dig depth with blade down.G H I J K L M N O<strong>EC20B</strong> XT 250 275 1240 1630 1075 1200 - 1360 3780<strong>EC20B</strong> XTV 240 230 1240 1630 975 1000 1350 1360 3780Ditch bucket500 mm 50 kg 62 l600 mm 55 kg 77 l1000 mm 102 kg 115 lP Q R S T U V W X<strong>EC20B</strong> XT 260 250 470 1620 1310 - 2210 980 1120<strong>EC20B</strong> XTV 260 250 470 1620 1310 - 2210 980 11207

STANDARD EQUIPMENTEngineDry-type air filter.Electric pre-heating device.Transparent diesel oil filter, pre-filter andsediment bowl.Oil sump sheet metal guard.Hand throttle.Electrical system12 V - 45 Ah maintenance-free battery.Horn.12 V power socket for inspection lamp.Undercarriage250 mm wide rubber tracks.Fixed or variable width undercarriageaccording to version.Dozer blade.Blade extensions with supports on the blade(variable width undercarriage).Towing and anchoring points.Remote lubrication of the slewing crown ring.Hydraulic systemAdditional double-acting hydraulic controlvalve for an attachment circuit with foldingcontrol pedal and circuit for direct return ofoil to the hydraulic tank.Attachment circuit piping (double-acting)as far as the bottom of the boom.Power-assisted control of the hydraulicoffset of the boom by the left control lever.Control of forward movement by two levers.Hydraulic oil cooler.Cab (cab version)Level 1 FOPS (Falling Objects ProtectiveStructure).TOPS (Tip-Over Protective Structure).ROPS (Roll-Over Protective Structure).Vinyl-covered multi-adjustable sprung seat.Non-slip floor and grab handles for access tothe driver’s cab.Seatbelt.Cab mounted on rubber mountings.Two working lights.Two-speed heating and ventilation.Cab heat adjustment.Front window with opening system powerassistedby two gas rams.Sliding window (right).Door stops.Provision for a radio (location for a radio andtwo speakers, aerial and electric wiringalready fitted).Interior lighting.Anti-corrosion protection of the cab.Windscreen wiper and washer (front).Emergency exit via the rear window.Canopy (Canopy version)Level 1 FOPS (Falling Objects ProtectiveStructure).TOPS (Tip-Over Protective Structure).ROPS (Roll-Over Protective Structure).Vinyl-covered all weather-multiadjustablesprung seat.Non-slip floor and grab handle for access tothe driver’s cab.Seat belt.Working light on the canopy frame.Instrumentation and monitoringMonitoring and warning light for: pre-heating,engine oil pressure, water temperature,battery charging, air filter restriction.Fuel gauge.Hour meter.Shut down for automatic switching offengine in the event of overheating or dropin oil pressure.Working equipment1900 mm long monobloc boom.1050 mm dipper.140º hydraulic boom offset.Cushion on the boom ram.Handling equipment for loads inferior to1000 kg (lifting hook on the bucket withload chart displayed in the driver’s cab).Remote lubrication of the bottom of theoffset ram.SafetyEngine safety start device: the left consolemust be raised to operate the starter.Nitrogen accumulator on the powerassistance circuit in order to be able to putthe equipment on the ground if the engineis switched off.Window-breaker hammer (cab).Key-lockable toolbox.Official approvalMachine conforming todirective nº 98/37EEC and its amendments.Sources emissions in the environmentconforming to directive 2000/14/CE.Handling device conforming to EN standard474-5.FOPS 1 conforming to ISO standard 3449.TOPS conforming to ISO standard 12117.Electromagnetic compatibility (EMC)conforming to directive nº 89/336 EECand its amendments.OPTIONAL EQUIPMENTWorking equipmentLong dipper (1150 mm).Mechanically-controlled quickreleaseattachment bracket.Hydraulic circuits for attachmentsHydraulic circuit for single or double-actingattachments (Auger...).Hydraulic circuit for operating a clam-shellbucket (opening/closing and rotationof the bucket).Push-pull connectors for attachment line.UndercarriageSteel tracks (230 mm wide).LightingAdditional working light on the boom.Additional rear working light.Rotating beacon.Environmental protectionBio-degradable hydraulic oil.Catalylic exhaust.Comfort and safetyRadio (cab).Anti-theft system (2 programmable codes).Rear wind-deflector on canopy.Battery isolator switch.Fabric seat (cab).Translation pedals.Retractable seatbelt.Safety valve on boom and dipper ram.Dual stage air filter.Audible travel warning.Document storage.MiscellaneousTool kit.Special customised paint(RAL specifications).8

<strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong> is different. It’s designed, builtand supported in a different way. That difference comes from anengineering heritage of over 170 years. A heritage of thinkingfirst about the people who actually use the machines. About howto help them be safer, more comfortable, more productive. Aboutthe environment we all share. The result of that thinking is agrowing range of machines and a global support networkdedicated to helping you do more. People around the world areproud to use <strong>Volvo</strong>. And we’re proud of what makes <strong>Volvo</strong>different – More care. Built in.All products are not available in all markets. Under our policy of continuous improvement, we reserve the right to change specificationsand design without prior notice. The illustrations do not necessarily show the standard version of the machine.<strong>Construction</strong> <strong>Equipment</strong>www.volvoce.comRef. No. 21 3 432 1162EnglishPrinted in Sweden 2008.01<strong>Volvo</strong>, BelleyCEX