INDUTAINER IBC combines the advantages of RIBC and FIBC

INDUTAINER IBC combines the advantages of RIBC and FIBC

INDUTAINER IBC combines the advantages of RIBC and FIBC

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

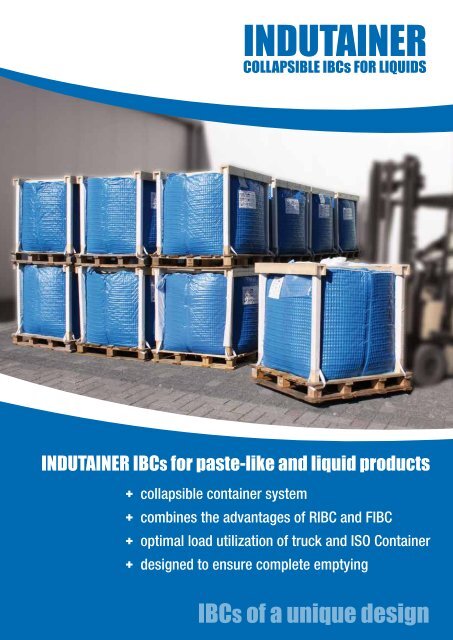

<strong>INDUTAINER</strong>COLLAPSIBLE <strong>IBC</strong>s FOR LIQUIDS<strong>INDUTAINER</strong> <strong>IBC</strong>s for paste-like <strong>and</strong> liquid productscollapsible container system<strong>combines</strong> <strong>the</strong> <strong>advantages</strong> <strong>of</strong> R<strong>IBC</strong> <strong>and</strong> F<strong>IBC</strong>optimal load utilization <strong>of</strong> truck <strong>and</strong> ISO Containerdesigned to ensure complete emptying<strong>IBC</strong>s <strong>of</strong> a unique design

Design <strong>and</strong> DimensionAll <strong>INDUTAINER</strong> <strong>IBC</strong>s are equipped with lifting loops for forklift h<strong>and</strong>ling, for suspended discharge, <strong>and</strong> placement ona discharge frame.Size Volume Filling Height930 x 930 x 550 mm 500 L 500 mm930 x 930 x 640 mm930 x 930 x 730 mm930 x 930 x 820 mm930 x 930 x 910 mm930 x 930 x 1000 mm930 x 930 x 1080 mm930 x 930 x 1160 mm600 L700 L800 L900 L1000 L1100 L1200 L600 mm690 mm780 mm870 mm960 mm1040 mm1120 mmType <strong>of</strong> Pallet Size PayloadCP 3CP 8 centred openingCP 9114x114x15 cm114x114x15 cm114x114x15 cm1000 kg1500 kg1500 kgCP pallets are st<strong>and</strong>ard pallets <strong>of</strong> <strong>the</strong> European chemical industryInner LinerLifting Loops Sewn into Vertical SeamsSafe Working Load SWLSafety Factor SF500 - 1500 kg5 : 1 Single Trip500 - 1000 kg6 : 1 Multi TripThe inner liner is glued to <strong>the</strong> side walls <strong>and</strong> to <strong>the</strong> base.The glued inner liner enables quick assembly, easy filling <strong>and</strong> facilitates quick <strong>and</strong> complete drainage.Filling HolesFilling Spouts: Ø 32 to 62 cmScrew Caps: Ø 1, 2 <strong>and</strong> 3 inchFilling SpoutScrew CapFilling SpoutFilling SpoutButterfly ValvePartial discharge possibleØ 1, 2 <strong>and</strong> 3 inchSlide ValvePartial discharge possibleØ 5 inchBase SpoutNo partial dischargeØ 16 to 32 cmFlat BaseDischarge by suctionor base cross cutMaterial Design PropertiesLDPE mono filmLDPE/EVOH/LDPE co-ex filmTop with filling spoutor screw capDefined gas barrier propertiesPhysiologically harmlessLDPE/PA/LDPE co-ex filmBody dimensionsDefined temperature resistancevariable as neededLDPE/AL/PET laminated filmVentilation valves upon requestBase according to graphsFluid Silicones Lubricant oils Textile Additives2

Filling <strong>and</strong> Emptying+Unique Featuresdesigned for quick <strong>and</strong>complete emptyingchoice <strong>of</strong> multiple basevalvesfits existing dischargedevicesGlued inner linereasy assemblyFilling spouteasy filling5 inch slide valveunhindered drainageCone-shaped base formed by using a discharge frameBase prior to discharge Base spout Butterfly valveThe 3 inch butterfly valve is suitable for low viscosity products. For high viscosity products <strong>the</strong> 5 inch slide valve or<strong>the</strong> base spout are preferred. The slide valve <strong>and</strong> <strong>the</strong> butterfly valve allow a partial discharge <strong>of</strong> <strong>the</strong> liquid product.<strong>INDUTAINER</strong> <strong>IBC</strong>s with a flat base are mostly used for sedimenting slurry. Emptying is done by cross-cutting <strong>the</strong>base. The flat base design is also <strong>the</strong> right choice for products to be discharged by suction.Products to be transported:3 Separating Agents Grinding Slurries Filter Cakes

Filling <strong>and</strong> EmptyingFree-st<strong>and</strong>ing on a discharge frameSuspended dischargeFree-st<strong>and</strong>ing on a palletDischarge FrameGluesPressure-Sensitive Powders <strong>and</strong> Granulates4

Transport <strong>and</strong> Storage+Unique Featuresmoisture resistantoptimal load utilization <strong>of</strong>truck <strong>and</strong> ISO Containerregulatory approval fortransportationDEKRA-approved load securing according toGerman regulations. On request we will sendyou information on safe load securing.Two layer stowage in a storage facilityOne layer stowage on truck22 <strong>INDUTAINER</strong> <strong>IBC</strong>s <strong>of</strong> 1100 kg each = 24,2 tTwo layer stowage in a 20’ Container20 <strong>INDUTAINER</strong> <strong>IBC</strong>s <strong>of</strong> 1000 kg each = 20 tBy means <strong>of</strong> four vertical wooden posts <strong>and</strong> two wooden cross girders <strong>the</strong> <strong>INDUTAINER</strong> <strong>IBC</strong> can properly be tieddown to <strong>the</strong> truck. In a 20’ container, a two layer stowage allows <strong>the</strong> best load utilization. The Indutainer <strong>IBC</strong> canalso be stacked two layers in a storage facility.Products to be transported:5 Fruit Concentrates Vegetable Pastes Food Additives

Safety <strong>and</strong> RecyclingDo not use h<strong>and</strong> or electric pallet trucksto avoid damaging <strong>the</strong> centre bottom valveStorage facilityNot more than two layer stackingRailway <strong>and</strong> truckOnly one layer stowage20‘ ISO ContainerTwo layer stowage allowedMaximum 174 °F/ 80 °CProduct filling temperatureSTRAIGHTmin. 21‘‘STRAIGHTForklift truckTransport <strong>of</strong> single<strong>INDUTAINER</strong> <strong>IBC</strong> onlyMove <strong>the</strong> forks straight into <strong>the</strong> pallet toavoid damaging <strong>the</strong> centre bottom valveSecurity adviceBecause <strong>of</strong> <strong>the</strong> sensitivity <strong>of</strong> woven polypropylene fabric to UV light <strong>the</strong> <strong>INDUTAINER</strong> <strong>IBC</strong> should be protectedfrom sunlight. Also, <strong>the</strong> <strong>IBC</strong> should be protected from rain to prevent water from collecting on top <strong>of</strong> <strong>the</strong><strong>INDUTAINER</strong> <strong>IBC</strong>.RecyclingThe <strong>INDUTAINER</strong> <strong>IBC</strong> is made <strong>of</strong> polypropylene, polyethylene <strong>and</strong> polyurethane. These plastics constitute ahighly valued organic fuel <strong>and</strong> are excellent materials for energy recovery. Please contact your environmentalprotection agency for recycling options.Single or Multi TripThe Single Trip <strong>INDUTAINER</strong> <strong>IBC</strong> with a Safety Factor (SF) <strong>of</strong> 5:1 is designed <strong>and</strong> intended to be used for onefilling only. The Multi Trip <strong>INDUTAINER</strong> <strong>IBC</strong> with a Safety Factor (SF) <strong>of</strong> 6:1 is designed <strong>and</strong> intended for a limitednumber <strong>of</strong> filling <strong>and</strong> discharge cycles. According to ISO 21898:2004, an <strong>IBC</strong> <strong>of</strong> this category must not be reusedif damaged. A repair is not allowed. The replacement <strong>of</strong> a removable inner liner is however permitted.Quality, Service <strong>and</strong> InnovationThe <strong>INDUTAINER</strong> <strong>IBC</strong> is produced within <strong>the</strong> EU by a contractual partner who is certified according toISO 9001:2008 <strong>and</strong> ISO 14001:2004. We are continuously aiming at improving <strong>the</strong> quality <strong>and</strong> design <strong>of</strong> ourproducts. It is our ambition to develop <strong>the</strong> best solutions for our customers.<strong>IBC</strong>s <strong>of</strong> a unique design6

<strong>INDUTAINER</strong>COLLAPSIBLE <strong>IBC</strong>s FOR LIQUIDS<strong>INDUTAINER</strong> GmbHAm Eggenkamp 13D-48268 Greven / GermanyPhone: +49 5975 9177 288Fax: +49 5975 9177 299E-Mail: info@indutainer.dewww.indutainer.de