Fluid Purification Solution for Hydraulic Oils, Lubricants - Pall ...

Fluid Purification Solution for Hydraulic Oils, Lubricants - Pall ...

Fluid Purification Solution for Hydraulic Oils, Lubricants - Pall ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

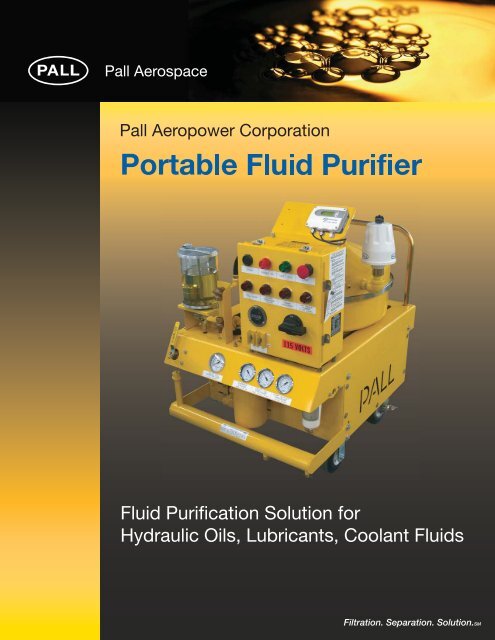

The Portable <strong>Fluid</strong> PurifierRemoval of water, gases, solventsand particulate from oils such as:• hydraulic fluids• lubrication fluids• coolants, and• synthetic fluidsPrevents pollution, increases equipmentreliability and per<strong>for</strong>mance whilereducing costly maintenance.Benefits of the Portable <strong>Fluid</strong> PurifierExtend <strong>Fluid</strong> Service Life• Experience significant reduction in oil change outdue to contamination; extend oil change intervalsReduce <strong>Fluid</strong> Disposal Costs andEnvironmental Risk• Decrease the need to store, maintain andtransport contaminated fluids <strong>for</strong> disposalPrevent Pollution / Recycle• Minimize fluid waste disposal and extendfluid service life through reuse / recycleImprove <strong>Hydraulic</strong> System Response• Encounter fewer costly operational delays• Benefit from increased system reliability• Experience improved system response withde-aerated fluidImprove On-Line Per<strong>for</strong>mance• Reduce system downtime resulting from fluidrelatedservice interruptionsReduce System Wear• Increase MTBUR• Maintain a smaller spare parts inventoryReturn on InvestmentLow operating and maintenance costs make the <strong>Pall</strong> Purifier cost effectiveand minimize the investment payback period2

The Optimal <strong>Fluid</strong> <strong>Purification</strong> SystemThe PAC portable fluid purifier is small, light-weight, energy efficient and highly mobile. The systemis designed to maximize ease of use, economy, reliability, and maintainability. It will operateunattended <strong>for</strong> extended periods of time with built-in safety features including: diagnostics <strong>for</strong> faultdetection with automatic shutdown, fault signal lights, and smart controls to signal the need <strong>for</strong> filterchangeout.<strong>Pall</strong>’s spinning disk purifier has been specially developed to minimize degradation of the workingproperties of the fluid being purified. The system employs mass transfer technologies whichare the most gentle to the fluids.PAC’s portable fluid purifier does not use desiccants, molecular sieves, high vacuum,or added heat typical of flash distillation units. It has minimal impact on the workingproperties of fluid.Alternate Processes and Potential Problems:PURIFICATION PROCESSDesiccantor Molecular SieveHigh VacuumAdded HeatPOTENTIAL PROBLEMSStrips out fluid additives. Potential <strong>for</strong> desiccant andmolecular sieve material to be released into the fluid.Strips the fluid of light ends and volatile additives. Canresult in fluid viscosity increase.Causes fluid oxidation, coking or charring. Stripsthe fluid of light ends and volatile additives. Canresult in fluid viscosity increase.<strong>Pall</strong> Aeropower Corporation (PAC) introduced its fluid purifier in 1965 to remove sea watercontamination from U.S. Navy submarine hydraulic systems. Today, PAC purifiers are used toprevent pollution, extend fluid service life, recycle fluids, and maintain optimum fluid cleanlinesslevels in ships, aircraft, military vehicles, ground support equipment, fluid test stands, and many otherapplications.The PAC portable fluid purifier is specially configured to extend the fluid service life of hydraulicfluids, lube fluids, polyalphaolefin (PAO) based fluids, coolants, phosphate ester fluids, poly-ol esterfluids, and many others.3

System Operation• Contaminated fluid is drawn into the spinning disk vacuum chamber through a mesh strainer. Afloat valve regulates the inlet flow, keeping it equal to the output of the discharge pump.• Oil entering the vacuum chamber impinges on the center of the spinning disk. As the disk rotates,oil flows outward to the edge of the disk, progressively decreasing in film thickness. The oil isthrown off the disk and breaks into very small droplets yielding a large surface area.• Maximizing surface area directly increases the water removal rate of fluid dehydrators. <strong>Pall</strong>’sunique spinning disk technology produces a uni<strong>for</strong>m surface area significantly greater than thatachieved by other mass transfer devices.• Ambient air is drawn into the vacuum chamber through an air breather filter. The air expands toapproximately five times its <strong>for</strong>mer volume, resulting in an 80% reduction relative humidity. Water,air and solvents are carried from the vacuum chamber with the dehumidified air flow as exhaust.• Dehydrated fluid from the vacuum chamber exits the purifier via a discharge pump through a 3μmabsolute non-bypass discharge filter with an extremely high dirt capacity (service life).4

Making a Great Product Even BetterThe <strong>Pall</strong> Water Sensor OptionWhen you need to know water contamination levels, the <strong>Pall</strong> water sensor is the answer.The <strong>Pall</strong> water sensor is option “W” on the <strong>Pall</strong> portable fluid purifier. This fast acting, highlyrepeatable in-line device measures relative humidity and temperature which are used to calculateparts per million (PPM) water content. <strong>Fluid</strong> relative humidity is the amount of dissolved water in afluid expressed as a percentage of the amount of water necessary to cause 100% saturation.This in-line device provides instant feedback on water contamination of the fluid being purified.5

Purifier SpecificationsFlow:Maximum Dimensions:Electrical RequirementsMaximum Weight:Operating Vacuum:Maximum Viscosity:Inlet Port:Outlet Port:3 gpm (11 L/m in.)36” L x 27 1/2”W x 35” H (91 cm X 70 cm X 89 cm)120V/1PH/60HZ - units draw 15 amps max. current.Many other electrical configurations are available. Referto table on page 7.410 lbs. (186 kg) dry weight24” Hg (610 mm Hg)1300 SSU (260 cSt)1” NPT3/4” NPTWARNING: Adequate venting precautions must be taken when purifying oil contaminated with toxic fluid. A pneumaticversion of the Purifier must be used <strong>for</strong> oils contaminated with flammable fluids with a flash point below 180˚F (82 ˚C).FeaturesThe PAC portable fluid purifier is easy to connect, simple to operate and requires minimum operatorattention. It uses standard line voltage and is easily connected to your system using inlet and outlethoses. There are no adjustments to make, no controls to set; unit is self-contained.System ReliabilityProven system with more than 3,000,000 operatinghours logged.Easily PortableSmall, lightweight, and mounted on wheels <strong>for</strong> highmobility.Service IndicatorsIndicator lights signal the condition of the filterswhen element change is required.Unattended OperationAutomatic controls will safely shut down the unitif fluid levels and pressures venture outside normallimitsHigh Efficiency Particulate Removal FilterSolid particulate removal is achieved using a highlyefficient 3 μm absolute filter with a minimum 99.5%gravimetric efficiency when tested per MIL-PRF-81836,and ß3 [5(6)] > 2000, when tested per ISO 16689.Unique Operating PrincipleRemoves free and dissolved water, as well as free,entrained, and dissolved gases, and particulatecontamination.InletvalveVacuum chamberfluid level indicatorOutletvalveHigh efficiency filter <strong>for</strong>particulate removalHigh efficiencyair breatherVacuumchamberControlboxGauge panel6

PE01078 -GG -G -G -GGCODETABLE 1VOLTAGE /FREQUENCYSeeTable 1SeeTable 2SeeTable 3SeeTable 412 120 V/60 HZ20 208 V/60 HZ23 230 V/60 HZ46 460 V/60 HZ57 575 V/60 HZ11 110 V/50 HZ22 220 V/50 HZ38 380 V/50 HZ44 440 V/50 HZTABLE 2CODE SEAL OPTIONH Buna-NZ VitonJ EPRTABLE 4CODE TEST FLUID CODE TEST FLUIDOMIT Not Specified50 * SKYDROL 50010 Mineral Oil - Drakeol 10B 51 * SKYDROL LD-411 MOBIL-DTE 1152 ** HYJET IV13 MOBIL-DTE 1356 MIL-PRF-560615 Omala 15057 MIL-PRF-8725716 MIL-DTL-171160 UNIVOLT 6017 MIL-PRF-173368 MIL-PRF-608318 FYRQUEL EHC70 MIL-PRF-702419 MIL-H-1945772 MIL-PRF-1767223 MIL-PRF-2369978 MIL-PRF-780824 MOBIL-DTE 2480 TURBO OIL 2380CODEOMITWTABLE 3SPECIALOPTIONS /ACCESSORIESNot SpecifiedWater Sensor25 MOBIL-DTE 25 83 MIL-PRF-8328240 FC-40 (3M Fluorinert) 87 MIL-PRF-87252 (PAO)46 MIL-PRF-4617090 2190-TEP47 * COOLANOL 2091 Dextron III Trans. <strong>Fluid</strong>48 * COOLANOL 25SEAL OPTION FOR TABLE 2BUNA N (NITRILE)TABLE 2 = HMIL-PRF-87252 MIL-PRF-87257VITONTABLE 2 = ZMIL-PRF-7808MIL-H-19457EPRTABLE 2 = JMIL-PRF-5606MIL-DTL-17111MIL-PRF-23699Type IV & V Phosphate EstersMIL-PRF-6083MIL-PRF-17331Turbo Oil 2380Hyjet ** IVMIL-PRF-46170MIL-PRF-17672Specific SyntheticsSkydrol * LD-4MIL-PRF-832822190-TEPSkydrol * 5008-4PAO CoolantsOrganic EstersPetroleum Base Numerous Others Numerous Others Numerous Others7

PollutionPrevention<strong>Fluid</strong>RecyclingWastestreamMinimization<strong>Fluid</strong> ServiceLife ExtensionAEPURIFENb