Profibus System Integration PDF 4.03MB - Schneider Electric

Profibus System Integration PDF 4.03MB - Schneider Electric

Profibus System Integration PDF 4.03MB - Schneider Electric

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

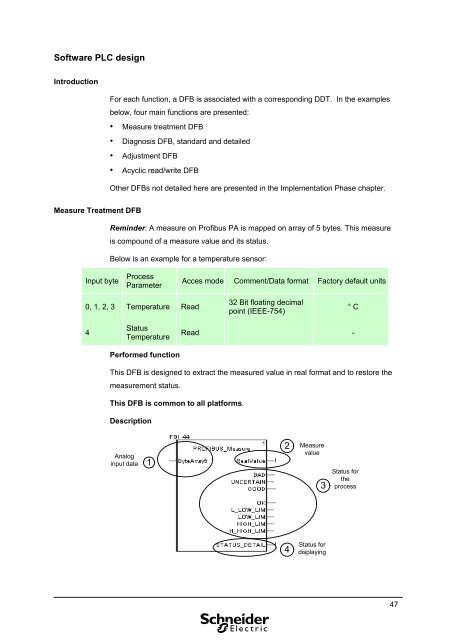

Software PLC designIntroductionFor each function, a DFB is associated with a corresponding DDT. In the examplesbelow, four main functions are presented:• Measure treatment DFB• Diagnosis DFB, standard and detailed• Adjustment DFB• Acyclic read/write DFBOther DFBs not detailed here are presented in the Implementation Phase chapter.Measure Treatment DFBReminder: A measure on <strong>Profibus</strong> PA is mapped on array of 5 bytes. This measureis compound of a measure value and its status.Below is an example for a temperature sensor:Input byteProcessParameterAcces mode Comment/Data format Factory default units0, 1, 2, 3 Temperature Read32 Bit floating decimalpoint (IEEE-754)° C4StatusTemperaturePerformed functionRead -This DFB is designed to extract the measured value in real format and to restore themeasurement status.This DFB is common to all platforms.DescriptionAnaloginput data12Measurevalue3Status fortheprocess4Status fordisplaying47