Floor Sheathing - OSBGuide - TECO

Floor Sheathing - OSBGuide - TECO

Floor Sheathing - OSBGuide - TECO

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

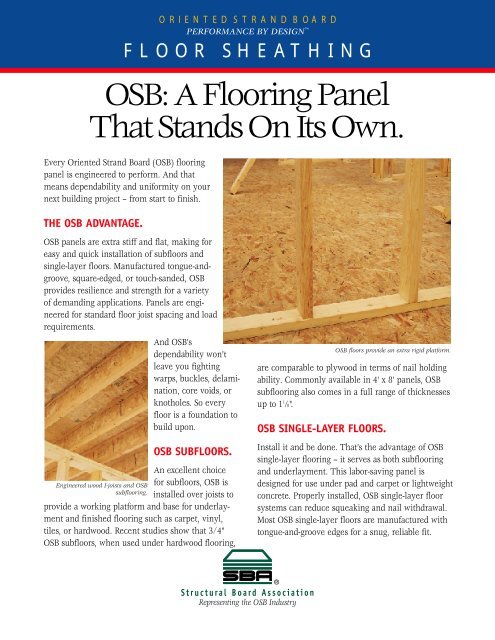

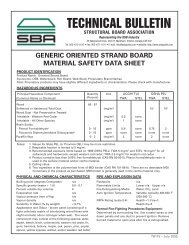

O R IE N T E D S T R A N D B O A R DPERFORMANCE BY DESIGN TMFLOOR SHEATHINGOSB: A<strong>Floor</strong>ing PanelThat Stands On ItsOwn.Every Oriented Strand Board (OSB) flooringpanel is engineered to perform. And thatmeans dependability and uniformity on yournext building project – from start to finish.THE OSB ADVANTAGE.OSB panels are extra stiff and flat, making foreasy and quick installation of subfloors andsingle-layer floors. Manufactured tongue-andgroove,square-edged, or touch-sanded, OSBprovides resilience and strength for a varietyof demanding applications. Panels are engineeredfor standard floor joist spacing and loadrequirements.Engineered wood I-joists and OSBsubflooring.And OSB’sdependability won’tleave you fightingwarps, buckles, delamination,core voids, orknotholes. So everyfloor is a foundation tobuild upon.OSB SUBFLOORS.An excellent choicefor subfloors, OSB isinstalled over joists toprovide a working platform and base for underlaymentand finished flooring such as carpet, vinyl,tiles, or hardwood. Recent studies show that 3/4"OSB subfloors, when used under hardwood flooring,are comparable to plywood in terms of nail holdingability. Commonly available in 4' x 8' panels, OSBsubflooring also comes in a full range of thicknessesup to 1 1 ⁄8".OSB SINGLE-LAYER FLOORS.OSB floors provide an extra rigid platform.Install it and be done. That’s the advantage of OSBsingle-layer flooring – it serves as both subflooringand underlayment. This labor-saving panel isdesigned for use under pad and carpet or lightweightconcrete. Properly installed, OSB single-layer floorsystems can reduce squeaking and nail withdrawal.Most OSB single-layer floors are manufactured withtongue-and-groove edges for a snug, reliable fit.®Structural Board A ssociationRepresenting the OSB Industry

GRADES & RATINGSOSB is manufactured to meet the Exposure 1durability classification, which means panels areappropriate for use where construction delays may beencountered. As with all wood products, care shouldbe taken to protect floor panels from excess moisture.OSB is manufactured to meet the performancerequirements of the voluntary product standardPS2-92 Wood Based Structural Use Panels, CSA 0325Construction <strong>Sheathing</strong> (and/or CSA 0437 OSB andWaferboard). OSB is certified to meet these standardsby APA – The Engineered Wood Association,<strong>TECO</strong>/PFS, PSI, or other major wood certificationorganizations. Structural 1 panels are for use whereshear and cross-panel strength are extra important,such as areas with seismic activity. Design values arenow available for OSB. Contact the Structural BoardAssociation for more information.ENHANCED FLOOR PERFORMANCEFor enhanced floor performance, OSB panels may befield glued and nailed or screwed to the floor supportsystem. Glue should also be applied to the T&G jointsystem. The adhesive shall be applied in accordancewith the adhesive manufacturer’s instruction. Forincreased floor performance or an engineered floorsystem, SBA recommends combining I-joists withpanels with a greater span rating. For detailedinformation on these methods, contact the StructuralBoard Association.DESIGN CRITERIA FOR FLOOR CONSTRUCTION (Minimum Panel Width – 24")Allowable Uniform <strong>Floor</strong> Loads for Rated OSB <strong>Sheathing</strong> Panels with Long Dimension Across Supports.Allowable LoadsPanel Panel Maximum (Pounds per square foot)Span Thickness Span Maximum MaximumRating (Inch) (Inches) Live Load Dead Load16 oc 7/16, 19/32 16 100 1020 oc 19/32, 5/8 20 100 1024 oc 23/32, 3/4 24 100 1032 oc 7/8, 1 32 100 1048 oc 1-1/8 48 55 10(1 psf = 0.048 kPa)SPAN RATINGSSubfloorsMaximumJoist Spacing Span Ratings Common Thicknesses16"24/16 7/16", 15/32", 1/2"32/16 15/32", 1/2"20"32/20 19/32", 5/8"40/20 19/32", 5/8"40/24 23/32", 3/4" (3)48/24 23/32", 3/4"24"(3)32/16 (1) 15/32", 1/2"40/20 (2) 19/32", 5/8"32" N/A(1)acceptable under 3/4" wood strip flooring installed at right angles to joists(2)acceptable under 1-1/2" cellular or lightweight concrete,or 3/4" wood strip flooring installed at right angles to joists(3)SBA recommends under lightweight concrete or 3/4" wood strip flooring(1" = 25.4 mm)1Panels are continuous over two or more spans and installed withthe long panel dimension perpendicular to supports.2Uniform live load deflection limitation: 1/360 of the span.3Edges must have tongue-and-groove joints or must be supportedwith blocking.4Panels in a given thickness may be manufactured in more thanone span rating. Panels with a span rating greater than the actualjoist spacing may be substituted for panels of the same thicknesswith a span rating matching the actual joist spacing.5Check local building codes for minimum fastening schedule.Combination Subfloor-Underlayment(Single <strong>Floor</strong> Grades)MaximumJoist Spacing Span Rating Common Thicknesses20" 20 oc 19/32", 5/8"24" 24 oc 23/32", 3/4" (3)32" 32 oc 7/8", 1"48" 48 oc 1-1/8"RememberSpace panels according to manufacturer’s instructions.Requirements for floor sheathing may vary throughout thecountry. Check with the local building authority for anyspecial requirements.(1) (2)®Structural Board A ssociationRepresenting the OSB Industry25 Valleywood Drive, Unit 27 • Markham, Ontario, Canada L3R 5L9 • Tel: (905) 475-1100 • Fax: (905) 475-1101Web Site: www.osbguide.comE-mail: info@osbguide.comMember of theWood Panel BureauMember of the SustainableForestry Certification CoalitionPrinted in CanadaEL809 09/01/5000