Troubleshooting the REN™ Oil Level Regulator Technical Bulletin

Troubleshooting the REN™ Oil Level Regulator Technical Bulletin

Troubleshooting the REN™ Oil Level Regulator Technical Bulletin

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

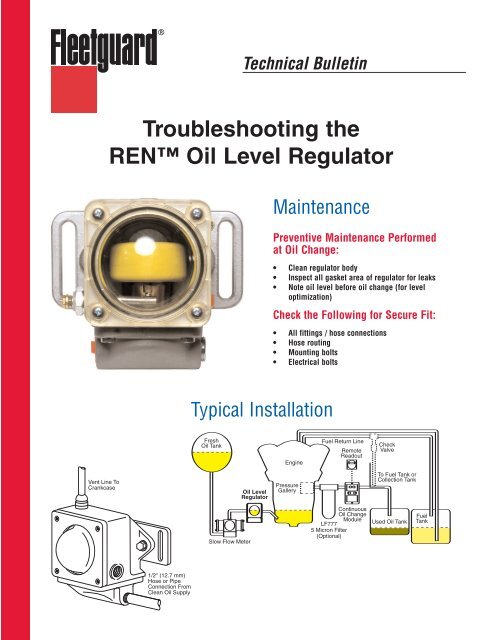

<strong>Technical</strong> <strong>Bulletin</strong><strong>Troubleshooting</strong> <strong>the</strong>REN <strong>Oil</strong> <strong>Level</strong> <strong>Regulator</strong>MaintenancePreventive Maintenance Performedat <strong>Oil</strong> Change:• Clean regulator body• Inspect all gasket area of regulator for leaks• Note oil level before oil change (for leveloptimization)Check <strong>the</strong> Following for Secure Fit:• All fittings / hose connections• Hose routing• Mounting bolts• Electrical boltsTypical InstallationFresh<strong>Oil</strong> TankEngineFuel Return LineRemoteReadoutCheckValveVent Line ToCrankcase<strong>Oil</strong> <strong>Level</strong><strong>Regulator</strong>PressureGalleryTo Fuel Tank orCollection TankSlow Flow MeterContinuous<strong>Oil</strong> ChangeModuleLF7775 Micron Filter(Optional)Used <strong>Oil</strong> TankFuelTank1/2" (12.7 mm)Hose or PipeConnection FromClean <strong>Oil</strong> Supply

<strong>Troubleshooting</strong>Overfill SituationProblem: Sight Glass FloodedProbable Causes:1. Excessive Pressure From <strong>Oil</strong> SupplyTankPressure at <strong>the</strong> regulator CANNOT exceed4 psi (27.6 kPa). Many variables affect headpressure. Verify pressure and reduce ifnecessary.2. Excessive Crankcase PressureLocate <strong>the</strong> auxiliary crankcase vent.Remove <strong>the</strong> brass vent plug in <strong>the</strong> top of<strong>the</strong> unit. Install a 1/4" NPT (6.4 mm) fittingwith a 3/8" (9.5 mm) ID hose (minimum)and route to a non-pressure or non-vacuumport (valve cover).Note: The port must be higher than <strong>the</strong> oillevel in <strong>the</strong> sump. For best performance avent line should be fitted.3. Base Adjustment IncorrectMake <strong>the</strong> following adjustments:a. Turn <strong>the</strong> engine off and check <strong>the</strong>engine oil level. If adjustment is needed,drain or add oil until <strong>the</strong> level is halfwaybetween <strong>the</strong> low and full markings on<strong>the</strong> dipstick.Note: This level should be <strong>the</strong> onemaintained. <strong>Level</strong>s higher than this canresult in excessive oil consumption.b. Start <strong>the</strong> engine.c. Adjust <strong>the</strong> regulator so that <strong>the</strong> oil levelcomes up to <strong>the</strong> center of <strong>the</strong> body.d. Tighten <strong>the</strong> mounting bolts.4. Float Assembly Failure (Rare)Contact Fleetguard Customer Assistance at<strong>the</strong> number shown below.<strong>Troubleshooting</strong>Underfill SituationProblem: Sight Glass EmptyProbable Causes:1. Base Adjustment IncorrectMake <strong>the</strong> following adjustment:a. Turn <strong>the</strong> engine off and check <strong>the</strong>engine oil level. If adjustment is needed,drain or add oil until <strong>the</strong> level is halfwaybetween <strong>the</strong> low and full markings on<strong>the</strong> dipstick.Note: This level should be <strong>the</strong> onemaintained. <strong>Level</strong>s higher than this canresult in excessive oil consumption.b. Start <strong>the</strong> engine.c. Adjust <strong>the</strong> regulator so that <strong>the</strong> oil levelcomes up to <strong>the</strong> center of <strong>the</strong> body.d. Tighten <strong>the</strong> mounting bolts.2. Hose or Fitting ObstructionCheck for plugged hoses or fittings going to<strong>the</strong> regulator. Unplug and clean, <strong>the</strong>nreconnect.Note: Follow suggested hose size andcommon hose routing to avoid kinking (perinstallation instructions).3. Float Assembly Failure (Rare)Contact Fleetguard Customer Assistance at<strong>the</strong> number shown below.TB05/04-1 - Rev 2©2004 Fleetguard Inc.Printed in <strong>the</strong> U.S.A.For more information, contact Customer Assistance at 1-800-22-FILTER (1-800-223-4583),fax 1-800-999-8664, or visit us at www.fleetguard.com