TS Refrigerated Air Dryers - Ingersoll Rand

TS Refrigerated Air Dryers - Ingersoll Rand

TS Refrigerated Air Dryers - Ingersoll Rand

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

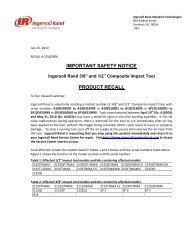

<strong>TS</strong> <strong>Refrigerated</strong> <strong>Air</strong> <strong>Dryers</strong>This sector provides products, services and solutions to enhance the efficiency and productivity of our commercial,industrial and process customers. Our <strong>Ingersoll</strong> <strong>Rand</strong> brand products including tools, pumps, material and fluid handlingsystems, microturbines, air compressors and air system components.www.air.ingersollrand.com<strong>Air</strong> Solutions<strong>Ingersoll</strong> <strong>Rand</strong> European Sales LimitedSwan Lane, Hindley Green, Wigan WN2 4EZ, UKTel: +44 (0) 1942 257171Fax: +44 (0) 1942 254162<strong>Ingersoll</strong> <strong>Rand</strong> compressors are not designed, intended or approved for breathing air applications. <strong>Ingersoll</strong> <strong>Rand</strong> does not approvespecialised equipment for breathing air applications and assumes no responsibility or liability for compressors used for breathing air service.Nothing contained on these pages is intended to extend any warranty or representation, expressed or implied, regarding the productdescribed herein. Any such warranties or other terms and conditions of sale of products shall be in accordance with <strong>Ingersoll</strong> <strong>Rand</strong>’sstandard terms and conditions of sale for such products, which are available upon request.Product improvement is a continuing goal at <strong>Ingersoll</strong> <strong>Rand</strong>. Designs and specifications are subject to change without notice or obligation.Printed in the UK. Feb 06© 2006 <strong>Ingersoll</strong>-<strong>Rand</strong> Company Limited CPN 22825145

Exceptional ReliabilityIntroducing the <strong>TS</strong> DryerA new non-cycling, refrigerated air dryer by <strong>Ingersoll</strong> <strong>Rand</strong>,the <strong>TS</strong> dryer is designed to improve reliability, productivityand efficiency, protect health and safety and lessenenvironmental impact.Micro-channel condenserTo accomplish this, the <strong>TS</strong> dryer incorporates several key technical innovations. Among these innovations areits 3-in-1 heat exchanger(s), micro-channel condenser, microprocessor and “Smart” drain.3-in-1 heat exchanger(s)3-in-1 integrated heat exchanger(s) increase the reliabilityof your compressed air system by:60°C inlet ratedHot, saturated inlet airDry, process air• Reducing leak paths and refrigeration valving• Integrating major components— pre-cooler and re-heater— heat exchanger— air/water separator• Providing consistent and stable dry, process air46°C ambient ratedCondensate dischargeReliability is increased through the use of 3-in-1 heatexchanger(s) and a micro-channel condenser3-in-1 heat exchanger(s) and a micro-channel condenser increase productivityThe integrated design of the 3-in-1 heat exchanger(s) and a micro-channel condenser providesquality compressed air throughout a wide range of operating parameters.• Decreases nuisance shutdowns• More tolerant of poor ventilation in the compressor room• Accepts higher inlet temperatures produced by fouled air compressor aftercoolers02 <strong>TS</strong> <strong>Refrigerated</strong> <strong>Air</strong> <strong>Dryers</strong> <strong>TS</strong> <strong>Refrigerated</strong> <strong>Air</strong> <strong>Dryers</strong> 03

Energy EfficiencyLow pressure drop with consistent temperature controlExcessive pressure drop increases the operating and life cycle costs of compressed airequipment. The <strong>TS</strong> minimises pressure drop by:• Optimising the connection sizesthroughout the <strong>Ingersoll</strong> <strong>Rand</strong>compression, filtering anddrying equipment• Integrating the moisture separatorinto the 3-in-1 heat exchanger• Banking heat exchangers on largerflow modelsInlet pressure0.15 - 0.26 bar(g)Reduce run time with the IntellisysmicroprocessorThe Intellisys microprocessor controller isstandard on all <strong>TS</strong> models.The controller displays:• Ambient temperature• Evaporator temperature and RH%(relative humidity)• Major component warning indicators• Preventative maintenance indicatorsThe <strong>TS</strong> dryer delivers dry, process air withminimal pressure dropDischarge pressureEfficiency• Energy saving efficiency mode reduces runtime on the dryer. When the aircompressor turns off, the dryer will cycleon and off to maintain a core evaporatortemperature (2°C - 9°C).• Energy saving cycling and the Power OutRestart Operation (PORO) are combinedwhen the efficiency mode is activated.• PORO enables automatic restarting of thedryer when a power outage occurs.The “smart” drain reduces system air losses• As ambient temperatures increase, so will the amount ofcondensate extracted by the dryer.• The “Smart” drain controls compressed air loss byautomatically adjusting its dwelltime with relation to ambienttemperature.04 <strong>TS</strong> <strong>Refrigerated</strong> <strong>Air</strong> <strong>Dryers</strong> <strong>TS</strong> <strong>Refrigerated</strong> <strong>Air</strong> <strong>Dryers</strong> 05

Health, Safety and EnvironmentImprove maintenance and service accessReduce refrigerant leaks with awith an open cabinet designmicro-channel condenser• Panel filters (standard equipment on allmodels) reduce condenser fouling.• Utilised by automotive and airconditioning industries because of its• Mounting the micro-channel condenser inefficiency and reliability.the roof further diminishes condenserfouling while improving access tomajor components.• Eliminates the soldered U-joints in thecommon tube in fin condenser, which areoften a source for refrigeration leaks.35Less refrigerantEnvironmentally friendly refrigerant• The micro-channel condenser’s superiorsurface area-to-volume ratio enables• <strong>Ingersoll</strong> <strong>Rand</strong> utilises R404-A in the<strong>TS</strong> Series dryer, which is a non-ozone-1a drastic reduction in refrigerant overdepleting refrigerant.conventional designs.462123456Hot, saturated inlet airHot gas refrigerantWarm liquid refrigerantCold gas/liquid refrigerantCool gas refrigerantDry, process air06 <strong>TS</strong> <strong>Refrigerated</strong> <strong>Air</strong> <strong>Dryers</strong> <strong>TS</strong> <strong>Refrigerated</strong> <strong>Air</strong> <strong>Dryers</strong> 07