ALUMINIZED STEEL TYPE 2 CORRUGATED STEEL PIPE

ALUMINIZED STEEL TYPE 2 CORRUGATED STEEL PIPE ALUMINIZED STEEL TYPE 2 CORRUGATED STEEL PIPE

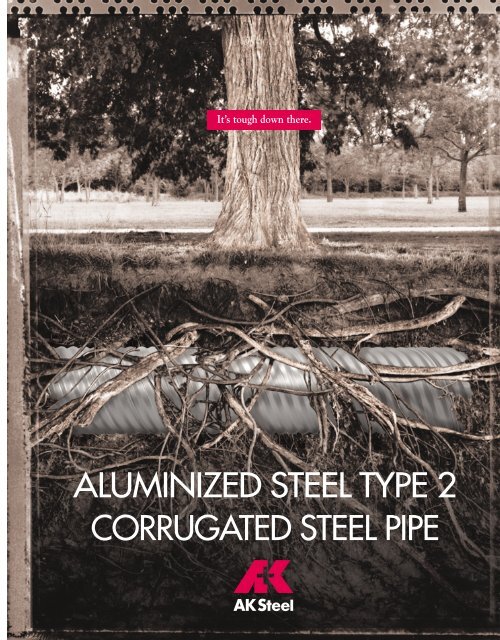

It’s tough down there.ALUMINIZED STEEL TYPE 2CORRUGATED STEEL PIPE

- Page 2 and 3: Aluminized Steel Type 2 Pipe for ad

- Page 4: Performance proven by 43-year field

It’s tough down there.<strong>ALUMINIZED</strong> <strong>STEEL</strong> <strong>TYPE</strong> 2<strong>CORRUGATED</strong> <strong>STEEL</strong> <strong>PIPE</strong>

Aluminized Steel Type 2 Pipe for added durability.2Strength of steel, corrosionresistance of aluminumCorrugated Steel Pipe manufacturedfrom Aluminized SteelType 2 offers the corrosion resistanceand surface characteristicsof aluminum with the strength andeconomy of Corrugated Steel Pipe.The product is fabricated fromsteel coils that have been hot dipcoated in a bath of commerciallypure aluminum. The coating hasuniform thickness on both sides ofthe sheet, with a strong metallurgicalbond between the metals. TheAluminized Steel Type 2 materialmeets AASHTO specificationsM274 and ASTM A 929.The coils are then fabricatedinto helically corrugated pipemeeting the requirements ofAASHTO specifications M36 andASTM A 760. Helically corrugatedsteel pipe has been a standardof the construction industry fordecades. Pipe is fabricated withlock seams or welded seamsdepending on the job requirements,and each pipe end can bereformed to provide at least twoannular corrugations.Excellent barrier protectionAluminum forms a passive aluminumoxide film that adds to theservice life by providing goodbarrier protection. This passive filmforms rapidly and maintains betterprotection over a wider environmentalrange than zinc reactionproduct films. The aluminum oxidepassive film is effective in both hardand soft water.The passive oxide film willendure as long as the free aluminumcoating layer lasts. When thislayer is eventually penetrated, thereis an underlying hard, thick aluminum-ironalloy layer that providesThe photomicrograph on the left shows how the thick alloy layer metallurgically bonds thealuminum coating to the steel base metal, as well as how the coating provides continuousprotection to the base metal. The same coating protection is provided to both sides of thesteel base metal.further corrosion protectionplus some significant abrasionprotection.Based on field studies of 42–43year installations, Aluminized SteelType 2 service life is estimated tobe 75 years minimum at 16 gagein the 5–9 pH and ≥1,500 ohm-cmresistivity ranges.In some cases, the pH/resistivityranges may be extended somewhatas is the case in arid regions wheremoisture availability is generallya controlling factor, and satisfactoryservice life may be realizedat soil resistivities somewhatbelow the 1,500 ohm-cm lowerlimit. In wetter climates, satisfactoryservice life may be realized atsoil pH values below the 5.0lower limit when resistivities arerelatively high.In general, however, environmentsoutside the recommendedpH/resistivity ranges should besubjected to additional testing tosee if conditions conducive toaccelerated corrosion actually exist.For example, low resistivity watersand soils may contain excessiveconcentrations of corrosive chlorideand sulfates salts. In addition, anydark or light gray, blue, or olivecoloredclay constituents observedin a heterogeneous soil should beisolated for pH measurement sincethese sometimes contain watersolubleheavy metal salts. Theseconstituents induce strong acidificationnecessitating the use of abituminous coating to ensurenormal soilside corrosion behavior.Environments that are faroutside the recommended pH/resistivity ranges should beavoided, including acid minewater,seawater, estuary brackish water,and sanitary/industrial sewage.Ideal for storm sewersAluminized Steel Type 2 corrugatedsteel pipe is an ideal material formunicipal storm sewers or anyStandard specifications1. AASHTO M274 (AluminizedSteel Type 2 material)and ASTM A 929.2. AASHTO M36 and ASTMA 760 (conduit, pipe.)3. AASHTO Standard BridgeDesign Specifications,Section 12 (structuraldesign) and ASTM A 796.4. ASTM A 798 (installation).

75 years minimum service life. And still counting.normal drainage project. AluminizedSteel Type 2 pipe offers adurable and economical alternateto reinforced concrete pipe. Featuresinclude light weight, longlengths, and joints that havepositive pull-apart resistance andthe ability to adjust to yieldingfoundations.Pipe and pipe-arch areavailable in four corrugations(2 2 /3" x 1 /2", 3" x 1", 125mm x25mm, and Spiral Rib’s 3 /4" x3/4" x 7 1 /2" rib corrugation) andin all standard diameters and16 gage through 10 gage.Long-term field testingBased on extensive data fromactual field installations datingback 43 years, Aluminized SteelType 2 is a superior product forstorm sewer and drainage projects.It has better corrosion resistancethan galvanized structures anddisplays better abrasion resistance.Prior to 1953, Aluminized SteelType 2 and galvanized steelculverts were exposed in sitesacross the U.S. These sites representeda variety of service conditionsincluding farm field drainage,fresh water swamps, alkali soils,and erosive applications. Testinstallations were sampled aftereight years and again after 24years. Weight loss data analyzedat all sites indicate Aluminized SteelType 2 provided significant additionalcorrosion resistance.In addition to the carefulsampling and evaluation accomplishedduring this 24-year program,simple visual inspectionrevealed that:• The appearance of AluminizedSteel Type 2 was clearly superiorto that of conventional metalliccoating.• The condition of AluminizedSteel Type 2 pipe inverts—a critical point in durabilitydesign—was excellent.In 1952–53, an additional 135composite culverts of AluminizedSteel Type 2 and galvanized steelwere installed in 20 states. Basedon the current conditions of thepipes available, the data indicatesa minimum 75-year service life for16 gage Aluminized Steel Type 2pipe when installed in the recommendedenvironment.Independent studiesMany independent studies havebeen performed that confirmAK Steel Corporation’s long-termfield test.This AluminizedSteel Type 2corrugated steelpipe was installedin 1953 inEl Dorado,California. It wasinspected in 1982and in 1995.Coupons wereremoved in 1995for evaluation bythe AK SteelResearch Centerand CALTRANS.▲▲This close-up view shows the AluminizedSteel Type 2 pipe installed in Garland,Maine, with the dark staining wiped awayto reveal the like-new underlying aluminum.▲AK Steel ResearchCenter’s corrosionengineers andMissouri D.O.T.material engineersinspect a 43-yearold AluminizedSteel Type 2 pipeinstallation. This isone of two culvertinstallations inCarter County,Missouri, installedin a series containinghalf AluminizedSteel Type 2 pipeand half galvanizedsteel pipe.3

Performance proven by 43-year field test42- and 43-year old Aluminized Steel Type 2 coupons taken from pipe inverts around the United StatesMarshall County, IAInstalled 1952Inspected 1995Lafayette County, MOInstalled 1952Inspected 1995Snohomish County, WAInstalled 1952Inspected 1995Morgan County, ILInstalled 1952Inspected 1995Bernalillo County, NMInstalled 1952Inspected 1995Oklahoma County, OKInstalled 1953Inspected 1995San Benito County, CAInstalled 1953Inspected 1995Decatur County, KSInstalled 1953Inspected 1995Newer pipe sites inspected. Same long-term performance expected.Richland County, SCInstalled 1978Inspected 1995Merrill Township, MEInstalled 1979Inspected 1995Montgomery County, MDInstalled 1980Inspected 1995Gwinnett County, GAInstalled in 1983Inspected 1995AK Steel has inspected many more pipe sites around the United States, and these field research studies indicate a minimum75-year service life for Aluminized Steel Type 2 Corrugated Steel Pipe installed in the recommended environment.Customer Service 800-331-5050AK Steel Corporation9227 Centre Pointe DriveWest Chester, OH 45069www.aksteel.comwww.alt2csp.comThe information and data in this bulletin areaccurate to the best of our knowledge and belief,but are intended for general information only.Applications suggested for the materials aredescribed only to help readers make their ownevaluations and are neither guarantees nor tobe construed as express or implied warrantiesof suitability for these or other applications.AK Steel and the AK Steel logo are registeredtrademarks of AK Steel Corporation.The product, engineeringand research informationin this literature isapplicable exclusivelyto AK Steel AluminizedSteel Type 2.4250-0221 10M CP 07/07