mine planning and operational excellence

mine planning and operational excellence

mine planning and operational excellence

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

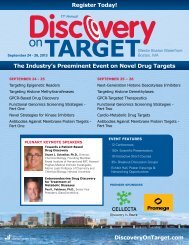

3rd AnnualMINE PLANNING AND OPERATIONAL EXCELLENCEA Must Attend for Open Cut Miners Across All Commodities28 – 31 January 2013Hilton Hotel, SingaporeTOP MINING LEADERSDavid SompiePresident Director,PT Newmont MinahasaRayaDr. Wisnu SusetyoGeneral Manager, HealthSafety Environment,PT AdaroDidik FotunadiManager, BusinessImprovement Division(BPID),PT Kaltim Prima CoalINTERNATIONAL EXPERTSRol<strong>and</strong>o R. CruzVice President, Operations,Nickel Asia Corporation,PhilippinesBasri KambatuGeneral Manager MineOperations Sorowako <strong>and</strong>Mine Operation Dispatch,PT Vale Indonesia TbkDr. Gatut AdisomaDirector of Operations,PT. Multi Harapan Utama(MHU Coal)Ery BudimanManager, Pakal Nickel Mine,PT Antam (Persero) TbkDaniel DakiniewiczMine Planning Engineer(Operations Planning),Fortescue Metals Group,AustraliaKey HighlightsInclude:• 10+ New Commercial <strong>and</strong> TechnicalProject Case Studies from the region’smining powerhouses – Indonesia,Australia <strong>and</strong> Philippines• 2 Exclusive Miners’ Panel Discussions~ Managing dem<strong>and</strong> volatility throughproduction scheduling & optimisation~ Optimising workforce safety in anOpen Cut Mine• Cost effective pit design <strong>and</strong> <strong>operational</strong><strong>planning</strong>• Increasing <strong>mine</strong> optimisation through<strong>operational</strong> efficiencies• Improving pit profitability through bestpractices in water management <strong>and</strong>flood mitigation• New developments in overburdenremoval <strong>and</strong> disposal• Ensuring ROI from technology <strong>and</strong>equipment implementationsPLUS! Pre <strong>and</strong> Post Conference Workshops:Production Scheduling <strong>and</strong> Forecasting in Open Cut Mine Planning28 JANUARY 2013Achieving Operational Efficiencies <strong>and</strong> Cost Effectiveness in Open CutMine Project Management31 JANUARY 2013Co-located with:Produced by:Tabletop Sponsor:www.opencutminingasia.comInternational OnlineMedia Partner:Media Partners:Asian Journal of Mining /Asian Mining ResearchSupported by:REGISTER NOW! Customer Service Hotline: +65 6508 2401

3rd AnnualMINE PLANNING AND OPERATIONAL EXCELLENCEDAY 1 | 29 JANUARY 2013, TUESDAY9.00 Chairman’s Opening RemarksPIT DESIGN AND OPERATIONAL PLANNING9.10 Strategic Open Pit Planning <strong>and</strong> Risk Management• Estimating capital costs <strong>and</strong> scheduling mining operations• Commercial feasibility of pit operations• Incorporating uncertainties <strong>and</strong> <strong>operational</strong> variables intoexisting plans• Evaluating the ROIsDavid Sompie, President Director, PT Newmont MinahasaRaya9.50 Developing Greenfield Open Pit Operations in Kalimantan• Strategic <strong>mine</strong> <strong>planning</strong> <strong>and</strong> financing• Reserves estimation, pit optimisation <strong>and</strong> relevant riskquantification• Infrastructure requirements <strong>and</strong> design criteria for pits,waste dumps, ramps <strong>and</strong> roads• Overcoming the <strong>operational</strong> challengesDr. Gatut Adisoma, Director of Operations, PT. Multi HarapanUtama (MHU Coal)10.30 Networking Coffee Break11.00 Environmental Protection <strong>and</strong> Management of Open PitMine Operations• AMDAL <strong>and</strong> environmental permit• Water <strong>and</strong> waste management systems in pit <strong>planning</strong>• Other aspects of environmental management <strong>and</strong>monitoring• Mine reclamation <strong>and</strong> closure planDr. Wisnu Susetyo, General Manager, Health Safety Environment,PT Adaro11.40 Managing Dem<strong>and</strong> Volatility through ProductionScheduling <strong>and</strong> Optimisation• Pit design <strong>and</strong> geology <strong>and</strong> impact on productionscheduling• Implementing key <strong>operational</strong> processes without affectinglong term plans• Optimising Mine Production through effective alignmentof short <strong>and</strong> long term <strong>planning</strong>Panelists:David Sompie, President Director, PT Newmont MinahasaRayaBasri Kambatu, General Manager Mine Operations Sorowako<strong>and</strong> Mine Operation Dispatch, PT Vale. Indonesia TbkDr. Gatut Adisoma, Director of Operations, PT. Multi HarapanUtama (MHU Coal)Daniel Dakiniewicz, Mine Planning Engineer (OperationsPlanning), Fortescue Metals Group, AustraliaMINERS’ DIALOGUE12.20 Aligning Operational Excellence with CommercialObjectives in Open Cut Mine Operations• Aligning <strong>and</strong> managing between Mine Planning <strong>and</strong> MineOperations• Manpower performance• Maintenance <strong>and</strong> Mine Operations• Measurement of Mine Operations PerformanceBasri Kambatu, General Manager Mine Operations Sorowako<strong>and</strong> Mine Operation Dispatch, PT Vale. Indonesia Tbk1.00 Networking Lunch BreakPRODUCTION SCHEDULING AND OPTIMISATION2.10 Minimising Production Shortfall through IntegratedPlanning, Payload Management <strong>and</strong> Production ControlSystem• Integrated <strong>planning</strong> to improve load & haul (L&H)productivity <strong>and</strong> equipment utilisation in unexplodedordnance (UXO) mining area• Payload management approach in low specific gravity (SG)material• Production control system approach to maintain fleetmatching• Managing fuel efficiency <strong>and</strong> unit costEdi Widodo, Superintendent Mining, MMG LXML SEPON, Gold& Copper Mine2.50 The Development of Pakal Nickel Mine• Mine Planning <strong>and</strong> how to make the best design• Heavy equipments <strong>and</strong> supporting units• Mine road development <strong>and</strong> Mine Facilities• Mining block test• Challenges to increase the ore production• Creating stockyards <strong>and</strong> overcoming the difficultiesEry Budiman, Manager, Pakal Nickel Mine, PT Antam(Persero) Tbk3.30 Networking Coffee BreakOVERBURDEN AND SLOPE MANAGEMENT4.00 Achieving Cost <strong>and</strong> Operational Efficiencies in OverburdenManagement <strong>and</strong> Haulage• Dumping methods in extreme locations <strong>and</strong> managing itsafely <strong>and</strong> effectively• Implementing overburden placement• Loading <strong>and</strong> haulage facilities• Reducing costs <strong>and</strong> achieving <strong>operational</strong> efficienciesDaniel Dakiniewicz, Mine Planning Engineer (OperationsPlanning), Fortescue Metals Group, Australia4.40 Innovations in Geotechnical Pit Slope Management forOptimum Coal Recovery <strong>and</strong> Improved Mine Safety• Economic factors to consider – strip ratio, mining costs <strong>and</strong>coal prices• Adapting pit design, depth, slope configuration <strong>and</strong> benchlayout to changing economics <strong>and</strong> mining conditions• Leveraging innovations <strong>and</strong> benefit through largeproduction efficiencies <strong>and</strong> advanced technologies• Slope Management~ Best Practices for pit slope management for miningsuccess~ Mining <strong>and</strong> geotechnical innovations~ Ground monitoring & control, reliable slide monitoring,better prediction of slope movements~ Extracting coal from areas of known <strong>and</strong> unknown slopeinstabilityWarren L. Tamblyn, Manager, Mine Geotechnical Services,PT. Bayan Resources Tbk5.20 Chairman’s Closing Remarks5.25 End of Conference Day 1REGISTER TODAY! +65 6508 2401 register@ibcasia.com.sg www.opencutminingasia.com

3rd AnnualMINE PLANNING AND OPERATIONAL EXCELLENCEDAY 2 | 30 JANUARY 2013, WEDNESDAY9.00 Chairman’s Opening Remarks9.10 Optimising Workforce Safety in an Open Cut Mine• Top 5 safety risks <strong>and</strong> hazards• Effective programs <strong>and</strong> methods to minimize the risks• Planning, design <strong>and</strong> <strong>operational</strong> initiatives to mitigaterisks• Changing culture through strategic recruitment <strong>and</strong>empowermentPanelists:Dr. Wisnu Susetyo, General Manager, Health SafetyEnvironment, PT AdaroDidik Fotunadi, Manager, Business Improvement Division(BPID), PT Kaltim Prima CoalLeonard Rowe, Graduate Drill <strong>and</strong> Blast Engineer, Rio TintoCoal, AustraliaMINERS’ DIALOGUEWATER MANAGEMENT9.50 Water Management in Open Pits <strong>and</strong> Mining Area• Pre <strong>and</strong> post studies of mining projects to maintainminimum catchment area• Treatment of silt: erosion <strong>and</strong> sedimentation• Mine infrastructure <strong>and</strong> drainage system• Acid Mine Drainage• Treatment for chemical <strong>and</strong> solvent (pH) <strong>and</strong> considerationsfor the community <strong>and</strong> water bodiesNibas Mahato, Manager, Geology, PT Bina Insan SuksesM<strong>and</strong>iri10.30 Networking Coffee Break11.00 Water Management for Sustainable Mining <strong>and</strong>Communities• Identifying <strong>and</strong> evaluating effective measure of <strong>mine</strong> waterfootprint• Reducing water consumption in production <strong>and</strong> process• Sustainable water supply for ecological <strong>and</strong> social needs• Best practices <strong>and</strong> strategies for water management inmining• Way forwardDr. Hishmi Jamil Husain, Environment Superintendent,Rio TintoEQUIPMENT AND TECHNOLOGY SELECTION11.40 Replacement of Coal Trucking Transportation with MelawanCrushing Plant <strong>and</strong> Western Overl<strong>and</strong> Conveyor• Background of project execution <strong>and</strong> objectives• Design basis• Economic <strong>and</strong> risk analysis• Ensuring optimum outputSupris Rudianto, Manager of Coal H<strong>and</strong>ling Facility (CHF) Project,Expansion Projects Division, PT Kaltim Prima Coal12.20 Achieving Pit Efficiencies through Computerised MinePlanning in Lateritic Mines• Overview of <strong>mine</strong>rals extraction at lateritic nickel <strong>mine</strong>s• Enabling <strong>mine</strong> efficiencies by applying technologies <strong>and</strong>best practices from other deposits (gold, copper <strong>and</strong> others)• Increasing productivity <strong>and</strong> maximizing the economic valueof deposits through computerised toolsRol<strong>and</strong>o R. Cruz, Vice President, Operations, Nickel AsiaCorporation, Philippines1.00 Networking Lunch Break2.10 Increased Productivity of KPC Big Diggers throughContinuous Improvement <strong>and</strong> Best Practices• Improvement processes <strong>and</strong> best practices for KPC BigDiggers• Challenges during improvement process• Improving productivity by 5%• Sustainability <strong>and</strong> how to maintain the performanceeffectivelyDidik Fotunadi, Manager, Business Improvement Division (BPID),PT Kaltim Prima CoalSTRATEGIC COST MANAGEMENT2.50 Tracking Blast Output to Achieve Cost Efficiency <strong>and</strong> MeetProduction Targets• Analyzing key benefits to achieve ultimate productiontargets• Systems, technologies & software <strong>and</strong> best practices torecord blast results• Managing costs• Utilising blast results to meet production targets• Cost cutting considerationsLeonard Rowe, Graduate Drill <strong>and</strong> Blast Engineer, Rio TintoCoal, Australia3.30 Networking Coffee Break4.00 Reducing Operating Costs through Grade ControlManagement – Tapunopaka Nickel Mine• Nickel ore mining activities• Ensuring ore availability for shipping/processing plantthrough ETO stockpile• Incurring additional material h<strong>and</strong>ling <strong>and</strong> operating costsby using ETO stockpile• Grade control drilling & management to ensure oreís quality• Eliminating ETO stockpile <strong>and</strong> additional costs from miningactivities through grade control systemArif Hindarto, Senior Mining Engineer, PT Antam(Persero) Tbk4.40 Assessing the Truckless Mine Option• In Pit Crushing & Conveying (IPCC)• Selection criteria – technical <strong>and</strong> commercial considerations• Applying IPCC under various mining conditions• Success factors for the <strong>planning</strong>, operations <strong>and</strong>maintenance of IPCC5.20 Conference Chairman’s Closing Remarks5.30 End of Conference Day 2“ABM Investama secures $300m mining contractEnergy solution provider PT ABM Investama Tbk (ABMM), throughwholly-owned subsidiary PT Cipta Kridatama, has secured a miningcontract worth US$300 million <strong>and</strong> is expecting to obtain at leastone more contract this year to achieve its business targets.www.thejakartapost.com, 5 March 2012Delta Dunia eyes 15% rise in overburden removal businessPublicly-listed mining service provider PT Delta Dunia Makmur istargeting for its overburden removal business, conducted throughsubsidiary PT Bukit Makmur M<strong>and</strong>iri Utama (Buma), to increase by 10to 15 percent this year.www.thejakartapost.com, 1 February 2012Bayan Unit Signs Coal Contract Extension with BumaGunungbayan Pratamacoal, a unit of coal <strong>mine</strong>r Bayan Resourcessigned an US$640 million extension of its mining service contract withBukit Makmur M<strong>and</strong>iri Utama.www.coalage.com, 25 January 2012“REGISTER TODAY! +65 6508 2401 register@ibcasia.com.sg www.opencutminingasia.com

3rd AnnualMINE PLANNING AND OPERATIONAL EXCELLENCEWORKSHOPSPRE-CONFERENCE WORKSHOP • 28 January 2013 • Monday (9am – 5pm)Production Scheduling <strong>and</strong> Forecasting in Open Cut Mine PlanningMiners are facing challenging tasks of ensuring that planned <strong>and</strong> forecasted production is a clear reflection of actual targets. Thisinteractive workshop will provide you with a practical step by step process to deter<strong>mine</strong> the best scheduling <strong>and</strong> forecastingmethodologies for your open cut <strong>mine</strong> operations.• Assessing current scheduling <strong>and</strong> forecasting methods• Improving forecasting strategies• Effective <strong>planning</strong> <strong>and</strong> scheduling• Operational initiatives required• Applying risk mitigation strategies <strong>and</strong> flexibility in open pit <strong>mine</strong> operations <strong>planning</strong>• Case studies <strong>and</strong> discussionsAbout Your Workshop Leader:Dipesh Dipu, Partner, Jenissi Management ConsultantsDipesh Dipu is the founder <strong>and</strong> partner at Jenissi Management Consultants. He has more than twelve years of experience instrategic <strong>and</strong> performance improvement consulting <strong>and</strong> financial advisory in the mining <strong>and</strong> energy sector with major focuson coal <strong>and</strong> metals. His extensive experience includes working with PricewaterhouseCoopers as a Principal Consultant forMining, CEO of Zambian Mining <strong>and</strong> Power Generation (subsidiary of Nava Bharat Ventures) <strong>and</strong> Director of Energy <strong>and</strong>Resources Consulting with Deloitte Touché Tohmatsu India Pvt. Ltd. Awarded the young mining engineer in year 2007 by MiningEngineer’s Association of India, Dipesh also sits on the editorial board of Mining Engineering Journal of Mining Engineers’Association of India.POST-CONFERENCE WORKSHOP • 31 January 2013 • Thursday (9am – 5pm)Achieving Operational Efficiencies <strong>and</strong> Cost Effectiveness in OpenCut Mine Project ManagementAll mining companies are looking to achieve <strong>operational</strong> targets <strong>and</strong> keeping costs low. However, they often face an uphillchallenge. This interactive <strong>and</strong> practical workshop will address cost control & efficiency mechanisms, resources optimization <strong>and</strong>techniques for boosting productivity in open pit <strong>mine</strong> operations.• Key challenges <strong>and</strong> cost areas in open pit <strong>mine</strong> operations• Dealing with uncertainties <strong>and</strong> variable costs• Selection of equipment <strong>and</strong> its role in cost effective <strong>and</strong> efficient <strong>mine</strong> operations• Improving equipment utilisation• Strategies for reducing <strong>operational</strong> costs – direct <strong>and</strong> indirect• Setting up key measures <strong>and</strong> control mechanismsSponsorship <strong>and</strong> Exhibition Opportunities✔ Do you have cutting edge mining technology or services that you want to showcase?✔ Are you on the lookout for potential BUYERS or a platform to increase your market share?✔ Interested to share a presentation or case study?If your answer is YES to any of the above questions, please contact Catherine Wong at +65 6508 2469 oremail: catherine.wong@ibcasia.com.sg today.REGISTER TODAY! +65 6508 2401 register@ibcasia.com.sg www.opencutminingasia.com

3rd AnnualMINE PLANNING AND OPERATIONAL EXCELLENCE28 – 31 January 2013Hilton Hotel, SingaporeA Must Attend forOpen Cut Miners AcrossAll CommoditiesWho Will You Meet?Mining Companies60%EquipmentProviders 10%Miners are increasingly looking for innovative ways to improveprofitability, reduce costs <strong>and</strong> to operate as optimally <strong>and</strong> costeffectively as possible to achieve production targets. Successful <strong>and</strong>efficient pit operations are a sure shot way to enhancing the bottomline <strong>and</strong> create competitive advantage in today’s market.Transportation<strong>and</strong> Logistics 5%TechnologyProviders 10%The 3rd Annual Open Cut Mine Planning <strong>and</strong>Operational Excellence Conference will address allfacets of Open Cut Mining <strong>and</strong> how <strong>mine</strong>rs can addvalue to operations.ContractMiners 5%EPC Companies 10%Technical innovations <strong>and</strong> commercial best practices will be discussedfor the entire <strong>mine</strong>ral extraction process including pit <strong>planning</strong>,overburden management, extraction efficiencies, water & wastemanagement <strong>and</strong> heavy equipment selection.Top Reasons To Attend• Asia’s ONLY Conference on Open Cut Mine Planning <strong>and</strong>Operational Excellence for <strong>mine</strong>rs <strong>and</strong> service providers• CO-LOCATED with 11th Annual Coal Markets – opportunityto network across both events• TRANSFORM your open pit <strong>mine</strong> challenges intoCOMMERCIAL SUCCESS• IMPROVE your profitability through strategic costmanagement <strong>and</strong> effective equipment & technology selection• PREVENT financial losses through effective productionscheduling <strong>and</strong> forecasting• IMPLEMENT effective dem<strong>and</strong> <strong>planning</strong> through scheduling<strong>and</strong> pit management• REVIEW water <strong>and</strong> waste management strategies forenhancing pit operationsSingapore 7%Malaysia15%Indonesia 40%Philippines 15% Australia 8%Vietnam 5%Hong Kong 3%Mongolia 5%China, PRC 2%IBC Asia’s Track Record in the MiningSector:“Good chance for networking <strong>and</strong> will participatein the next event for sure.”Vasily Tsarev, President, Bantry Corporation Ltd“Insightful <strong>and</strong> compact conference.”Michael Thirnbeck, President Director, PT Iriana MutiaraIdenburgREGISTER TODAY! +65 6508 2401 register@ibcasia.com.sg www.opencutminingasia.com