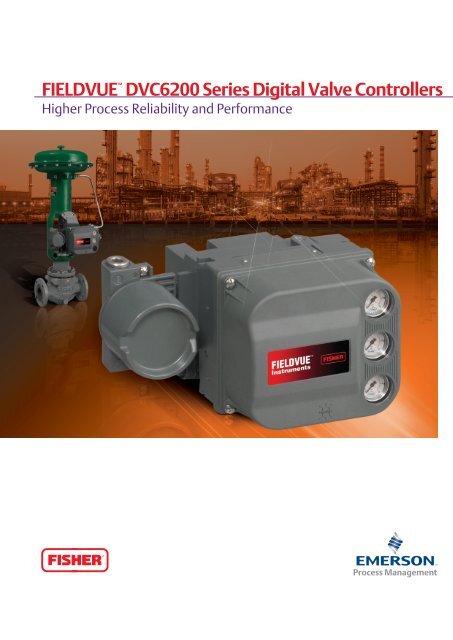

FIELDVUE™ DVC6200 Series Digital Valve Controllers

FIELDVUE™ DVC6200 Series Digital Valve Controllers

FIELDVUE™ DVC6200 Series Digital Valve Controllers

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FIELDVUE <strong>Digital</strong> <strong>Valve</strong> <strong>Controllers</strong><strong>DVC6200</strong>, <strong>DVC6200</strong>f, <strong>DVC6200</strong>pNo Sliding Parts to WearLinkage-less, non-contactfeedback technology has no slidingparts to wear. A magnet arrayand Hall Effect sensor are usedto detect valve position. With nolinkage to wear, loosen, corrode,or vibrate, it can handle harshenvironments and nonstop cycling.Wireless RealizedThe Smart Wireless THUM adapter allows you to easilyand cost-effectively accesscontrol valve assemblydiagnostics wirelessly.Separate WiringCompartmentThe sealed terminal box isolatesfield-wiring connections fromother areas of the instrumentand keeps water and harshatmosphere away fromelectronic components.Encapsulated ElectronicsElectronic circuitry on the printedwiring board is fully encapsulatedand isolated from the terminal box,conduit, and plant environment.

Aprocess control plant, regardless of industry, makes moneybased on its ability to minimize variability and maximizeavailability. Performance and reliability are the foundation forthe FIELDVUE family of digital valve controllers. Their role is tomaintain control valve position, diagnose the assembly, and enablepredictive maintenance.FIELDVUE Performance on Fisherand Non-Fisher Control <strong>Valve</strong>sThe FIELDVUE <strong>DVC6200</strong> <strong>Series</strong> digitalvalve controller mounts to any pneumaticactuator. Non-Fisher valves can beequipped with FIELDVUE instruments toimprove performance and reliability.Modular Design MakesMaintenance Quick and EasyThe master module design allowsfast replacement of the I/P converter,relay, gauges, and printed wiringboard without disturbing themounting, field wiring, or calibration.Reliability. With well over one million instruments installed,FIELDVUE digital valve controllers have earned high praisesfrom companies that employ their technology to improve plantavailability. Built for extreme conditions, they have proventhemselves by surviving difficult process environments in thefollowing industries: refining, chemical, nuclear, oil and gas,power, and pulp and paper. They are premier performers incycle life.Performance. Plant operators rely on FIELDVUE digital valvecontrollers to reduce process variability. The instruments arepaired with Fisher control valves to achieve precise positioningaccuracy and fast response to process changes. They worktogether to provide unmatched dynamic performance.Diagnostics. FIELDVUE digital valve controllers protect yourprocess by giving a view of the valve’s actual position and operatingcharacteristics. Performance Diagnostics run continuously, analyzingvalve and actuator data while the valve remains in service.If and when problems are detected, information can bedirected to the appropriate personnel automaticallywhen installed in a PlantWeb system.In the past, locally verifying proper control valveperformance required technicians to use laptops inthe field. Now, local diagnostic tests can be runwith ease and mobility using <strong>Valve</strong>Link Mobilesoftware on a handheld field communicator,PDA, or smartphone.Application Breadth. FIELDVUE digital valve controllers areused on many control valve styles. FIELDVUE instruments driveboth sliding-stem linear valves, such as the Fisher GX, and quarterturnrotary style valves, such as the Fisher Control-Disk. FIELDVUEinstruments use interchangeable components, so spare partsrequirements are reduced.Maintenance. Many design elements make FIELDVUE digitalvalve controllers truly unique. These elements provide significantmaintenance advantages that make FIELDVUE instruments yourbest choice in the quest for improved plant performance.Internally Mounted GaugesSupply and output gauges areunder the cover, fully protectedfrom the environment and againstrough handling, helping assuremaintenance-free performance.Integration. FIELDVUE digital valve controllers are availablewith either the HART, ® WirelessHART, ® Foundation fieldbus, orPROFIBUS ® communication protocol. AMS <strong>Valve</strong>Link SNAP-ON software provides full instrument diagnostics capabilities withinDeltaV and Ovation process control systems. <strong>Valve</strong>Link DTMsoftware can be used with any process control system thatsupports FDT/DTM technologies.Contact your local Emerson Process Management sales office formore information or to make a purchase. Their highly skilled andexperienced applications personnel are ready to help you takeadvantage of the many benefits of FIELDVUE digital valve controllers.

SpecificationInputElectricalClassificationOutput SignalAvailable Mounting<strong>DVC6200</strong>HART ®Analog input signal: 4−20 mA DC, nominal;split ranging available.Minimum voltage available at instrument terminalsmust be 10.5 VDC for analog control, 11 VDC forHART communication.Hazardous Area Approvals:• CSA— Intrinsically Safe, Explosion-proof,Division 2, Dust Ignition−proof• FM— Intrinsically Safe, Explosion-proof,Non−Incendive, Dust Ignition-proof• ATEX— Intrinsically Safe and Dust, Flameproofand Dust, Type n and Dust• IECEx— Intrinsically Safe, Flameproof, Type nElectrical Housing:• CSA— Type 4X, IP66• FM— NEMA 4X• ATEX— IP66• IECEx— IP66<strong>DVC6200</strong>f and <strong>DVC6200</strong>pFoundation fieldbus and PROFIBUS ®Voltage Level: 9 to 32 volts.Maximum Current: 19 mA.Reverse Polarity Protection: Unit is not polaritysensitive.Termination: Bus must be properly terminated perISA SP50 guidelines.Hazardous Area Approvals:• CSA— Intrinsically Safe and FISCO, Explosionproof,Division 2, Dust Ignition−proof• FM— Intrinsically Safe and FISCO, Explosionproof,Non−Incendive, Dust Ignition−proof• ATEX— Intrinsically Safe, FISCO, and Dust,Flameproof and Dust, Type n and Dust• IECEx— Intrinsically Safe and FISCO, Flameproof,Type nElectrical Housing:• CSA— Type 4X, IP66• FM— NEMA 4X• ATEX— IP66• IECEx— IP66Pneumatic signal, up to 95% of supply pressure, maximum span 9.5 bar (140 psig)• Integral mounting to the Fisher GX control valve and actuator system.• Integral mounting to Fisher rotary actuators.• Remote mount.• Sliding-stem linear applications.• Quarter-turn rotary applications.• <strong>DVC6200</strong> <strong>Series</strong> digital valve controllers can also be mounted on other actuators that comply withIEC 60534-6-1, IEC 60534-6-2, VDI/VDE 3845 and NAMUR mounting standards.© Fisher Controls International LLC 2011 All Rights Reserved.FIELDVUE, THUM, PlantWeb, <strong>Valve</strong>Link, and Control-Disk are marks owned by one of the companies in theEmerson Process Management business division of Emerson Electric Co. Emerson Process Management,Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks arethe property of their respective owners.Emerson Process ManagementMarshalltown, Iowa 50158 USASorocaba, 18087 BrazilChatham, Kent ME4 4QZ UKDubai, United Arab EmiratesSingapore 128461 Singaporewww.EmersonProcess.com/FisherThe contents of this publication are presented for informational purposes only, and while every effort hasbeen made to ensure their accuracy they are not to be construed as warranties or guarantees, expressor implied, regarding the products or services described herein or their use or applicability. All sales aregoverned by our terms and conditions, which are available upon request. We reserve the right to modifyor improve the designs or specifications of such products at any time without notice. Neither Emerson,Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection,use, or maintenance of any product. Responsibility for proper selection, use, and maintenance of anyproduct remains solely with the purchaser and end user.D351908X012 / MX6 (H:) / Feb11