C35-10

C35-10

C35-10

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

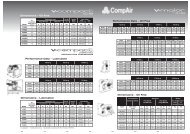

C200TS-24 – C270TS-920.0 – 27.0 m 3 / minProduct range DLT 2701Patented bi-turbo technology = Low cost of ownership!A radical new approach to energy conservation.The CompAir TurboScrew patented bi-turbo technologymakes these compressors outstanding in their class.On average site conditions where the demand variesbetween idle, part load and full load, the TurboScrewconsumes up to 30 % less fuel than most of theconventional compressors on the market.TurboScrew TechnologyCompAir’s TurboScrew compression system is a radical newapproach to energy conservation. It uses a Cummins turboassisted engine powering a CompAir screw compressor unitwith the addition of an engine exhaust gas drive turbine,pre-compressing the suction inlet air before it enters thecompression chamber.24 V electric SystemEasy access side wing doorsensures sufficient powerreserves in case of coldstarts and a safe run-upabilityoffering excellentaccessibility for easymaintenanceCummins QSB 6.7robust 6-cylinder turbochargeddiesel engine withan additionally integratedsecond turbo-charger for thepre-compression of the inletair of the com pressor.Soft startextends the engine life time byreducing engine stress duringstart-up and allowing the engineto reach running temperaturewith the compressor unloadedBolted single sheetsThe steel canopy is massgalvanised and electrostaticallycoated, offeringexcellent protectionagainst damage andcorrosion. With boltedsingle sheets, exchangeis both quick and easySmall footprint & one of the lightest in classThe lightweight TurboScrew compressors canbe towed by a vehicle with a maximum towingweight of 3500kg and is great for getting tohard- to-access sites.Potential Fuel SavingsBased on average site running conditions, overlifetime of <strong>10</strong>,000 hours, fuel savings of up to 30 %can be achieved when compared with equivalentconventional compressors of this output range.This represents up to 20% of total lifetime costs.Your benefit: significant cost savings!Investment (Purchase Price)Fuel costTurboScrewService &Maintenance<strong>10</strong> %15 %55 %20 %TurboScrew fuel savings = 20 % of lifetime cost