Series 45 Axial Piston Open Circuit Pumps Technical Information ...

Series 45 Axial Piston Open Circuit Pumps Technical Information ...

Series 45 Axial Piston Open Circuit Pumps Technical Information ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

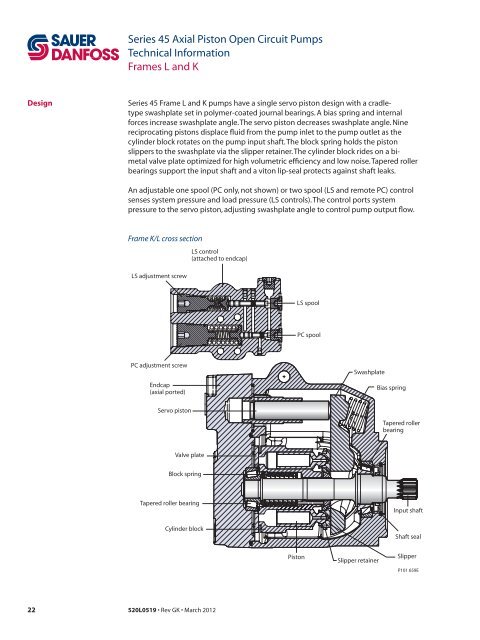

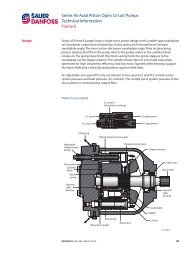

<strong>Series</strong> <strong>45</strong> <strong>Axial</strong> <strong>Piston</strong> <strong>Open</strong> <strong>Circuit</strong> <strong>Pumps</strong><strong>Technical</strong> <strong>Information</strong>Frames L and KDesign<strong>Series</strong> <strong>45</strong> Frame L and K pumps have a single servo piston design with a cradletypeswashplate set in polymer-coated journal bearings. A bias spring and internalforces increase swashplate angle. The servo piston decreases swashplate angle. Ninereciprocating pistons displace fluid from the pump inlet to the pump outlet as thecylinder block rotates on the pump input shaft. The block spring holds the pistonslippers to the swashplate via the slipper retainer. The cylinder block rides on a bimetalvalve plate optimized for high volumetric efficiency and low noise. Tapered rollerbearings support the input shaft and a viton lip-seal protects against shaft leaks.An adjustable one spool (PC only, not shown) or two spool (LS and remote PC) controlsenses system pressure and load pressure (LS controls). The control ports systempressure to the servo piston, adjusting swashplate angle to control pump output flow.Frame K/L cross sectionLS adjustment screwLS control(attached to endcap)LS spoolPC spoolPC adjustment screwEndcap(axial ported)SwashplateBias springServo pistonTapered rollerbearingValve plateBlock springTapered roller bearingCylinder blockInput shaftShaft seal<strong>Piston</strong>Slipper retainerSlipperP101 659E22 520L0519 • Rev GK • March 2012

<strong>Series</strong> <strong>45</strong> <strong>Axial</strong> <strong>Piston</strong> <strong>Open</strong> <strong>Circuit</strong> <strong>Pumps</strong><strong>Technical</strong> <strong>Information</strong>Frames L and K<strong>Technical</strong> Specifications L Frame K FrameFor general operatingparameters, including fluidviscosity, temperature, andinlet and case pressures,see page 13. For systemdesign parameters,including installation,filtration, reservoir, and linevelocities, see page 15.For definitions of pressureand speed ratings,see page 14. For moreinformation on externalshaft loads, see page 16;mounting flange loads,see page 17.Unit L25C L30D K38C K<strong>45</strong>DMaximum Displacement cm³ [in³] 25 [1.53] 30 [1.83] 38 [2.32] <strong>45</strong> [2.75]Working InputSpeedMinimumWorkingMaximumPressureFlow at rated speed (theoretical)Input torque at maximumdisplacement (theoretical)at 49° C [120°F]Mass moment of inertia ofinternal rotating componentsWeight<strong>Axial</strong> portsExternal ShaftLoadsBearing Life(1800 rpm, noexternal shaftloading)Mounting flangeload moments500 500 500 500Continuous min -1 (rpm) 3200 3200 2650 2650Maximum 3600 3600 2800 2800bar [psi]l/min[US gal/min]N•m/bar[lbf•in/1000 psi]kg•m²[slug•ft²]260 [3770] 210 [30<strong>45</strong>] 260 [3770] 210 [30<strong>45</strong>]80[21]0.398[243]0.00169[0.00125]96[25.4]0.477[291]0.00161[0.00119]100.7[26.6]0.605[369]0.00184[0.00135]119.3[31.5]0.716[438]0.00203[0.00150]19 [42]kg [lb]Radial ports 24 [53]External N•m [lbf•in] 61 [540] 61 [540] 76 [673] 76 [673]moment (M e)Thrust in (T in),out (T out)at 140 bar[2030 psi]at 210 bar[30<strong>45</strong> psi]at 260 bar[3770 psi]Vibratory(continuous)Shock(maximum)N [lbf ] 1000 [225] 1000 [225] 1200 [270] 1200 [270B 10hoursN•m [lbf•in]49100 24600 35300 1960014100 7230 11 400 62006590 — 5870 —1005 [8895]3550 [31420]Order codeR S P C D E F G H J K L M NCode descriptionCodeRSPCDEFGHJKLMNProduct Frame, Variable <strong>Open</strong> <strong>Circuit</strong> PumpRotationDisplacementControl TypePressure Compensator SettingLoad Sense SettingNot UsedChoke OrificeGain OrificeInput Shaft/Auxiliary Mount/EndcapDescriptionShaft Seal/Front Mounting Flange/Housing PortsDisplacement LimiterSpecial HardwareSpecial Features520L0519 • Rev GK • March 201223

<strong>Series</strong> <strong>45</strong> <strong>Axial</strong> <strong>Piston</strong> <strong>Open</strong> <strong>Circuit</strong> <strong>Pumps</strong><strong>Technical</strong> <strong>Information</strong>Frames L and KOrder code (continued)R S P C D E F G H J K L M NR Frame L Frame K Frame025C 030D 038C 0<strong>45</strong>DKR K Frame, variable displacement open circuit pump • •LR L Frame, variable displacement open circuit pump • •S RotationL Left Hand (counterclockwise) • • • •R Right Hand (clockwise) • • • •P Displacement025C 025 cm³/rev [1.53 in³/rev] •030D 030 cm³/rev [1.83 in³/rev] •038C 038 cm³/rev [2.32 in³/rev] •0<strong>45</strong>D 0<strong>45</strong> cm³/rev [2.75 in³/rev] •L Frame K FrameC Control type025C 030D 038C 0<strong>45</strong>CPC Pressure Compensator • • • •LB Load Sensing/Pressure Comp. with internal bleed orifice • • • •LS Load Sensing/Pressure Comp. • • • •RP Remote Pressure Compensator • • • •EB Electric on/off, 12VDC, Normally Closed, Deutsch • • • •EA Electric on/off, 12VDC, Normally <strong>Open</strong>, Deutsch • • • •D PC setting (2 digit code, 10 bar increments)Example 25 = 250 bar (3625 psi)10–21 100 to 210 bar [1<strong>45</strong>0 to 30<strong>45</strong> psi] • • • •22-26 220 to 260 bar [3190 to 3771 psi] • • • •ELoad sensing setting (2 digit code, 1 bar increments)Example 20 = 20 bar (290 psi)12–36 12 to 36 bar [174 to 522 psi] • • • •NN Not applicable (pressure compensated only controls) • • • •F Not usedNN Not applicable • • • •G Pilot/Choke OrificeN None (standard) • • • •H Gain Orifice3 1.0 mm diameter • • • •24 520L0519 • Rev GK • March 2012

<strong>Series</strong> <strong>45</strong> <strong>Axial</strong> <strong>Piston</strong> <strong>Open</strong> <strong>Circuit</strong> <strong>Pumps</strong><strong>Technical</strong> <strong>Information</strong>Frames L and KOrder code (continued)R S P C D E F G H J K L M NJ Input ShaftC213 tooth, 16/32 pitchC315 tooth, 16/32 pitchK10.875 inch straight keyedK20.875 inch straight keyed (long)T11.0 inch TaperAuxiliary Mount/Endcap StyleAuxiliary Description Endcap Style Inlet Porting Outlet Porting Endcap Description CodeNone <strong>Axial</strong> O-Ring Boss O-Ring Boss Inlet - SAE O-Ring boss port (1.875 inch threads)Outlet - SAE O-Ring boss port (1.3125 inch threads)Control - Left SideNone <strong>Axial</strong> Split Flange Split Flange Inlet - Code 61 Split Flange Port 4 Bolt (1.25 inch port 0.4375 inch threads)Outlet - Code 61 Split Flange Port 4 Bolt (1 inch port 0.375 inch threads)Control - Left SideNone <strong>Axial</strong> Split Flange Split Flange Inlet - Code 61 Split Flange Port 4 Bolt (1.25 inch port M10 threads)Outlet - Code 61 Split Flange Port 4 Bolt (1 inch port M10 threads)Control - Left SideNone Radial O-Ring Boss O-Ring Boss Inlet - SAE O-Ring boss port (1.875 inch threads)Outlet - SAE O-Ring boss port (1.3125 inch threads)Control - Right SideNone Radial Split Flange Split Flange Inlet - Code 61 Split Flange Port 4 Bolt (1.5 inch port 0.5 inch threads)Outlet - Code 61 Split Flange Port 4 Bolt (1 inch port 0.375 inch threads)Control - Right SideNone Radial Split Flange Split Flange Inlet - Code 61 Split Flange Port 4 Bolt (1.5 inch port M12 threads)Outlet - Code 61 Split Flange Port 4 Bolt (1 inch port M12 threads)Control - Right SideRunning Cover Radial O-Ring Boss O-Ring Boss Inlet - SAE O-Ring boss port (1.875 inch threads)Outlet - SAE O-Ring boss port (1.3125 inch threads)Control - Right SideRunning Cover Radial Split Flange Split Flange Inlet - Code 61 Split Flange Port 4 Bolt (1.5 inch port 0.5 inch threads)Outlet - Code 61 Split Flange Port 4 Bolt (1 inch port 0.375 inch threads)Control - Right SideSAE-A, 11 teeth Radial O-Ring Boss O-Ring Boss Inlet - SAE O-Ring boss port (1.875 inch threads)Outlet - SAE O-Ring boss port (1.3125 inch threads)Control - Right SideSAE-A, 9 teeth Radial O-Ring Boss O-Ring Boss Inlet - SAE O-Ring boss port (1.875 inch threads)Outlet - SAE O-Ring boss port (1.3125 inch threads)Control - Right SideSAE-A, 9 teeth Radial Split Flange Split Flange Inlet - Code 61 Split Flange Port 4 Bolt (1.5 inch port 0.5 inch threads)Outlet - Code 61 Split Flange Port 4 Bolt (1 inch port 0.375 inch threads)Control - Right SideSAE-B, 13 teeth Radial O-Ring Boss O-Ring Boss Inlet - SAE O-Ring boss port (1.875 inch threads)Outlet - SAE O-Ring boss port (1.3125 inch threads)Control - Right SideSAE-B, 13 teeth Radial Split Flange Split Flange Inlet - Code 61 Split Flange Port 4 Bolt (1.5 inch port 0.5 inch threads)Outlet - Code 61 Split Flange Port 4 Bolt (1 inch port 0.375 inch threads)Control - Right SideSAE-B, 13 teeth Radial Split Flange Split Flange Inlet - Code 61 Split Flange Port 4 Bolt (1.5 inch port M12 threads)Outlet - Code 61 Split Flange Port 4 Bolt (1 inch port M12 threads)Control - Right SideSAE-BB, 15 teeth Radial O-Ring Boss O-Ring Boss Inlet - SAE O-Ring boss port (1.875 inch threads)Outlet - SAE O-Ring boss port (1.3125 inch threads)Control - Right SideSAE-BB, 15 teeth Radial Split Flange Split Flange Inlet - Code 61 Split Flange Port 4 Bolt (1.5 inch port 0.5 inch threads)Outlet - Code 61 Split Flange Port 4 Bolt (1 inch port 0.375 inch threads)Control - Right SideNFNMNPNGNKNRRGRKTGAGAKBGBKBRVGVK520L0519 • Rev GK • March 201225

<strong>Series</strong> <strong>45</strong> <strong>Axial</strong> <strong>Piston</strong> <strong>Open</strong> <strong>Circuit</strong> <strong>Pumps</strong><strong>Technical</strong> <strong>Information</strong>Frames L and KOrder code (continued)R S P C D E F G H J K L M NJInput Shaft/Auxiliary Mount/EndcapAvailable CombinationsL FrameK Frame025C 030D 038C 0<strong>45</strong>DC2AG* • • • •C2BG* • • • •C2NF* • • • •C2NG** • • • •C2NK** • •C2NM** • •C2NP** • •C2NR* • •C2RG* • • • •C2TG* • • • •C3AG* • • • •C3AK** • •C3BG* • • • •C3NF* • • • •C3NG** • • • •C3NK** • •C3RG* • • • •L FrameK Frame025C 030D 038C 0<strong>45</strong>DC3TG* • • • •C3VG* • •K1AG* • •K1NF* • • • •K1NG** • • • •K1RG* • •K2AG* • • • •K2BG* • • • •K2NF* • • • •K2NG** • • • •K2NM** • •K2RG* • • • •T1BG* • •T1NF* • • • •T1NG** • • • •T1RG* • • • •* PLB or AAA Displacement limiter options only ** KNB Displacement limiter options onlyL FrameK FrameK Shaft seal025C 030D 038C 0<strong>45</strong>DA Single (Viton) • • • •K Mounting flange and housing port style6 SAE-B Flange 2-bolt/SAE O-ring boss ports • • • •K Not usedN Not applicable • • • •L Displacement limiterAAA Adjustable, factory set at max angle • • • •KNB None • • • •PLB None (plugged) • • • •M Special hardwareNNN None • • • •N Special featuresNNN None • • • •26 520L0519 • Rev GK • March 2012

<strong>Series</strong> <strong>45</strong> <strong>Axial</strong> <strong>Piston</strong> <strong>Open</strong> <strong>Circuit</strong> <strong>Pumps</strong><strong>Technical</strong> <strong>Information</strong>Frames L and KPerformance L25CFlow and power data valid at 49°C [120°F] and viscosity of 17.8 mm²/sec [88 SUS].Flow vs. speedInput power vs. speedFlow (l/min)100806040202420161284Flow (US gal/min)Power (kW)5040302010260 bar [3770 psi]210 bar [30<strong>45</strong> psi]140 bar [2030 psi]605040302010Power (hp)00 500 1000 1500 2000 2500 3000 3500-1Speed min (rpm)0P101 970E00 500 1000 1500 2000 2500 3000 3500-1Speed min (rpm)0P101 971EEfficiencyEfficiency (%)System Pressure: 260 Bar -Inlet Pressure: 1.0 Bar abs -Inlet Temperature: 49C10095Volumetric Efficiency908580Overall Efficiency7570656055500 500 1000 1500 2000 2500 3000Input Speed (rpm)P108 408ENoise (DBA)Noise8075706560Inlet Pressure: 1.0 Bar abs -Inlet Temperature: 60CGeneral Operating Range260 bar - No Flow140 bar - Full Flow55500 500 1000 1500 2000 2500 3000Input Speed (rpm)P108 409EThe chart on the rightshows allowable inletpressure and speed atvarious displacements.Greater speeds and lowerinlet pressures are possibleat reduced displacement.Operating outside ofacceptable limits reducespump life.Inlet pressure vs. speedInlet Pressure (bar abs)1.61.51.41.31.21.11.00.90.80.7100% 90% 80%0.62800 3000 3200 3400 3600 3800 4000-1Shaft Speed min (rpm)86420369(psi gauge)(in Hg vac)P101 972E520L0519 • Rev GK • March 201227

<strong>Series</strong> <strong>45</strong> <strong>Axial</strong> <strong>Piston</strong> <strong>Open</strong> <strong>Circuit</strong> <strong>Pumps</strong><strong>Technical</strong> <strong>Information</strong>Frames L and KPerformance L30DFlow and power data valid at 49°C [120°F] and viscosity of 17.8 mm²/sec [88 SUS].Flow vs. speedInput power vs. speedFlow (l/min)100806040202420161284Flow (US gal/min)Power (kW)5040302010210 bar [30<strong>45</strong> psi]140 bar [2030 psi]605040302010Power (hp)00 500 1000 1500 2000 2500 3000-1Speed min (rpm)0P101 973E000 500 1000 1500 2000 2500 3000-1Speed min (rpm)P101 974EEfficiencyEfficiency (%)System Pressure: 210 Bar - Inlet Pressure: 1.0 Bar abs -Inlet Temperature: 49C100Volumetric Efficiency95908580Overall Efficiency7570656055500 500 1000 1500 2000 2500 3000Input Speed (rpm)P108 410ENoise210 bar [30<strong>45</strong> psi]dB(A)1800 min -1 (rpm) Rated SpeedL30D 66 70The chart on the rightshows allowable inletpressure and speed atvarious displacements.Greater speeds and lowerinlet pressures are possibleat reduced displacement.Operating outside ofacceptable limits reducespump life.Inlet pressure vs. speedInlet Pressure (bar abs)1.61.51.41.31.21.11.00.90.80.7100% 90% 80%0.62800 3000 3200 3400 3600 3800 4000-1Shaft Speed min (rpm)86420369(psi gauge)(in Hg vac)P101 972E28 520L0519 • Rev GK • March 2012

<strong>Series</strong> <strong>45</strong> <strong>Axial</strong> <strong>Piston</strong> <strong>Open</strong> <strong>Circuit</strong> <strong>Pumps</strong><strong>Technical</strong> <strong>Information</strong>Frames L and KPerformance K38CFlow and power data valid at 49°C [120°F] and viscosity of 17.8 mm²/sec [88 SUS].Flow vs. speedInput power vs. speedFlow (l/min)12510075502500 500 1000 1500 2000 2500-1Speed min (rpm)302520151050P101 975EFlow (US gal/min)Power (kW)605040302010260 bar [3770 psi]140 bar [2030 psi]00 500 1000 1500 2000 2500-1Speed min (rpm)80706050403020100P101 976EPower (hp)EfficiencyEfficiency (%)System Pressure: 260 Bar -Inlet Pressure: 1.0 Bar abs -Inlet Temperature: 49C10095Volumetric Efficiency908580Overall Efficiency7570656055500 500 1000 1500 2000 2500 3000Input Speed (rpm)P108 411ENoise (DBA)Noise8075706560Inlet Pressure: 1.0 Bar abs -Inlet Temperature: 60C55500 500 1000 1500 2000 2500 3000Input Speed (rpm)P108 412EGeneral Operating Range140 bar - Full Flow260 bar - No FlowThe chart on the rightshows allowable inletpressure and speed atvarious displacements.Greater speeds and lowerinlet pressures are possibleat reduced displacement.Operating outside ofacceptable limits reducespump life.Inlet pressure vs. speedInlet Pressure (bar abs)1.61.51.41.31.21.11.00.90.80.7100% 90% 80%0.62200 2400 2600 2800 3000-1Shaft Speed min (rpm)86420369(psi gauge)(in Hg vac)P101 977E520L0519 • Rev GK • March 201229

<strong>Series</strong> <strong>45</strong> <strong>Axial</strong> <strong>Piston</strong> <strong>Open</strong> <strong>Circuit</strong> <strong>Pumps</strong><strong>Technical</strong> <strong>Information</strong>Frames L and KPerformance K<strong>45</strong>DFlow and power data valid at 49°C [120°F] and viscosity of 17.8 mm²/sec [88 SUS].Flow vs. speedInput power vs. speedFlow (l/min)140120100806040203530252015105Flow (US gal/min)Power (kW)605040302010210 bar [30<strong>45</strong> psi]140 bar [2030 psi]8070605040302010Power (hp)00 500 1000 1500 2000 2500-1Speed min (rpm)0P101 978E00 500 1000 1500 2000 2500-1Speed min (rpm)0P101 979EEfficiencyNoiseEfficiency (%)System Pressure: 210 Bar -Inlet Pressure: 1.0 Bar abs -Inlet Temperature: 49C10095Volumetric Efficiency908580Overall Efficiency7570656055500 500 1000 1500 2000 2500 3000Input Speed (rpm)P108 413ENoise (DBA)807570656055Inlet Pressure: 1.0 Bar abs - Inlet Temperature: 60CGeneral Operating Range210 bar - No Flow140 bar - Full Flow500 500 1000 1500 2000 2500 3000Input Speed (rpm)P108 414EThe chart on the rightshows allowable inletpressure and speed atvarious displacements.Greater speeds and lowerinlet pressures are possibleat reduced displacement.Operating outside ofacceptable limits reducespump life.Inlet pressure vs. speedInlet Pressure (bar abs)1.61.51.41.31.21.11.00.90.80.7100% 90% 80%0.62200 2400 2600 2800 3000-1Shaft Speed min (rpm)86420369(psi gauge)(in Hg vac)P101 977E30 520L0519 • Rev GK • March 2012

<strong>Series</strong> <strong>45</strong> <strong>Axial</strong> <strong>Piston</strong> <strong>Open</strong> <strong>Circuit</strong> <strong>Pumps</strong><strong>Technical</strong> <strong>Information</strong>Frames L and KHydrauilic ControlsPressure Compensated ControlsSchematicResponse/Recovery Times(ms) Response RecoveryL25C 30 90L30D 30 100K38C 30 105K<strong>45</strong>D 30 110M2BPC Setting RangeModel bar psiL25C 100–260 1<strong>45</strong>0–3770L30D 100–210 1<strong>45</strong>0–30<strong>45</strong>K38C 100–260 1<strong>45</strong>0–3770K<strong>45</strong>D 100–210 1<strong>45</strong>0–30<strong>45</strong>L2S L1 P101 980LegendB = OutletS = InletL1, L2 = Case drainM2 = System pressure gauge portRemote Pressure Compensated ControlsResponse/Recovery Times(ms) Response RecoveryL25C 30 90L30D 30 100K38C 30 105K<strong>45</strong>D 30 110SchematicBXPC Setting RangeModel bar psiL25C 100–260 1<strong>45</strong>0–3770L30D 100–210 1<strong>45</strong>0–30<strong>45</strong>K38C 100–260 1<strong>45</strong>0–3770K<strong>45</strong>D 100–210 1<strong>45</strong>0–30<strong>45</strong>M2L2SL1P101 981LegendB = OutletS = InletL1, L2 = Case drainM2 = System pressure gauge portX = Remote PC port520L0519 • Rev GK • March 201231

<strong>Series</strong> <strong>45</strong> <strong>Axial</strong> <strong>Piston</strong> <strong>Open</strong> <strong>Circuit</strong> <strong>Pumps</strong><strong>Technical</strong> <strong>Information</strong>Frames L and KHydraulic Controls(continued)Load Sensing/Pressure CompensatedControlsSchematicXResponse/Recovery Times(ms) Response RecoveryL25C 30 70L30D 30 70K38C 30 80K<strong>45</strong>D 30 80M2BPC Setting RangeModel bar psiL25C 100–260 1<strong>45</strong>0–3770L30D 100–210 1<strong>45</strong>0–30<strong>45</strong>K38C 100–260 1<strong>45</strong>0–3770K<strong>45</strong>D 100–210 1<strong>45</strong>0–30<strong>45</strong>LS setting rangeModel bar psiAll 12-40 174-580L2S L1 P101 982LegendB = OutletS = InletL1, L2 = Case drainM2 = System pressure gauge portX = LS signal portLoad Sensing Control with Bleed Orifice/Pressure CompensatedLB SchematicXResponse/Recovery Times(ms) Response RecoveryL25C 30 70L30D 30 70K38C 30 80K<strong>45</strong>D 30 80M2BPC Setting RangeModel bar psiL25C 100–260 1<strong>45</strong>0–3770L30D 100–210 1<strong>45</strong>0–30<strong>45</strong>K38C 100–260 1<strong>45</strong>0–3770K<strong>45</strong>D 100–210 1<strong>45</strong>0–30<strong>45</strong>LS setting rangeModel bar psiAll 12-40 174-580L2SL1 P101 983LegendB = OutletS = InletL1, L2 = Case drainM2 = System pressure gauge portX = LS signal port32 520L0519 • Rev GK • March 2012

<strong>Series</strong> <strong>45</strong> <strong>Axial</strong> <strong>Piston</strong> <strong>Open</strong> <strong>Circuit</strong> <strong>Pumps</strong><strong>Technical</strong> <strong>Information</strong>Frames L and KElectric ControlsConnectorsDescription Quantity Ordering NumberMating Connector 1 Deutsch® DT06-2SWedge Lock 1 Deutsch® W25Socket Contact (16 and 18 AWG) 2 Deutsch® 0462-201-16141Sauer-Danfoss mating connector kit 1 K296571 2P003 480Continuous Duty Operating Range120Percent of Rated Voltage (%)11010090807060Operating Range50-40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90 100Ambient Temperature (°C)P108 415ENormally Closed On/Off Electric PressureCompensated ControlsSchematicXResponse/recovery times*(ms) Response RecoveryL25C 30 90L30D 30 100K38C 30 105K<strong>45</strong>D 30 110M2BPC control setting rangeModel bar psiL25C,K38CL30D,K<strong>45</strong>D100-240 bar [1<strong>45</strong>0-3480 psi]100-210 bar [1<strong>45</strong>0-30<strong>45</strong> psi]LS setting rangeModel bar psiAll 12-40 174-580L2SLegendB = OutletS = InletL1, L2 = Case drainM2 = System pressure gauge portL1P106 04<strong>45</strong>20L0519 • Rev GK • March 201233

<strong>Series</strong> <strong>45</strong> <strong>Axial</strong> <strong>Piston</strong> <strong>Open</strong> <strong>Circuit</strong> <strong>Pumps</strong><strong>Technical</strong> <strong>Information</strong>Frames L and KElectric Controls(continued)Normally <strong>Open</strong> On/Off Electric PressureCompensated ControlsSchematicXResponse/recovery times*(ms) Response RecoveryL25C 30 90L30D 30 100K38C 30 105K<strong>45</strong>D 30 110M2BPC control setting rangeModel bar psiL25C,K38CL30D,K<strong>45</strong>D100-260 bar 1<strong>45</strong>0-3370100-210 bar 1<strong>45</strong>0-30<strong>45</strong>LS setting rangeModel bar psiAll 12-40 174-580L2SLegendB = OutletS = InletL1, L2 = Case drainM2 = System pressure gauge portL1P106 04934 520L0519 • Rev GK • March 2012

<strong>Series</strong> <strong>45</strong> <strong>Axial</strong> <strong>Piston</strong> <strong>Open</strong> <strong>Circuit</strong> <strong>Pumps</strong><strong>Technical</strong> <strong>Information</strong>Frames L and KInput shaftsCodeC2Description13 tooth spline16/32 pitch(ANSI A92.1 1970 - Class 5)Maximum torque rating¹N•m [lbf•in]288 [2546]DrawingØ18.82[0.74] MAXØ21.72 ± 0.09[0.855 ±0.004]13 TOOTH16/32 PITCH30° PRESSURE ANGLE20.638 [0.813] PITCH DIAFILLET ROOT SIDE FITCOMPATIBLE WITH ANSI B92.1-1970CLASS 5 ALSO MATES WITHFLAT ROOT SIDE FIT8 ± 0.475[0.31 ±0.02]15.2 ±0.5[0.6 ±0.02]COUPLING MUST NOTPROTRUDE BEYONDTHIS POINT33[1.3]P101 993EC315 tooth spline16/32 pitch(ANSI A92.1 1970 - Class 5)404 [3575]15 TOOTH16/32 PITCH30° PRESSURE ANGLE23.813 [0.938] PITCH DIAFILLET ROOT SIDE FITCLASS 5 ALSO MATES WITHFLAT ROOT SIDE FITØ21.92MAX [0.863]Ø25.27 ± 0.12[0.995 ±0.005]8± 0.475[0.31 ±0.02]COUPLING MUST NOTPROTRUDE BEYONDTHIS POINT23.35 ± 0.5[0.92 ±0.02]38[1.5]P101 994ET1Ø 25.4 mm [1 in]1:8 taper (SAE J501)362 [3200]25. 4[1 ]69.89 REF[2.75]26.97[1.06]6.299 +0.025-0.000[0.248 +0.001 -0.000 ]-0.00022.225 +0.254[0.875 +0.000-0.010 ]WOODRUFF KE YØ22.22 GA UGE[0.87]3/4-16UNF-2A THD8 ± 0.8[0.31 ±0.03]34.92± 0.63[1.375 ±0.025]125 TAPER PER METERCOMPATIBLE WITH SAE J50125.4 [1] NOMINAL SHAFT DIAMETER9.42 ± 0.3[0.37 ±0.01]GA UGEC OUPLING MUST NO TPR OT RUDE BEY ONDTHIS POINTP101 996E1. See Input shaft torque ratings, page 18 for an explanation of maximum torque.520L0519 • Rev GK • March 201235

<strong>Series</strong> <strong>45</strong> <strong>Axial</strong> <strong>Piston</strong> <strong>Open</strong> <strong>Circuit</strong> <strong>Pumps</strong><strong>Technical</strong> <strong>Information</strong>Frames L and Kinput shafts(continued)CodeK1DescriptionØ 22.23 mm [0.875 in]33 mm [1.3 in]Maximum torque rating¹N•m [lbf•in]305 [2700]Drawing6.35 [0.25]x 12.7 [0.50] LONGSQUARE KEY24.89 +0-0.25[0.98 +0-0.01 ]Ø22.2 ±0.025[0.874 ±0.001]8± 0.8[0.31 ±0.03]K2Ø 22.23 mm [0.875 in]63 mm [2.48 in] long305 [2700]COUPLING MUST NOTPROTRUDE BEYONDTHIS POINT33 [1.3]P101 997E6.35 [0.25]x 38.1 [1.5] L ONGSQU ARE KE Y24.89 +0-0.25[0.98 +0-0.01 ]Ø22.2 ±0.025[0.874 ±0.001]8 ± 0.3[0.315 ±0.035]CO UPLING MUST NO TPR OT RUDE BEY ONDTHIS POINT63[2.48]P101 998E1. See Input shaft torque ratings, page 18 for an explanation of maximum torque.36 520L0519 • Rev GK • March 2012

<strong>Series</strong> <strong>45</strong> <strong>Axial</strong> <strong>Piston</strong> <strong>Open</strong> <strong>Circuit</strong> <strong>Pumps</strong><strong>Technical</strong> <strong>Information</strong>Frames L and KInstallation drawings<strong>Axial</strong> Ported EndcapØ25.4[1]OUTLETSYSTEM PORT ‘B’3<strong>45</strong> BAR [5000] PSI]SPLIT FLANGE BOSSPER ISO 6162SAE J518CODE 61with 3/8 - 16 UNCX 20 [0.787] MIN THDØ31.8[1.25]INLETSYSTEM PORT ‘S’276 BAR [4000] PSI]SPLIT FLANGE BOSSPER ISO 6162SAE J518CODE 61with 7/16 - 14 UNCX 17 [0.669] MIN THDSERVO PRESSUREGAGE PORTISO 11926-1SAE J1926/13/4-1652.37[2.062]58.72[2.312]26.19[1.031]33[1.30]Split Flange Ports30.18[1.188]33[1.30]SYSTEMPORT B(OUTLET)ISO 11926-1 ISO 11926-1SAE J1926/1SAE J1926/11 5/16-121 7/8-1233[1.3]O-Ring Boss Ports33[1.3]SYSTEMPORT S(INLET)P108 416E<strong>Axial</strong> Ported Endcap Installation Dimensions182.4[7.18]181.9[7.16]99[3.9]6.7[0.26]SYSTEM PRESSUREGAGE PORT M2ISO 11926-1SAE J1926/19/16-18orM14x1.5-6HLS SIGNALPORT XISO 11926-1SAE J1926/17/16-20155.2[6.11]134.3[5.29]62[2.44]70.4[2.77]37[1.46]M2223.2[8.79]167.7[6.6]105.8[4.16]80[3.15]67.7[2.67]67.7[2.67]15[0.59]CASE DRAINPORT L1ISO 11926-1SAE J1926/17/8-14R1 MAX[0.04]CASE DRAINPORT L2SPOTFACE DEPTHCASE DRAINPORT L1SPOTFACE DEPTHØ 101.57 ± 0.025[3.999 ± 0.001]APPROXIMATECENTER OFGRAVITY32[1.26]Ø14.3[0.563]2X97.4[3.83]CW146[5.75]CCW73[2.87]121.9[4.8]132[5.2]APPROXIMATECENTER OFGRAVITY25.8[1.02]Third-angleprojectionmm [in]172.6[6.8]SYSTEM PORTS S & BSPOTFACE DEPTH175.1[6.89]9.4[0.37]80[3.15]CASE DRAINPORT L2ISO 11926-1SAE J1926/17/8-14P106170E520L0519 • Rev GK • March 201237

<strong>Series</strong> <strong>45</strong> <strong>Axial</strong> <strong>Piston</strong> <strong>Open</strong> <strong>Circuit</strong> <strong>Pumps</strong><strong>Technical</strong> <strong>Information</strong>Frames L and KInstallation drawings(continued)Radial Ported Endcap Split Flange PortsØ25.4[1]OUTLETSYSTEM PORT ‘B’3<strong>45</strong> BAR [5000] PSI]SPLIT FLANGE BOSSPER ISO 6162SAE J518CODE 61with 3/8 - 16 UNCX 20 [0.787] MIN THDØ38.1[1.5]INLETSYSTEM PORT ‘S’207 BAR [3000] PSI]SPLIT FLANGE BOSSPER ISO 6162SAE J518CODE 61with 1/2 - 13 UNCX 27 [1.063] MIN THD52.37[2.062]69.92[2.753]166[6.54]29.19[1.031]35.85[1.411] 166[6.54]P106 171E80[3.15]Radial Ported Endcap O-ring Boss PortsCASE DRAINPORT L1ISO 11926-1SAE J1926/17/8 -14R1 MAX[0.04]37[1.46]134.3[5.29]146[5.75]112.8[4.44]APPROXIMATECENTER OFGRAVITY155.2[6.11]62[2.44]BSYSTEM PORT B(OUTLET)ISO 11926-1SAE J1926/11 5/16 -12166[6.54]9.4[0.37]Ø101.57 ± 0.025[3.999 ± 0.001]32[1.26]80[3.15]166[6.54]20.7[0.81]SYSTEMPORT S(INLET)ISO 11926-1SAE J1926/11 7/8 -12CASE DRAINPORT L2ISO 11926-1SAE J1926/17/8 -14P108 418ERadial Ported Endcap Rear View95[3.74]95[3.74]95[3.74]95[3.74]SYSTEMPORT SINLETSYSTEMPORT BOUTLETSYSTEMPORT BOUTLETSYSTEMPORT SINLETThird-angleprojectionmm [in]94.5[3.72]SYSTEM PORT SSPOTFACE DEPTH94.5[3.72]SYSTEM PORT BSPOTFACE DEPTHRight Hand Rotation (CW)94.5[3.72]SYSTEM PORT BSPOTFACE DEPTH94.5[3.72]SYSTEM PORT SSPOTFACE DEPTHLeft Hand Rotation (CCW)P108 419E38 520L0519 • Rev GK • March 2012

<strong>Series</strong> <strong>45</strong> <strong>Axial</strong> <strong>Piston</strong> <strong>Open</strong> <strong>Circuit</strong> <strong>Pumps</strong><strong>Technical</strong> <strong>Information</strong>Frames L and KInstallation drawings(continued)207.9[8.19]Radiall Ported Endcap Installation Dimensions90.5[3.56]67.7[2.67]99[3.9]LS SIGNAL PORT XSPOTFACE DEPTH4.4[0.17]CASE DRAINPORT L2SPOTFACE DEPTH132[5.2]119.4[4.5]LS STANDBYPRESSUREADJUSTMENTPCPRESSUREADJUSTMENTSYSTEM PRESSUREGAGE PORT M2ISO 11926-1SAE J1926/19/16 -18207[8.15]15[0.59]80[3.15]67.7[2.67]CASE DRAINPORT L1SPOTFACE DEPTHCASE DRAINPORT L1ISO 11926-1SAE J1926/17/8 -14R1 MAX[0.04]Ø14.3[0.563]2X134.3[5.29]CW73[2.87]146[5.75]146[5.75]112.8[4.44]CCWAPPROXIMATECENTER OFGRAVITYAPPROXIMATECENTER OFGRAVITY155.2[6.11]62[2.44]BSYSTEM PORT B(OUTLET)ISO 11926-1SAE J1926/11 5/16 -12166[6.54]37[1.46]9.4[0.37]Ø101.57 ± 0.025[3.999 ± 0.001]32[1.26]80[3.15]166[6.54]P108 420E20.7[0.81]SYSTEMPORT S(INLET)ISO 11926-1SAE J1926/11 7/8 -12CASE DRAINPORT L2ISO 11926-1SAE J1926/17/8 -14Front Mounting Flange - SAE-B two bolt99[3.9]6.7[0.26]APPROXIMATECENTER OFGRAVITY121.9[4.8]132[5.2]CWCCWØ14.3[0.563]2X146[5.75]73[2.87]Third-angleprojectionmm [in]P108 421E520L0519 • Rev GK • March 201239

<strong>Series</strong> <strong>45</strong> <strong>Axial</strong> <strong>Piston</strong> <strong>Open</strong> <strong>Circuit</strong> <strong>Pumps</strong><strong>Technical</strong> <strong>Information</strong>Frames L and KInstallation drawings(continued)SAE-A auxiliary mounting pad8.8[0.35] Min.PER SAE J744228.53[8.997]MOUNTIN GFLANGE3/8-16UNC-2BTHD17.8 [0.70] MI NTHD DEPTHR 0.51 MA X[0.020]Ø88.62[3.49]Ø82. 6 +0.08 -0[3.252 +0.003 -0 ]106.4[4.19]53.2 [2.09]O-RING SEAL REQUIREDREF 82.22 [3.237] I.D.X2.62 [0.103] CROSS SECTIONP/N 50003731.95[0.08]8.1 ± 0.7[0.319 ±0.028]59.65[2.35]MIN SHAF TCLEARANC ESpecificationsCoupling 9-tooth 11-toothP101999ESpline minimum 12.6 mm [0.50 in] 13.5 mm [0.53 in]engagementMaximum torque 107 N•m [950 lbf•in] 147 N•m [1300 lbf•in]C OUPLING-SAE A:SPLINE:11 TO OT H16/32 PIT CH30° PRESSURE ANGLE17.463 [0.6875] PIT CH DI AFILLET RO OT SIDE FITPER SAE B92.1-1970, CLASS 6C OUPLING-SAE A:SPLINE:9T OO TH16/32 PIT CH30 ° PRESSURE ANGL E14.288 [0.5625] PIT CH DI AFILLET RO OT SIDE FITPER ANSI B92.1-1970, CLASS 6SAE-B auxiliary mounting pad8.8[0.35]Min.PER SAE J744224.15[8.82]MOUNTIN GFLANGE1/2-13UNC-2BTHD19.7 [0.76] MI NTHD DEPTHR2 MA X[0.08]Ø105.64[4.159]Ø101.65 +0.08 -0[4.002 +0.003 -0 ]146[5.75]73[2.87]O-RING SEAL REQUIREDREF 101.32 [3.989] I.D .X1.78 [0.070] CROSS SECTIO NP/N 726935MIN SHAF TCLEARANC E55.27[2.18]SpecificationsCoupling 13-tooth 15-tooth1. 3[0.05]11 ± 0.13[0.43±0.01]Spline minimum 13.2 mm [0.52 in] 16.1 mm [0.63 in]engagementMaximum torque 171 N•m [1512 lbf•in] 171 N•m [1512 lbf•in]C OUPLING-SAE BSPLINE:13 TO OT H16/32 PIT CH30° PRESSURE ANGLE20.638 [0.8125] PIT CH DI AFILLET RO OT SIDE FITPER ANSI B92.1-1970 CLASS 6C OUPLING-SAE B-BSPLINE:15 TO OT H16/32 PIT CH30 ° PRESSURE ANGL E23.813 [0.9375] PIT CH DI AFILLET RO OT SIDE FITPER ANSI B92.1-1970 CLASS 6P104000E40 520L0519 • Rev GK • March 2012

<strong>Series</strong> <strong>45</strong> <strong>Axial</strong> <strong>Piston</strong> <strong>Open</strong> <strong>Circuit</strong> <strong>Pumps</strong><strong>Technical</strong> <strong>Information</strong>Frames L and KInstallation drawings(continued)Auxiliary Mounting Pad - Running Cover212.7[8.37]P106 077E122.8[4.83]Electric Solenoid, Left Side101.1[3.98]6.3[0.25]Deutsch type(2) pin connectorThird-angleprojectionmm [in]144.5[5.69]167.8[6.61]9.5[0.37] 16.9[0.67]4.7[0.18]P108 425EElectric Solenoid, Right Side16.9[0.67]9.5[0.37]Deutsch type(2) pin connector191.1[7.52]212.8[8.38]144.5[5.69]167.8[6.61]6.3[0.25]4.7[0.18]P108 426E520L0519 • Rev GK • March 201241

<strong>Series</strong> <strong>45</strong> <strong>Axial</strong> <strong>Piston</strong> <strong>Open</strong> <strong>Circuit</strong> <strong>Pumps</strong><strong>Technical</strong> <strong>Information</strong>Frames L and KDisplacement limiterL and K Frame open circuit pumps areavailable with an optional adjustabledisplacement limiter. This adjustablestop limits the pump’s maximumdisplacement.Setting rangeL25C 0 to 25 cm³ [0 to 1.53 in³]L30DK38C0 to 30 cm³ [0 to 1.83 in³]0 to 38 cm³ [0 to 2.32 in³]Cross-SectionK<strong>45</strong>D 0 to <strong>45</strong> cm³ [0 to 2.75 in³] P104 084Displacement per turnL25C 1.20 cm³/rev [0.07 in³/rev]L30DK38CK<strong>45</strong>D1.43 cm³/rev [0.09 in³/rev]1.81 cm³/rev [0.11 in³/rev]2.15 cm³/rev [0.13 in³/rev]Installation Dimensions222[8.74]83.3[3.28]P104 065E42 520L0519 • Rev GK • March 2012