Chapter 4: Activated Sludge Modelling - IqTMA-UVa

Chapter 4: Activated Sludge Modelling - IqTMA-UVa

Chapter 4: Activated Sludge Modelling - IqTMA-UVa

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

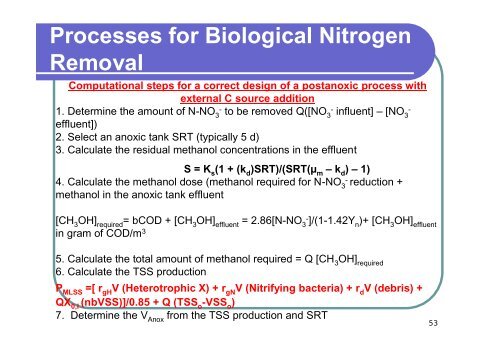

Processes for Biological NitrogenRemovalComputational steps for a correct design of a postanoxic process withexternal C source addition1. Determine the amount of N-NO 3-to be removed Q([NO 3-influent] – [NO 3-effluent])2. Select an anoxic tank SRT (typically 5 d)3. Calculate the residual methanol concentrations in the effluentS = K s(1 + (k d)SRT)/(SRT(µ m– k d) – 1)4. Calculate the methanol dose (methanol required for N-NO 3-reduction +methanol in the anoxic tank effluent[CH 3OH] required= bCOD + [CH 3OH] effluent= 2.86[N-NO 3-]/(1-1.42Y n)+ [CH 3OH] effluentin gram of COD/m 35. Calculate the total amount of methanol required = Q [CH 3OH] required6. Calculate the TSS productionP MLSS=[ r gHV (Heterotrophic X) + r gNV (Nitrifying bacteria) + r dV (debris) +QX 0,I(nbVSS)]/0.85 + Q (TSS o-VSS o)7. Determine the V Anoxfrom the TSS production and SRT53