Building a sustainable enterprise - Chambal Fertilisers - Home

Building a sustainable enterprise - Chambal Fertilisers - Home

Building a sustainable enterprise - Chambal Fertilisers - Home

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong><strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>Sustainability is about celebrating diversity; having compassion for all sentientbeings; accepting that all life forms are inter-connected and inter-dependent on eachother as strands in a web and believing that, the welfare of one is fundamentallydependent on the welfare of all.Equally, sustainability is about preserving and enriching Mother Nature; sharingresources; being concerned about the well-being of future generations; and believingthat, there’s enough on this planet for one’s need rather than for one’s greed.At <strong>Chambal</strong>, we are committed to building a <strong>sustainable</strong> <strong>enterprise</strong> for thebenefit of our present and future generation of stakeholders. We have integrated<strong>sustainable</strong> practices into our business strategies and operations.Our first Corporate Sustainability Report looks at the progress made by us intackling the three biggest challenges on our <strong>sustainable</strong> journey – economicprosperity, social development and justice, and environmental integrity.7

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>Our objective is to builda <strong>sustainable</strong> <strong>enterprise</strong>that effectively balancesfinancial strengths withsocial and environmentalresponsibilities.“Treat the Earth well.We do not inherit the Earth from our ancestors;we borrow it from our children.”Native American saying9

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>We are committedto enhancing theenvironmental profileof <strong>Chambal</strong> by investing ineco-friendly technologiesand practices across thebusiness value chain.“The world is one large, integrated familywith a common fate, where every one impactseveryone else.”Source unknown11

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>We are empoweringemployees and developingtheir knowledge and skillsets, so that they realisetheir true potential anddrive <strong>Chambal</strong>’s growth.“Sustainable development is a dynamic processwhich enables all people to realize theirpotential, and to improve their quality of life, inways which simultaneously protect and enhanceEarth’s life support systems.”Source unknown13

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong><strong>Chambal</strong> is a caste,gender and religionneutral organisation,committed to creatinginclusive growth andequal opportunity.“The closer we get to a virtuous circle, in whichour work, our home life, our ethics and ourspirituality are mutually reinforcing, the closerwe will be to achieving genuine sustainability.”James Wilson15

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>We are building lastingsocial capital throughinterventions in theinfrastructure, healthcare and eductiondomains.“The frog does not drinkup the pond in which he lives.”Native American proverb17

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong><strong>Chambal</strong> is committedto deliver <strong>sustainable</strong>top-line and bottom-linegrowth while maintainingthe highest corporategovernance standards.“Someone is sitting in the shade today becausesomeone planted a tree a long time ago.”Source unknown19

About the Report<strong>Chambal</strong> <strong>Fertilisers</strong> and ChemicalsLimited (“<strong>Chambal</strong>”) worksclosely with the farmers and ruralcommunities towards realising itsvision of a <strong>sustainable</strong> world. Thiscommunication is part of a broaderdisclosure process, which includes<strong>Chambal</strong>’s Annual Report and otherpublications.Purpose and Audience ofReportingThis report is our maiden attemptat reviewing our performance acrossthe triple bottom-line i.e. Economic,Environment and Social parameters.Through this report, we wish tocommunicate with our stakeholdersabout our <strong>sustainable</strong> developmentpolicies, practices and performance.Defining the Report ContentThis report covers topics andindicators that have significantEconomic, Environmental andSocial impacts. The report has beenprepared in accordance with theGlobal Reporting Initiative (GRI)Sustainability Reporting (2006) –GRI G3 Guidelines.Indicator Selection andApplication levelAs per GRI G3 guidelines, thereare 79 performance indicatorsfrom which we have selected keyindicators pertaining to our industryto prepare this report. The reporthas been prepared as per the BApplication level.Boundary, Scope and DataCollectionThe report boundary coversour two Urea plants at Gadepan,District Kota, Rajasthan (India)unless otherwise stated. The financialdata reported is for <strong>Chambal</strong><strong>Fertilisers</strong> and Chemicals Limitedfor the period April 1, 2009 toMarch 31, 2010. The environmentaland social data pertains to AgriBusiness only. Being the first year ofreporting, most of the performanceindicators have been presentedfor three years - FY 2007-08, FY2008-09 and FY 2009-10 in orderto show trends, wherever possible.In a few instances, informationhas been included for the year inwhich a policy or action plan wasimplemented. Since this is our firstreport, we have included significantawards and recognitions that wereceived in the last five years. Theperformance data does not includedata from residential township atGadepan (Kota) and informationrelated to traded products, unlessotherwise explicitly stated. However,township case studies have beenincluded at a few places. All financialfigures in the report are in IndianRupees, unless otherwise indicated.This report was made possiblethrough the collaborative efforts ofour various departments: Finance,Legal & Secretarial, Environment,Utilities, Technical, Stores, HumanResources, CSR and CorporateCommunications.DisclaimerThe terms “<strong>Chambal</strong>”, “theCompany”, “CFCL”, “theorganisation”, “we”, “us”, refers to<strong>Chambal</strong> Fertlisers and ChemicalsLimited and is used purely forconvenience sake and is notintended to mislead the reader.AssuranceTo make our initiative credible,we have sought the services ofindependent consultant, Ernstand Young Pvt. Limited to givean assurance on the contentsof the report. Their findings andobservations are noted in theassurance letter attached later inthe report.Any query with respect to thisreport may be addressed to:Corporate Communications<strong>Chambal</strong> <strong>Fertilisers</strong> and Chemicals Ltd.Corporate One, First Floor5 Commercial Centre, JasolaNew Delhi - 110 025Phone: +91 11 46581300 / 41697900Fax: + 91 11 40638679E-mail: corpcomm@chambal.in20

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>Triple Bottom-line StrategySustainability has been and remainsa key watchword of our times.<strong>Chambal</strong> <strong>Fertilisers</strong> and ChemicalsLimited has been at the forefrontof integrating social, economicand environmental parameters, inthe way it conducts its business.The Company understands that‘sustainability’ will determine thelevel of its economic success and thenation’s well-being.Global Sustainability Trends<strong>Chambal</strong> keeps itself abreast withglobal sustainability concerns likeenergy consumption, eco-friendlypackaging, responsible labelingand voluntary programmes likeResponsible Care, IFA guidelines,etc. The Company has alsoimplemented voluntarily codes likeProcess Safety Management (PSM)to ensure high level of safety at itsplants. The Company endeavours tobenchmark itself with the best at theinternational level through initiativesof International Fertilizer Associationand other international bodies.Fertiliser In d u s t ryI. Industry StructureUrea production capacity in Indiahas been stagnant for the last 11years. The present production ofUrea in our country is 21.1 millionMT against the demand of 26.4million MT. This gap is met throughimports. India imported over 5.2million MT of Urea during financialyear 2009 -10. The dependenceon imports of this vital nutrient isincreasing and reaching the levelswhere future food security could bejeopardized. Therefore, there is anurgent need to increase domesticproduction of Urea.II. Developments inGovernment PoliciesThe new Fertiliser Investment Policyfor Urea was notified last year.The main feature of this policy isthe shift from ‘cost plus’ approachto ‘Import Parity Price’ basis forthe new investments i.e. Revamp,Brownfield, Greenfield or RevivalProjects. The policy is predicatedupon the continued availabilityof gas supplies at a fair price. TheGovernment is currently working ona suitable amendment to the policyaccording to which cost of energyabove a level would be borne bythe government. The Governmenthas also notified the operation ofthe Nutrient Based Subsidy (NBS)Scheme for Potassic and Phosphaticfertilisers although Nitrogenousfertilisers have been currently keptout of the purview of the policy.21

Under NBS, the Government fixessubsidies based on nutrient contentin a product rather than a formulabased subsidy linked to a product.The new policy seeks to emphasizethe balanced nutrition of the soilconsistent with rational economicprinciples.Ri s k s a n d Op p o rt u n i t i e sI. OpportunitiesIn view of the supply-demandoutlook for Urea, there is anopportunity for us to expand ourfertiliser business.Our focus has been to supply tothe Indian farmer a bigger basketof products by adding morevarieties of seeds, newer moleculesfor crop protection and othermicronutrients.II. ChallengesThe largely agrarian Indian societyis facing innumerable challenges likevagaries of weather, food security,and crop failure due to naturalcalamities. <strong>Chambal</strong> is committedto hand-hold the farmers throughdifficult times. To maintain highoutput from limited land resources,<strong>Chambal</strong> demonstrates betterways of doing agriculture throughmultiple interventions at thefield level. Ripple effects of theseactivities are discernable as moreand more farmers are adoptingthese practices.<strong>Chambal</strong>’s soil management initiativeis a pioneering move in this regard.Till date, <strong>Chambal</strong> had conductedover 450,000 soil and water sampletests at its Agriculture DevelopmentLaboratories at Sriganganagar andAgra. Based on the condition andnature of the soil, the agro-climaticzone, available irrigation methodsand infrastructure, we advise thefarmers on the correct use ofmacro and micro nutrient inputs;crop rotation and good agriculturalpractices. The Company also set-upsmodel farms for demonstrationon latest agri-practices and cropdiversification.Sustainability Pa r a m e t e r sI. Economic Performance2008-09 saw the world in the gripof one of the worst economic crisesin the last 50 years. In India, theGovernment cushions the farmerfrom international price fluctuationsby subsidizing fertiliser, therefore,the economic downturn did notsignificantly impact the sector.<strong>Chambal</strong> <strong>Fertilisers</strong> has done wellduring 2009-10 despite delayedand sub-normal monsoon duringKharif 2009. The Company’s ProfitBefore Tax increased by 13% overthat of 2008-09. The Company soldover 2 million MT of Urea duringthe year, marginally higher thanprevious year. <strong>Chambal</strong> notched uprecord pesticide and micronutrientsales amounting to Rs. 227 crore, agrowth of 28.60% over the previousyear. There has been a strong focuson the supply of quality tradedproducts over last 2-3 years whichis reflected in the increased sales ofpesticides, seeds and micronutrients.II. Environmental Protection,Health and SafetyThe Company believes in <strong>sustainable</strong>development of society in which itoperates. Accordingly, it has takenvarious initiatives and implementedenvironment protectionprogrammes such as ground waterrecharging through rainwaterharvesting, energy conservationmeasures, use of solar energy, etc.(a) Environment Management<strong>Chambal</strong> has established andmaintained an IntegratedManagement System basedon OHSAS-18001:2007, ISO-14001:2004 and ISO-9001:2000 forEnvironmental, Occupational Health& Safety and Quality. Details of ourefforts in improving environment arebriefly given below:(i) Green belt – The areasurrounding our Gadepan complexis experiencing a positive changein ecology due to development ofa dense green belt/forest inclusiveof about 2.3 lac trees in an areaof about 213 hectares under the“Operation Green” programme.Planting of new trees is a continuousprocess at Gadepan complex. TheGreen belt provides habitat to morethan 100 species of birds.(ii) Natural Resources – Waterand gas are the two key naturalresources we use for production ofUrea. From the beginning, water hasbeen invaluable for us by virtue ofour location in a water-scarce statewhere its source is non-perennial.22

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>To overcome this challenge wehave been working tirelessly forthe last ten years to reduce ourwater consumption per Urea tonneas well as implementing rainwaterharvesting. We are also committednot to use ground water for ouroperations. Waste water is beingused in maintaining the greenbelt through a 65 kilometer longirrigation network spread all overthe Gadepan complex, which, inturn, helps in saving fresh water. Weconstructed a check dam in 2003-04 and plan to construct anotherone in 2010-11 for rainwaterharvesting. As a result of ourcontinuous efforts, our 2 units atGadepan are amongst the lowestwater consuming plants in theindustry. The trend of consumptionshows a continual improvement.During the year, the specificconsumption of water was 5.05cubic meter per MT of Urea.The Company strives to make itsplants as energy efficient as possibleand continually reviews variousschemes to conserve energy. Theinternational oil prices have a directbearing on the gas prices due to aclose correlation between the oiland the gas prices. We have a basketof sources from which natural gas issupplied to our plants at Gadepan.(iii) Waste Management – TheCompany is managing and operatingwell-designed programmes/treatment facilities to controlpollution. The Company continuesto follow the 3R concept – Reduce,Re-use and Re-cycle the effluentsbeing generated.The Company has adopted bestmethods to manage Solid/HazardousWaste disposal after propercategorization. Separate bins areprovided for collection of variouscategories of waste. Horticulturewaste is converted into manure.(b) Safety Management<strong>Chambal</strong> believes in buildingand maintaining excellent safetyculture among its employees andcontractor workforce. The aim isto prevent/ minimize all incidentsand injuries, investigate all incidentsincluding first aid injuries and nearmisses followed by implementationof ‘Corrective and Preventiveactions’. We ensure that all jobsare adequately supervised, usingnecessary ‘Personnel ProtectiveEquipment’ and strictly followingsafety precautions. We regularlyconduct safety reviews and auditsto create a proactive and learningorganisation.Fertiliser plants in India are classifiedas hazardous by the Governmentof India since they carry the risk ofspillage/leakages of chemicals likeNaphtha, Chlorine and Ammonia.Our commitment to ‘Zeroaccidents’ on account of spills ofany hazardous material confirmsthat Safety is an area of paramountimportance to us. Over the years,we have been able to practicallyeliminate usage of naphtha exceptin emergency situations. Wecontinuously review and upgradeour technologies and other safetymeasures to control accidental spillsand Ammonia leakages.The Company implemented theProcess Safety Management (PSM)system developed by AmericanInstitute of Chemical Engineers(AICHE), USA in its operations.Unlike USA, PSM system isnot mandatory in India but theCompany has adopted it to focuson excellence through continualimprovement of existing systemsand employee involvement in safeoperation of plants.(c) Health & HygieneThe Company accords high priorityto hygiene monitoring at theworkplace. It carries out employees’health assessment throughperiodical medical examinations.The plant and processes arecontinuously upgraded to improveworkplace hygiene and healthstandards. We impart necessarytraining to the employees and otherworkers to enhance their awarenesstowards health related matters.Comprehensive Work EnvironmentMonitoring is carried out in-houseas well as through external agencieson a regular basis to prevent anyoccupational disease.(d) Quality ManagementAdequate attention is accorded tomaintain quality of end product andprocesses. Stringent monitoringof defined parameters is done and23

improvement opportunities areavailed for continual improvement.Apart from periodic internal audits,external audits are carried out byreputed agencies like DNV andNational Safety Council of India.The gaps identified in the audits arerectified through an action plan.III. Corporate SocialResponsibility (CSR)<strong>Chambal</strong> is committed towardsthe development of areas in thevicinity of the plants at Gadepan. TheCompany’s CSR programme “UttamRoshani” has been designed toachieve <strong>sustainable</strong> economic, socialand environmental development. Theprogramme covers infrastructuredevelopment, health and hygiene,education, livelihood generation,women empowerment, agricultureand animal husbandry, etc. TheCompany also plans to build toiletsfor Below Poverty Line (BPL)households and supply drinkingwater under the Public PrivatePartnership (PPP) model afternecessary approvals from the localadministration.The Company operates a mobileHealth Care Unit in 14 surroundingvillages. A team of doctors andvolunteers provide free medicalcheck-up and medicines to peopleat their doorstep. In addition,the Medical Centre in Gadepancampus provides free service tosick people from surroundingareas. Ambulance facilities arealso provided to them round theclock for taking serious patientsto Kota in time of emergency. Thepatients can also avail the servicesof visiting specialists for treatment.Camps for various ailments relatedto eye, gynecology, respiratoryand skin diseases, family planning,blood donation, immunization andfree health check ups are regularlyorganized.To provide quality education tochildren of our employees as wellas from nearby villages, we haveestablished a school inside ourcampus at Gadepan which is beingupgraded from 8th standard to 10thstandard. Currently, there are 285students in the school, out of which109 are from nearby villages. TheCompany provides free mid-daymeal to all children.IV. Human ResourcesExperienced manpower is a keyasset and <strong>Chambal</strong> firmly believein nurturing this all importantresource. The Company is an equalopportunity employer, committedto include human resourcesfrom diverse social, economic,cultural, educational and regionalbackgrounds, thus embracinginclusivity and diversity.The opportunities and challengesthat sustainability presents arenot going to diminish and it iscritical that the Company has a‘Comprehensive SustainabilityStrategy’ in place. We believethat our maiden sustainabilityreport would help us assessthe sustainability metrics andestablish the baseline sustainabilityperformance for our agribusiness. Itwill help us in flagging-up any issuesor barriers of our SustainabilityManagement Systems. This reportwill also put us firmly on the roadwhere we will be able to articulatelong-term sustainability targets.24

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>Business Footprint• Overview• Performance at a Glance• Business Bandwidth• Market Presence• Brands and Products• Awards and Recognitions• Economic Footprint25

Business Footprint“I believe that industry must always act in public interest. We, inbusiness and industry, owe a commitment to the people to protect,preserve and improve the environment in which we operate.”Late Dr. K. K. Birla, Founder-Chairman,<strong>Chambal</strong> <strong>Fertilisers</strong> and Chemicals LimitedOverview<strong>Chambal</strong> <strong>Fertilisers</strong> and ChemicalsLimited was promoted by ZuariIndustries Limited (a part of theK. K. Birla Group) in 1985. Today,we are one of the largest privatesector fertiliser producers in India.Our two hi-tech nitrogenousfertiliser (Urea) plants are locatedat Gadepan in Kota district ofRajasthan (India). Built at a priceof over INR 25 billion, the twoplants produce more than 2million tonnes of Urea per annum.The first plant was commissionedin 1993 and second in 1999.These plants use state-of-the-arttechnology from Denmark, Italy,United States and Japan.Shareholder Category% HoldingPromoters 53.23Financial Institutions, Banks & Mutual Funds 11.18NRIs, Foreign Nationals, Overseas Corporate Bodies(OCBs), Foreign Institutional Investors (FIIs)12.32Indian Public 23.27Total 100.00Table 1: Shareholder Category<strong>Chambal</strong> is a diversifiedconglomerate and operates in thefollowing segments:• <strong>Fertilisers</strong> & other Agri-inputs• Shipping• TextilesThe equity shares of the Companyare listed at the National StockExchange of India Ltd. and theBombay Stock Exchange Ltd. Ourshareholding pattern as on 31stMarch 2010 is given in Table 1.26

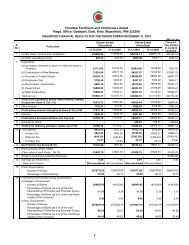

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>Performance at a GlanceWe have achieved many milestones and set performance benchmarks for ourselves in FY 2009-10.ProductionSales 1Record sales of Urea, Ammonia, Pesticides and Micro-nutrientsin Financial Year 2009-10Traded ItemsPerformance SnapshotFY 2007-08 FY 2008-09 FY 2009-10 UnitUrea 2.00 1.92 2.031 Million MTUrea 2.01 1.98 2.014 Million MTDi - ammonium Phosphate 22361 220973 141647 MTMuriate of Potash 33249 45356 86498 MTSingle Super Phosphate 51293 26875 697 MTPesticides 944 1269 1625 Million INRMicro-nutrients 202 406 423 Million INRSeeds 284 403 298 Million INRProfit Before Tax (PBT) 2681 3181 3588 Million INRProfit After Tax (PAT) 2038 2306 2491 Million INREmployees 832 860 853 NumberEnergy 4536524 4398353 4407733 GcalSpecific Energy ConsumptionGadepan I 5.621 5.676 5.640 Gcal/MT UreaGadepan II 5.551 5.565 5.432 Gcal/MT UreaGHG Emissions 1094314.14 1096975.795 1032994.534 MT CO 2Water Discharge 1382868 1334005 1307807 m 3Air EmissionsUrea Dust 725.02 757.73 751.33 MTAmmonia 460.66 438.46 502.38 MTNO x377.41 383.05 399.47 MTTable 2: Performance at a glance1Ammonia Sales for the FY 2007-08, 2008-09 and 2009-10 was 0.0014 Million MT, 0.005 Million MT and 0.014 Million MT respectively27

Market presence in about 20,000 village outlets, in 10 statesBusinesses BandwidthOur Agri Business comprisesmanufactured Urea and tradingof other fertilisers and agri-inputssuch as micro-nutrients, seeds,pesticides, etc. Over the years, wehave consolidated our position inagri-business and diversified intoother sectors. India Steamship -our shipping division owns andoperates six Aframax tankerswith a combined capacity ofover 600,000 DWT. Birla TextileMills – our textiles division, islocated at Baddi in Solan districtof Himachal Pradesh, India. TheTextile Mill has a state-of-theartcotton and synthetic yarnspinningunit, with a capacity ofover 83,000 spindles.Considering the likely growthin Urea consumption inIndia in the years to comeand existing demand-supplygap, increasing the installedcapacity is an urgent businessimperative for <strong>Chambal</strong>. Wewill decide on our expansionplans once there is clarity onthe policy framework andcommitment of gas supply.In addition, we have otherbusiness interests through oursubsidiaries. We also have ajoint venture in Morocco formanufacturing phosphoric acid.Market Presence<strong>Chambal</strong> caters to the needs offarmers in ten states in north,central and western India througha vast marketing networkcomprising 11 regional offices,about 1300 dealers and 20,000village level outlets.The Company operates in thefollowing states:• Bihar• Chattisgarh• Gujarat• Haryana• Jammu & Kashmir• Madhya Pradesh• Punjab• Rajasthan• Uttar Pradesh• Uttarakhand28

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>Promoting transformative change in Indian agriculturethrough multi-disciplinary solutionsBrands and ProductsThe key driver of <strong>Chambal</strong>’s agribusinessis a vision to provideintegrated crop solutions toIndian farmers. At the forefront ofthis vision is our flagship UttamBandhan programme, which isone of the largest technologybasedinterventions by a privatesector fertiliser company, whichis ensuring revitalisation andreclamation of cultivable landin rural India. <strong>Chambal</strong> suppliesproducts for each stage of thecrop cycle and provides serviceswhich help promote <strong>sustainable</strong>agriculture. The Companyprovides, through its dealers, Ureaand other agri-inputs like DAP(Di-Ammonium Phosphate), MOP(Muriate of Potash), SSP (SingleSuper Phosphate), pesticides,seeds and other micro nutrients.Most of these products aresourced from reputed suppliersand sold under the ‘Uttam’umbrella brand. Today, theCompany has attained a leadershipposition in the pesticide businessin North India.29

Awards and RecognitionsWe believe in continued self-assessment and thus regularly participate in different national and internationalbenchmarking initiatives and award programmes. Our contribution to the industry, the environment and thesociety has been recognised over the years. Some of the awards and recognitions received by the Companyin the last five years are as follows:30

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>Economic FootprintThe global economy recoveredpartially in financial year 2009-10after the economic slowdownwitnessed in the previousyears. India and other emergingeconomies led the revival ingrowth momentum. Against a 7.5%GDP growth rate 2 recorded in thesecond quarter of 2008-09, Indiaregistered a 7.9% GDP growthin the corresponding quarterin 2009-10. The recovery of themarkets saw the internationalprices of oil increase to the rangeof 75-85 USD per barrel, aftera steep drop in the first quarterof the fiscal year 2009-10. Sincenatural gas prices are stronglycorrelated to oil prices, our costof production also fluctuates.Increasing oil prices have led toan increase in the price of regasifiedLNG, which constitutesa considerable proportion of ournatural gas sources. To cushion usfrom such extreme fluctuations,we have requested theGovernment of India to replace apart of our RLNG quantum withgas from the KG-D6 basin.The highly regulated policyenvironment for the fertilisersector has resulted in stagnationof Urea production in the country,with only a marginal increase incapacity since 1999. Increasingimports and rising prices of inputmaterials led to higher subsidyoutgo for the Government andzero incentives for manufacturesto develop new products andexpand capacity. Recognisingthe long term detrimentalimpacts of such a trend on thefood security of the nation, theGovernment promulgated newfertiliser policies, which are beingintroduced in a phased manner.The latest on the policy frontis the Nutrient Based Subsidy(NBS) for phosphatic and potassicfertilizers, where the prices willbe fixed on the basis of specificnutrients rather than the finalproduct. Though nitrogenousfertilisers are currently outsidethe purview of this policy, we areclosely tracking developments onthe policy front.We are committed to creatinglong-term incremental value for allour stakeholders. The Companyperformed satisfactorily in FY2009-10, which saw higher Ureaproduction at 2.031 million MTas against 1.918 million MT in2008-09. FY 2009-10 also sawsales jump to 2.014 million MTas against 1.976 million MT in theprevious year. The satisfactoryperformance was a directconsequence of better capacityutilization and de-bottlenecking/ restructuring undertaken inGadepan I and II plants.2007-2008Million INR2008-2009Million INR2009-2010Million INREconomic Value Generated (EVG) 28264.70 47245.86 36457.08Economic Value Distributed (EVD)Operating Costs 23900.00 41829.45 30954.28Employee benefits and wages 724.59 906.00 986.07Payment to providers of capital 1699.64 2072.42 1701.21Payment to government (Indian) 770.11 1002.70 1228.95Community Investments 8.84 6.18 18.20Economic Value Retained 1161.51 1429.13 1568.37Table 3: Economic contribution at a glance2Economic Survey of India 2009-1031

We achieved record pesticideand micro-nutrient salesamounting to INR 1797.7million and INR 471.6 millionrespectively during 2009-10. OurProfit Before Tax (PBT) and ProfitAfter Tax (PAT) increased by12.8% and 8.02% respectively ascompared to 2008-09. EBIDTAincreased to INR 5451.7 millionin 2009-10 from INR 4667.9million in 2008-09.The decrease in EconomicValue Generated in 2009-10 ascompared to the previous yearwas mainly due to decrease inturnover of DAP and MOP.The Company provided adividend of INR 1.90 per equityshare in the reporting year asagainst INR 1.80 per equity sharein 2008-09. The total dividendoutgo increased from INR 876.5million (including dividend tax)in 2008-09 to INR 922.1 million(including dividend tax) in 2009-10. However, the aggregatepayment to providers of capitaldecreased mainly due to decreasein financial expenses. The decreasein our total subsidy income toINR 16323.96 million in 2009-10 from INR 25393.48 million in2008-09 can be attributed mainlyto decline in the subsidy on DAPand MOP.32

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>Accountability Framework• Governance Committees• Investor Services• Code of Conduct and Ethics• Associations33

Accountability Framework<strong>Chambal</strong> is guided by the beliefthat businesses play an importantrole in nation building. In orderto gain stakeholders’ trust andconfidence for long-term businesssuccess, values and principlesneed to be embedded in theDNA of the organisation. Ourcore strength of producingand marketing plant nutrientsmakes us a key contributor forachieving the goal of national foodsecurity. This entrusts greaterresponsibility on our shouldersto conduct our business as perhigh standards of ethics andgovernance. The recent failuresin corporate governance, theeconomic slowdown and spotlighton excessive CEO paymentshave reinforced the belief thatcorporate governance is notonly about checks and balances;but also about imbibing a cultureof excellence and duty towardscustomers, shareholders, societyand unwavering commitment to<strong>sustainable</strong> development. TheBoard of Directors strives tocreate an environment, which isconscience driven, accountableand ensures that the managementand employees act with integrityand responsibility. As thehighest decision making bodyof the organisation, the BoardNon-Executive ChairmanBoard of DirectorsCo-ChairmanVice-ChairmanIndependent Directorsrelentlessly pursues long-termcorporate values and sets thestrategic framework for growth.As on 31 March 2010, the Boardcomprised 10 Directors, includingone Managing Director and nineNon- Executive Directors, ofwhich five were IndependentDirectors.Mr. S K PoddarMr. S S BhartiaMr. H S BawaMr. C S NopanyMr. R N BansalMr. D BasuMr. K N MemaniMs. Radha SinghMr. Marco Ph. A. WadiaExecutive Managing Director Mr. Anil KapoorTable 4: Constitution of Board of Directors34

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>Governance CommitteesThe Board of Directors reviews the performance of the Company from time to time. There are sevencommittees of the Board of Directors, which have been delegated specific powers and responsibilities.Senior officials of the Company help the Directors in the discharge and implementation of their duties. TheCompany pays only sitting fees to the Non-Executive Directors for attending the meetings of the Board andits committees.1. Audit Committee: TheCommittee deals with all mattersprovided in clause 49 of theListing Agreement and section292A of the Companies Act, 1956.Additionally, the Committee’sterms of reference includes:• Approve the internal auditprogramme.• Review with the statutoryauditors their findings,observations, suggestions,internal control systems, scopeof audit, other related mattersand major accounting policiesfollowed by the Company.• Review the contracts enteredinto by the Company valuingmore than INR 75 million andthe contracts entered intowith the parties included inthe register maintained underSection 301 of the CompaniesAct, 1956, if any.• Review internal audit reportsrelated to internal controlweaknesses.2. Investor GrievanceCommittee: The Committeehas the responsibility to approvematters relating to allotmentof securities; issue of duplicatecertificates; review and redressinvestor grievances; decide ondates of book closure/recorddates, etc.3. Remuneration Committee:The Committee recommendsappointment of ManagingDirector(s)/Whole TimeDirector(s). It also reviews andapproves remuneration includingthe compensation package,annual increment, incentives,additional perquisites, etc. of theManaging Director(s)/Whole TimeDirector(s) and Senior Executivesof the Company.4. Banking and FinanceCommittee: Approves varioustypes of borrowings includingworking capital facilities, loans,etc., and other matters specificallydelegated by the Board from timeto time.5. Project MonitoringCommittee: The Committeewas formed to review progress ofrevamp projects and to approvecontracts of a certain value.6. Quarterly Results ReviewCommittee: The Committeewas formed to deal with all thematters pertaining to approval ofthe unaudited quarterly results ofthe Company.7. Compensation Committee:The Committee was formedto formulate EmployeesStock Option Scheme and itsadministration.Investor ServicesAs on 31 March 2010, we had abase of 207,308 shareholders. Toprovide prompt service to theinvestors through quick redressof investor grievances, we have anin-house investor service centre.The motto of ‘high investorsatisfaction’ is being pursuedthrough proactive actions likereaching out to investors regularly,35

timely reminder to investorsabout unclaimed corporatebenefits, etc. We also have aCode of Internal Procedures andConduct for Trading in Securitiesof the Company. This code, interalia, prohibits purchase and saleof shares of the Company by itsDirectors, Officers, designatedacts as a guidance document forsuggestive behavior in dealingwith the Company, fellowdirectors, employees and theexternal operating environment.The purpose of this code ofconduct is to promote conductof business in an efficient andtransparent manner and to meetcompliance, conflict of interest,bribery and corruption, safety,environment and health, financialand operational integrity etc.The code 3 is available at www.chambalfertilisers.in/Code_of_Conduct.pdfemployees and their dependentswhile in possession of unpublishedprice sensitive information relatingto the Company.Code of Conduct and EthicsIn order to maintain thehighest standards of ethics andgovernance while conductingof our business and dealings,we have adopted a ‘Code ofConduct and Ethics’. The Codeits obligations to shareholdersand all other stakeholders. Thiscode of conduct is also a tool incarrying out the Company’s socialresponsibility in a more effectivemanner. It is applicable to Boardof Directors and members ofcore management team includingmembers of management onelevel below executive directorsand all functional heads. The Codecovers issues like regulatoryAssociationsWe are actively involved indebates and discussions relating topublic policies. We are members ofvarious industry associations andsafety councils both in India andabroad. We regularly participatein various industry forums, shareinsights and present viewpointson issues related to business,environment, society, etc.3For additional information regarding the governance of the Company, please refer to our Annual Report and website - www.chambalfertilisers.in/Investors.asp36

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>Encouraging Inclusive Decision-making• Engaging with Stakeholders37

Encouraging Inclusive Decision-makingEngaging with StakeholdersWe believe that stakeholderengagement is central tosustainability. It enables us tothink broadly about issues andtheir impacts and also helps usin formulating mutually beneficialstrategies. Open and honestcommunication through a varietyof traditional and innovative wayswith our stakeholders providesus with valuable insights regardingemerging trends, business risksand opportunities. It also helpsus in clearly defining our businessgoals, which are critical tomaintaining our competitive edge.We encourage our stakeholdersto continuously engage in dialoguewith us so that we can maximizethe value we create for them.The stakeholders important tous are regulators / government,employees, investors, customers,auditors, suppliers / vendors,local communities, industryassociations, civil society, mediaand academia. We engage withthem regularly and keep theminformed about our activities. Theway we engage with each of thesestakeholder groups, depends onthe nature of our relationshipwith them. The key stakeholdersand main discussion issues arelisted in the diagram below andengagement methods with variousstakeholders are covered inrelevant sections of this report.Government of India andRegulators: Due to the nature ofour business, we regularly interactwith three ministries of theGovernment of India - Ministryof Chemicals and <strong>Fertilisers</strong>,Ministry of Environment andForests and the Ministry ofPetroleum. Our interactionswith these ministries thoughneed based are very regular. Weinteract as and when requiredwith the Ministry of Environmentand Forests regarding issuespertaining to project clearances,etc. The Ministry of Petroleumis a key stakeholder since itis responsible for ensuringuninterrupted supply of ourmost important raw material, i.e.natural gas. The State PollutionControl Board, the FactoriesInspectorate and the RailwayBoard are the key governmentagencies with whom we interactvia formal correspondences suchas circulars and responses, one-tooneformal dialogue, submissionof reports, etc. Statutory andbusiness requirements primarilygovern the mode and frequencyof our interactions with thesestakeholders.Employees: Our employeesare our most importantresource. We conduct monthlyPerformance Analysis meetingswith our senior managementto review performance ofthe Company. PerformanceManagement Systems enables usto interact with our employeeson a half-yearly and annualbasis. Such interactions help usin defining their performanceimprovement plans, careerdevelopment plans and identifytheir training needs. Theirfeedback is also useful forimproving our environmental andsocial performance.Other regular modes ofinteraction with our employeesinclude intranet, SAP portal,employee functions like – cultural38

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>programmes, festival celebrations,quiz shows, sports activities, etc.Our quarterly in-house magazine‘At <strong>Chambal</strong>’ disseminatescompany news, publishesinformation on achievements ofemployees and their families andis a perfect medium to promotecreativity amongst our employees.<strong>Chambal</strong> Infoline, our weeklyemail newsletter provides anoverview of the recent happeningsof our industry. We encouragedepartments to organise annualpicnics for employees and theirfamilies to promote camaraderieand a sense of belonging. Ourinteraction with contractualemployees is focused on trainingson safety issues.Investors and Lenders: Werecognise that investors andlenders are one of the mostimportant stakeholder groupsfor business sustainability.Communicating to them aboutour uncompromising integrity,performance and our futurestrategies helps us to gain theircontinued trust and support.Their feedback also facilitates inrefining our business approachand strategies. We engage withthem via traditional and newcommunication methods. Forinstance, we mail our annualreports and half yearly resultsto them; and regularly appraiseBSE and NSE about importantcorporate developments. Wereceive queries, grievances,feedback from our shareholdersthrough e-mails, letters and phone.We have a dedicated InvestorService Centre, which acts asa direct interface between usand our investors for addressingtheir grievances. The InvestorsGrievance Committee of theBoard monitors the status ofinvestors’ requests, queries,grievances, etc.Suppliers/Vendors: Effectiveengagement with membersof our supply chain is crucialto our business. We conductannual vendor appraisalsand weekly meetings of ourcontract committee for vendordevelopment. We engage with ourcontractors to create a “buy-in”from them on the values andprinciples of the Company. Manyof our contractors and suppliersare associated with us sincebeginning.Customers: We make constantefforts to garner feedbackfrom our customers. It helpsus in providing them with highquality products and innovativesolutions to meet their needs.Our primary and most significantcustomer base is the Indianfarming community. We interactwith them on a regular basisthrough meetings, jeep campaigns,farmer factory visits, SMS service,Hello Uttam phone helpline anda dedicated farmer website. Wecirculate a quarterly newsletter--“<strong>Chambal</strong> Ki Chitthi” in threevernacular languages, whichcontains information on farmingrelated issues. We conductcustomer satisfaction surveysperiodically with our dealers togauge their satisfaction with ourproduct and service delivery.We regularly organise dealermeets and training programmes39

for farmers, retailers and otherchannel partners including plantvisits at Gadepan.Local Communities: We areaware that we derive our licenseto operate from the communitiesin which we function. They arethe key partners in our growth.We believe that establishingparticipatory communicationprocesses with them wouldenable us to give increasedreturn on investments toour shareholders and help uscontribute to development atthe grassroots level. To developa robust corporate socialprogramme management strategy,we conducted community needassessment exercises based ona participatory rural appraisalapproach under Uttam Roshaniprogramme. We are in constantdialogue with reputed NGOsto help us strengthen ourcommunity development plans.For a long span of time, wehave been conducting periodichealthcare camps, animalhusbandry / livestock camps,vocational training and educationprogrammes, in association withour ladies club named ‘UttamMahila Samiti’. Our weekly radioprogramme, ‘Uttam Bandhan TeenSawal’ which disseminates croprelated information is aired on AllIndia Radio (AIR), Kota.Industry Associations: Weare members of various industryforums like Confederation ofIndian Industry (CII), FertiliserAssociation of India (FAI),Rajasthan Chamber of Commerceand Industry and InternationalFertiliser Industry Association(IFA). Our Managing Director wasthe Chairman of the NorthernRegion Committee of FAI in thereporting year and continues tobe a director on the FAI Board.Our Company is represented inthe quarterly board meetings ofFAI and engages in discussionson issues of importance tothe fertiliser industry. Weregularly interact with FICC(Fertilizer Industry CoordinationCommittee) primarily on subsidyrelated issues. We also participatein various forums / eventsconducted by CII, FAI, etc.Civil Society, Media andAcademia: Engaging with thesegroups is a regular process at<strong>Chambal</strong>. We try to address theconcerns of civil society in ourbusiness strategies and practices.We undertake advertisingcampaigns, conduct corporateinterviews and circulate pressreleases as and when required.We disseminate information ona continuous basis through ourdynamic company website. Wefacilitate interaction of farmerswith research institutions,particularly agriculture institutesto enable them to accessinformation.40

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>Conserving Natural Capital• Reducing our Carbon Footprint• Climate Change and Global Food Security• Efficient Management of Resources• Other Air Emissions• Spill Management System• Reducing our Water Footprint• Responsible Effluent Management• Responsible Waste Management• Contributing to Biodiversity Conservation• Enduring Efforts Towards Environmental Conservation41

Conserving Natural CapitalOur long-term economicsustainability is dependentupon our ecosystem and weare determined to reduce ourenvironmental footprint. Wealso realise that environmentalexcellence is a long journey ofincessant efforts and incrementalimprovements; and that, many-atimesdecisions taken to reduceour carbon footprint might notresult in direct, tangible financialbenefits. The Company hasadopted a broad and progressiveattitude towards environmentprotection that looks beyond thefinancial bottom-line. The focuson triple-bottom-line strengthensour resolve to protect theenvironment. We take a holisticapproach to identify all significantimpacts of our operations onthe environment and whereverpossible, implement mitigationmeasures after prioritising them.The environmental controlmeasures have been embeddedin the design of the plants andin the manufacturing process.Raw material, water and energyconsumption and emissionsare material issues for ourorganisation. We have establishedsystems to monitor, analyse, settargets and develop action plansto reduce the same. Additionally,we have successfully maintainedour standards as per ISO14001:2004 certification.Reducing our CarbonFootprintEnergy is central to developmentdue to its widespread utility in allspheres of life. The energy usagealso has serious ramificationson climate change. The fertiliserindustry is one of the energyintensive sectors. Manufacturingof Urea involves substantial usageof energy. Our commitment to<strong>sustainable</strong> development makesus carry out technological andoperational advancements toreduce our energy consumption,utilise waste heat, strive forrenewable energy options anduse energy efficient products,wherever possible. At <strong>Chambal</strong>,we use approximately 5.4 to 5.7MKCal of energy for producingone tonne of Urea. Reductionof energy consumption is ofutmost importance to us. We haveundertaken a major revamp ofour Gadepan-II plant. As a result,we have reduced the energyconsumption from 5.57 MKCal/MT Urea in FY 2008-09 to 5.43MKCal/MT Urea in FY 2009-10.We have implemented manyenergy saving initiatives over thelast three years, as detailed inTable 6.42

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>Gadepan-II was designed touse Natural Gas /Naphtha as afeedstock. Due to non-availabilityof Natural Gas, we had to useNaphtha as feed-stock andfuel since its commissioningin 1999. Naphtha producessubstantial amount of surplusCarbon dioxide, which is ventedinto the atmosphere. With thecommissioning of the LNGterminal at Dahej and KG-D6 gas,we have successfully changed thefeedstock usage at Gadepan-II –from Naphtha to Natural Gas. Weare now operating both our plantswith Natural Gas.The Indian fertilizer industry hasbeen permitted a maximum waterconsumption of 8 cubic metersper tonne of Urea for Gas basedUrea plants, as per the Guidelinesof “Corporate Responsibility forEnvironment Protection” (CREP).<strong>Chambal</strong> has made substantialprogress over the years inreducing water consumption, from5.59 cubic meters/MT of Urea inFY 2000-01 to 5.05 cubic meters/MT Urea in FY 2009-10.We participate in variousbenchmarking surveysconducted for ammonia-Ureamanufacturing facilities at thenational and international levels.In 2006-07, we participatedin International FertilizerAssociation benchmarking surveyrelating to energy efficiency andCO 2emissions. 93 ammoniamanufacturing units locatedin 33 countries participatedin the survey (it also included36 ammonia units from theEurope Fertilizer ManufacturersAssociation). The results of thissurvey are given in Table 5.Bench Marking Parameter Status Gadepan-1 Status Gadepan-2Net Energy efficiency, GJ/MT NH 3(LHV)CO 2Generation, Recovery and Direct Emissions byPlant; Mass Basis, yearly average MT/yrGeneration, Recovery and Direct Emissions by PlantSpecific Basis, yearly average, MT CO 2/MT NH 3CO 2Direct, Indirect, and Net Emissions by Plant;Mass Basis, yearly average, MT/yrCO 2Direct, Indirect, and Net Emissions by Plant;Specific Basis, yearly average, MT CO 2/MT NH 3Table 5 Results of benchmarking study done by IFA1st Quartile,Ranked 19th among 931st Quartile,Ranked 15th among 931st Quartile,Ranked 5th among 931st Quartile,Ranked 18th among 931st Quartile,Ranked 5th among 932nd Quartile,Ranked 25th among 932nd Quartile,Ranked 27th among 932nd Quartile,Ranked 9th among 932nd Quartile,Ranked 34th among 932nd Quartile,Ranked 12th among 9343

Key energy saving initiativesUnitEstimatedEnergy Saving2007-2008Gadepan-ISoftware correction in anti surge control loop to close the antisurge valve of CO 2compressors in Urea-I.Gcal/MTUrea0.018Gadepan-IReplacement of steam vent control valve in SPG (class III toclass IV)Gcal/MTUrea0.0012Installation of VFD at various locationsInstallation of Kellog Reforming Exchanger in Ammonia-I andfurnace modificationInstallation of additional ammonia converter and additionalloop boiler in Ammonia-I2008-2009Installation of vacuum Pre-concentrator (2Nos.) and MP-predecomposer (2Nos.) in Urea-IGcal/MTUrea0.198Use of C-3 off gases as a fuel to Primary Reformer.Change of BFW pre-heaters configuration from series toparallel to reduce pressure drop in front endParallel line from methanator to Synthesis Gas Compressor forreducing pressure dropGadepan-IIProvision of new control valve to save the compression energyin refrigeration compressor in Ammonia-II.Gcal/MTUrea0.0034Gadepan II2009-2010Replacement of tube bundles of steam with finned tubebundles.Installation of additional synthesis gas converter & additionalloop boiler in Ammonia-IIGcal/MTUrea0.169Parallel arrangement of LTS and LTS guard reactorsTable 6: Energy saving initiatives44

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>Natural gas fulfills almost theentire quantum of fuel needfor our manufacturing process.However, we do purchase a smallamount of electricity from thenational grid which constituted0.08% of our total energy (fuel)consumption for the last threeyears. Also, in case of nonavailabilityof gas we use naphthaas fuel; We used 2421.30 MT ofnaphtha (Gadepan-I & II) in thereporting period which is 0.58%percentage of our total energyconsumption. Our direct energyconsumption (i.e. primary energyconsumed as fuel) in 2009-10for Gadepan I and II plants was2.41 million Gcal and 1.98 millionGcal respectively. Direct energyconsumption at our Gadepan-Iplant increased by approximately8% during the reporting perioddue to increase in ammonia/ Ureaproduction and plant stabilizationafter revamp. Gadepan II saw adecrease of approximately 8% inenergy consumption during thefinancial year 2009-10.45

Climate Change and GlobalFood SecurityAccording to the FourthAssessment Report of the IntergovernmentalPanel on ClimateChange (IPCC), direct agriculturalemissions made up 10-12%of total anthropogenic GHG(Greenhouse Gas) emissions in2005. Climate change has emergedas an issue of critical importancewith major implications forlogistics, operations, marketsand stewardship of fertilisercompanies. It is estimated thatfertiliser production is responsiblefor approximately 1.2% of thetotal emission of greenhousegases 4 in the world, consistingof 0.3% of pure CO 2, 0.3% asN 2O and 0.6% as flue gas CO 2.Since the fertiliser industry andthe agriculture sector are interdependent,they are both highlyvulnerable to climate change.Fertiliser companies need to thinkof innovative solutions to counterthe risks and capitalize on theopportunities that climate changepresents for agriculture and foodsecurity. Risks of climate change-erratic precipitation patterns,extreme weather conditions, etc.can adversely affect agriculturalyield. This could severely impactour biggest customer base –the farmers and the country’seconomic sustainability.We are aware that the usephase of our major product,i.e., nitrogenous fertilisersis responsible for significantemissions of the highly potentgreenhouse gas – Nitrous Oxide.It is proven that improvednutrient management practicesmay partially offset increasedemissions 5 .This has the potential to createnew business opportunities46wherein the Company can provideintegrated nutrient managementsolutions to farmers.Under the Energy ConservationAct 2001, Government of Indiahas identified nine highly energyintensive industrial sectorsincluding the fertiliser industry.Within these sectors, based onthe scale of operations, companieshave been notified as DesignatedConsumers. With respect to thefertiliser sector the criteria forbeing Designated Consumer isa minimum energy consumptionof 30000 oil equivalent tonnes/year. <strong>Chambal</strong>, along with 30companies in the fertilisersector has been identified as aprobable Designated Consumer.In order to enhance costeffectivenessof improvementsin energy efficiency in large,energy intensive industries, amarket-based mechanism of4G. Kongshaug Hydro Agri Europe, Norway, Energy Consumption and Greenhouse Gas Emissions in Fertilizer Production5Smith, P., D. Martino, Z. Cai, D. Gwary, H. Janzen, P. Kumar, B. McCarl, S. Ogle, F. O’Mara, C. Rice, B. Scholes and O. Sirotenko (2007) “Agriculture.” In Climate Change 2007:Mitigation. Contribution of Working Group III to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change (B. Metz, O.R. Davidson, P.R. Bosch,R. Dave and L.A. Meyer, eds.). Cambridge University Press, Cambridge, UK, and New York, NY, USA.

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>Perform, Achieve & Trade (PAT) isproposed, under which certificatesof energy savings can be traded.Therefore, climate change is agovernance issue, a regulatoryissue, and a matter of strategicrisk management for us. Giventhe strong management focus onenergy efficiency and optimisticmarket scenario, the feriliserindustry is well poised to benefitfrom the regulatory opportunityposed by the proposed PATscheme.Honouring our commitment forGHG reduction per tonne ofUrea, we decreased our specificCO 2emissions from 0.626 tonne/MT of Urea in 2008-2009 to 0.571tonne/MT of Urea in 2009-10 inGadepan I, and from 0.523 tonne/MT of Urea in 2008-09 to 0.446 inthe reported year in Gadepan II.Efficient Management ofResourcesBesides natural gas (which is ourmain raw material), we consumeprocess chemicals like PolyAlumina Chloride, Sulphuric Acid,Material Unit FY 2007-08 FY 2008-09 FY 2009-10Natural Gas 000’ Sm 3 744920.85 722337.00 805018.94Hydrochloric Acid MT 1289.00 1209.80 1451.36Sulphuric Acid MT 955.00 795.97 851.40Lye MT 584.00 561.53 670.38Poly Alumina Chloride MT 154.00 119.01 102.46Packaging Bags Nos’ 39801493 38646840 40570664Production Unit FY 2007-08 FY 2008-09 FY 2009-10Ammonia Million MT 1.14 1.10 1.18Urea Million MT 2.00 1.92 2.03Table 7: Material consumptionHydrochloric Acid, Lye, catalystsand resins in significant quantities.The conservation of resources isa fundamental economic principlefor us and we strive continuallyto use our materials efficiently.Our specific consumption (pertonne of Urea) of natural gas asfeedstock increased slightly whencompared to FY 2008-09 primarilydue to additional ammoniaproduction during the reportingperiod inspite of reduction inspecific energy consumption.The specific consumption ofassociated process chemicals andUrea bags remained similar ordecreased when compared to FY2008-09.Other Air EmissionsAmmonia, Urea dust, andoxides of Nitrogen are thekey air emissions from ourmanufacturing process. We haveefficient and regularly maintaineddust extraction and prill bucketsystems. A natural draft prilling6Excludes GHG emissions due to venting and flaring during plant upsets / trips and plant process.7Higher absolute CO 2emission is attributed to 12% increase in production in 2009-10, however the specific CO 2emission per ton has substantially reduced.47

FY 2007-08 FY 2008-09 FY 2009-10kg CFC-11 equivalent(ODS emission)40.69 35.37 25.03Table 8: Ozone Depleting Substance (ODS) emissionParameter Unit FY 2007-08 FY 2008-09 FY 2009-10NO xMT 377.41 383.05 399.47Urea Dust MT 725.02 757.73 751.33Ammonia MT 460.66 438.46 502.38Production Unit FY 2007-08 FY 2008-09 FY 2009-10Ammonia Million MT 1.14 1.10 1.18Urea Million MT 2.00 1.92 2.03Table 9: Air emission load (Yearly average values are being reported)tower with extra height andscrubbers installed at appropriateplaces aids in reduction ofemission loads. Since the dustcollected is primarily Urea, it issent to the Urea unit, where itis dissolved in Urea solution andreprocessed. Due to environmentfriendly technology selection,strict control on plant processesand continuous monitoring of airpollution control equipment, ourspecific air emission (MT of airpollutant / MT to Urea produced)has remained the same over theyears.Spill Management SystemWe have well-definedEnvironmental Operation ControlProcedures (OCP). These OCPshave laid down guidelines toprevent and manage spills. Weregularly conduct integrity checksfor the reactors, vessels, flanges,valves, pipelines, etc., for leaks. Inorder to keep a regular check, thedrains are monitored at specifiedintervals and these observationsare recorded and reported tothe management. GV (GeomarcoVetro Coke) and Benfield Solution,Chlorine, Ammonia, Urea, Oil,Freon and Naphtha, are a few ofthe substances for which we havewell defined spill managementsystems in place. During thereporting period, we did not haveany significant spills.48

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>Reducing our WaterFootprintIt has been forecast 7 that by 2030,the demand for water in Indiawould be 1.5 trillion m 3 due toincreased food production for aburgeoning population. As againstthis projected demand, India’scurrent water supply is only 740billion m 3 and a severe shortfall isexpected by 2030. India is locatedin a water scarce region and,factoring in the climate changerepercussions, water securityis one of the most importantenvironmental issues facing thecountry.At <strong>Chambal</strong> we are continuouslymaking efforts to conserve suchan increasingly critical resourceby harvesting, recycling andreusing water. In addition totracking our water use, we haveinstalled water-saving fittingsand equipment, and conductedawareness programs for ouremployees. We carry out wateraudits periodically. In additionto building rainwater harvestingstructures to maintain the groundRain Water HarvestingDue to scarcity of water in our operating area, waterconservation is an important article of faith for us. To mitigatethe problem of water scarcity, we have taken important stepsin water conservation. One such step was the constructionof a Check Dam on the Kalisindh river, with a water holdingcapacity of approximately 7 million m 3 . The benefits of theCheck Dam have been significant.• Improved underground water level in the vicinity;• Improved availability of water for drinking and agriculturalpurposes;• Provided an avenue for pisciculture; and• Become a support for a rapidly growing flora and fauna.Another Check Dam is being envisaged, in consultation withgovernment of Rajasthan on the river Parwan. The CheckDam will have a water hold-up capacity of approximately 3.4million m 3 .Ground Water RechargingIn collaboration with the Department of Hydrology, IndianInstitute of Technology, Roorkee, we are developing rainwaterharvesting systems in our plant premises. 13 potentiallocations where water can be harvested and stored (12 insidethe premises and 1 outside the plant) have been identified.Additionally, we have constructed two recharge wells.7Charting our water future: Economic frameworks to inform decision making49

water table, we use treated wastewater for irrigation purposesfor the green belt around ourplants. <strong>Chambal</strong> practically haszero discharge of waste water.Our main source of raw water isthe monsoon-fed Kalisindh river.To protect us and the nearbycommunities from the vagariesof monsoon, we built a checkdam on the river way back in FY2002-2003. In FY 2009-2010, ourtotal water withdrawal (includingfor the township) from the riverwas 11,011,305 m 3 . Replacementof older drift eliminators by newcellular type drift eliminators inthe cooling towers resulted inreduction of drift water losses.This, coupled with reduction inlosses in the drinking water andfire water networks, has enabledus to reduce our specific waterconsumption 8 (m 3 /ton of Urea)for production of Urea from 5.20in 2008-2009 to 5.05 for thereporting year.8For specific water consumption calculation total water is taken as water used at units Gadepan-I & Gadepan-II (excluding township consumption)50

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>Responsible EffluentManagementUnder the guiding policy of “atsource treatment of effluents andrecycling of treated effluents backinto the process”, we initiated thefollowing recycling processes atthe design stage itself:• Ammonia and Urea processcondensates are treated inammonia and Urea plantsrespectively and recycled intothe process after passing themthrough the demineralisationplant.• Turbine condensate is alsorecycled into the processafter treatment in thedemineralisation plant.• Boiler blow down water is reusedas cooling water make-up.Rest of the effluent water from allthe process streams – DM planteffluent and cooling towers blowdowns are sent to the EffluentTreatment Plant (ETP). The treatedwater is stored in the holdingpond and utilised for irrigatingthe landscape. It is only during theParameter Unit FY2009-10monsoon season that the holdingpond treated effluent is dischargedinto the river after meeting thepre-set conditions.Nearly 87% of waste water isrecycled back into the system,and the balance amount is usedin the irrigation network withinthe complex. We do not usefreshwater for irrigation orhorticultural purposes. Due toour continuous efforts, waterrecycled in the reported periodincreased to 87.70% from 87.04%in the previous year.During FY 2009-10, we discharged1,307,807 m 3 of water on land forirrigation and into the river.Responsible WasteManagementPermissible Limits(mg/l)Biological Oxygen Demand mg/l 10 30Chemical Oxygen Demand mg/l 69.5 250Nitrate Nitrogen mg/l 5.7 10Total Ammonical Nitrogen mg/l 5.4 50Total Dissolved Solids mg/l 1400 N.A.Total Kjeldahl Nitrogen mg/l 18.4 100Total Suspended Solids mg/l 81 100Table 10: Effluent discharge and their permissible limitsWe have developed acomprehensive wastemanagement manual underHealth, Safety, Environment &51

Quality (HSEQ) system andhave categorised wastes ashazardous and non-hazardousfor differentiated management,identified the point of generationand established procedures fordisposal. We have also definedwaste types to ensure maximumrecyclability. Various departmentsstore waste at designated places,which is then transferred tocentralised waste collection bins.Thereafter, the stores departmenthas the responsibility to handleand dispose off the waste. Sinceenvironmental and economicburdens of waste disposal andtreatment are high, <strong>Chambal</strong> isalmost a zero-disposal-to-landfillcompany for non hazardous waste.We are able to sell / recycle mostof our solid waste.Type of bio-medicwasteHP Planet Partner ProgrammeWe were the first Company in the region to partner with HewlettPackard in their unique “HP Take Back Programme”, which involvescollection of used / unserviceable ink cartridges, toners and otherhardware products from customers under its extended producerresponsibility initiative. We ensure that all our employees drop off thespent HP products in the collection bins. Till date, we have returned1789 inkjet / toner cartridges to HP for eco-friendly disposal.Horticulture waste from thetownship is being compostedin the NADEP pits (a compostmethod developed by NaryanDevrao Pandri Pandey) and theresulting manure is used in theplantations. We have also signedan agreement with the BhabhaAtomic Research Centre (BARC)for adopting the Nisargruna 9process based compost plant sothat the horticulture waste ofapproximately 2 tonnes/day can beTreatment and DisposalAmount (Kgs)Sharp waste Autoclaved and Buried 4.58Contaminated wasteDisposable wasteTable 11: Biomedical waste disposed off in the year 2009-10Name of WasteDisposedType of wasteAutoclaved, chemicallytreated and buriedTreated chemically andburiedUnitFY2007-08FY2008-09524.824.82FY2009-10Spent Oil Hazardous MT 11.88 21.576 23.36Spent Catalyst Hazardous MT 66.95 0 83.16Ferrous Scrap MSdrumHazardous MT 0.28 0.72 1.09Lead Acid Battery Hazardous MT 1.32 4.61 0.45HDPE Scrap Non - Hazardous MT 39.46 42.43 44.19Paper Non - Hazardous MT 8.01 11.74 10.91MS Scrap Non - Hazardous MT 84.58 57.95 313.87PVC Non - Hazardous MT 1.99 4.86 12.85Table 12: Major categories of Waste Disposed offcomposted in a shorter period oftime and the biogas generated canbe utilized in the hostel facility.There is a foolproof segregationsystem of domestic waste at thekitchen level itself. Thereafter,bio-degradable waste goesfor composting and non biodegradablewaste is recycledthrough sale. Further, we havebanned use of polythene bags inour township since FY 2007-08and the township is now 100%free of polythene bags. This is astep towards reduction in nonbio-degradable waste.Inside the factory, we havecolour coded and labeled wastecollection bins and storageareas, and for many wastes,we have restricted access toauthorised personnel. We havealso organized awareness buildingand sensitization sessions foremployees across the board.The wastes generated in ourplants largely comprise used oil,spent catalyst, lead batteries,ferrous waste and waste HDPEbags. We dispose off hazardouswaste (except bio-medical wastes)to authorized external agenciesfor the transportation, treatmentand final disposal of such waste.Due to the remoteness of ouroperating location and thewaste quantities generated,we do not have an authorisedwaste collector for the biomedicalwaste generated at ourOccupational Health Centre9Nisargruna- is an indigenous technology for small scale application developed by Bhaba Atomic Research Centre, Mumbai (BARC) to convert organic solid waste intobiogas and manure.

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>(OHC). The various categoriesof waste that are generated atOHC are waste sharps, wastecontaminated with bodily fluidsand tubings, catheters, intravenousset, etc. However, we ensure thatthis waste, too, is disposed off inan environment friendly manner.Table 11 provides the detailsof the major categories andquantities of bio-medical wastedisposed off and the disposalmethod. We strictly adhere to alllaws and norms for storage anddisposal of wastes.Contributing to Bio-diversityConservationSince different species contributedirectly to the well-being of the‘ecosystem’, the healthy survivalof future generations and inmeeting development goals, it is ofType ofexpenditureWaste disposal,emissions treatmentand remediation costsPrevention andenvironmentalmanagement costsDescription of expenditureCost of treating the wastewater or disposing solidwaste/sludge to an external contractor or destination+ operating and maintenance cost.Cost for employing external authorities for lab testingand samplingAnnual costs of ISO 14001 and other suchcertifications for management systemsDirect and Variable cost incurred inmillion INRFY 2007-08 FY 2008-09 FY 2009-100.84 0.86 1.120.19 0.19 0.190.15 0.15 0.23License to operate, pollution certificates 0.19 0.27 0.27Table 13: Expenditure on environmental management (Data has been rounded off)1.37 1.47 1.8153

critical importance that diversityof species be protected. In thiscontext, agriculture plays a keyrole.Agriculture, in its objectiveto meet the fibre and bioenergyneeds of a burgeoningpopulation, has led to manmadechanges in habitats andmicro-environments. This, inturn, has negatively impactedthe very survival of diversespecies. As a Company whosecore business is crop nutrients,there is, quite understandably,a limit to our ability to bringabout transformative change.However, our vision andcommitment to work for thegreater environmental good hasled us to initiate some significantbio-diversity conservationmeasures. We have set up a fundin collaboration with HadotiNaturalists Society (a local body),and the Forest Department,Government of Rajasthan toconserve wildlife and preserve thehabitat of endangered species likethe Great Indian Bustard, BlackBuck, and Chinkara at SorsanPreserve which is located closeto our manufacturing facility.We have also joined hands withthe Rajasthan Government’sHarit Rajasthan initiative.Our pro-active attitude andenthusiasm towards environmentconservation have helped usdevelop 500 acres of green oasis(approximately 50% of the totalland area) in the midst of a rocky,barren and dry land allotted tous. This green oasis houses twoplants and a township with all thenecessary amenities for morethan 400 employees and theirfamilies. We have planted manylocal and exotic plants in thepremises based on sound scientificevaluation and developed waterbodies so that our interventiondoes not negatively impact thelocal flora and fauna. As a resultof our efforts in the last twodecades, the area in and aroundthe plant campus has becomean abode for many endangeredand migratory species of birds.To sensitize employees and theirfamilies on environment issues, weregularly organize nature walks,poster competitions, nukkadnataks, tree plantations and birdwatching trips.<strong>Chambal</strong> has been associatedwith the Bombay Natural HistorySociety (BNHS) from inception.We frequently interact with BNHSon environmental issues. Officialsof BNHS visit the campus andadvise us on improving the florain the plant complex. In 2009-10, BNHS helped us organize aworkshop on environment for<strong>Chambal</strong>’s senior officials. Wealso continuously engage withthem for promoting <strong>sustainable</strong>development- creating botanicaland butterfly gardens; andpreserving aquaculture resources,plantations, forests and scrublands.Most significantly, our townshipis ISO-14001 and OSHAS-18001certified. Our environment effortswere recognised by the RoseSociety of Rajasthan who haveconferred on <strong>Chambal</strong> the bestIndustrial Township award.Enduring Efforts towardsEnvironmental ConservationWell-articulated and clear policies,guidelines, and managementsystems ensure that we operatein a manner that protectsboth human health and theenvironment. Our environmentalmanagement metrics, auditingand reporting are evaluatedperiodically and environmentalmonitoring of various parametersis done regularly. We have awell-equipped environmentallaboratory which conforms tothe guidelines promulgated bythe Ministry of Environment andForests, and Central and StatePollution Control Boards. Wemonitor the stacks associatedwith the boilers and the prilltowers on a weekly basis,conduct ambient air and noisemonitoring on a periodic basis.The monitoring schedule iswell-defined in our managementsystems. Our expenditure onenvironmental managementfor the reported year was INR1.81 million; approximately62% of it was spent on wastedisposal, emissions treatment andremediation costs.During the reporting year wehad no non-compliance withenvironmental regulations andwe continue to maintain ourcertification of ISO 14001: 2004and OHSAS 18001:2007.<strong>Chambal</strong>’s Eco-friendlyTownship: 500 acres of greencover, about 100 species offlora, about 100 species of birds(including migratory birds), morethan 500 peacocks, monkeys, andmany non-predatory animals54

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>Valuing Human Capital• Our People• Empowering the Workforce• Employee Benefit Schemes• Workplace Safety• Caring for Employees• Equal Opportunities for All• Ensuring ‘Child Labour Free’ Operations• Industrial Relations55

Valuing Human CapitalFor us, employees are our mostvaluable assets and we believethat empowered employeesare paramount for businesssustainability. Their dedicationand commitment ensures smoothand efficient functioning of ourbusiness. We believe that the skillsand performance of our employeesare key factors for ensuring thefuture success of business, sowe invest significant time andresources for employee trainingand career development. Safeoperations and work place safetyis a top priority for <strong>Chambal</strong>. Wehave various welfare schemesfor our employees and are highlyvigilant about avoiding humanrights abuses in the Company.Our PeopleAs on 31 March 2010, our totalemployee strength in Agri Businessdivision was 853. In addition, weengaged 882 contract workersduring the reporting year.To ensure business excellence,it is imperative for us to pursueinnovative HR programmes toattract and retain quality talent.Our success in this endeavouris illustrated by our steadilydecreasing employee turnoverpercentages over the last threeyears. We saw the highestturnover in the less-than-30-year age group in the reportingyear. We have a vibrant youngworkforce- the average age of ouremployees is 35.72 years.We have a well-structured andtime-bound career progressionpolicy for our employees.In 2009-10, we revisited thepromotion policy for the nonmanagementcadre and revised itto accommodate faster growthaspirations.Management LevelFY 2007-08 FY 2008-09 FY 2009-10Male Female Male Female Male FemaleSenior Management 17 0 17 0 20 0Middle & JuniorManagement411 1 431 3 449 5Workmen 326 10 311 10 334 11GETs / TMOs / MTs 33 2 33 1 9 0Trainees 30 0 54 0 25 0Table 14: Composition of workforce (excluding contract workers) by category and gender56

<strong>Building</strong> a <strong>sustainable</strong> <strong>enterprise</strong>Steadily declining employee turnover rateEmpowering the WorkforceProfessional growth of ouremployees and strengtheningof the leadership pipeline isa strategic priority for ourorganisation. We invest inholistic development of ouremployees through mentoring,on-the-job training and variousinternal as well as externaltraining programmes. We followa structured approach toidentify the training needs of ouremployees through the annualPMS (Performance ManagementSystem). The captured needs arecategorised and evaluated fororganising customised trainingprogrammes. Based on theassessment, a Training Calendaris developed and circulated to allemployees of the organisation.As a part of our training initiatives,we include all contractualworkers for training on varioussubjects related to emergencyhandling, first aid, workplacesafety, fire fighting, usage of PPEs(Personal Protective Equipment),environment management,general health and hygiene.During 2009-10, around 50 HSEQ(Health, Safety, Environment &Quality) training programmeswere conducted, where morethan 800 contractual workersparticipated. Additionally, due tothe nature of the operations inthe Urea Product Handling Plant,we provided customised safetytraining on a regular basis tocontract workers.To encourage employees toseek additional educationalqualifications, we havecollaborated with the BirlaInstitute of Technology andSciences (BITS) Pilani, one ofIndia’s premier engineeringinstitutes. Employees withdiploma in engineering orgraduation in science can enrollwith the institute and get a degreein process engineering, if they fulfillcertain laid down criterion. Forthis, 70% of tuition fee and 50%of admission fee is contributedby the Company. Till date, 45employees have benefited fromthis scheme. The Company alsosponsored 9 employees duringthe year for a 15-day ManagementDevelopment Programme at IIM,Bangalore. We have initiated aSelf-Development Scheme foremployees to enhance theirknowledge and skills bandwidth byenrolling in professional trainingcourses. Under this scheme,50% of the tuition fee subjectto a maximum of INR 50,000 isreimbursed by the Company.10Workforce includes permanent employees and trainees and excludes contractual workers57

Training Programmes in FY 2009-10Internal HSEQ TrainingFire fighting and emergency handling, safety in materialhandling in Urea Product Handling (UPH) plant, electricalsafety, awareness of ISO 9001, HAZOP, HAZAN, etc.External HSEQ TrainingBehavior based safety management, e-waste management,hazard identification and risk management, industrialsafety and occupational health, prevention andmanagement of chemical accidents, etc.Management levelparticipantsNon-management levelparticipantsManagement levelparticipantsNon-management levelparticipants144 217 18 44Employee Benefit Schemes<strong>Chambal</strong> has various employeebenefit schemes based on thephilosophy that securing ouremployees’ financial future iscritical for our sustained growth.The <strong>Chambal</strong> Employee SeniorStaff Superannuation Fund and<strong>Chambal</strong> Non-managementEmployees Superannuation Fundprovide for pension benefits toemployees. The Provident Fundscheme is managed by <strong>Chambal</strong>through a Trust. Employees whohave completed 5 years of serviceare also eligible for Gratuityand the Company’s EmployeesGroup Gratuity Trust Fundprovides for Gratuity benefit.Life insurance benefit to eachemployee is also covered underGratuity and SuperannuationSchemes. All employees areeligible for the Group PersonalAccident Scheme, Group HealthInsurance Scheme and GroupTerm Solution Scheme. Incase of accidents, the PersonalAccident Scheme ensurescompensation for treatmentexpenses, permanent / partialdisability, permanent / temporaryloss of earning capacity includingsalary component and deathcoverage. The Health InsuranceScheme covers hospitalisationexpenses of employees and theirfamily members, while under theTerm Solution Scheme life, eachemployee is insured. All retiredemployees are covered underthe Group Health InsurancePolicy up to the age of 85 years.Vehicle and furniture loans areprovided to employees accordingto eligibility at low interest rates.The Company also provideshousing loans to employees. Allmanagement grade employees aresupported for membership of oneprofessional body, wherein theannual membership fee is borneby the Company. The Companyhas tied up with medicos/hospitalsfor regular preventive healthcheck up of senior employees.1. Appreciating EmployeeContributionWe believe that engagingemployees in planning anddesigning operational strategiesincreases the efficiency of ourprocesses. Accordingly, we haveinstituted an employee suggestionscheme. The suggestions areevaluated by a committee andselected suggestions are dulyawarded.58