DRIVE SOLUTIONS FOR E.O.T. CRANES - vulkan group

DRIVE SOLUTIONS FOR E.O.T. CRANES - vulkan group

DRIVE SOLUTIONS FOR E.O.T. CRANES - vulkan group

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

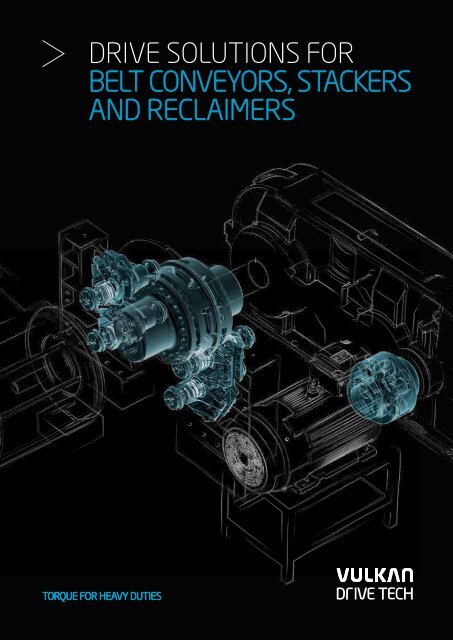

Contents010204ContentsApplication RequirementsSolutions08101214161820FlexomaxDenflexElectromagnetic BrakesElectrohydraulic BrakesHydraulic BrakesRAIL CLAMPSBackstops2425Product RangeProduct Application RangeDrive Solutions for Belt Conveyors, Stackers and ReclaimersVulkan Drive Tech01

INDUSTRIAL APPLICATIONSVULKAN Drive Tech provides a wide range of fl exible couplings,braking systems and resilient mounts, based engineering andknow how applied into more than 20 different types of applications,within six different industrial markets segments.OIL & GAS – Onshore & offshore plants involve thelarge-scale use of compressors, blowers, pumps and fans withinthe processing chain of fl uids and gasses. Our torsional fl exible& torsional rigid couplings and brakes will preserve the bestfunctionality of diesel engines, electric motors and turbines inthe vast majority of working profi les and environments.MINING – Stackers, reclaimers, regenerative conveyorsbelt, mills and crushers are just a few examples of the heavyduty machinery that requires specifi c high speed & low speedcouplings, service & emergency braking systems, backstops andresilient mounts. Our approach to such demanding applications isto deliver engineered tailor-made solutions.BULK MATERIAL HANDLING – Gear couplings,electromagnetic service brakes, hydraulic emergency brakes,hydraulic rail clamps for E.O.T. gantry cranes, torsional highlyfl exible couplings and resilient mounts for construction machineryunderline the wide product portfolio and engineering capacity ofVULKAN Drive Tech.ENERGY – Power generation by means of wind turbines,hydro turbines and steam turbines, requires drive solutions thatare capable of withstanding high dynamic torque load and highspeed. VULKAN Drive Tech responds to such requirements withhigh-quality hydraulic brakes, composite materials and integratedelectronic power controls.IRON & STEEL – Continuous ingot castings and hot& cold laminating machinery are typical examples of steelworkequipment where the drives are subjected to dust, dirt and hightemperatures. Operational safety and reliability of the drive componentsand minimum service downtime are the main requirementsthat our pneumatic disc brakes, maintenance-free fl exiblecouplings and disc couplings must fulfi ll.SPECIAL APPLICATIONS – The unique skills andknowhow developed during more than 120 years of experiencemakes VULKAN Drive Tech a reliable partner for drive componentsthat simply cannot be selected out of a catalogue. Test benches,railways, agricultural machinery and gantry cranes for aerospaceequipment are just a few of the challenges that we deal with on adaily basis.

CUSTOMER BENEFITSOur mission is to offer our customers the most reliable products,with the right level of customization, state-of-the-art design, deliveredwithin the requested time, supported by local service closestto where it is needed. Choosing VULKAN Drive Tech means tochoose innovation, technological leadership, and highly specifi csolutions with maximum customer benefi t.TAILOR-MADE <strong>SOLUTIONS</strong> – We propose to our customers diversifi ed systems solutions that can respond positivelyto their requirements in terms of products features, custom solution design, and the operating conditions and economy of theapplication. VULKAN Drive Tech provides the reliable products and related engineering services that your application needs.ENGINEERING – We have considerable experience and knowhow regarding the most advanced braking technology andtorsional & linear vibrations calculations and measurements. Besides the most advanced 3D CAD CAM systems that are usedby our Design Department, we have developed state-of-the-art calculations programs to to simulate product performances inrelation to the specifi c application. More than fi fty of our engineers dedicate themselves on a daily basis to fulfi lling the requirementsof our customers.IN-HOUSE TESTING – VULKAN Drive Tech has in-house test center to perform either static or dynamic tests up to 5.000kNm. This ensures we can back up the claims regarding technical performances that are listed in our catalogue, recreating themost severe operating conditions our products will face within their lifetimes. This strategic service is performed to implement ourengineering know-how and create a new breakthrough into state-of-the-art power transmission and braking systems technology.PRODUCTION – VULKAN Drive Tech comprises fi ve wholly-owned manufacturing sites worldwide and this is where thecore of our products come to life. International Quality Standards guarantee our customers that the Services and Productspurchased from VULKAN Drive Tech are simply Top Quality Products which deserved to be branded with our “V” Logo.WORLD-WIDE SERVICE – 17 wholly-owned subsidiaries and more than 30 offi ces worldwide demonstrate the closecontact we can offer to our customers. Our key areas of competence include application engineering, sales, after sales andtechnical support. Furthermore, service and spare part depots have been established throughout the world. And the shortestroutes for material to their point of installation, as well as the fl exibility and mobility of our technicians, ensure a prompt backupservice all over the world.

REQUIREMENTS02Vulkan Drive TechDrive Solutions for Belt Conveyors, Stackers and Reclaimers

Iron ores, coal, precious minerals and similar materials needto be transported from mines to different points of use – suchas processing plants or stocking piling – for sea transportationto other end users. Conveyor belts, stackers and reclaimersare the main machinery used for this purpose. The expectedperformances of these applications are extremely high andrequire powerful and reliable drives with power ratings upto 10,000 kW and transportation capacity up to 15,000 tonsper hour.Couplings are generally installed onto either high speed andlow speed shafts of the drive train in order to compensatemisalignments between the motor and the gearbox. Alternatively,they can be installed between the gearbox and the pulleywhen the drive train is on a separate base frame from thepulley drum (typical configuration of high powered conveyors).The coupling compensates misalignments due to thermalexpansions phenomena, as well as reduces shock loadstransmissions. Inclined conveyors do also require safetyequipment, in the unlike event of emergency conditionssuch as failure of the drive train, rolling back of the beltor overspeeding of regenerative conveyor belts. For thesepurposes either backstops and brakes systems have to beproperly selected. Motor stalling torque, run back torque, conveyorstopping time, conveyor speed, are just few mandatoryvariables to be considered into couplings, backstops and brakessystem design.Drive Solutions for Belt Conveyors, Stackers and Reclaimers Vulkan Drive Tech03

SolutionSTo face all of these requirements, VULKAN Drive Tech haproduct portfolio that is specific for belt conveyors applicationscouplings, torsional rigid couplings, service and emergency bfocusing on the following three major key aspects:EfficiencyTailor-made solutionsTo minimise service and machinery laydown costs, VULKAN Drive Tech has developedcouplings with special elastic elementsthat are made of chemical contaminationresistant materials. These increase thelifetime of the products considerably.Brakes are equipped with special sealingsthat guarantee no contamination of potentiallydangerous dust to internal brakescomponents. Backstops are equipped withadditional oil reservoir tanks, which increasethe operating time between services.Due to the unique nature of each beltconveyor, it is simply impossible to takeanother approach to the application ofits products, if not the one of customisedsolutions. Our engineers are at the disposalof our customers to ensure that the besttailor-made solution is developed. A proposalthat can satisfy either technical and economicrequirements that each project specificallydemands: a customised solution withstandard design products.04Vulkan Drive TechDrive Solutions for Belt Conveyors, Stackers and Reclaimers

s developed an extensive, including torsional flexiblerakes and backstopsDesignCouplings, brakes and backstops havean extremely high interaction rate withinthe design of a conveyor belt drive train.VULKAN Drive Tech provides specific designsto closely match the integrated installationof couplings and brakes (or backstops), witha view to optimising product performances.State of the art engineering, 3D CAD tools,in-house testing are the foundation ofVulkan know-how.Drive Solutions for Belt Conveyors, Stackers and ReclaimersVulkan Drive Tech05

SolutionSProduct portfolioFLEXOMAX page 08 DENFLEX page 1006 Vulkan Drive Tech Drive Solutions for Belt Conveyors, Stackers and Reclaimers

ELECTROMAGENTICBRAKES page 12ELECTROHYDRAULICBRAKES page 14HYDRAULICBRAKES page 16RAIL CLAMPS page 18BACKSTOPS page 20Drive Solutions for Belt Conveyors, Stackers and ReclaimersVulkan Drive Tech07

featuresFLEXIBLE COUPLINGSFLEXOMAX G, FLEXOMAX GBN, FLEXOMAX GSNThe three different designs available are FLEXOMAX G, FLEXOMAXGSN and FLEXOMAX GBN; each of which is developed to fulfillspecific requirements in terms of nominal torque transmission,shock loads absorption, axial, radial and angular misalignmentscapacity. The elastic element of the three designs differs as regardsmaterial and geometry and this means that it complies witheven the most demanding application requirements. FLEXOMAXis available in more than 30 different versions and 50 differentsizes. This ensures it will fit the requirements of almost any application.The FLEXOMAX coupling is suitable for reverse rotation and istypical of electric motor drives. The claws and elastic elementdesign mean that FLEXOMAX is a maintenance-free product asit does not require any special type of servicing or maintenance.The wearing of the elastic element is minimised by the materialused, which is NBR for FLEXOMAX G and polyurethane forFLEXOMAX GSN and GBN. FLEXOMAX is suitable for compensatingaxial, radial and angular misalignments due to thermalgrowth and dynamic misalignments of the machinery.The modular design of the couplings allow the creation of specificversions to fit almost any kind of machinery, such as, forexample, FLEXOMAX GH, with intermediate spool to enable theremoval of the pump’s impeller without the need to move themachinery. Other examples are the FLEXOMAX GGTB, GSND-TBand GBND-TB, which are provided with an integrated brake discin order to properly accommodate the installation of a service orparking brake as well. The radial removal of the elastic element isa common feature of all FLEXOMAX G, GSN and GBN designs, soas to enable the most straightforward replacement of the elementwith minimum costs.EfficiencyTailor-madesolutionsDesignMore products of this series:Product key factsAllows to compensate axial, radialand angular misalignments.Limited maintenance required.Protect the drivetrain from shockloads.Modular design with high customisationdegree possibilities.Radial removability of the coupling withoutmoving the connected machinery.Possibility to integrate braking discs orpulleys within the coupling.Available in different designs G-GSN-GBN to satisfy the most restrictedapplications' requirements.Reverse functionality.Compact design.FLEXOMAX G: Nominal Torque Range: 0.02 to 48.60 kNm andshaft accommodation up to ø 250 mmFLEXOMAX GSN: Nominal Torque Range: 0.003 to 20.00 kNmand shaft accommodation up to ø 250 mmFLEXOMAX GBN: Nominal Torque Range: 3.6 to 64.44 kNm andshaft accommodation up to ø 600 mmFlexomax GFlexomax GBNDrive Solutions for Belt Conveyors, Stackers and ReclaimersVulkan Drive Tech09

DENFLEXNominal Torque Range: 1.00 – 560.00 kNmDenflexDENFLEX is a tooth gear coupling that is torsionally rigid and usedfor synchronous torque transmission. The tooth gear profile allowsthe transmission of high torque values within minimum sizing of thecoupling and compensates axial, radial and angular misalignmentswith low reaction forces generation.10 Vulkan Drive Tech Drive Solutions for Belt Conveyors, Stackers and Reclaimers

featuresRIGID COUPLINGSDENFLEXIt is particularly suitable for low speed shaft applications where hightorque within limited size and weight is mandatory. The modulardesign of its components allows a huge variety of design compositions,which in turn fit even the most demanding applications.The tooth profile is the core of this coupling and DENFLEX featuresa specific design that guarantees the minimum surfacecontact area between teeth. This ensures that friction and theconsequent wearing of the parts is reduced, hence increasingthe lifetime of the product. The spline design of the tooth sleevesallows DENFLEX to compensate high axial misalignments; in addition,the round tooth profile compensates either radial or angularmisalignments as well. A complete system of sealings and gasketsprevent the gears area from becoming contaminated by dust oraggressive elements that could reduce the internal lubricant lifetimeor even damage the gears.DENFLEX, with standard lubrication, can be used for an operationenvironment temperature ranging from -10°C up to 90°C. Meanwhile,special lubrication is available on demand for more extremeenvironmental conditions. The reduced number and modulardesign of the components make DENFLEX a highly customisableproduct. Indeed, it is available in more than 30 different versionsand 17 sizes that are suitable for shaft accommodation up toø 450 mm.A special version is also available on demand that features hardenedteeth and is able to transmit an additional 30-40% (dependingon size) of torque, within the same dimensions of thestandard coupling.EfficiencyTailor-madesolutionsDesignProduct key factsHigh torque transmission within limiteddimensions.Long lasting working condition betweenservice operations.High axial misalignment capacity.More than 30 different configurations available.Possibility to integrate braking discs orpulleys within the coupling.High torque transmission version (+30%)available on demand.High axial misalignment capacitywith minimised reaction forces to theconnected machinery.Synchronous torque transmission.Sealed against aggressive contaminants.Modular design.Drive Solutions for Belt Conveyors, Stackers and ReclaimersVulkan Drive Tech11

electromagneticBRAKESNominal Torque Range: 0.01 – 25.00 kNmELECTROMAGNETIC DISC BRAKELarge fans machinery might require service and parking brakes dueto the high inertias of the machinery components. VULKAN DriveTech has a wide range of failsafe ELECTROMAGNETIC BRAKES usedfor this scope, which are specifically designed to comply with service,parking or emergency working profiles.12 Vulkan Drive Tech Drive Solutions for Belt Conveyors, Stackers and Reclaimers

featuresBRAKESELECTROMAGNETIC DISC BRAKE, ELECTROMAGNETIC DRUM BRAKEEach brake model can be equipped with a variety of accessoriesto comply with the most demanding applications that require reliableproduct performances within the most extreme operating conditions.The VULKAN Drive Tech power supply portfolio completesthe brakes product range that we are able to offer.VULKAN Drive Tech ELECTROMAGNETIC BRAKES are failsafe brakesthat are available in either disc or drum configuration (AISE11 Standard). They have been designed to ensure a minimumoperating reaction time of 0.2 seconds and to support repetitivebraking operations up to 700 cycles per hour. Laboratory testshave shown that VULKAN Drive Tech brakes are maintenance-freefor up to 4,000,000 cycles.VULKAN Drive Tech offers the following main customisation possibilities:automatic lining wear compensation system, brakes positionsensors, pads worn out sensors, automatic or manual brakerelease mechanism, organic and sintered pads that are asbestosfree.Furthermore, the complete range of solid and self-ventilateddiscs with integrated flexible couplings are also available and thesecomplete the scope of supply.EfficiencyTailor-madesolutionsDesignProduct key factsFailsafe brake.0,2 seconds reaction time.Maintenance-free up to 4,000,000 cycles.Left and right installation versions.Brake and pads status monitoring available.Braking torque tuning capacity.Available in either disc or drum configuration.Shunt or series coil available.Automatic lining wear compensation system.Each brake is equipped with a power supply unit to operate it; asregards the calipers, the power supply units can also be equippedwith different electric/electronic circuits to better suit the specificrequirements of the applications.More products of this series:Electromagneticdrum brakeDrive Solutions for Belt Conveyors, Stackers and ReclaimersVulkan Drive Tech13

electroHYDRAULICBRAKESNominal Torque Range: 0.20 – 17.80 kNmElectrohydraulic DISC BRAKEWhen service brakes do not require a high degree of manoeuvring, auseful alternative to ELECTROMAGNETIC BRAKES could be electro-HYDRAULIC BRAKES. Available in either a disc or drum configuration,VULKAN Drive Tech electroHYDRAULIC BRAKES are of a failsafetype and do not require the combined installation of a powersupply to operate the caliper, which means an economic advantageat installation.14 Vulkan Drive Tech Drive Solutions for Belt Conveyors, Stackers and Reclaimers

featuresBRAKESELECTROHYDRAULIC DISC BRAKE, ELECTROHYDRAULIC DRUM BRAKEA wide range of accessories is also available for this product family,which includes automatic lining wear compensation system,pads worn out control and sintered pads. Our applications engineeringdesk will provide the right configuration according to thespecific requirements of the customer.VULKAN Drive Tech ElectroHYDRAULIC BRAKES are spring appliedand released by means of an electrohydraulic thruster thatcan be fed by 220-380 or 440 VAC and that has been designedaccording to the DIN 15430 standard. The nominal braking torquevalue can be manually adjusted in order to properly fit each applicationand the electrohydraulic thruster can be equipped withdelay valves for smooth braking operation.The ElectroHYDRAULIC BRAKES family is available in three differentcaliper sizes, seven different thruster models and 13 discconfigurations. This ensures that the braking features of eachcaliper can be properly set. Furthermore, it is possible to manuallyadjust the nominal braking torque value of each brake tofine tune the performance of the brakes on-site. Automatic liningwear compensation system, brakes position sensors, pads wornout sensors, automatic or manual brake release mechanism, andasbestos-free organic and sintered pads, are the main customisationpossibilities that VULKAN Drive Tech offers.EfficiencyTailor-madesolutionsDesignMore products of this series:Product key factsFailsafe Brake.Easy and fast installation on site.Compliance to DIN 15430 Standard.Left and right installation versions.Brake and pads status monitoring available.Braking torque tuning capacity.Available in either disc or drum configuration.Modular design to fit different thruster intothe same caliper.Automatic lining wear compensation system.ElectroHYDRAULICdrum brakeDrive Solutions for Belt Conveyors, Stackers and ReclaimersVulkan Drive Tech15

HydraulicBRAKESNominal Torque Range: 0.11 – 171.00 kNmHydraulic disc BRAKERegenerative conveyors need braking systems that are capable ofpreventing overspeeding of the belt during normal operations andemergency stopping in critical conditions. As proportional brakingand high dynamic torque due to machinery inertias are the main featuresto be considered, HYDRAULIC BRAKES are the prime productsfor this application.16 Vulkan Drive Tech Drive Solutions for Belt Conveyors, Stackers and Reclaimers

featuresBRAKESHYDRAULIC DISC BRAKEThe VULKAN Drive Tech HYDRAULIC BRAKES portfolio includesa wide range of calipers with all of the relevant accessories, suchas a hydraulic power pack, electronic control unit and specialelectronic braking monitoring system that is able to continuouslycontrol the speed of the conveyor and apply proportional brakingtorque. This prevents overspeeding and guarantees the belt willstop within the desired time without overstressing of the belt itself,regardless of the load percentage of the conveyor.EfficiencyProduct key factsFailsafe brake.Proportional braking capacity.High braking force capacity.VULKAN Drive Tech HYDRAULIC BRAKES are available in eitherpositive (hydraulic applied and spring released) or negative (springapplied and hydraulic released) configuration and in single springdesign for disc floating conditions, or double spring design forfixed disc conditions. The SH line is the prime product used foremergency operations into the belt conveyor. Available in nine differentsizes, this double spring caliper can be easily installed onany disc diameter and thickness thanks to its adjustable design.A manual lining wear compensation system, brakes position sensors,pads worn out sensors, manual brake release mechanism,and organic and asbestos-free sintered pads are the main customisationpossibilities offered by VULKAN Drive Tech.Tailor-madesolutionsDesignBrake and pads monitoring status available.Possibility to install on any disc diameterand thickness.Digital proportional braking system controlunit.Mono and dual spring design.6 different hydraulic power pack units.Lining wear compensation system.VULKAN Drive Tech also provides a wide range of hydraulic powerpacks with different hydraulic performances such as the simple“On/Off” CH1 circuit or the most complex and sophisticated CH6“Digital Proportional Braking system” which has the possibility ofseveral custom accessories.Drive Solutions for Belt Conveyors, Stackers and ReclaimersVulkan Drive Tech17

Rail ClampSNominal Torque Range: 50.00 – 400.00 kNmRAIL CLAMPSAlso known as the “Storm Brake”, this product is largely used on portcranes, stackers, reclaimers and gantry cranes, where extreme windsmight affect stability. They provide stability during abnormal operatingconditions by literally clamping the crane to its foundations: rails.18 Vulkan Drive Tech Drive Solutions for Belt Conveyors, Stackers and Reclaimers

featuresBRAKESRAIL CLAMPSVULKAN Drive Tech Rail Clamps are composed of a spring appliedor counterweight applied brake, which is then hydraulicallyreleased. Designed to meet the most critical applications andweather conditions, the rail clamps are provided with treated alloysteel jaws enabling better clamping effort performance.The hydraulic power pack is designed in such a way as to guaranteethe clamp remains open without requiring the frequent startingof the motor. This prolongs the lifetime of the hydraulic valvesand components in general. To stop the clamps from accidentallyclosing, they are equipped with “open/close” status sensors, andthere is also a flow control valve used, the purpose of which is toenable time controlled closing during clamping. Available in sevendifferent sizes, VULKAN Drive Tech Rail Clamps are supplied tomatch a specific rail profile and can be designed for either frontfastening or top fastening installation.VULKAN Drive Tech Engineering is available for the design and selectionof rail clamps, which are based on the wind requirementsof single projects and machinery layout.EfficiencyTailor-madesolutionsDesignProduct key factsClamping force up to 400 kN.Long lasting static open condition withoutengaging of the motor pump.Redundant pressure switches to preventfailure risk.Suitable for any rail profile.Front or top fastening version.With or without hydraulic power pack.Secure rail side clamping jaws system.Clamp status monitoring system toprevent accidental closing.Articulated structure to avoid unnecessaryfriction with rails.Drive Solutions for Belt Conveyors, Stackers and ReclaimersVulkan Drive Tech19

BackstopSNominal Torque Range: 0.001 – 578.00 kNmLOW SPEED BackstopVULKAN Drive Tech provides backstops for either high speed shaftor low speed shaft installations. The bearings can be sprag lift off orroller type, with or without radial bearing support and torque arm.Backstops are also available for pulley shaft end installation or shaftthrough installation and most sub-components are symmetrical inorder to simplify their assembly in relation to the free rotation side,blocking direction and torque arm positioning.20 Vulkan Drive Tech Drive Solutions for Belt Conveyors, Stackers and Reclaimers

featuresBackstops and FlywheelsLOW SPEED BACKSTOPS, HIGH SPEED BACKSTOPSThe labyrinth sealing system guarantees optimal working conditionsfor the bearings and rollers, which have been designed fora standard lifetime of 10,000,000 stopping cycles. Furthermore,extra oil reservoir tanks for either pulley shaft end design (T) orshaft through installation design (P) are available to increase theoperating working hours between maintenance service intervals.Finish bores according to customer specification with relativenumber and type of keyways, together with different torque armdesigns and lengths complete the backstop custom design possibilities.This ensures compliance with the requirements of eachindividual project.Every VULKAN Drive Tech backstop is supplied with internal testcertification that shows the operating conditions test it has beensubjected to and which corresponds to the field working conditionsto which it must comply.The sprag lift off design with radial support bearing, such as BA& BC, are generally installed on high speed shafts. Meanwhile,Design 261, with cylindrical rollers and radial bearings, is typicallyinstalled on low speed shafts.EfficiencyTailor-madesolutionsDesignProduct key factsOperating lifetime of the bearing for10,000,000 cycles.Steel hardened components and labyrinthsealing system for long lasting of internalcomponents.Different torque arms typology available.Extra oil reservoir tank.Reaction force balancing device on demand.Cylindrical rollers or sprag lift offtype available.Through shaft or free end shaftinstallation design.Blocking direction orientation possibility.More products of this series:HIGH SPEEDBACKSTOPDrive Solutions for Belt Conveyors, Stackers and ReclaimersVulkan Drive Tech21

Notes22 Vulkan Drive Tech Drive Solutions for Belt Conveyors, Stackers and Reclaimers

Drive Solutions for Belt Conveyors, Stackers and ReclaimersVulkan Drive Tech23

PRODUCT RangeFor Belt Conveyors, Stackers and Reclaimers11Flexomax Gpage 0812FLEXOMAX GSN13 FLEXoMAX GBNpage 08 page 0816DENFLEXpage 1018ElectromagneticDISC Brakepage 1219ElectromagneticDRUM Brakepage 1221ElectrohydraulicDisc Brakepage 1422ElectrohydraulicDRUM Brakepage 1423Hydraulic discBrakeSpage 1624 Vulkan Drive Tech Drive Solutions for Belt Conveyors, Stackers and Reclaimers

Market Oil & Gas MinApplicationCompressors /BlowersPumps /FansBelt Conveyors /Stackers /ReclaimersHIGHLY FLEXIBLE COUPLINGS1RATO S Series•2RATO R SERIES•3RATO DS SERIES•4EZR SERIES5VULASTIK L SERIES • •6789VULKARDAN E SERIESVULKARDAN L SERIESVULKARDAN P SERIESINTEGRAL SHAFT SUPPORT•••FLEXIBLE COUPLINGSRIGID COUPLINGSBRAKES1011121314151617181920MEGIFLEX B SERIES•FLEXOMAX G SERIES • •FLEXOMAX GSN SERIES • •FLEXOMAX GBN SERIES • •SPEFLEX SERIESPINOFLEX SERIES • •DENFLEX SERIESDISCFLEX SERIES • •••ELECTROMAGNETIC DISC BRAKES • •ELECTROMAGNETIC DRUM BRAKES • •PNEUMATIC DISC BRAKES21ELECTROHYDRAULIC DISC BRAKES•22ELECTROHYDRAULIC DRUM BRAKES•23HYDRAULIC DISC BRAKES•24RAIL CLAMPS•BACKSTOPS AND FLYWHEELS25HIGH SPEED BACKSTOPS•26LOW SPEED BACKSTOPS•RESILIENT MOUNTS27T SERIES • •28VD SERIES • •29 VDM SERIES • •24 RAIL CLAMPS25 HIGH SPEED26 LOW SPEEDPAGE 1830 CV 2000 SERIES BACKSTOP• BACKSTOP •PAGE 20PAGE 20<strong>DRIVE</strong>LINE COMPONENTS 31 COMPOSITE SHAFTING •

Market Oil & Gas MinApplicationCompressors /BlowersPumps /FansBelt Conveyors /Stackers /ReclaimersHIGHLY FLEXIBLE COUPLINGS1RATO S Series•2RATO R SERIES•3RATO DS SERIES•4EZR SERIES5VULASTIK L SERIES • •6789VULKARDAN E SERIESVULKARDAN L SERIESVULKARDAN P SERIESINTEGRAL SHAFT SUPPORT•••FLEXIBLE COUPLINGSRIGID COUPLINGSBRAKES1011121314151617181920MEGIFLEX B SERIES•FLEXOMAX G SERIES • •FLEXOMAX GSN SERIES • •FLEXOMAX GBN SERIES • •SPEFLEX SERIESPINOFLEX SERIES • •DENFLEX SERIESDISCFLEX SERIES • •••ELECTROMAGNETIC DISC BRAKES • •ELECTROMAGNETIC DRUM BRAKES • •PNEUMATIC DISC BRAKES21ELECTROHYDRAULIC DISC BRAKES•22ELECTROHYDRAULIC DRUM BRAKES•23HYDRAULIC DISC BRAKES•24RAIL CLAMPS•BACKSTOPS AND FLYWHEELS25HIGH SPEED BACKSTOPS•26LOW SPEED BACKSTOPS•RESILIENT MOUNTS27T SERIES • •28VD SERIES • •29VDM SERIES • •30CV 2000 SERIES • •31<strong>DRIVE</strong>LINE COMPONENTS COMPOSITE SHAFTING •