Manual optoNCDT 240x (PDF, 2.5 MB) - Micro-Epsilon

Manual optoNCDT 240x (PDF, 2.5 MB) - Micro-Epsilon

Manual optoNCDT 240x (PDF, 2.5 MB) - Micro-Epsilon

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SENSORS & SYSTEMSAuthority in Displacement MeasurementC ONon-ContactDisplacement andThickness MeasuringInstruction <strong>Manual</strong><strong>optoNCDT</strong> 2401/2402

MICRO-EPSILONMESSTECHNIKGmbH & Co. KGKönigbacher Strasse 15D-94496 OrtenburgTel. 0 85 42/1 68-0Fax 0 85 42/1 68-90e-mail info@micro-epsilon.dewww.micro-epsilon.comCertificated acc. to DIN EN ISO 9001: 2008V1.2

Contents1. Safety ...................................................................................... 51.1 Symbols Used........................................................................................ 51.2 Warnings ................................................................................................ 51.3 Notes on CE Identification ..................................................................... 51.4 Proper Use ............................................................................................. 61.5 Proper Environment ............................................................................... 62. Functional Principle, Technical Data ..................................... 72.1 Short Description ................................................................................... 72.2 Measurement Principle ........................................................................... 82.3 Glossary ................................................................................................. 82.4 Typical Applications ............................................................................... 8<strong>2.5</strong> Sensor .................................................................................................... 92.6 Control Elements Controller ................................................................... 92.7 Light Source......................................................................................... 102.8 Technical Data IFS2401 ........................................................................ 102.9 Technical Data IFS2402 ........................................................................ 113. Delivery ............................................................................... 123.1 Supplied Items ..................................................................................... 123.2 Storage ................................................................................................ 124. Installation and Assembly .................................................. 124.1 Mounting and Dimensions of Sensors.................................................. 134.1.1 Start of Measuring Range .................................................................... 154.1.2 Circumferential Clamping ..................................................................... 154.2 Sensor Cable ....................................................................................... 164.3 Controller Dimensions .......................................................................... 174.4 Electrical Connections ......................................................................... 174.4.1 Power supply ....................................................................................... 174.4.2 RS232/RS422 Interface ........................................................................ 174.4.3 USB Interface ....................................................................................... 184.4.4 Analog Output...................................................................................... 184.4.5 Synchronization ................................................................................... 184.4.6 Digital I/O, Encoder ............................................................................. 195. Operation............................................................................. 215.1 Commissioning .................................................................................... 215.2 Displacement Measuring ...................................................................... 215.3 Thickness Measurement ....................................................................... 215.4 Acquiring the Dark Signal .................................................................... 225.5 Analog Output...................................................................................... 225.6 Adjustment of the LED Brightness........................................................ 235.7 Adjustment of the Measuring Rate ....................................................... 235.8 Light Intensity ....................................................................................... 235.9 Synchronized Controller and Encoder Data......................................... 245.10 Triggering ............................................................................................. 245.10.1 Trigger Modes ...................................................................................... 245.10.2 Trigger Input ......................................................................................... 245.10.3 Start Trigger ......................................................................................... 255.10.4 Level Trigger......................................................................................... 255.10.5 Edge Trigger ........................................................................................ 255.10.6 Latch Trigger ........................................................................................ 265.10.7 Software Trigger ................................................................................... 265.10.8 Maximum Trigger Frequency ............................................................... 265.11 Response Time .................................................................................... 275.12 Double Frequency ............................................................................... 286. Serial Interface.................................................................... 306.1 Data Format ......................................................................................... 316.2 Command Syntax ................................................................................ 32<strong>optoNCDT</strong>2401

6.3 Data Transmission Formats .................................................................. 326.3.1 ASCII .................................................................................................... 326.3.2 Binary ................................................................................................... 336.4 Transmitted Data .................................................................................. 346.4.1 Available Data ...................................................................................... 346.4.2 Meaning of the Data............................................................................. 346.4.3 Data Selection...................................................................................... 356.5 Data Decoding ..................................................................................... 366.5.1 Displacement Measuring Mode ........................................................... 366.5.2 Thickness Measuring Mode ................................................................. 366.5.3 Decoding the Barycenter Values .......................................................... 376.5.4 Decoding the State Data ..................................................................... 376.6 Commands .......................................................................................... 386.6.1 Sensor Selection .................................................................................. 386.6.2 Measuring Rate .................................................................................... 386.6.3 Displacement and Thickness Measurement ......................................... 406.6.4 Analog Output...................................................................................... 406.6.5 Dark Signal .......................................................................................... 416.6.6 Fast Dark Signal................................................................................... 416.6.7 Refractive Index .................................................................................... 426.6.8 Light Source Brightness ....................................................................... 426.6.9 Averaging ............................................................................................. 426.6.10 Spectral Averaging ............................................................................... 436.6.11 Hold Last Valid Value ........................................................................... 436.6.12 Trigger Functions ................................................................................. 436.6.13 Get Controller Configuration ................................................................ 456.6.14 Detection Threshold ............................................................................. 466.6.15 Light Source Test ................................................................................. 476.6.16 Auto-adaptive Dark Signal ................................................................... 476.6.17 Auto-adaptive Light Source Brightness ................................................ 476.6.18 First Signal Maximum ........................................................................... 486.6.19 Watchdog ............................................................................................ 506.6.20 Save the Controller Configuration ........................................................ 506.6.21 Serial Number, Software Version .......................................................... 506.6.22 Reset Encoder Counter ........................................................................ 506.6.23 Setting the Zero Values ........................................................................ 516.6.24 Missing Signal in Thickness Measurement Mode ................................. 516.6.25 Selection Light Source ......................................................................... 526.6.26 Switch on Double Frequency ............................................................... 526.6.27 Select Frequencies for Double Frequency ........................................... 526.6.28 Transmitted Intensity in Double Frequency Mode................................ 526.7 Command List...................................................................................... 536.8 HyperTerminal ...................................................................................... 557. IFD2401 Tool ....................................................................... 567.1 Preparation for Measurements ............................................................. 567.2 Installation ............................................................................................ 567.3 Working with the IFD2401 Tool ............................................................ 587.3.1 Elements in the Main Window .............................................................. 587.3.2 Interface ............................................................................................... 587.3.3 CCD ..................................................................................................... 597.3.4 Displacement Measuring ...................................................................... 597.3.5 Thickness Measuring ............................................................................ 598. Warranty .............................................................................. 609. Decommissioning, Disposal ............................................... 6010. Troubleshooting .................................................................. 6111. Reset to Factory Setting..................................................... 6212. Maintenance ........................................................................ 62<strong>optoNCDT</strong>2401

Safety1. SafetyThe handling of the system assumes knowledge of the instruction manual.1.1 Symbols UsedThe following symbols are used in this instruction manual:DANGER! - imminent dangerWARNING!- possible dangerous situationIMPORTANT!- application tips and information1.2 Warnings• Avoid banging and knocking the sensor and the controller> Damage or destruction of the sensor and/or the controller• Power supply must be connected in accordance with the safety regulations forelectrical equipment> Damage or destruction of the controller• Protect the cables against damage> Failure of the measuring device• Protect the ends of the sensor cable (fibre optics) against pollution> Failure of the measuring device• Sensor and controller are matched together. Do not interchange> Loss of specified technical data1.3 Notes on CE IdentificationThe following applies to the Series 2401/2402 <strong>optoNCDT</strong> measurement system:EMC regulation 2004/108/ECProducts which carry the CE mark satisfy the requirements of the EMC regulation2004/108/EC "Electromagnetic Compatibility" and the European standards (EN) listedtherein.The EC declaration of conformity is kept available according to EC regulation, article10 by the authorities responsible atMICRO-EPSILON MESSTECHNIKGmbH & Co KGKönigbacher Straße 15D-94496 OrtenburgThe system is designed for use in industry and to satisfy the requirements ofthe standards• EN 61000-6-3: 2007• EN 61000-6-2: 2005The systems satisfy the requirements if they comply with the regulations described inthe operating manual for installation and operation.<strong>optoNCDT</strong>24015

Safety1.4 Proper Use• The series 2401/2402 measuring system is designed for use in industrial areas.• It is used- for measuring displacement, distance and thickness- for in-process quality control and dimensional testing• The measuring system may only be operated within the limits specified inthe technical data (chap. 2.8 and 2.9).• The system should only be used in such a way that in case of malfunctions orfailure personnel or machinery are not endangered.• Additional precautions for safety and damage prevention must be taken forsafety-related applications.1.5 Proper Environment• Protection class sensor:IP40 (Only with sensor cable connected)• Protection class controller: IP40• Lenses are excluded from protection class. Contamination of the lenses leadsto impairment or failure of the function.• Operating temperature: 10 ... 50 °C• Storage temperature: -30 ... 70 °CWICHTIG!The protection class islimited to water (nopenetrating liquids orsimilar).• Humidity:• Pressure:5 - 95 % (not condensing)atmospheric pressure• EMC: acc. EN 61 000-6-3: 2007EN 61 000-6-2: 2005<strong>optoNCDT</strong>24016

Functional Principle, Technical Data2. Functional Principle, Technical Data2.1 Short DescriptionThe <strong>optoNCDT</strong>2401/2402 consists of a sensor and controller which are connected witha fibre-optic sensor cable.The sensor is totally passive, since it incorporates no heat sources or moving parts,thus avoiding any thermal expansion which could affect the accuracy of the sensormeasuring process.Certain precautions are necessary when handling the fibre-optic sensor cable whichconnects the sensor to the controller, such as avoiding bending the fibre to a radius ofcurvature of less than 30 mm. Moreover, the operator must ensure that the ends of thefibre are at all times either connected to the sensor and the controller, or are fitted withtheir protective caps, in order to avoid any possibility of contaminating the tips of thefibre.The controller incorporates a LED light source and converts the light signals receivedfrom sensor, calculates distances via its on-board DSP processor, as well as providingdisplay and data transmission functions via the RS232 or USB link or via the 0 – 10 Vanalog output.ControllerDSPRS232/422 andUSBPolychromaticLight SourceSpectrometerDA-ConverterAnalogoutputFibre-optic ConnectorSensorFig. 2.1: Block diagram <strong>optoNCDT</strong> 2401/2402<strong>optoNCDT</strong>24017

Functional Principle, Technical Data2.2 Measurement PrinciplePolychromatic white light is focused onto the target surface by a multi-lens opticalsystem.The lenses are arranged such that the white light is dispersed into amonochromatic light by controlled chromatic deviation. A certain distance is assignedto each wavelength by a factory calibration. Only the wavelength which is exactlyfocussed on the target is used for the measurement. This light reflected from the targetsurface is passed via a confocal aperture to the receiver which detects and processesthe spectral changes.This unique measuring principle enables displacements and distances to be measuredwith high precision. Both diffuse and specular surfaces can be measured. With transparentmaterials a one sided thickness measurement can be accomplished along with thedistance measurement. Since the emitter and receiver are arranged in one axis,shadowing is avoided.IMPORTANT!Sensor and controller arematched together.Due to excellent resolution and small spot diameters surface structures can bemeasured. Note that measurement incertainly may occur, if the structure dimensionsare similar to the spot diameter, or if the acceptable tilt on a structure, e.g. turning rill,is exceeded.2.3 GlossarySMR Start of measuring range. Minimum distance between sensor front andmeasuring objectMMR MidrangeEMR End of measuring range (Start of measuring range + measuring range).Maximum distance between sensor front and measuring object.MR Measuring range10Signal50SMR MMR EMR DisplacementMeasuringRange (MR)SensorSMRMeasuringobjectFig. 2.2: Measuring range and controller output signal2.4 Typical Applications• Measure profiles or surface topographies, when the sensor is combined witha 3D measurement station,• Measure surface reflectivities – in which case the sensor behaves like amicroscope, but provides the advantage of greater depth of field,• Measure thickness (from a few tens of microns to several millimetres) oftransparent materials.<strong>optoNCDT</strong>24018

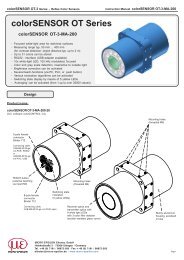

Functional Principle, Technical Data<strong>2.5</strong> SensorThe sensors are interchangeable: the same controller can store up to 20 differentcalibration tables corresponding to different sensors. The sensor is totally passive,since it incorporates no heat sources or moving parts, thus avoiding any thermalexpansion which could affect the accuracy of the measuring process.IMPORTANT!Protect the ends of thesensor cable (fibre optics)and the sensor lensagainst pollution.2.6 Control Elements ControllerOn / OffSwitchRS232/422interfaceUSB interfaceLEDsDigital I/O (encoder)SensorinputPower supplyExternallight sourceAnalog output,SynchronizationResetAnalog outputDark signalacquisitionFig. 2.3: Front view controllerLEDs on the controllerErrorRedOrangeOffLight source test failsData overflow error, data non-evaluableNo errorIntensityOffSingle frequency modeNo signalDouble frequency modeNo signalRedSignal saturatedSignal saturated for both frequenciesGreenSignal intensity is comfortableSignal intensity is comfortableOrangeSignal intensity is lowNo relevanceMeasureOffGreenOrangeNo measuring object or outside the measuring rangeMeasuring object in midrange(between 15 and 85 % FSO)Measuring object at the intermediate zone of the measuringrange (between 0 and 15 % FSO or 85 and 100 % FSO)<strong>optoNCDT</strong>24019

Functional Principle, Technical Data2.9 Technical Data IFS2402Model (standard)IFS2402-0.4IFS2402-1.5IFS2402/90-1.5IFS2402-4IFS2402/90-4IFS2402-10IFS2402/90-10Measuring rangeStart of measuringrangeSpot diameterLinearityResolution400 μm 1.5 mm 1.5 mm 3.5 mm <strong>2.5</strong> mm 6.5 mm 6.5 mmapprox. 1.5 mm 0.9 mm <strong>2.5</strong> mm 1) 1.9 mm <strong>2.5</strong> mm 1) <strong>2.5</strong> mm 3.5 mm 1)10 μm 20 μm 20 μm 20 μm 20 μm 100 μm 100 μm~0.3 μm 1.2 μm 1.2 μm ~3.0 μm 2.0 μm 13 μm 13 μm≤± 0.08 % FSO≤± 0.2 % FSO0.016 μm 0.06 μm 0.06 μm 0.14 μm 0.10 μm ≤0.7 μm ≤0.7 μm0.004 % FSO0.01 % FSOWeightMax. allowed angle of reflection indirect reflectionMeasuring rateAmbient lightLight sourceProtection class (sensor/controller)Operation temperatureStorage temperatureOutputSupplySensor cable (fiber optic cable)ControllerElectromagnetic compatibility (EMC)50 g± 8° ± 5° ± 5° ± 3° ± 3° ± 1.5° ± 1.5°selectable from 100 Hz up to 2000 Hz, optional 30 kHz30.000 lxLEDIP 40+10 up to +50 °C-30 °C up to 70 °C2x 0 - 10 V (15 bit) / RS 232 / RS 422 / USB 2.024 VDCintegral cable: standard 2 m option up to 50 mbending radius: 30 mm (static), 40 mm (dynamic)dimensions (W x H x D):168 x 138 x 111.5 mm (6.61 x 5.43 x 4.39 inches)functions: touch keys, trigger, synchronization, storage of up to 20 configurations (for sensorswith different ranges)according to EN 61000-6-3: 2007 and EN 61000-6-2: 2005FSO = Full Scale Output1) Start of measuring range (SMR) measured from sensor axisAll data based on constant ambient temperature during measurement against an'optical flat' glass target in direct reflection.<strong>optoNCDT</strong>240111

Delivery3. Delivery3.1 Supplied Items1 Sensor1 Sensor cable1 Controller1 Test log1 Instruction manualOnce unpacked, check immediately for completeness and transit damage. If damageis found or the shipment is incomplete, please contact the manufacturer or supplierimmediately.3.2 StorageStorage temperature:Relative humidit:-30 to +70 °C (-22 °F to +158 °F)5 to 95 % (non-condensing)4. Installation and AssemblyThe sensors of the series IFS<strong>240x</strong> are optical sensors, which are used to measure inμm-range. Be careful in mounting and installation!Connect the controller to a power supply (+24 VDC)External light source:If your sensor is equipped with an external light source, connect the light box to the“Ext. light source“ socket located on the controller front panel using the illuminatoroptical fiber.IMPORTANT!Handle optical sensors withcare.The light beam must bedirected perpendicular ontothe surface of the target toavoid measuring errors.SensorSensor cableController Wiring Power supplyAnalogevaluation deviceIndustrial PCUSB/RS232/RS422<strong>optoNCDT</strong>240112

Installation and Assembly4.1 Mounting and Dimensions of SensorsMounting area0.12 (.005)SMR 3.4 (.13)ø27 1 (1.06)ø20 (.79)28 (1.10)37.6 (1.48)218.7 (8.61)ø6 (.24)ø20.3 (.80)SMR 9.9 (.39)0.3 (.01)Mounting area8.3 (.33)ø27 1 (1.06)ø20 (.79)28 (1.10)37.6 (1.48)178.2 (7.02)ø11 (.43)ø23.6 (.80)1 (.04)SMR10.0 (.39)Mounting area8.3 (.33)ø27 1 (1.06)ø20 (.79)28 (1.10)37.6 (1.48)176.1 (6.93)ø11 (.43)ø23.6 (.80)3 (.12)SMR 16.3 (.64)8.3 (.33) Mounting areaLegend:mm(inches)ø27 1 (1.06)ø20 (.79)28 (1.10)37.6 (1.48)145.5 (5.73)ø11 (.43)ø23.6 (.80)IFS2401-0,12 IFS2401-0,4 IFS2401-1 IFS2401-3ø32 (1.26)ø27 (1.06)ø27 1 (1.06)ø20 (.79)ø27 1 (1.06)ø20 (.79)10 (.39)SMR 27.0 (1.06)Mounting area8.3 (.33)28 (1.10)37.6 (1.48)ø11 (.43)ø23.6 (.80)IFS2401-10145.5 (5.73)22 (.87)SMR 20.2 (.80)Mounting area28 (1.10)37.6 (1.48)IFS2401-25151.8 (5.98)ø8 (.31)191.5 (7.54)149.2 (5.87)105.7 (4.16)Mounting areaSMR 67.0 (2.64)ø50.0(1.97)+0.2-0.1ø28.3 (1.11)17<strong>2.5</strong> (6.79)59.7 (2.35)57.5 (2.26)Mounting areaSMR 213 (8.39)+0.2ø59-0.1(2.32)ø45 (1.77)Not to scaleSMR = Start of measuring range1) Tolerances of the mounting diameter: +0.2 / -0.1 mm8.5(.33)IFS2400-1024(.94)IFS2400-24<strong>optoNCDT</strong>240113

Installation and AssemblyContinuation dimensionaldrawings of the sensors197 (7.75)4x M4x10SMR63 (2.48) 167 (6.57)¯95 (3.74)¯62 (2.44)Lens ø1.8(.07)20(.78)¯45 (1.77)¯21(.82)15(.59)-0,15-0,1020(.78)30(1.18)+0,1540 +0,05(1.57)132.6 (5.22)34.4(1.35)IFS2400-20(01)Fiber-optic ø2.1(.08)Bend protectionand cord gripTitanium housing+0ø4(.16)TitaniumhousingSMR68 (2.68) 15(.59)Fiber-optic ¯2.1(.08)Bend protectionand cord grip-0.2SMR6.25 (.25)3 (.12) 6.251.94(.08)15(.59)69±0.1 (2.72±.004)¯4(.16)+0-0.2Mounting area<strong>2.5</strong>(0.1)73.25 (2.88)MRMR2 (.08)IFS2402-0,4/1,5/4/10IFS2402/90-1,5/4/10<strong>optoNCDT</strong>240114

Installation and Assembly4.1.1 Start of Measuring RangeFor each sensor a minimum distance to the measurement object must be maintained.SensorSMRMeasuring objectFig. 4.3: Start of measuring range (SMR), the smallest distance between sensor faceand measuring object.SensorFS 2401-0,12Start of measuring range3.4 (.13I )SensorFS 2402-0,4Start of measuring range1.5 (.06I )Legend:mm(inches)I FS 2401-0,49.9 (.39)I FS 2401-110.0 (.39)I FS 2401-316.3 (.64)I FS 2401-1027.0 (1.06)I FS 2400-1067.0 (2.64)I FS 2401-2520.2 (.80)I FS 2400-24213.0 (8.39)I FS 2402-1,50.9 (.04)I FS 2402/90-1,50.5 (.02)I FS 2402-41.9 (.07)I FS 2402/90-40.5 (.02)I FS 2402-10<strong>2.5</strong> (.10)I FS 2402/90-101.5 (.06)Not to scale4.1.2 Circumferential ClampingThe IFS <strong>240x</strong> sensors can be mounted with a mounting adapter. This type of sensormounting offers maximum reliability because the sensor is clamped around its cylindricalhousing. It is absolutely necessary in difficult installation environments, e.g. on machines,production plants etc.30 (1.18)23 (.91)20 (.79)10(.39)30 (1.18)13(.51)MA2400for sensors 2400/2401consisting of a mountingblock and a mountingring7(.28)M5x0.8 - 6H10(.39)Sensor IFS with mounting adapterMountingringDimensionADimensionBSensorAM A2400-27ø 27 (1.06)ø46(1.81)IFS 2401-xBM A2400-50ø 50 (1.97)ø66(2.60)IFS 2400-10M A2400-59ø 59 (2.32)ø75(2.95)IFS 2400-24Fig. 4.1a: Circumferential clamping with MA240022 (.87)22 (.87)3 (.12) 3 (.12) 1.5±0.14 (.16)2x M47.5(.30)11 (.43)Dia.4 H9Dia.ø3.43 (.12)12 (.47)5 (.20) 4.5 (.18)3x M4Dia. 84 (.16)4.5 (.18)15 (.59)MA2402for sensors 240220 (.79)Fig. 4.1b: Circumferential clamping with MA2402Tolerances 4 H9:+30 μm0<strong>optoNCDT</strong>240115

Installation and Assembly4.2 Sensor CableThe sensor and controller are connected with a fiber optic cable. Sensor cables with 50m (164 ft) length are possible. The user may not shorten or lengthen these fiber opticcables. Usually, a damaged cable can not be repaired.Avoid strictly- any soiling of the connectors,- mechanical load,- strong bendings of the cable.Minimum bending radius: 30 mm (singular)40 mm (regular).IMPORTANT!Remove the protective capon the sensor cable onlydirectly before the assemblyin the sensor. Thisavoids a contamination ofthe optical path.Mounting steps:- Loose the protective sleeve at the sensor.- Lead the sensor cable through the protective sleeve.- Remove the protective cap on the sensor cable andkeep it.- Lead the locking pin at the sensor cable into the cavityat the sensor.- Screw together sensor cable and sensor.- Screw the protective sleeve on the sensor.Then connect the fiber opticcable to the controller takingcare for correct orientation ofthe cable connector.To disconnect sensor cable:To remove the optical fiber from its socket first press on thelocking lever, then pull the connector.<strong>optoNCDT</strong>240116

Installation and Assembly4.3 Controller DimensionsWhen mounting the controller keep the touch keys, connectors and LEDs free forwatching!168 (6.61)162 (6.38)111.5 (4.39)opto NCDT 2401128 (5.04)138 (5.43)Fig. 4.4: Dimensioned drawing of the controller4.4 Electrical Connections4.4.1 Power SupplyConnect the controller with apower supply (24 VDC/1A). Usethe connector on the front side ofthe controller, see Fig. 4.5.If your controller is equipped withan external light source, connectthe light source to a mains socket.Fig. 4.5: Connectors for powersupplyDC24 V (+)GND4.4.2 RS232/RS422 InterfaceThe same connector is used for the RS232or RS422 interface. The configuration isdone through the 12-pole socket. ForRS422 operation connect pin "5V (+)" and"RS422", see Fig. 4.6. Do not connectpin "5V (+)" and "RS422" for RS232operation.RS 232RS 422USB6 5 4 3 2 1The RS232/RS422 connector is a RJ11type connector.Fig. 4.6: Controller with configured RS4225V (+)RS 422<strong>optoNCDT</strong>240117

Installation and AssemblyPin Name Description3 RX Receiver4 GND Ground5 TX TransceiverTab. 4.1: Pin assignment RS232Pin Name Description2 RX - Receiver - (differential input)3 RX + Receiver + (differential input)4 GND Ground5 TX + Transceiver + (differential output)6 TX - Transceiver - (differential output)Tab. 4.2: Pin assignment RS4224.4.3 USB InterfaceThe USB 2.0 connector, see Fig. 4.6, is a standard B-type connector. An USB 2.0 highspeedcompliant cable is required.USB 2.0 works with a transmission rate of circa 40 <strong>MB</strong>its/s.Go to www.micro-epsilon.com/link/opto/2401 and then “IFC Tool“ for an USB driver, seechap. 6.4.3 also.IMPORTANT!Interface with USB 2.0required4.4.4 Analog OutputThe two 0 ... 10V analog outputs areconnected to the 12-pole socket, see Fig.4.7.Output 1: Pin 5 and Pin 6 (left to right)Output 2: Pin 7 and Pin 8 (left to right)The “Zero” button may be used to set theanalog output to zero level.Fig. 4.7: Analog outputsZeroAN. OUT 1GNDAN. OUT 2GND4.4.5 SynchronizationInput and output for synchronization areconnected to the 12-pole socket, see Fig.4.8.Characteristics: TTL, 0 ... 5 VPin 1: Sync in (input synchronization)Pin 2: GND (ground)Pin 3: Sync out (output synchronization)Pin 4: GND (ground)Fig. 4.8: Connectors for synchronizationSYNC INGNDSYNC OUTGND<strong>optoNCDT</strong>240118

Installation and AssemblyThe "Sync out" signal is a TTL signal with measurement rate, which is permanentlyavailable and which does not require any special configuration. One "Sync out" pulse isemitted for each data point measured. Irrespective of the measuring rate, the "Syncout" goes high at the end of the exposure time.Exposure timeSync out10 μsFig. 4.9: Timing of the "Sync out" signal4.4.6 Digital I/O, EncoderUp to three encoders can be connectedto the 20-pole Digital I/O connector, seeFig. 4.10. Connector type: MDR.Fig. 4.10: Connector for encodersPin Description Colorencoder cable IFC2401/24311 Ground blue2 A+, Encoder 1 white3 B+, Encoder 1 brown4 A+, Encoder 2 green5 B+, Encoder 2 yellow6 A+, Encoder 3 grey7 B+, Encoder 3 pink20 +5 VDC redTab. 4.3: Pin assignment Digital I/OPin 8 up to Pin 19 are not connected on the Digital I/O.<strong>optoNCDT</strong>240119

Electrical signal is a single ended TTL level (+5 V) referenced toGND.Track A and B of a single encoder are connected toA+ and B+ with common GND1.Max pulse frequency <strong>2.5</strong> Mhz.Counting pulses:Track A and B allow the detection of direction,therefore the encoder pulse can increase or decrease the counter value.The encoder pulses are not counted as quadrature butas single pulse. The count value is increased or decreased with eachnew pulse of track A.In order to map the encoder value with a sensor reading,the counter is updated for a valid signal during 50 % of the exposure ofthe sensor.Max possible counter value before overflow:2^30 (1,073,741,824)The counter value can be preloaded with the$RCD command to 536,870,912.Data format:Each encoder reading can be selected as a transmitteddata package.In binary format a data package consists of 2 bytes as minimumseparated by a 0xFF delimiter (0xFF twice).A data package is always sent with the High Bytebefore the Low Byte.Since the counter value can reach 2^30, each encodervalue is transferred as 2 packages of a 15bit word. ( low word beforehigh word, see Chap.6.4.1)<strong>optoNCDT</strong>240120

Operation5. Operation5.1 Commissioning- Connect the controller with a power supply, siehe Chp. 4.4.1.- Connect sensor and controller with the sensor cable (fibre-optic cable).- Switch on the unit by operating the "Power" switch (see Fig. 2.3).Startup procedure lasts about 10 seconds. The LED indicators on the front side of thecontroller go on and off. At the end of the startup, the sensor starts measuring.If you use an external light source switch on the light source first, then the controller.5.2 Displacement MeasuringPosition the sensor facing to the target to be measured then slowly advance the sensor(or the target) to reach SMR which corresponds to the sensor being used. As soon asthe target enters the measuring range of the sensor the LED "Measure", see Fig. 2.3, onthe front panel of the controller indicates it.Important: The distance values increase as the measurement target moves away fromthe sensor.5.3 Thickness MeasurementIn the thickness measuring mode the sensor analyzes two signals reflected from the twosurfaces of a transparent measuring object. The controller calculates the intensity anddisplacement of surface 1 (front face, i.e. the nearest face), the displacement andintensity of surface 2 (rear face), and the thickness.Align the sensor perpendicularly to the object to be measured. Make sure that themeasuring object is in midrange (= SMR + 0.5 * MR). As soon as the first surface(displacement 1) is in the measuring range of the sensor the LED "Measure", see Fig.2.3, on the front panel of the controller indicates it.The LED gives no advice about theattendance of the second surface in the measurement range of the sensor.IMPORTANT!The light beam must bedirected perpendicular ontothe surface of the target toavoid measuring errors.Please refer to the technicaldata for the maximum tiltbetween sensor andmeasuring object.SMR MRFig. 5.1: One-sided thickness measurement against transparent materialsMinimum measurable thickness of material: 8 % of sensor measuring rangeMaximum measurable thickness of material: sensor measuring range x materialrefrective index of measurement materialFor the calculation of a correct thickness value the controller needs the refractive indexof the measuring object. To allow for the spectral variation of the refractive index in themeasuring range the controller features refractive index files.The file contains the changingof the refrective index of a known measurement material inside the measuringrange.D 1D 2ThicknessSMR =Start of measuring range<strong>MB</strong> =Measuring rangeD 1/2 =Displacement 1/2IMPORTANT!The controller uses the twostrongest peaks forthickness calculation.If one surface is outside the measuring range the controller produces only a signal forthe displacement, intensity and barycenter. This can be although too, if a signal islocated below the threshold value. In the default setting (see chap.6.6.24), the controllertransmitts for the displacement 1 and the intensity 1 non-zero values.The other data items including thickness are set to zero.<strong>optoNCDT</strong>240121

Operation5.4 Acquiring the Dark SignalThe dark signal of the sensor represents an intrinsic offset level generated by parasiticreflections inside the controller, which must be taken into account for the controller tobe able to operate correctly. The level of the dark signal depends on the sampling rate.The dark signal should be acquired at all sampling rates in order to be able to subtractit while the controller is measuring. A dark signal acquisition is performed duringadjustment by the manufacturer, but must be repeated at regular intervals.Procedure:- Remove the measuring object from the measuring range or cover the sensor with apiece of paper.- Press the “Dark” button on the front panel of the controller, see Fig. 2.3.The LED's "Error", "Intensity" and "Measure" start flashing. This operation lasts a fewseconds. During this time the sensor records the dark signal. When finished, the 3 LEDson the front panel of the controller blink on and off simultaneously and show the resultof the dark signal measurement.Green: Well dark signalOrange: Dark signal level is too high at low measuring rates, but it is still possible tomeasure at higher measuring ratesRed: Dark signal level is too high at all measuring rates.- Remove the piece of paper. The sensor can be used in the normal way.High dark signalIf the color of the blinking LED is orange or red, on completion of the dark signalacquisition sequence this means that the acquired dark signal is too high. This isgenerally caused by one of the following reasons:- Light was not completely blanked off during the entire operation. In this case, applya piece of paper over the sensor and repeat the operation.- The light level of the used external light source is too high for working with lowmeasuring rates. In this case you may adjust the light source light level.IMPORTANT!For each measuring ratethe dark signal must bemeasured for the first time.IMPORTANT!In order to perform a darksignal acquisition, it isessential that there is nothingwithin the measuringrange or even better toblank off the light beam byapplying a piece of paperover the sensor.IMPORTANT!The controller needs awarm-up time of at least 15min. before acquiring thedark signal.5.5 Analog OutputThe controller features two analog outputs (0 ... 10 V) located on the 12-pole socket,see Fig. 4.7. Both outputs are fully configurable by the operator (see Chap. 6.6.4). Thevalues were coded with 15 bits internally and output via a DA- converter.The outputs feature selectively a displacement/thickness measurement or the intensitysignal.Use the "Zero" button, see Fig. 4.7, to reset the analog output to 0 V. Move themeasuring object to the start of measuring range and press the "Zero" button to stopthe relative measurement.Notice:Depending on the measuring mode, see Chap. 6.6.3, the data are output on theanalog outputs.<strong>optoNCDT</strong>240122

Operation5.6 Adjustment of the LED BrightnessIf your sensor is equipped with an external light source, please skip this chapter.The LED brightness may be adjusted by "$LED" command, see Chap. 6.6.8. Place apiece of white paper in front of the sensor and observe the spot of light emitted bythe sensor.Move the paper forward and backward to find the focus plane where the spotbrightness is maximal. Use the "$LED0" command to disappear the light spot.The controller features an operation mode (“auto adaptive LED” mode) in which theLED brightness is automatically adjusted to the signal level. This mode is described inChap. 6.6.17.5.7 Adjustment of the Measuring RateMove the measuring object in midrange, see Fig. 2.2. Adjust the measuring rate so thatthe signal intensity will be strong but not saturate. For it track the "Intensity" LED, seeFig. 2.3. Single frequency mode Double frequency modeOff No signalNo signalRed Signal saturatedSignal saturated for both frequenciesGreen Well signalWell signalOrange Signal intensity is low No relevanceIf the "Intensity" LED is red, increase the measuring rate.If the "Intensity" LED is orange, reduce the measuring rate.If the signal is saturated at the lowest rate, decrease the LED brightness.Notice: Always set the measuring rate and the LED brightness so that the “Intensity”LED is green. When the signal is low (orange “Intensity” LED) or saturated (red“Intensity” LED) the sensor still measures, but measurement quality may be deteriorated.See Chap. 6.6.2 for detailed informations on the measuring rate adjustment.5.8 Light IntensityThe controller measures periodically the quantity of light reflected by the measuringobject. The result is a percentual value called intensity. Its value depends on severalparameters:- Measuring rate controller- The local slope on the measuring object (angle between the optical axis and thenormal to the surface at the measured point)- The reflectivity of the sample in subject to the wavelength 0- The level of light emission of the LED- The brightness of the LED in subject to the wavelength 0- The response of the photodetector in subject to the wavelength 0In standard operation mode (“single frequency”) the exposure time is constant so thatthe observed intensity variations are directly related to the intensity reflected from thesample. In the “double frequency” mode both factors vary at the same time so that theinterpretation of the Intensity data may be difficult. For this reason a new parameter, the“normalized intensity” is computed. This is an intensity computed for a fixed frequency(the high frequency), so that it is directly related to the sample characteristics. See thechapters 5.12 and 6.28 also.The detected wavelength varies within the measurement range. Thus the intensity0measured at a given point on the measuring object varies when the measuring object ismoved within the measurement range. For each point in the measuring range, the valueof the intensity of the CMOS line varies between 0 % and 100 %.<strong>optoNCDT</strong>240123

OperationBeyond that, the controller is saturated. Saturation is indicated by the "Intensity" LED(red, see Fig. 2.3). The saturation refers to the original signal of the CCD line.In the “Double Frequency” mode the “Intensity” LED indicator on the front panel iscorrelated to the high frequency.Summary- Measurement quality is good when the “Intensity“ LED is green.- If the LED color is red, increase the measuring rate or lower the LED brightness.- If the LED color is orange, lower the measuring rate or increase the LED brightness.5.9 Synchronized Controller and Encoder DataSynchronization signals and trigger modes are not required for synchronizing thecontroller with digital encoder readings: This task is performed automatically by thecontroller.All you need to do is• Connect the encoders to the “Digital I/O" connector on the front panel as describedin Chap. 4.4.6• Reset each encoder counter by positioning it at the origin point of the motion rangeand sending the “Reset Encoder Counter” (“$RCD”) command, see Chap. 6.6.22.• Configure the controller to transmit encoder data as well as data measured by thecontroller, see Chap. 6.4.5.10 TriggeringThe <strong>optoNCDT</strong>2401 measurement output is controllable through an external triggersignal (electrical signal in conjunction with a command). Thereby the anaog and digitaloutput is affected. Triggering does not influence the preset measuring rate. Thesynchronization input, see Fig. 4.8, is used for external triggering. By default, all triggermodes are disabled and the controller transmits data without interruption immediatelyafter startup.5.10.1 Trigger ModesThe measurement output in trigger mode can be controlled with the flange as well asthe level of the trigger signal. Implemented trigger conditions:- Rising edge,- Falling edge,- High level or- Low level.Set the trigger conditions (edge or level) with the "$TRF" command (see Chap. 6.6.12).5.10.2 Trigger InputThe "Sync in" input, see Fig. 4.8, is used for triggering with an external signal (TTLcharacteristics). The duration of the "Sync in" pulses should be at least 1.2 μs.<strong>optoNCDT</strong>240124

Operation5.10.3 Start TriggerThe simplest trigger mode is the “Start” trigger. It is enabled by sending the “$TRG”command. On receipt of the command, the controlller stands by for the trigger signalat the "Sync in“ input, see Fig. 5.2. Once the first "Sync in“ pulse is received, thecontroller exits the “Start” trigger mode and resumes to normal operation. Additional"Sync in“ pulses are simply ignored. If the trigger signal is not sent, the function can beexit with the sign "$". The controller resumes to normal operation.$TRGSyncAnalog outputDigital outputFig. 5.2: Time schedule of the „Start trigger" function5.10.4 Level TriggerIn the “Start/Stop on State” trigger mode, data transmission starts and stops accordingto the state of the "Sync in“ signal. Use the "$TRF" command to set the active state.Use the "$CTN" command to stop this trigger mode.$TRNSyncAnalog outputDigital outputFig. 5.3: Time schedule of the level triggering5.10.5 Edge TriggerThe “Start/Stop on Edge” trigger mode is similar to the “Start/Stop on State”, with onedifference: data transmission starts and stops by successive "Sync in“ pulses and notby changes in signal state. Use the "$TRF" command to set the active edge. Use the"$TRS0" command to stop this trigger mode.$TRSSyncAnalog outputDigital outputFig. 5.4: Time schedule of the edge triggering<strong>optoNCDT</strong>240125

Operation5.10.6 Latch TriggerIf the “Sync in” signal is received, the controller transmits the data of a preset numberof measured points and stops immediately. If the controller gets the "$TRE0" command,the controller exits the “Latch” trigger mode and resumes to normal operation.Use the "$CTN" command to stop this trigger mode.$TREnSyncAnalog outputDigital outputFig. 5.5: Time schedule of the latch triggering5.10.7 Software TriggerThe “STR” command may be used as a software trigger in the “TRE” and “TRS” triggermodes. Obviously, the software trigger does not have the temporal precision of thehardware trigger.Note: The command "STR" is not poosible in the mode "TRN". Use the "TRS" modeinstead.5.10.8 Maximum Trigger FrequencyThe maximum trigger frequency, so the frequency of "SYNC IN"- pulses, is limited bythe time response of controller. The controller needs several cycles for measuring andconverting.1. Exposing: Gathering of arrived light ( Measuring)2. Reading: Conversion and storing of light signals as digital values3. Computationf max= Maximum trigger frequency4. Data transmissionM R= Measuring rateLevel and Edge Trigger= Internal process timeExampleMeasuring rate = 2000 Hz, T = 0.2 ms, A = 1 (without averaging);E= 1/(2/2000 + 0.0002)s = 833.3 HzfmaxAT EAN(Computation, datatransmission)= Averaging rate= Number of data packetsLatch TriggerAExampleMeasuring rate = 2000 Hz, T = 0.2 ms, N = 5, A = 2;E= 1/((1 + 5 * 2)/2000 + 0.0002)s = 175.4 Hzfmax<strong>optoNCDT</strong>240126

Operation5.11 Response TimeExposureSync OutEncoder readingReadingComputationAnalog outputi-1T EXPi-1 i i+1 i+2i-2RS232, data transmis-ssion,see $SODi i+1 i+2 i+3T ROT RSi-2i i+1T SOi-1 i i+1i-1T PRii+2i+1i-2 i-1 i i+1i = CounterT EXP= 1/ff = Measuring ratee

OperationExposureSync Outencoder readingReadingComputationT RO(i)f1 (i)f2 (i+1)f1 (i+1)f2 (i+2)f1 (i+2)f2T EXP2T EXP1(i-1)(i)T SO(i-1)f2 (i)f1 (i)f2 (i+1)f1 (i+1)f2 (i+2)f1 (i+2)f2(i-1)f1T PR(i+1)(i+2)(i-1)f2 (i)f1 (i)f2 (i+1)f1 (i+1)f2 (i+2)f1Analog output(i-2)(i-1)(i)(i+1)RS232, data transmission,see $SOD(i-1) (i) (i+1)T RSFig. 5.9: Continuous acquisition, no averaging, double frequencyT RST RSExposureSync OutEncoder readingReadingComputation(i)f1,1 (i)f2,1 (i)f1,2 (i)f2,2 (i+1)f1,2 (i+1)f2,2 (i+1)f1,2 (i+1)f2,2T EXP1 T EXP2(i-1)(i)(i+1)T SO(i-1)f2,2 (i)f1,1 (i)f2,1 (i)f1,2 (i)f2,2 (i+1)f1,1 (i+1)f2,1 (i+1)f1,2T RO(i-1)f1,2 (i-1)f2,2 (i)f1,1 (i)f2,1 (i)f1,2 (i)f2,2 (i+1)f1,1 (i+1)f2,1 (i+1)f1,2T PRAnalog output(i-2)(i-1)(i)RS232, data transmission,see $SOD(i-1)T RS(i)T RSFig. 5.10: Continuous acquisition, averaging = 2, double frequency5.12 Double FrequencyIn this mode the controller adapts itself in real time to the intensity of the signalreceived from the sample. This mode is useful for samples characterized by strong,rapid point-to-point reflectivity variations, such as samples composed of highlyreflective metallic motifs deposited on glass. For such samples it is difficult to select ameasuring rate that is well suited to all measured points, as a rate which gives sufficientintensity from the glass surface will generate saturation on the metallic surface. Anotherexample when the “double frequency” mode is useful is that of samples comprisingdeep holes or sharp slope variations.GlassMetalFig. 5.11: Intensity distributionIntensityIMPORTANT!With the operation modes- Auto-adaptive Dark Signal,and- Auto-adaptive Light SourceBrightnessthe operation mode doublefrequency is not authorized.Only the query "$DFA? isauthorized.<strong>optoNCDT</strong>240128

OperationIn the “double frequency” mode the sensor switches permanently between 2frequencies- low frequency f1 (long exposure time) and- high frequency f2 (short exposure time).It computes the data independently for each frequency, and then selects, for eachmeasured point, the optimal frequency.The criteria for selecting the optimal frequency are resumed in the following table:Case Low frequency High frequency Selected frequency1 Saturated Saturated high2 Saturated Correct measurement high3 Saturated No measurement low4 Correct measurement Correct measurement low5 Correct measurement No measurement low6 No measurement No measurement highExample: Suppose that f L= 100 Hz (low frequency) and f H= 500 Hz (high frequency).On metallic surfaces the signal at 100 Hz is saturated and the signal at 500 Hz iscorrect. So the controller selects the high frequency (500 Hz). On glass substratemeasurements with 100 Hz are correct but with 500 Hz the signal is too low (nomeasurement). The controller selects the low frequency. Note that the high frequency islimited to 1850 Hz.Each couple of acquisitions (one with long exposure and the other with short exposure)is called “a cycle”. The sensor delivers one “synchro out” signal per cycle. Measureddata are transmitted once per cycle on the digital outputs and updated once per cycleon the analog output.The cycle rate f cis given by the relation: 1/f c= 1/f1 + 1/f2IntensityThe intensity measured by the sensor depends, on one hand, on the characteristics ofthe sample like reflectivity, slope (see Chap. 5.8) and on the other, on the exposuretime. In standard operation mode (“single frequency”) the exposure time is constant sothat the observed intensity variations are directly related to the intensity of reflectedfrom the sample. In the “double frequency” mode both factors vary at the same time sothat the interpretation of the Intensity data may be difficult. For this reason a newparameter, the “normalized intensity” is computed. This is an intensity computedfor a fixed frequency (the high frequency), so that it is directly related to the samplecharacteristics.Arrangement:- ILF is the intensity measured for the low frequency- IHF is the intensity measured for the high frequencyThe following table shows the difference between the “raw” (standard) intensity and the“normalized” intensity.Available intensities in « Double Frequency » modeSelected Frequency « Raw » Intensity « Normalized » IntensityLow (f1) ILF ILF * f1/f2High (f2) IHF IHFBy default, the transmitted Intensity data is the “Normalized” one. This option may bemodified using the “DFI” command.<strong>optoNCDT</strong>240129

Compatibility with other commands/modesThis mode is compatible with most other commands and modes, and in particular with- triggering,- averaging and- manual setting of the LED brightness.It is not compatible with- auto-adaptive light source brightness, Chap. 6.6.17- auto-adaptive dark signal, Chap. 6.6.16- spectral averaging, Chap. 6.6.10- fast dark signal, Chap. 6.6.6.CommandResponse when the controller is in “double frequency”modeAAL, ADK, FDK, AVS Not authorizedDRKAuthorizedTRG, TRE, TRN, TRS, TRF AuthorizedAVR, HLVAuthorizedLEDAuthorizedAuthorized. Variables can be modified during doubleFRQ, TEX, SRAfrequency mode. The controller operates with the newvalues, if the controller quits the double frequencymode.6. Serial InterfaceThe controller features two types of serial interfaces for controlling the controller andmeasurement output. The following chapter describes this possibilities for the RS232/RS422. The command language, the data transmission format are identical for the twotypes of serial interfaces.When switched on, the controller transmits data according to the last configuration. Onreceipt of character "$" the controller stops sending data and waits for the remainingcommand characters. Each received character (including $) is echoed back. If thecommand includes parameters, the final "CR" character is echoed as well. When thecontroller receives a complete command and has completed the correspondingactions, it returns the string „ready CRLF“ and switches back to normal operation.Received command is illegal:response is echo+ “invalid code“Received command is legal put parameter values are illegal:response is echo + “not valid“.Command and its parameters are legal but execution has failed:response is echo +””error“.The "HyperTerminal ® " program contains a user-friendly surface for serial communicationwith the controller, see Chap. 6.8.<strong>optoNCDT</strong>240130

Serial Interface6.1 Data FormatController and PC need the same data transmission settings.Transmission rate: As high as possible 1Data format: 8 data bits, no parity, one stop bitThe "Baud rate” command sets the baud rate of the controller.Baud rateFunction Set/request the controller baud rateFormat $BAUn or $BAU?Parameter n = 9600, 19200, 38400, 57600, 115200, 230400 or 4608001) The controller offersbaud rates up to 460.8kBaud. Note that standardPC COM ports (COM1,COM2) are limited to 115.2kBaud.Note that this command has no effect on the PC baud rate that should be setindependently.Limitation of the baud rateThe maximum number of data values inside a frame transmissible simultaneously permeasured point via the serial interface depends on the controller measuring rate and onthe interface baud rate. As far as possible, the highest baud rate available should beused. The tables below specify the data value transmission capability according to theinterface baud rate and the measuring rate.Measuring rateBaud rate9600 19200 57600 115200 230400 460800100 Hz 1 3 9 16 16 16200 Hz _ 1 4 9 16 16500 Hz _ _ 1 3 7 151000 Hz _ _ _ 1 3 72000 Hz _ _ _ _ 1 3Tab. 6.1: Max. number of transmissible data values in ASCII formatMeasuring rateBaud rate9600 19200 57600 115200 230400 460800100 Hz 3 8 16 16 16 16200 Hz 1 3 13 16 16 16500 Hz _ _ 4 10 16 161000 Hz _ _ 1 4 10 162000 Hz _ _ _ 1 4 10Tab. 6.2: Max. number of transmissible data values in binary formatExample: If you want to transmit displacement and intensity (2 data values permeasured point) at 1000 Hz, use the ASCII mode with a baud rate of at least 230400 oruse the binary mode with a baud rate of at least 115200.In case the number of transmitted packets specified by the "SOD" command exceedsthe limit, the “Error” led turns to orange and the “data overflow” bit in the “State” datais set.<strong>optoNCDT</strong>240131

Serial Interface6.2 Command Syntax- Every command transmitted to the sensor must start by a "$" character.- Every command must end with a "" (carriage return, line feed) sequence.- Command name consists of 3 capital case letters.- When a command has one or more parameters, the parameters come immediatelyafter the command name.- There should be no comma between the name of the command and the firstparameter.- When a command includes several parameters, the parameters are separated bycommas.- For a query the parameter is replaced by “?”6.3 Data Transmission FormatsThe sensor provides the ASCII format and the binary format for data transmission.6.3.1 ASCIIASCIIFunction Configure the controller to ASCII transmission formatFormat $ASCResponse NoneIn ASCII format, 5 characters (digits) are transmitted for each data value. The datavalues inside a frame are separated by commas, and the successive frames areseparated by sequence.Example:Measuring mode: ThicknessData selected: Thickness, Displacement 1, Displacement 2The data values inside a frame are identified as A, B, C etc. Frame separation with.The table below shows the first 36 characters transmitted.x x x x x , x x x x x ,Thickness - A Data value separation Displacement 1 - A Data value separation1 2 3 4 5 6 7 8 9 10 11 12x x x x x LF CR x x x x xDisplacement 2 - A Frame separation Thickness - B13 14 15 16 17 18 19 20 21 22 23 24X = digit (0 ... 9), x x x x x , x x x x xData value separation Displacement 1 - B Data value separation Displacement 2 - B25 26 27 28 29 30 31 32 33 34 35 36Tab. 6.3: String of an ASCII data transmission<strong>optoNCDT</strong>240132

Serial Interface6.3.2 BinaryBinaryFunction Configure the controller to binary transmission formatFormat $BINResponse NoneEach data value (16 bit data item) transmitted by the controller is coded with twosuccessive bytes (first H-Byte, then L-Byte). Successive frames are separated by twoconsecutive bytes .The data item is comprised of two consecutive bytes (H-byte/L-byte).The byte isadditionally provided with a "0" as MSB.Start 1 7 Bit H-Byte Stop Start 0 7 Bit L-Byte StopConversion of the binary data format:For conversion purposes the high and low bytes must be identified, The MSB in theH-Byte deleted and the remaining 15 bits compiled into 15 bit data item.Reception:H-Byte 0 D14 D13 D12 D11 D10 D9 D8L-Byte D7 D6 D5 D4 D3 D2 D1 D0Result of conversion:D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0Example:Measuring mode: DisplacementSelected data: Displacement, IntensityThe data values inside a frame are labeled with A, B etc.The table below shows the first 12 bytes transmitted.H-Byte L-Byte H-Byte L-Byte 0xFF 0xFF H-Byte L-Byte H-Byte L-Byte 0xFF 0xFFDisplacement - A Intensity - A Frame separation Displacement - B Intensity -B Frame separation1 2 3 4 5 6 7 8 9 10 11 12Tab. 6.4a: String of a binary data transmissionNote: The MSB for a data item can not be 0xFF, because all the data are encodedeither with 12 bits or with 15 bits. Thus if three successive 0xFF bytes appear in thedata flow, the first 0xFF is necessarily the LSB for a data value and the next two 0xFFconstitute the frame separator.Example:Measuring mode: DisplacementSelected data: Displacement, Intensity, Encoder 2The data values inside a frame are labeled with A, B etc.The table below shows the first 12 bytes transmitted.H-Byte L-Byte H-Byte L-Byte H-Byte L-Byte H-Byte L-Byte 0xFF 0xFF H-Byte L-ByteEncoder 2 Encoder 2FrameDisplacement - A Intensity - ADisplacement - Blower 15 bit higher 15 bit separation1 2 3 4 5 6 7 8 9 10 11 12Tab. 6.4b: String of a binary data transmission<strong>optoNCDT</strong>240133

Serial Interface6.4 Transmitted Data6.4.1 Available DataThe controller measures several data values in parallel at each measured point of themeasuring object. The table below shows the available data values for both measuringmodes.The controller combines the maximum of 16 different data values to a measured pointin a frame.Data value index Displacement Thickness measurement0 Displacement Thickness1 not used Displacement 1st surface2 Current LED brightness Displacement 2nd surface3 Intensity Current LED brightness4 not used Intensity 1st surface5 not used Intensity 2nd surface6 Barycenter Barycenter 1st surface7 not used Barycenter 2nd surface8 State State9 Counter Counter10 Encoder 1 = lower 15 bit Encoder 1 LSB11 Encoder 1 = higher 15 bit Encoder 1 MSB12 Encoder 2 = lower 15 bit Encoder 2 LSB13 Encoder 2 = higher 15 bit Encoder 2 MSB14 Encoder 3 = lower 15 bit Encoder 3 LSB15 Encoder 3 = higher 15 bit Encoder 3 MSBTab. 6.5: Summary of all available data values6.4.2 Meaning of the DataMeasuring mode displacement:- Displacement is the distance between measuring object and sensor less SMR.- Intensity is the signal level as percentage of the dynamic range of the controller.- Barycenter is the position of the spectral peak on the internal photodetector.Measuring mode thickness measurement:- There are two displacement values, two intensity data and two barycenter data forthe two surfaces of the measuring object and one thickness value. Surface one is theone closer to the sensor.SMRD = DisplacementSMR = Start of measuring rangeMR = Measuring rangeDMRThe encoder counter data allows reading of digital encoder synchronously with thecontroller data.The counter, auto-adaptive mode data and state data are described in Chap. 6.5.4.<strong>optoNCDT</strong>240134

Serial Interface6.4.3 Data SelectionThe "Set Digital Output Data" command enables the user to determine the content of aframe to be transmitted.Set Digital Output DataFunction Set/request the data to be transmitted$SODn0,n1,n2,n3,n4,n5,n6,n7,n8,n9,n10,n11,n12,n13,n14,n15Formator $SOD?Ni = 0 (Data are not transmitted)Ni = 1 (Data are transmitted on the RS232/422 interface)ResponseNi = 9 (Data are transmitted on the USB interface)i = 0 … 15 (Index data item)Note: The last null values may be omitted for convenience, e.g.$SOD1,0,0,1,0,0,0,0,0,0,0,0,0,0,0 may be replaced by $SOD1,0,0,1.IMPORTANT!On the RS232/422 interfacethe transmission capacitydepends on the measuringrate and the data format.Before sending the $SODcommand, check that thenumber of data itemsselected is compatible withthese parameters in orderto avoid data overflow.Examples:- In the displacement measuring mode the displacement value and the intensity (seeTab. 6.5) should be transmitted for each measured point via the RS232/422 interface.The following command must be sent to the controller:$SOD1,0,0,1,0,0,0,0,0,0,0,0,0,0,0 (or $SOD1,0,0,1).- In the displacement measuring mode the displacement value (see Tab. 6.5) shouldbe transmitted for each measured point via the USB interface. The followingcommand must be sent to the controller: $SOD9,0,0,0,0,0,0,0,0,0,0,0,0,0,0 (or$SOD9).<strong>optoNCDT</strong>240135

Serial Interface6.5 Data Decoding6.5.1 Displacement Measuring ModeTo obtain the displacement in μm, use the following relationship:Displacement (μm) = (Transmitted value : 32767) x MR (μm)Note: The displacement value is encoded with 15 bits (0 ... 32767).6.5.2 Thickness Measuring ModeTo obtain the displacement and thickness in μm, use the following relationships:Thickness (μm) = (Transmitted value : 32767) x MR (μm) x KThe transmitted value is already set off against the refractive index. You may change therefractive index with the command $SRI. In order to optimise the output resolution, thedisplacement data scale in the thickness measuring mode is different than that in thedisplacement measuring mode. The reason for this difference is that the effectivemeasuring range in thickness measuring mode ismultiplied by the refractive index.Note: The thickness value and the displacement values are encoded with 15 bits (0 ...32767).IMPORTANT!Default setting for the scalefactor K is 2.0. Use the$CEE command to changethis value.K ≤ 5.Displacement 1st surface (μm) = (Transmitted value : 32767) x MR (μm) x KDisplacement 2nd surface (μm) = (Transmitted value : 32767) x MRh (μm) x KThe K parameter may be modified. This is required in the rare situation when therefractive index of the sample to be measured is greater than 2.0.<strong>optoNCDT</strong>240136

Serial Interface6.5.3 Decoding the Barycenter ValuesTo obtain the position of the barycenter in pixels, use the following relationship:Barycenter = (Transmitted value : BS) + BOThe Position of the spectral peak on the photodetector signal is encoded with 15 bits(0 ... 32767).BS = Barycenter scaleBO = OffsetDefault setting:BS = 32 ($CEB),BO = 520 ($CRB)6.5.4 Decoding the State DataThe state data is an aggregate of various flags.Bit Flag Bit Flag0 HLV barycenter 2nd surface 8 Selected frequency 11 HLV barycenter 1st surface 9 Error light source test2 HLV displacement 2nd surface 10 Data overflow RS232/422 transmission3 HLV displacement 1st surface 114 HLV thickness 125 HLV Intensity 2nd surface 136 HLV Intensity 1st surface 147 Saturation flag 15 0Tab. 6.6: State informations from the controllerHLV = Hold last valueThe HLV bits are set if the corresponding data are not measured but hold as last validvalue in “Hold last value” mode.The saturation flag indicates a signal saturation and refers to the original signal of theCCD sequence. It is set at the same time when the “Intensity” LED color turns to red.1) The “selected frequency” flag is significant on double-frequency mode only.0 indicates that the high frequency was selected,1 indicates that the low frequency was selected.Note: This bit replaces the “Trigger Flip-flop” bit of previous versions.The “light source test failure” flag indicates that the light source should be replaced.Note that this bit is set at the same time as the “Error” LED turns red. If the light sourcetest is disabled, this bit is always zero.The “data overflow” flag indicates that the number of transmitted data directed to theRS232/RS422 port exceeds the maximum number of transmissible data. This bit is setat the same time as the “Error” LED turns orange.Counter DataThe counter data is an aid for software developers who wish to check that there is nodata loss in their acquisition software. The 15 bit counter is reset each time a triggercommand (TRE, TRN, TRS or TRG) is sent.Auto-Adaptive ModeIn the “auto-adaptive rate” mode this data contain the instantaneous LED brightnesscoded with 8 bits (0 ... 255). This may be useful for analyzing the relative intensity ofthe signal returned from the measuring object as in this mode the intensity data ispractically constant.Relative Intensity = Intensity : nn = Auto adaptive mode data value<strong>optoNCDT</strong>240137

Serial Interface6.6 Commands6.6.1 Sensor SelectionThe controller may accept up to 20 calibration tables corresponding to 20 differentsensors. Before a measurement is performed the controller needs the information whichsensor is connected.FunctionFormatParameter/Value returnedExampleSelect confocal sensorSet/request the sensor type$SENn or $SEN?n = calibration index, corresponds to a two digit integer between 0and 19$SEN05This command is used to obtain the measurement range of the sensor currentlyselected.ScaleFunction Request the currently used measuring rangeFormat $SCAValue returned Measuring range in microns6.6.2 Measuring RateThe measuring rate of the controller may be managed by two methods.- Selection of a preset measuring rate from a list (“Preset Rate”)- Definition of a specific measuring rate (“Free rate” or “Exposure Time”)The first method, which is simple and easy to use, is recommended for mostapplications. In this method, the sampling rate is defined by its index. The secondmethod provides greater flexibility in the choice of the measuring rate:The “free” measuring rate can be specified in Hz, or the exposure time (inverse of thefree rate) can be specified in μs. This chapter describes the different methods, followedby some examples.Selecting a preset Measuring RateThe controller provides 5 preset sampling rates.Index Measuring rate (Hz) Exposure time (μs)00 free rate free exposure time01 100 1000002 200 500003 400 250004 1000 100005 2000 500Tab. 6.7: Measuring rates and related exposure times in the controllerFunctionFormatParameter/Value returnedPreset rateSet/request the index of a preset measuring rate$SRAn or $SRA?n = measuring rate, corresponds to a two digit integer between 0and 5Note: The "$SRA00" command selects the free measuring rate. The free rate may be setby the “Free rate“ command or by the “Exposure time“ command described below.Free Measuring RateThe ‘Free Rate’ command is used to set the controller measuring rate to a free valuebetween 100 Hz and 2000 Hz, or to request the value of the free rate. The index of thefree rate in the list of preset rates is 00 (see Tab. 6.7). The last value set to the freerate or the exposure time may be later activated by sending “$SRA0”.<strong>optoNCDT</strong>240138

Serial InterfaceNote: The controller may modify slightly the specified value of the free rate in order tocomply with its internal constraints (the exposure time in μs should be an integer) andreturns the real value immediately after the echo.Free rateFunction Set/request the value in Hz attributed to the free rateFormat $FRQn or $FRQ?Parameter n = value of the free sampling rate, in Hz (5 digit integer between100 and 2000Value returned m ( 5 digit integer between 100 and 2000) is the closest ratevalue m>=n such that the exposure time in μs is an integerExample Command: $FRQ1995Response: $FRQ1995 1996Explication: 1996 Hz corresponds to an integer exposure time (501μs).Exposure TimeThe ‘Exposure time’ command is used to set/request the free exposure time in thecontroller. Specify any integer exposure time between 00500 and 10000 μs.The free measuring rate is set to 1 000 000/exposure time (μs).FunctionFormatParameterExposure timeSet/request the exposure time$TEXn or $TEX?n = value of the free exposure time, in μs (5 digit integer between00500 and 10000)ExamplesThe following table contains the commands “Preset Rate”, “Free Rate” and “ExposureTime” alternately used and interrogates the controller to view the results of eachcommand.Command Comment Sensor response$SRA04 Sets the preset measuring rate index to 4 (1000 Hz) $SRA04 ready$SRA? Interrogates the controller for the index of the current $SRA?04 readypreset measuring rate$FRQ? Interrogates the measuring rate in Hz $FRQ?01000 ready$TEX? Interrogates the exposure time in µs$TEX?010001000 = 1 000 000 / 1000$TEX00530 Sets the exposure time to 530 µs$TEX00530 00530 ready(and sets the measuring rate index to 0)$FRQ? Interrogates the measuring rate in Hz$FRQ?18861886 = 1 000 000 / 530$FRA? Interrogates the current measuring rate index $FRA?00 ready$FRQ1995 Sets the free measuring rate to 1995 Hz$FRQ1995 1996The controller selects a close value of 1996 Hz$TEX? Interrogates the exposure time in µs$TEX?00501501 = 1 000 000 / 1996$TEX00120 Attempts to set the exposure time to a non-authorized value $TEX120 not valid ready$SRA01 Sets the preset measuring rate index to 1 (100 Hz) $SRA01 readyThis ends the “free rate” mode$FRQ? Interrogates the measuring rate in Hz $FRQ?00100 ready$SRA00 Sets the measuring rate index to 0 (= free measuring rate) $SRA00 ready$FRQ? Interrogates the measuring rate in Hz, 1996 Hz is the lastvalue attributed to the free measuring rate$FRQ?1996Tab. 6.8: Instruction sequence to the controller Befehlsfolge an den Controller and the effects on it<strong>optoNCDT</strong>240139

Serial Interface6.6.3 Displacement and Thickness MeasurementThis command allocates a measuring mode to the controller.Index Measuring mode0 Displacement measuring1 Thickness measuringThe "Mode" command is used to set/request the index of the current measuring mode.ModeFunction Set/request the current measuring modeFormat $MODn or $MOD?Value returned n = measuring mode index (0 or 1)6.6.4 Analog OutputConfiguring an analog output consists:- specifying the data item (displacement, thickness, intensity etc.) to an output,- output scaling, invertingAnalog OutputFunction Sets the analog output characteristicFormat $ANAn,m,p,qParameter n = ID of Analog output to configure (0 or 1)m = ID of the data item (0 … 7), see Chap. 6.4.1p = Start value for Vmin (0 V)q = End value for Vmax (10 V)Output characteristicp < qp > qConditions: 0

Serial Interface6.6.5 Dark SignalSee Chap. 5.3 to get detailed information on the "Dark Signal" function. This signaldepends on the sampling rate: it increases with the exposure time (reciprocal of thesampling rate).Acquiring and saving the dark signalThe "Dark" command records and saves the dark signal in the FLASH memory of thecontroller for all sampling rates in succession. If the level of the dark signal is too highfor low rates, the controller returns the index of the lowest measuring rate which isusable (see "Set Sampling rate" command), and lower sampling rates are inhibited.When finished, the controller returns to the last sampling rate used before dark signalacquisition.DarkFunction Acquire and save dark signalFormat $DRKValue returned Index of the lowest sampling rate usableGetting the minimal rate authorized after dark signal acquisitionThe "Minimal Rate" command is used to get the minimal measuring rate authorizedafter last dark operation.Minimal rateFunction Get the minimal authorized measuring rate (query only)Format $FRMValue returned Lowest measuring rate in Hz6.6.6 Fast Dark SignalThe "Fast Dark" command only refreshes the dark signal for the current measuring rate,without saving the acquisition in the EEPROM. If the dark signal measured is too high,the controller returns a "not valid " string and the previous dark signalcontinues in use.This command has two optional arguments:- n is an integer indicating the number of successive acquisitions to be averaged inorder to obtain the reference dark signal (default value = 40).- m indicates the influence of the acquisitions made on the new reference dark signalaccording to the formula:New dark signal = (m x reference dark signal + (100 - m) x old dark signal)FunctionFormatParameter/Value returnedFast darkAcquire the dark signal for the current measuring rate only withoutsaving in the controller$FDK or $FDKn,mn = averaging factor for dark signal, range 1 … 99m = weighting factor, range 1 … 100Returns "Ready" or "Not valid"<strong>optoNCDT</strong>240141

Serial Interface6.6.7 Refractive IndexThe measuring object refractive index is necessary in the “Thickness” measuring mode.Setting a constant refractive indexFunction Set/request the measuring object refractive indexFormat $SRIx or $SRI?Value returned x = refractive index, up to four decimal digitsExample $SRI1.5142Selecting a refractive index fileRefractive index files are used to describe the variation of refractive index within themeasuring range. The “Refractive index file” command is used to load a previouslysaved refractive index file.FunctionFormatParameterRefractive index fileLoad the refractive index file$INFnn =0: constant refractive index (determined by last SRI command)n = 1 … 8: ID of an existing refractive index fileValue returned s: material namex1,x2: the minimal and maximal refractive index values in the fileCommand: $INF3 or $INF?Response: $INF3,"BK7", 1.5090, 1.5253Example Command: $INF0Response: $INF0,"CONSTIND", 1.520, 1.520IMPORTANT!Refractive index files allowspecifying the variation ofthe refractive index of agiven measuring objectwithin the measuring range.The refractive index filenames are up to 8characters long and havethe “ind” suffix.They are generated bymeasuring a sample whosethickness is known.Note: Note the material name “CONSTIND” is attributed in case the file ID is 0.6.6.8 Light Source BrightnessThis command is exclusively possible for users, who do not use an external lightsource.LED brightnessFunction Set/request the light source brightnessFormat $LEDn or $LED?Value returned n = brightness level, range 0 … 100For each frequency there exists a minimal brightness level below which the LED cannotgo:Measuring rate Minmal brightness level Maximal brightness levelUp to 500 Hz 10 % 100 %500 Hz … 2000 Hz 25 % 100 %$LED0 – puts the LED off$LEDX with X minimal level sets the LED to the minimal level$LEDX with X > minimal level sets the LED to level X.6.6.9 AveragingThe averaging of the measurements by the controller improves the signal noise ratio.When the averaging factor is greater than 1, the controller transmits data in accordancewith the following formula:ff T= f S/ MT= Data transmission ratef S= Measuring rateM = Averaging factor<strong>optoNCDT</strong>240142

Serial InterfaceThus for a measuring rate of 1000 Hz and an averaging factor of 10, the sensor provides100 measurement points per second. In order to obtain measurements withoutaveraging, set the averaging to 1.Averaging is especially useful for ambitious measuring objects, for which the signal islow even at the minimum measuring rate. Sometimes averaging is used simply toreduce the data transmission rate. The command $AVR does not effect the analogoutput.FunctionFormatParameter/Value returnedData averagingSet/request data averaging$AVRn or $AVR?n = averaging, range 1 … 1000IMPORTANT!Do not use high averagingfor moving samples. Thisreduces the transverseresolution and may causefalse measurements.IMPORTANT!The controller calculatesarithmetic averages.6.6.10 Spectral AveragingThe averaging is performed on the photodetector signals before processing.FunctionFormatParameter/Value returnedSpectral averagingSet/request spectral averaging$AVSn or $AVS?n = averaging, range 1 … 9996.6.11 Hold Last Valid ValueThe “Hold last value mode” command is useful for measuring objects with a greatnumber of non measurable points, due to large local slopes or due to a very lowreflectivity. When measuring such samples it may be convenient that the value deliveredfor those positions will not be zero. Instead, the sensor sends the last valid value.Note: If a measurement can not be calculated from the given data and the lastmeasured value is transmitted the corresponding "Hold last value" bit in the status datais set.FunctionFormatParameter/Value returnedHold last valueSet/request max. number of points for "Hold last value mode"$HLVn or $HLV?n = max number of points to hold, range 1.. 9996.6.12 Trigger FunctionsStart TriggerThe "Start Trigger" command switches the controller into standby mode, waiting for atrigger signal at the "Sync in“ input (see Chap. 4.4.5).As soon as a rising edge or a falling edge 1 , whichever has been selected by the “Selectactive edge” command is detected at the "Sync in“ input, the controller startsmeasuring with a delay of 1 exposure time (exposure time {μs} = 1000000/measuringrate) and a repetition time of 1.2 μs.Note: The emission of “Sync out” signals stops and restarts together with datatransmission.1) Setup by thecommand "Select activeedge"FunctionFormatStart triggerPut the controller on standby pending receipt of an external triggersignal. Upon receipt of the trigger signal, the controller startsmeasuring at the programmed measuring rate.$TRG<strong>optoNCDT</strong>240143

Serial InterfaceFollowing a "Start Trigger" command it is possible to disarm the trigger and restartacquisition without receiving a trigger pulse using the "Continue" command or transmitthe string "$" to the controller.FunctionFormatParameter/Value returnedContinueDisarms the start trigger function and resumes normal operation$CTNNoneLevel TriggerThe "Start/stop on state" command switches the controller into standby mode for leveltriggering, waiting for a trigger signal at the "Sync in“ input (see Chap. 4.4.5). Datatransmission is enabled when the “SYNC IN” signal is in the active state. The activestate (high or low) is determined by the “TRF” command.Start/stop on stateFunction Enable/Disable data output through state triggering on the "SyncIn" inputFormat $TRNbParameter/ b = 1/0Value returnedPulse rate See Chap. 5.10.8Note: On each transition of the “Sync in” signal from non-active state to active state,the “flip flop” bit in the state data changes.Edge TriggerThe "Start/stop on edge" command switches the controller into standby mode for edgetriggering, waiting for a trigger signal at the "Sync in“ input (see Chap. 4.4.5). Datatransmission is enabled and disabled alternatively by successive “Sync in” pulses. Usethe "TRS" command to define the edge characteristics.Start/stop on edgeFunction Enable/Disable data output through edge triggering on the "SyncIn" inputFormat $TRSbParameter/ b = 1/0Value returnedPulse rate See Chap. 5.10.8Note: On each second “Sync in” pulse the “flip flop” bit in the state data changes.Software TriggerThe “STR” command may be used as a software trigger in the “TRE” and “TRS” triggermodes. Obviously, the software trigger does not have the temporal precision of thehardware trigger.FunctionFormatParameter/ReturnedSoftware triggerReplaces the hardware trigger in the "TRE" or "TRS" modes$STRNoneNote: In the “TRG” mode, the $ sign or “$CTN” command may be used as softwaretrigger. If you wish to use the software trigger avoid the “TRN” mode. Use the “TRS”mode instead.<strong>optoNCDT</strong>240144