Davey Hydrascan Instructions - Dural Irrigation

Davey Hydrascan Instructions - Dural Irrigation

Davey Hydrascan Instructions - Dural Irrigation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

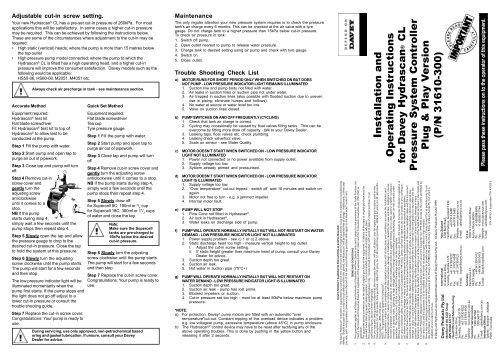

Adjustable cut-in screw setting.<br />

Your new <strong>Hydrascan</strong> ® CL has a pre-set cut-in pressure of 260kPa. For most<br />

applications this will be satisfactory. In some cases a higher cut-in pressure<br />

may be required. This can be achieved by following the instructions below.<br />

These are some of the circumstances where adjustment to the cut-in may be<br />

required:<br />

High static (vertical) heads; where the pump is more than 15 metres below<br />

the top outlet<br />

High pressure pump model connected; where the pump to which the<br />

<strong>Hydrascan</strong> ® CL is fitted has a high operating head, and a higher cut-in<br />

pressure will improve the consumer satisfaction. <strong>Davey</strong> models such as the<br />

following would be applicable:<br />

HS50-06, HS60-08, M2051, M4051 etc.<br />

Always check air precharge in tank - see maintenance section.<br />

Quick Set Method<br />

Equipment required:<br />

Flat blade screwdriver<br />

Tea cup<br />

Tyre pressure gauge<br />

Step 1 Fill the pump with water.<br />

Step 2 Start pump and open tap to<br />

purge air out of pipework.<br />

Step 3 Close tap and pump will turn<br />

off.<br />

Step 4 Remove cut-in screw cover and<br />

gently turn the adjusting screw<br />

anticlockwise until it comes to a stop.<br />

NB If the pump starts during step 4,<br />

simply wait a few seconds until the<br />

pump stops then repeat step 4.<br />

Step 5 Slowly draw off:<br />

for Supercell 8C; 190ml or 3 / cup 4<br />

for Supercell 18C; 380ml or 11 Accurate Method<br />

Equipment required:<br />

<strong>Hydrascan</strong><br />

/ cups 2<br />

of water and close the tap.<br />

Step 6 Slowly turn the adjusting<br />

screw clockwise until the pump starts.<br />

The pump will start for a few seconds<br />

and then stop.<br />

Step 7 Replace the cut-in screw cover.<br />

Congratulations: Your pump is ready to<br />

use.<br />

® test kit<br />

Flat blade screwdriver<br />

Fit <strong>Hydrascan</strong> ® test kit to top of<br />

<strong>Hydrascan</strong> ® to allow test to be<br />

conducted at the pump.<br />

Step 1 Fill the pump with water.<br />

Step 2 Start pump and open tap to<br />

purge air out of pipework.<br />

Step 3 Close tap and pump will turn<br />

off.<br />

Step 4 Remove cut-in<br />

screw cover and<br />

gently turn the<br />

adjusting screw<br />

anticlockwise<br />

until it comes to a<br />

stop.<br />

NB If the pump<br />

starts during step 4,<br />

simply wait a few seconds until the<br />

Note:<br />

pump stops then repeat step 4.<br />

Make sure the Supercell<br />

Step 5 Slowly open the tap and allow<br />

tanks are pre-charged to<br />

15kPa below the desired<br />

the pressure gauge to drop to the<br />

desired cut-in pressure. Close the tap<br />

cut-in pressure.<br />

to hold the system at this pressure.<br />

Step 6 Slowly turn the adjusting<br />

screw clockwise until the pump starts.<br />

The pump will start for a few seconds<br />

and then stop.<br />

The low pressure indicator light will be<br />

illuminated momentarily when the<br />

pump first starts. If the pump stops and<br />

the light does not go off adjust to a<br />

lower cut-in pressure or consult the<br />

trouble shooting guide.<br />

Step 7 Replace the cut-in screw cover.<br />

Congratulations: Your pump is ready to<br />

use.<br />

During servicing, use only approved, non-petrochemical based<br />

oring and gasket lubrication. If unsure, consult your <strong>Davey</strong><br />

Dealer for advice.<br />

Maintenance<br />

The only regular attention your new pressure system requires is to check the pressure<br />

tank’s air charge every 6 months. This can be checked at the air valve with a tyre<br />

gauge. Do not charge tank to a higher pressure than 15kPa below cut-in pressure.<br />

To check air pressure in tank:<br />

1. Switch off pump.<br />

2. Open outlet nearest to pump to release water pressure.<br />

3. Charge tank to desired setting using air pump and check with tyre gauge.<br />

4. Switch on.<br />

5. Close outlet.<br />

Trouble Shooting Check List<br />

a) MOTOR RUNS FOR SHORT PERIOD ONLY WHEN SWITCHED ON BUT DOES<br />

NOT PUMP - LOW PRESSURE INDICATOR LIGHT REMAINS ILLUMINATED<br />

1. Suction line and pump body not filled with water.<br />

2. Air leaks in suction lines or suction pipe not under water.<br />

3. Air trapped in suction lines (also possible with flooded suction due to uneven<br />

rise in piping; eliminate humps and hollows).<br />

4. No water at source or water level too low.<br />

5. Valve on suction lines closed.<br />

b) PUMP SWITCHES ON AND OFF FREQUENTLY (CYCLING)<br />

1. Check that tank air charge is correct.<br />

2. Cycling may occasionally be caused by float valves filling tanks. This can be<br />

overcome by fitting more draw off capacity - talk to your <strong>Davey</strong> Dealer.<br />

3. Leaking taps, float valves etc. check plumbing.<br />

4. Leaking check valve/foot valve.<br />

5. Scale on sensor - see Water Quality.<br />

c) MOTOR DOESN’T START WHEN SWITCHED ON - LOW PRESSURE INDICATOR<br />

LIGHT NOT ILLUMINATED<br />

1. Power not connected or no power available from supply outlet.<br />

2. Supply voltage too low.<br />

3. System already primed and pressurised.<br />

d) MOTOR DOESN’T START WHEN SWITCHED ON - LOW PRESSURE INDICATOR<br />

LIGHT IS ILLUMINATED<br />

1. Supply voltage too low.<br />

2. ”Over temperature” cut-out tripped - switch off, wait 10 minutes and switch on<br />

again.<br />

3. Motor not free to turn - e.g. a jammed impeller.<br />

4. Internal motor fault.<br />

e) PUMP WILL NOT STOP<br />

1. Flow Cone not fitted in <strong>Hydrascan</strong> ® .<br />

2. Air lock in <strong>Hydrascan</strong> ® .<br />

3. Water leaks on discharge side of pump.<br />

f) PUMP WILL OPERATE NORMALLY INITIALLY BUT WILL NOT RESTART ON WATER<br />

DEMAND - LOW PRESSURE INDICATOR LIGHT NOT ILLUMINATED<br />

1. Power supply problem - see c) 1 or c) 2 above.<br />

2. Static discharge head too high - measure vertical height to top outlet.<br />

i. Adjust the cut-in screw setting.<br />

ii. If static height greater than maximum head of pump, consult your <strong>Davey</strong><br />

Dealer for advice.<br />

3. Suction depth too great.<br />

4. Suction air leak.<br />

5. Hot water in suction pipe (75°C+)<br />

g) PUMP WILL OPERATE NORMALLY INITIALLY BUT WILL NOT RESTART ON<br />

WATER DEMAND - LOW PRESSURE INDICATOR LIGHT IS ILLUMINATED<br />

1. Suction depth too great.<br />

2. Suction air leak - pump has lost prime.<br />

3. Blocked impellers or suction.<br />

4. Cut-in pressure set too high - must be at least 50kPa below maximum pump<br />

pressure.<br />

*NOTE:<br />

a) For protection, <strong>Davey</strong> ® pump motors are fitted with an automatic "over<br />

temperature"cut-out. Constant tripping of this overload device indicates a problem<br />

e.g. low voltageat pump, excessive temperature (above 45°C) in pump enclosure.<br />

b) The '<strong>Hydrascan</strong> ®' control device may have to be reset after rectifying any of the<br />

above operating troubles. This is done by pushing in the yellow button and<br />

releasing it after 2 seconds.<br />

DAVEY PRODUCT GUARANTEE FOR AUSTRALIA & NEW ZEALAND<br />

The <strong>Davey</strong> <strong>Hydrascan</strong>® controller is guaranteed for a period of two years from the date of original purchase to be free of material or manufacturing<br />

defects. Should any part fail as a result of such defects within this period, the <strong>Hydrascan</strong>® will be repaired free of charge. Additionally, a three year<br />

pro-rata, parts only guarantee commencing from the end of the two years following purchase shall apply to the <strong>Hydrascan</strong>® control unit.<br />

Installation and<br />

Operating <strong>Instructions</strong><br />

for <strong>Davey</strong> <strong>Hydrascan</strong>® CL<br />

Pressure System Controller<br />

Plug & Play Version<br />

(P/N 31610-300)<br />

TERMS AND CONDITIONS<br />

1. This guarantee applies to all states and territories of Australia and New Zealand only and is subject to the provisions of the Trade Practices Act<br />

(Aust.), the Goods and Consumer Protection Legislation of the various Australian states and the Consumers Guarantee Act 1993 (NZ) as<br />

applicable.<br />

2. The guarantee period commences on the date of original purchase of the equipment. Evidence of this date of original purchase must be<br />

provided when claiming repairs under guarantee. It is recommended you retain all receipts in a safe place.<br />

3. This guarantee covers parts and workshop labour only. Goods should be forwarded, with proof of date of original purchase, to an<br />

Authorised <strong>Davey</strong> Service Centre freight paid.<br />

4. The pro-rata parts only guarantee means that after two years the owner will pay all labour costs for repairs and pay for parts used on the<br />

following basis: for 25-36 months from purchase - 40% of list price; for 37-48 months from purchase - 60% of list price; for 49 -60 months<br />

from purchase - 80% of list price.<br />

NOTE: This guarantee only applies to <strong>Hydrascan</strong>®.<br />

5. This guarantee is subject to due compliance by the original purchaser with all directions and conditions set out in the Installation and<br />

Operating <strong>Instructions</strong>. Failure to comply with these instructions, damage or breakdown caused by fair wear and tear, negligence, misuse,<br />

incorrect installation, chemical or additives in the water, inadequate protection against freezing, rain or other adverse weather conditions,<br />

corrosive or abrasive water, lightning or high voltage spikes or through unauthorised persons attempting repairs are not covered under<br />

guarantee. The product must only be connected to the voltage shown on the nameplate.<br />

6. Without limiting the original purchaser’s entitlements under the Trade Practices Act (Aust.), the Goods & Consumer Protection Legislation of<br />

the various Australian states, or the Consumers Guarantee Act 1993 (NZ), <strong>Davey</strong> shall not be liable for any loss of profits or any consequential,<br />

indirect or special loss, damage or injury of any kind whatsoever arising directly or indirectly from the product or any defect.<br />

7. Where the Trade Practices Act (Aust.), the Goods and Consumer Protection Legislation of the various Australian states and the Consumers<br />

Guarantee Act 1993 (NZ) does not apply, <strong>Davey</strong> shall not be liable for any loss of profits or any consequential, indirect or special loss,<br />

damage or injury of any kind whatsoever suffered by the purchaser arising directly or indirectly from the product or any defect and the<br />

purchaser shall indemnify <strong>Davey</strong> against any claim by any other person whatsoever in respect of any such loss, damage or injury.<br />

8. Nothing in this guarantee is intended to have the effect of contracting out of the provisions of the Trade Practices Act (Aust.), the Goods and<br />

Consumer Protection Legislation of the various Australian states and Consumers Guarantee Act 1993 (NZ) except to the extent permitted by<br />

the various Acts and this guarantee is to be modified to the extent necessary to give effect to that intention.<br />

9. <strong>Davey</strong> may be collecting personal information from you in order to provide you with a service. <strong>Davey</strong> Pumps Pty Ltd promises only to use<br />

this information in accordance with the Provisions of the Privacy Act 1988 (Cth) and the Privacy Policy of <strong>Davey</strong> Pumps Pty Ltd which is<br />

available at www.davey.com.au.<br />

® <strong>Davey</strong> and <strong>Hydrascan</strong> are registered trade marks of <strong>Davey</strong> Products Pty Ltd. © <strong>Davey</strong> Products Pty Ltd 1999<br />

New Zealand<br />

220A Bush Road,<br />

North Harbour, Auckland 1330<br />

Ph: +64 9 914 3680<br />

Fax: +64 9 914 3685<br />

Website: www.daveynz.co.nz<br />

E-mail: sales@daveynz.co.nz<br />

International<br />

6 Lakeview Drive,<br />

Scoresby, Australia 3179<br />

Ph: +61 3 9730 9222<br />

Fax: +61 3 9753 4248<br />

AH: +61 3 9730 9121<br />

E-mail: export@davey.com.au<br />

Please pass these instructions on to the operator of this equipment.<br />

U.S.A.<br />

1005 N. Commons Drive<br />

Aurora, Illinois 60504<br />

Ph: +1 630 898 6976<br />

Fax: +1 630 851 7744<br />

Website: www.daveyusa.com<br />

E-mail: sales@daveyusa.com<br />

P/N 49105-3 Supersedes P/N 49105-2<br />

Germany<br />

Kantstrasse 47,<br />

04275 Leipzig<br />

Ph: +49 341 301 0412<br />

Fax: +49 341 301 0413<br />

E-mail: <strong>Davey</strong>Europ@aol.com<br />

<strong>Davey</strong> Products Pty Ltd<br />

Member of the GUD Group<br />

ABN 18 066 327 517<br />

Head Office and Manufacturing<br />

6 Lakeview Drive,<br />

Scoresby, Australia 3179<br />

Ph: +61 3 9730 9222<br />

Fax: +61 3 9753 4100<br />

Website: www.davey.com.au<br />

Customer Service Centre<br />

Ph: 1300 367 866<br />

Fax: 1300 369 119<br />

E-mail: sales@davey.com.au<br />

Interstate Offices<br />

Sydney – Brisbane – Adelaide<br />

Perth - Townsville

Congratulations on your purchase of a high quality, Australian built <strong>Davey</strong><br />

<strong>Hydrascan</strong>®. All components have been designed and manufactured to give<br />

trouble free, reliable operation.<br />

Your new ‘<strong>Hydrascan</strong>®’ is an electronic flow control device – a <strong>Davey</strong> designed<br />

product that enables the use of a highly efficient pump design and offers the<br />

following benefits:–<br />

1. Enables the pump to deliver a constant flow of water particularly at low flow<br />

rates – reducing the inconvenience of pressure variation in showers etc.<br />

2. Provides automatic “cut-out” protection should the pump run out of water or<br />

overheat.<br />

Before installing your new <strong>Hydrascan</strong>®, please read all instructions carefully as<br />

failures caused by incorrect installation or operation are not covered by the<br />

guarantee. Your <strong>Hydrascan</strong>® is designed to handle clean water. The system<br />

should not be used for any other purpose without specific referral to <strong>Davey</strong>. The<br />

use of the system to pump flammable, corrosive and other materials of a<br />

hazardous nature is specifically excluded.<br />

WARNING: Some insects, such as small ants, find electrical devices<br />

attractive for various reasons. If your pump enclosure is susceptible<br />

to insect infestation you should implement a suitable pest control plan.<br />

The <strong>Hydrascan</strong>® Part No. 31610-300 consists of:<br />

<strong>Hydrascan</strong>® controller with leads fitted<br />

<strong>Hydrascan</strong>® connection flange with oring<br />

<strong>Hydrascan</strong>® connection nut<br />

Thread tape<br />

Fitment of <strong>Hydrascan</strong>® Kit<br />

The <strong>Hydrascan</strong>® control unit fits onto the outlet of the pump.<br />

1. Tank connection inlet<br />

2. <strong>Hydrascan</strong>® control unit<br />

3. Flow cone<br />

4. Connection Nut<br />

5. Supercell Pressure Tank*<br />

6. <strong>Hydrascan</strong>® outlet<br />

*Purchased separately or as part of bundled kits KH8C or KH18C<br />

Assembly<br />

Step One<br />

Ensure the discharge is clean and free of obstructions. This is<br />

especially important on the outside of the discharge.<br />

Step Two<br />

Slide the connector nut over the discharge.<br />

Step Three<br />

Slide the oring over the discharge as shown. The oring can<br />

be placed anywhere on the outside of the discharge<br />

between 2mm below the top and the connector nut.<br />

Step Four<br />

Screw the discharge fitting (flange) into discharge of the<br />

pump. There is no need to use thread tape on this flange.<br />

You may care to apply a small amount of loctite 577 to the<br />

thread on the flange (DO NOT USE THREAD PASTE).<br />

When the connector nut is pulled up into position to engage<br />

the <strong>Hydrascan</strong> ® , the oring will be also pulled up into its correct position.<br />

Make sure the flow cone is secured in place in the <strong>Hydrascan</strong> ® body. Position<br />

the <strong>Hydrascan</strong> ® control unit on top of the pump and tighten the connection nut.<br />

Make sure the flow cone is secured in place in the <strong>Hydrascan</strong> ® body. Position<br />

the <strong>Hydrascan</strong> ® control unit on top of the pump and tighten the connection nut.<br />

The <strong>Hydrascan</strong> ® control unit is capable of 360° rotation to enable the most<br />

convenient positioning of the discharge piping. Loosening the connection nut<br />

enables convenient adjustment.<br />

Fit the Supercell pressure tank to the tank connection inlet with thread tape.<br />

Firmly hand tighten.<br />

DO NOT USE THREAD SEALING COMPOUNDS, HEMP OR PIPE DOPE!<br />

Pipe Connections<br />

For best performance use P.V.C. or polythene pipe at least the same diameter<br />

as the <strong>Hydrascan</strong>® outlet.<br />

Larger diameter pipe may be used to minimise resistance to flow when<br />

pumping longer distances.<br />

Flexible pipe will help alignment during installation, as well as reduce noise<br />

transfer during operation.<br />

The <strong>Davey</strong> <strong>Hydrascan</strong>® fitted to this pump has a low pressure<br />

indicator light mounted on its side panel, adjacent to the<br />

yellow reset button. This light will be illuminated whenever<br />

the <strong>Hydrascan</strong>® senses low pressure. The light will only work<br />

when unit is connected to the correct electrical supply.<br />

Power Connection<br />

Connect lead to power supply designated on pump label, do not use<br />

long extension leads as they cause substantial voltage drop, poor pump<br />

performance and may cause motor overload.<br />

The electrical connections and checks must be made by a qualified<br />

electrician and comply with applicable local standards.<br />

Electrical Power Surge Protection<br />

An electrical power surge or spike can travel on the supply lines and cause<br />

serious damage to your electrical equipment. The <strong>Hydrascan</strong> ® CL fitted to this<br />

pump has a metal oxide varistor (MOV) fitted to help protect it’s circuit. This<br />

MOV is a “sacrificial” device, meaning that it effectively gradually destroys itself<br />

every time it takes a surge. The MOV is not a lightning arrestor and may not<br />

protect the <strong>Hydrascan</strong> ® CL if lightning or a very powerful surge hits the pump unit.<br />

If the installation is subject to electrical power surges or lightning we strongly<br />

recommend the use of a suitable surge protection device on ALL electrical<br />

equipment.<br />

Plug and Play Options<br />

Your <strong>Hydrascan</strong>® controller can be used to convert a compatible "plug and play"<br />

<strong>Davey</strong> pump into an automatic water pressure system.<br />

The motor leads fitted to your <strong>Hydrascan</strong>® has a special connection plug fitted.<br />

It can be used to fit the automatic controller device to a compatible "plug and<br />

play" <strong>Davey</strong> pump.<br />

Disconnection: Holding the plugs with both hands, unscrew the ribbed locking<br />

collar, then pull the plug ends apart.<br />

Reconnection: Holding a plug end in each hand, push the ends together. The<br />

ends can only be pushed together in one orientation - DO NOT force them.<br />

Once pushed home, the ribbed locking collar can be screwed closed.<br />

NOTE: There is no need to use tools to undo or tighten the locking<br />

collar.<br />

In accordance with AS 3350.2.41 we are obliged to inform you that this pump is<br />

not to be used by children or infirm persons and must not be used as a toy by<br />

children.<br />

IP55 Compliant Connection<br />

For some installations, such as wet areas in dairies, the pump is required to be<br />

IPX5 compliant. The special "plug and play" lead connections can be made IP55<br />

compliant if required.<br />

To obtain IP55 compliant connection of the pump leads including those for the<br />

automatic control device (if fitted) you will need to fix the enclosed screw into the<br />

special plug. This screw is to be inserted into the pre-drilled hole once the plugs<br />

have been connected.<br />

NOTE: Under NO circumstances use other than the provided screw.<br />

Water Quality<br />

Abrasive Materials<br />

The pumping of abrasive materials will cause damage to the<br />

<strong>Hydrascan</strong>® which will then not be covered by the guarantee.<br />

*NOTE:<br />

For protection, the <strong>Davey</strong> pump motors are fitted with an automatic<br />

reset thermal overload, constant tripping of this overload indicates a<br />

problem e.g. low voltage at pump, excessive temperature (above 50°C)<br />

in pump enclosure.<br />

WARNING: Automatic reset thermal overloads will allow the pump to<br />

restart without warning. Always disconnect the pump motor from the<br />

electrical supply before maintenance or repairs.<br />

WARNING: When servicing or attending pump, always ensure power is<br />

switched off and lead unplugged. Electrical connections should be<br />

serviced only by qualified persons.<br />

Care should also be taken when servicing or disassembling pump to<br />

avoid possible injury from hot pressurised water. Unplug pump, relieve<br />

pressure by opening a tap on the discharge side of the pump and allow<br />

any hot water in the pump to cool before attempting to dismantle.<br />

IMPORTANT:<br />

DO NOT USE petroleum based fluids or solvents (e.g. Oils, Kerosene,<br />

Turpentine, Thinners, etc) on the plastic pump components or seal<br />

components.<br />

Where the water being pumped contains high levels of<br />

dissolved solids (hard water) or biological organisms, a<br />

scale build up on the <strong>Hydrascan</strong> ® CL sensor plate may<br />

occur over time. This will cause the pump to cycle at<br />

higher than normal flow rates (eg while using the<br />

shower). To fix the problem, clean the sensor plate,<br />

using a blunt object, such as a timber icy pole stick or<br />

toothbrush - as illustrated.<br />

WARNING: Do not use hydrocarbon based or hydrocarbon propelled<br />

sprays around the electrical components of this controller.<br />

After Sales Service<br />

For professional after sales service or repair contact your <strong>Davey</strong> Dealer.<br />

For assistance in locating your nearest dealer contact the <strong>Davey</strong> Customer<br />

Centre on 1300 367 866