Solar, Biomass and Hybrid Dryers - BioEnergy Discussion Lists

Solar, Biomass and Hybrid Dryers - BioEnergy Discussion Lists

Solar, Biomass and Hybrid Dryers - BioEnergy Discussion Lists

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

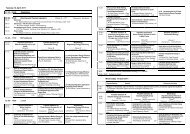

Telescopic chimney110 cmTop cover88 cm58.5cm φWater SealFixed chimney,10 cm φ22 cmGrate, with holesSt<strong>and</strong>(optional)Figure 7.4: The charring drum(ii) Briquette MouldThe briquette mould is made up of mild steel. It consists of three parts: the bottomplate with nineteen protruding rods each 13 mm in diameter, outer cylindrical coverto fit the bottom plate, <strong>and</strong> a perforated plate to slide down along the rods into thecylinder, as shown in Figure 7.5.(iii) Charring ProcedureAll types of biomass materials can be used in a charring drum for char production. Ifthe biomass material is too loose (e.g.: pine needles, leaves, etc.), then they can bemade into small bundles of 7-10 cm diameter <strong>and</strong> up to 60 cm length. Dependingupon the type of biomass, about 40-100 kg of biomass can be carbonized in thecharring drum to get a yield of 25-35% char over a period of 2 - 3 hours.First, the conical grate with fixed chimney is placed inside the drum <strong>and</strong> thetelescopic chimney is placed over the fixed chimney as shown in Figure 7.4. One totwo kilograms of dried leaves or twigs are spread uniformly over the conical grate40