Solar, Biomass and Hybrid Dryers - BioEnergy Discussion Lists

Solar, Biomass and Hybrid Dryers - BioEnergy Discussion Lists

Solar, Biomass and Hybrid Dryers - BioEnergy Discussion Lists

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

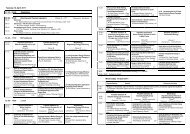

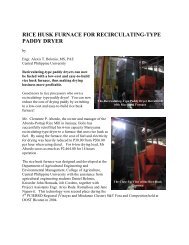

supporting st<strong>and</strong> are similar to that already presented in Package 5. The biomassstove-heat exchanger-chimney assembly is the only addition to the solar cabinetdryer. Therefore, only the design details of biomass stove-heat exchanger-chimneyassembly is described here.Table 7.1: Technical specifications of the solar-biomass hybrid cabinet dryerSl. No. Parameter Specifications1. <strong>Solar</strong> collector area 3.2 m 22. No. of glazing Single3. Loading Opening of doors at backside4. No. of doors 35. No. of trays 96. Air circulation Natural7. <strong>Biomass</strong> stove type Combustion type stove8. Fuels for stove fuels: fuelwood, wood chips, twigs, honeycombbriquettes9. Stove size 0.6m x 0.3m x 0.15m10. Heat exchanger Finned aluminum pipe (rectangular)11. Height of flue gaschimney1.7 m12. Drying capacity 10 kg-fresh13. Constructionmaterials14. Approx. cost NRs. 50,000**1 US$ = 74 NRs (Nepalese Rupees), March 2004Wood, steel sections, window glass, GI sheets,aluminum sheets, MS sheets, glass wool,aluminium screws & rivets<strong>Biomass</strong> StoveHoneycomb charcoal-briquettes are a popular <strong>and</strong> cheap cooking fuel in certainparts of rural Nepal. The briquettes are made by mixing charcoal <strong>and</strong> clay <strong>and</strong>moulding cylindrical briquettes with a honeycomb-like cross section. A stove whichcan utilise the honeycomb briquettes to supply hot air for drying was thereforethought to be an attractive option for solar-biomass hybrid dryers. This stove wasdeveloped at AIT under the RETs in Asia programme within a fellowship study byRECAST, Nepal. The honeycomb briquette stove was found to provide hot air asteady temperature of 50-60°C inside the drying chamber. Only minimumsupervision was needed for the stove during operation. The dried products werealso of excellent quality due to indirect contact drying.37