Solar, Biomass and Hybrid Dryers - BioEnergy Discussion Lists

Solar, Biomass and Hybrid Dryers - BioEnergy Discussion Lists

Solar, Biomass and Hybrid Dryers - BioEnergy Discussion Lists

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

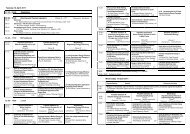

stove at one end <strong>and</strong> a chimney at the other. Noting that the maximum permissibletemperature for fruits <strong>and</strong> vegetable drying is about 60°C, the design temperature atthe outlet of the heat exchanger should not be less than this value.Eight galvanised iron (GI) pipes with outer diameter 50 mm <strong>and</strong> inner diameter 44mm are used to provide the required heat transfer area of the heat exchanger; thetubes are arranged in a staggered manner, as shown in Figure 3.2. The tube bank isplaced inside mild steel shell of length: 1.72 m, width: 0.6 m <strong>and</strong> height: 0.16 m.120mm70mmFigure 3.2: Arrangement of tubes in the heat exchangerThe stove is made of mild steel <strong>and</strong> has a cross-sectional area of 0.3m x 0.275m <strong>and</strong>height 0.4 m; it has a grate punched with 44 holes of diameter 1.5 cm. The insidewalls of the stove are insulated with castable refractory cement. For supplyingdrying air at 70°C, the rate of briquette consumption is about 2.45 kg/hr.The chimney, which provides the draft needed for flue gas from the stove to flowthrough the heat exchanger tubes, has a cross-sectional area of 0.275m x 0.16m <strong>and</strong>height 1 m.Figure 3.3: <strong>Biomass</strong> stove-heat exchanger unit without insulation22