SXL Segmented Shaft Seal Brochure - Thordon Bearings

SXL Segmented Shaft Seal Brochure - Thordon Bearings

SXL Segmented Shaft Seal Brochure - Thordon Bearings

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

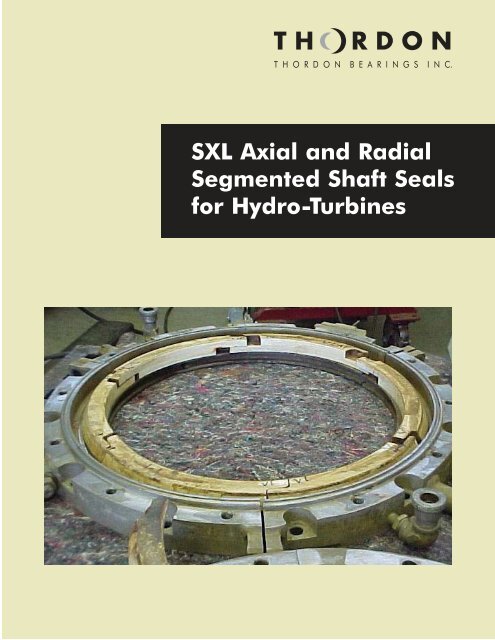

T H O R D O N B E A R I N G S I N C.<strong>SXL</strong> Axial and Radial<strong>Segmented</strong> <strong>Shaft</strong> <strong>Seal</strong>sfor Hydro-Turbines

<strong>SXL</strong> SEGMENTED SHAFT SEALS FOR HYDRO-TURBINESWith over 25 years experience supplying main shaftguide, wicket gate and operating mechanismbearings to the hydro power industry, <strong>Thordon</strong> is theproven choice for performance and value in bothrehabilitation and new turbine projects. In addition tosupplying bearings, <strong>Thordon</strong> has also beensupplying segmented shaft seals to the hydro powerindustry for more than 25 years. <strong>Thordon</strong> <strong>SXL</strong> has aproven track record as a segmented shaft sealmaterial replacing carbon graphite seals.In addition to proven product performance, <strong>Thordon</strong>is also an industry leader in polymer research anddevelopment, and in application engineering. Aspart of its ongoing research and developmentprogram, <strong>Thordon</strong> has built its own test facility forsegmented shaft seals. This facility duplicates theoperating environment of turbine shaft seals andenables <strong>Thordon</strong> to test various design andconfiguration options. The results of this programhave enabled <strong>Thordon</strong> to investigate the design of<strong>Thordon</strong> <strong>SXL</strong> segmented shaft seals, to determinethe performance parameters of the material and towork on the development of new design options toimprove the performance of <strong>Thordon</strong> <strong>SXL</strong> seals.<strong>Thordon</strong> <strong>SXL</strong> <strong>Segmented</strong> <strong>Shaft</strong> <strong>Seal</strong> SystemsOperating parameters for <strong>Thordon</strong> <strong>SXL</strong> segmentedshaft seals are generally similar to those for carbongraphite seals in terms of maximum interfacepressure and minimum leakage rate. <strong>Thordon</strong>segmented shaft seals have been designed forshafts up to 2000mm (80") diameter. They can bedesigned for use in either radial or axial sealingsystems.The main shaft seal of a turbine usually operatesunder high PV-value conditions and may also befrequently exposed to abrasives in the water.<strong>Thordon</strong> segmented shaft seals are a provensolution working in both clean and abrasive ladenwater. The seal may be located below (see Figure 1)or above the main shaft guide bearing depending onthe system arrangement.Based on <strong>Thordon</strong>'s R&D testing and fieldexperience, <strong>Thordon</strong> segmented shaft seals areable to operate in a wide range of PV-values withthe maximum water pressure tested up to 0.7 MPa(100 psi).Figure 1. <strong>SXL</strong> <strong>Segmented</strong> <strong>Shaft</strong> <strong>Seal</strong>sDepending on the shaft size, number of segments,machining precision of segments, sealed waterpressure and shaft speed, the amount of leakagecan vary widely. It is difficult to predict the leakagerate accurately at the design stage. However, R&Dtesting has confirmed that for a radial segmentedseal consisting of 6 segments running on a 400 mm(15.75") diameter shaft, the leakage rate would befrom 10 to 40 l/min (2.6 to 10.6 US gal./min).Additional advantages of the segmented sealdesign include easy installation and replacementwithout removing the shaft. Disassembly of othermachine parts may not be required.<strong>Thordon</strong> <strong>SXL</strong> vs. Carbon Graphite<strong>Segmented</strong> shaft seals for turbines havetraditionally been made from carbon graphite.These seals have low friction and can accept asignificant amount of heat. Carbon graphite is,however, very fragile. It is not unusual to damageseveral segments during installation. Carbongraphite also does not resist the abrasion which canoften be present in the water flowing through aturbine. The elastomeric nature of <strong>Thordon</strong> <strong>SXL</strong>gives it superb impact or shock resistance. <strong>SXL</strong>offers the advantages of being almost unbreakableand also of being much more abrasion resistant.Optimal sealing performance for <strong>SXL</strong> can beachieved with an injection of clean water betweenthe first and second rings of the seal. <strong>Thordon</strong> <strong>SXL</strong>seals can normally replace existing carbon sealswithout any significant changes to the systemdesign.

Radial <strong>Seal</strong>sTypical radial segmented seals comprise threestages (rings) of interlocking segments (Figure 2).Each ring has both dynamic (against the shaft) andstatic (against the housing) sealing actions.Figure 2. <strong>SXL</strong> Radial <strong>Shaft</strong> <strong>Seal</strong> Segments<strong>SXL</strong> radial shaft seal segmentsAxial <strong>Seal</strong>sAn axial segmented shaft seal works in a similarfashion to conventional mechanical seals. The<strong>Thordon</strong> axial seal design provides the injectionwater into the central groove of the seal ring (Figure4). The seal segments are normally attached to thestationary tubine casing.Figure 4. Axial <strong>Segmented</strong> <strong>Shaft</strong> <strong>Seal</strong> Design<strong>SXL</strong> axial shaft sealFirst stage seals are normally reversed comparedwith the two upper rings, to allow introduction of ahigher-pressure injection flow between the first andsecond rings. (see Figure 3) This higher pressureflow (1.10 to 1.15 times turbine pressure) functionsas a seal lubricant, coolant and a barrier preventingabrasives in the turbine water from entering the sealfaces. A garter spring functions to hold the segmentswith a nominal light force against the shaft duringperiods of shutdown and low pressure and also tomaintain the integrity of the seal ring within thehousing cavity. In normal operation, the seal ring ispressed against the shaft by the force of the water inthe turbine.Figure 3. Radial <strong>Segmented</strong> <strong>Shaft</strong> <strong>Seal</strong> Designclean water injection<strong>Thordon</strong> axial segmented shaft seals are particularlysuitable for extremely large diameter shafts. It is notunusual for <strong>Thordon</strong> to install an axial seal with ringdiameter 4000mm (160") or larger. Figure 5 showsone section from a whole sealing ring of an <strong>SXL</strong> axialsegmented shaft seal.Figure 5. <strong>SXL</strong> Axial <strong>Shaft</strong> <strong>Seal</strong> SegmentShown inverted from Figure 4<strong>SXL</strong> segmented shaft seal rings

Application Information and Design ParametersAlthough <strong>Thordon</strong> <strong>SXL</strong> segmented shaft seals cannormally be used as a direct replacement for carbongraphite, it is recommended to review theprospective application with <strong>Thordon</strong> <strong>Bearings</strong>.When evaluating an installation, as much aspossible of the information and design parameterslisted below should be supplied to <strong>Thordon</strong> forreview.• Water pressure being sealed (water pressureinside turbine)• <strong>Shaft</strong> diameter• <strong>Shaft</strong> rotating speed (rpm)• Water quality (clean or abrasive) over the year(i.e. is there spring run-off with abrasives?)• Environmental (water) temperature• Maximum leakage flow allowed• Turbine arrangement (Vertical or Horizontal)• Existing seal design, if application is retrofit• Is a clean, pressurized flush available?Customer Focused To Support Your ImmediateAnd Future NeedsSupply and Service: Geared to provide responseto customer needs, <strong>Thordon</strong> <strong>Bearings</strong> understandsthe importance of fast delivery and reduced downtime. <strong>Thordon</strong> marine and industrial bearings can bedesigned to accommodate the requirements of thecustomer and shipped quickly.Application Engineering: <strong>Thordon</strong> Bearing’sengineers work closely with customers to provideinnovative bearing and seal system designs thatmeet or exceed the technical requirements of theapplication.Quality: <strong>Thordon</strong> <strong>Bearings</strong> Inc. is a Canadiancompany manufacturing to ISO 9001:2000 QualitySystem requirements. With over 35 yearsexperience in polymer bearing design, applicationengineering and manufacturing, <strong>Thordon</strong> marineand industrial bearings are recognized worldwide forboth quality and performance.Your Local <strong>Thordon</strong> DistributorT H O R D O N B E A R I N G S I N C.ZERO POLLUTION | HIGH PERFORMANCE | BEARING SYSTEMS<strong>SXL</strong>Seg<strong>Shaft</strong>.12.20093225 Mainway Drive, Burlington, Ontario L7M 1A6 CanadaTel: +1.905.335.1440 Fax: +1.905.335.4033www.<strong>Thordon</strong><strong>Bearings</strong>.comISO 9001:2008CGSBRegistration #93649