TEXTILE RESEARCH ASSOCIATIONS - Ministry of Textiles

TEXTILE RESEARCH ASSOCIATIONS - Ministry of Textiles

TEXTILE RESEARCH ASSOCIATIONS - Ministry of Textiles

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

a n n u a l r e p o r t 0 4 - 0 5CHAPTER XIII<strong>TEXTILE</strong> <strong>RESEARCH</strong> <strong>ASSOCIATIONS</strong>COTTON <strong>TEXTILE</strong> <strong>RESEARCH</strong>ASSOCIATIONThere are eight Textile ResearchAssociations (TRAs) receivingfinancial support from the <strong>Ministry</strong><strong>of</strong> <strong>Textiles</strong>, <strong>of</strong> these the following are CottonTextile Research Associations (CTRAs):(1) Ahmedabad Textile Industry’sResearch Association (ATIRA),Ahmedabad;(2) Bombay Textile ResearchAssociation (BTRA), Mumbai;(3) South India Textile ResearchAssociation (SITRA) Coimbatore; and(4) Northern India Textile ResearchAssociation (NITRA), Ghaziabad.ATIRADuring 2003-04, research anddevelopment activities at ATIRA weredirected towards developing cost effectivetechniques, product innovation, improvingproduct (yarn/fabric) quality, ensuringutilities (energy and water) conservation,improving productivity and machinerymaintenance. The projects in most <strong>of</strong> thecases were <strong>of</strong> applied nature and <strong>of</strong>immediate application to the industry.ATIRA’s notable performance during thisyear has been as follows:It undertook nearly a dozen R&D projectswith industry sponsorship.It completed the following R&D projects:Like other TRAs, these CTRAs aretextile industry promoted private bodies,set up and promoted by the textileindustry <strong>of</strong> the respective region forcarrying out research and providingthem various services includingconsultancy, testing, training andresearch etc. Their main sources <strong>of</strong>earnings include government grants,subscriptions from member-mills, feesfor the services provided etc. TheCTRAs have an elected Chairman, whois normally a renowned industrialist <strong>of</strong>the region and is in overall in-charge <strong>of</strong>the functions <strong>of</strong> these CTRAs.●●●●●Hydrogen Peroxide Based ColdBleaching Process for HandProcessing Sector;Optimisation <strong>of</strong> Ginning ProcessParameters <strong>of</strong> Low MicronaireIndian Cottons;Improving Elongation <strong>of</strong> Yarns spunfrom Indian Cotton;Development <strong>of</strong> BiodegradableHydrogel;Hydrogen Peroxide based coldbleaching process for handprocessing sector; and161

m i n i s t r y o f t e x t i l e s●Developed electronic gadgetry formeasuring important dimensionalcharacteristics <strong>of</strong> spinning ring.It provided guidance to a number <strong>of</strong>ginning and pressing factories <strong>of</strong> GujaratState, and they have been benefitedthrough implementation <strong>of</strong> upgradedginning technology in their units.Its powerloom service centres conducted13 seminars/workshops cumdemonstrations <strong>of</strong> modern shuttlelesslooms for creating awareness <strong>of</strong>modernisation in the decentralizedweaving sector.Eight booklets on various activities <strong>of</strong>Powerloom Service Centre andGovernment Schemes in English as wellas in Gujarati have been published for thebenefit <strong>of</strong> powerloom industry.Consultancy was provided to 219powerloom units. About 19 majorconsultancies were carried out forimproving fabric quality, increasingproductivity, efficiency and damagecontrol.Training programme was arranged duringNovember – December 2003 on“Orientation to Textile Technology” forPowerloom Owners <strong>of</strong> Ahmedabad.Twenty HRD programmes for on-the-jobtraining was imparted to 378 powerloomweavers.Environmental audit for Schedule 1Industries (highly polluting chemicalindustries) is very important and highlyremunerative activity. Audit work wascarried out by ATIRA in 11 industriesduring the year.ATIRA was involved in the exercise <strong>of</strong>issuing ‘No pollution load” certificate to theindustries which are interested in changingtheir product-mix as well as productivity.Such certificates help the industries inseeking clearance from Governmentauthorities for either getting permission tochange the product-mix or for production<strong>of</strong> new chemicals or productivity.ATIRA organized the following seminarsfor disseminating R&D knowledge to theparticipants from textile industry:●●●●●Emerging scenario in clothingindustry <strong>of</strong> INDIA and ASIA;Energy Management in the IndianIndustry: A global perospective;Nanotechnology in Textile: The nextWave;Fuel savings through intelligentcontrol in manually fired boilers; andControlled sorption “Tool Box” forright first time dyeing.As many as 51 different training courseswere <strong>of</strong>fered by ATIRA during the periodand over 200 textile mills/units tookadvantage <strong>of</strong> the same.Over 10,000 samples were tested duringthe year (including yarns, fabrics,accessories and instrument calibration)During the year 4 new developments werelicensed and 4 patents were filed (<strong>of</strong> these2 patents were sealed).162

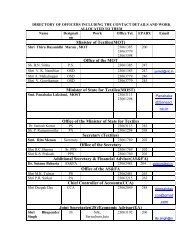

m i n i s t r y o f t e x t i l e s●viability studies, (ii) vetting outrestructuring proposals, (iii) scrutiny<strong>of</strong> revival proposals, (iv) valuation <strong>of</strong>fixed assets <strong>of</strong> textile units, (v)certification <strong>of</strong> modernization /renovation done by the mills, (vi)equipment verification and (vii)control panel valuation.Services provided by BTRA duringthe period are at Table 13.1.Table 13.1(a) Technical investigations 286carried out(b) Technical enquiries attended 295(c) Local mill visits made 1,617(man-days)(d) Outstation mill visits made 264(man-visits)(e) Number <strong>of</strong> samples tested 14,544(f) Number <strong>of</strong> reports issued 6,249provide technical consultancy,testing services, training in loomworking, loom maintenance,disseminating information throughtraining progrmmes, workshops,demonstrations and discussions.Liaison visits are made by BTRAstaff to have a first-hand view <strong>of</strong>the problems faced by thePowerloom weavers / processorsand on the spot suggestions aremade. The Eco-laboratory <strong>of</strong>BTRA, set up at Ichalkaranji,undertakes testing <strong>of</strong> textile fibres,yarns, fabrics and auxiliaries asper eco-parameters. It also carriesout water and effluent analysis andphysical / chemical analysis. Theactivities <strong>of</strong> these centres duringthe period under review are atTable 13.2.Table 13.2Activities Ichalkaranji Solapur Madhavnagar-vitaTotal yarn and fabric samples tested 5,630 1,192 569Number <strong>of</strong> technical assistance / 228 51 180trouble shooting consultancy givenTotal number <strong>of</strong> man-days spent for 1,717 1,352 200the technical workTotal training progarmmes conducted 7 13 8Total people trained 134 69 47Total units surveyed 16 50 181●BTRA runs three PowerloomService Centres (PSCs) atIchalkaranji, Solapur andMadhavnagar-vita. In order toimprove the quality, operatingefficiency and productivity <strong>of</strong>Powerloom clusters, BTRA PSCsSITRADuring the year under review, scientificwork in SITRA was carried out on 41projects covering product quality,operational studies, energy conservation,unconventional fibres, machinery164

a n n u a l r e p o r t 0 4 - 0 5development, process and productdevelopment. Out <strong>of</strong> 41 on-going projects,14 were completed during the year. Fournew developments—SITRA Enercool(control system for cooling towers), SITRAEner TFO (energy saving TFO spindle),SITRA-CIM (monitoring and informationsystem for combers) and SITRA Micro-Control (auto levelers for draw frames)have been licensed for commercialproduction.In the area <strong>of</strong> Human ResourcesDevelopment, SITRA organised 17different training programmes for technicaland managerial personnel and 6programmes for labour, wherein a total <strong>of</strong>1449 personnel have been trained. UnderInternational training, 45 participants from19 different countries were trained.As a part <strong>of</strong> SITRA’s services todecentralised sector, it rendered 2220consultancy services like machineryvaluation, techno-economic viability study,project appraisal etc; the number <strong>of</strong>designs produced were 1348 and 25,228samples were tested, 56 trainingprogrammes were <strong>of</strong>fered wherein 634participants have been trained.A wide range <strong>of</strong> services were <strong>of</strong>fered bythe Computer Aided DesignCentres(CADCs) during the year. Closeto 600 designs were developed and asmany as 20 training programmes were<strong>of</strong>fered. The Centres have also rendered220 consultancy services.The SITRA-AEPC Knit-Wear ServiceCentre, among its various services, hastrained 150 young candidates through its“Knitwear Manufacturing Technique andManagement” Programme covering allaspects <strong>of</strong> knit garment manufacturing.The Centre has tested 5,858 yarn andfabric samples and also <strong>of</strong>fered 15consultancy services to various problemsreferred by the knitters.During the year SITRA has brought out19 publications which includes 11research reports. Besides, SITRAScientists have contributed 38 technicalpapers for publication in various technical/managerial journals. SITRA was recipient<strong>of</strong> six awards for research work andtechnical publications during the year.NITRAThe NITRA has completed 19 projects and8 projects are in the pipeline. A few <strong>of</strong> thenotable projects being handled areDevelopment and Standardization <strong>of</strong>Technology for Improving Aesthetic andComfort for Operation on Terry Towel,Development <strong>of</strong> Cost Effective and Ec<strong>of</strong>riendlyBleaching <strong>of</strong> Natural Textile FibresUsing Advanced Oxidation Technique,Development <strong>of</strong> X-ray Opaque Fabric,Discharge Printing on Direct and ReactiveDyed Cotton Made-ups : A New Approach,Development <strong>of</strong> Anti-Microbial and BloodRepellent Fabric, Treatability on CompleteBiodegradation <strong>of</strong> Textile Waste WaterThrough Aerobic cum Anaerobic Route,Development <strong>of</strong> UV Resistant Fabric andDevelopment <strong>of</strong> PLC Based Instrument toMeasure Steam Consumption at IndividualPoint. In addition to above NITRA has alsoconducted collaborative research withreputed houses like LUWA India,165

m i n i s t r y o f t e x t i l e sSurgewear Ltd., Mordi Processors,Executive Garments, Pasupati Spinningand Weaving Mills, Raj Vidya Kendra,Winsome Spectrum, Sara Elgi Group andZydex Industries etc.NITRA has also developed some state <strong>of</strong>the art instruments like Fabric HandTesting Instrument (for measuring fabrichand), Draftometer (instrument formeasuring drafting force for sliver androving; useful for spinning <strong>of</strong> dyed fibres),Friction Tester (instrument for measuringfabric and fibre friction) and S<strong>of</strong>t and HardCore Yarn Attachment at Ring Frame andModified Wrap Reel (to measure s<strong>of</strong>t coreyarn count).The NITRA conducted 90 technicalconsultancy jobs on different parameters<strong>of</strong> textile, garment and allied industry.NITRA’s Environment Division developedtechniques to recover and reuse theeffluents discharged from textile dyeingunits without using Reverse Osmosis(RO). The first water recovery plant wascommissioned in one <strong>of</strong> the processingplants situated in Ghaziabad three yearsback. After fine-tuning the intricacies <strong>of</strong>the technology <strong>of</strong> water recovery, NITRAhas successfully commissioned waterrecovery plants in Rajasthan and Haryana.The system is capable to recover andreuse about 50% to 70% <strong>of</strong> the processingeffluent back into the process house.Energy conservation is another areawhere NITRA has rendered services to itsmembers. In the last year NITRA’s energyteam conducted a number <strong>of</strong> energy audits(thermal, electrical, power quality,humidification, air conditioning, D.G. setsand compressors) by which the mills couldsave to the tune <strong>of</strong> 10% to 20% <strong>of</strong> theirenergy bill.NITRA has been designated as a nodalagency by the <strong>Ministry</strong> <strong>of</strong> <strong>Textiles</strong> forassessing technical viability(TEV) <strong>of</strong> textileindustry for availing the benefit <strong>of</strong>restructuring their debt pr<strong>of</strong>ile under the“Debt Restructuring Package forOrganised Textile Mills”. NITRA hascompleted TEV Study in 30 different unitsduring the reported period.NITRA’s labs have carried out 5164 testingjobs on different parameters <strong>of</strong> textiles,dyes, chemicals and effluents during thereported period. It also carried out 43fabric defect analyses. Its S<strong>of</strong>twareDevelopment Centre developed threelatest s<strong>of</strong>twares <strong>of</strong> different nature,suitable for small and medium scaleindustry at a very nominal price. AmongstHRD activities, to educate the industry,NITRA organised 45 workshops /seminars / training programmes / lecturemeets / talk sessions for the benefit <strong>of</strong>textile, garment and non-textile unitsspreading across length and breadth <strong>of</strong>the country as well for the development <strong>of</strong>its own workforce.SYNTHETIC & ART SILK MILLS<strong>RESEARCH</strong> ASSOCIATION.(SASMIRA), MUMBAIThe Synthetic & Art Silk Mills’ ResearchAssociation (SASMIRA), Mumbai is a cooperativeventure set up by the man-madetextile industry <strong>of</strong> India with the primeobjective <strong>of</strong> rendering scientific andtechnical assistance to the textile industry.166

a n n u a l r e p o r t 0 4 - 0 5SASMIRA is engaged in various activitiesviz. research and development,instrumentation, technical education,dissemination <strong>of</strong> technical information andorganizing seminars and conferences.The funding from <strong>Ministry</strong> <strong>of</strong> <strong>Textiles</strong>towards the plan grants for researchprojects has been curtailed from thecurrent financial year and it is proposedto decrease the non- plan grant by 10%yearly for the coming year and thesponsored projects from the <strong>Ministry</strong> <strong>of</strong><strong>Textiles</strong> have been discontinued.However, SASMIRA has initiated series<strong>of</strong> other activities to fill the gap <strong>of</strong> fundscreated.Under the package for restructuring highcost debts <strong>of</strong> textile units in the organizedsector, the <strong>Ministry</strong> <strong>of</strong> <strong>Textiles</strong> hasdesignated SASMIRA for assessing thetechnical viability <strong>of</strong> these units. In thecurrent financial year SASMIRA hasundertaken four viability studies for thespinning, texturising, weaving andprocessing units namely Man-MadeSpinner (I) Ltd, Yashasvi Yarns Ltd, PalSynthetics and Angad Pal Industries Pvt.Ltd., respectively. SASMIRA hasconducted customized courses andtraining programmes on various topics intextiles namely on printing technology andnarrow width weaving.SASMIRA has been identified as “Centre<strong>of</strong> Excellence” – Technical <strong>Textiles</strong>. It<strong>of</strong>fers specialized testing services as wellas technical know-how for the technicaltextiles industry. In order to support thefield <strong>of</strong> technical textiles SASMIRA is inthe process <strong>of</strong> publishing monographs onvarious topics on technical textiles.SASMIRA has documented information ontechnical textiles for the Expert Committee<strong>of</strong> Technical <strong>Textiles</strong> (ECTT).SASMIRA is now accredited by NationalAccreditation Board for Testing andCalibration Laboratories (NABL). Thecertificate is a general requirement forcompetence <strong>of</strong> testing and calibrationlaboratory as per “ISO/IEC 17025”. Inorder to serve textile industriesSASMIRA is interacting with variousindustrial hubs like Bhiwandi, Tarapur,Umergaon etc. SASMIRA haveconducted various seminars on EnergyConservations and case studies in textilewet processing in Bhiwandi. Similarseminars have been planned forUmergaon and Tarapur industrial hubsduring this financial year.Research and development staffs haveattended various seminars conducted bydifferent Institutes and ResearchOrganisations. SASMIRA have published11 research and review papers in reputedIndian and International Journals and 6papers are under printing.SASMIRA has participated in InternationalTextile Machinery (ITME) India 2004during December 4-11, 2004. Variousactivities <strong>of</strong> Research and Developments,Instrumentation, Publications andTechnical and Training Services werehighlighted during this exhibition. Variousparticipants all over India and abroadshowed keen interest in the activities <strong>of</strong>SASMIRA.167

m i n i s t r y o f t e x t i l e sMAN MADE <strong>TEXTILE</strong>S<strong>RESEARCH</strong> ASSOCIATION(MANTRA), SURATMan-Made <strong>Textiles</strong> Research Association(MANTRA), Surat concentrating on manmadefibres has been taking up needbasedR&D projects in the areas relatedto the quality and productivityimprovement, product development,energy, ecology and environment.MANTRA is recognized as a Scientific andIndustrial Research Organization by the<strong>Ministry</strong> <strong>of</strong> Science & Technology,Government <strong>of</strong> India. The activities <strong>of</strong>MANTRA are primarily aimed at plannedand healthy growth <strong>of</strong> the decentralizedsector. Local textile manufacturingindustries have benefited greatly from theR&D work successfully pursued byMANTRA.The core activity <strong>of</strong> MANTRA beingResearch & Development, theorganization completed four <strong>Ministry</strong> <strong>of</strong><strong>Textiles</strong> funded projects and thefindings have been disseminated toindustry by various means. During theperiod under consideration, MANTRAworked on two on-going projects.Details <strong>of</strong> completed and on-goingprojects are given below.Completed projects <strong>of</strong> MANTRA in2003-04:1. Development <strong>of</strong> air-intermingledelastane combination yarns forstretch fabrics;2. Application <strong>of</strong> formaldehyde freefinishes to man-made fibre fabricssuch as tencel, viscose, polyesterand their blends and performanceevaluation <strong>of</strong> the finished fabrics;3. Flame retardant finishing based oneco-friendly formulations forviscose, polyester and their blends;and4. Application <strong>of</strong> cationic dyes toanionically modified nylon and theirperformance evaluation incomparison with cationic dyedyeable polyester and regular nylonwith special reference to fastnessproperties.On-going projects <strong>of</strong> MANTRADevelopment <strong>of</strong> novel stack-disc frictionunits made from the combination <strong>of</strong>polyurethane (s<strong>of</strong>t) friction discs with otherhard materials’ friction discs and qualityevaluation <strong>of</strong> draw-textured yarns madetherefrom.Development <strong>of</strong> lightweight reusableprotective fabrics from micro deniersynthetic filament yarns.MANTRA has a Computer Aided DesignCentre and two Powerloom ServiceCentres at Sachin and Pandesara. Thepresent activities <strong>of</strong> these units includetraining <strong>of</strong> weavers for quality fabricproduction, design development on loom,testing and technical service support forloom modernization activity, etc., for localWeavers’ Co-operative Societies andweavers in respective areas. As regardsPSC Sachin, it has been shifted to a newlocation in GIDC area.MANTRA has been recognized as aSchedule-I Auditor by Gujarat Pollution168

a n n u a l r e p o r t 0 4 - 0 5Control Board (GPCB). During the yearunder consideration, the team working onenvironmental issues undertookAdequacy and Efficacy certification for 18industries.MANTRA, in collaboration with M/s KothariInfo Tech Ltd., has developed a s<strong>of</strong>twarefor Computer Colour Matching and hasalso developed a huge data base in thisrespect. Also, MANTRA conducted asurvey on “Waterjet looms” in and aroundSurat. Area-wise catalogue and othertechnical details have been compiled. Thisinformation will be used in a study onproduct planning and development.INDIAN JUTE INDUSTRIES<strong>RESEARCH</strong> ASSOCIATION(IJIRA), KOLKATAThe Indian Jute Industries ResearchAssociation (IJIRA), Kolkata registeredunder West Bengal Societies RegistrationAct, 1961, is an autonomous CooperativeResearch Organisation mainly funded bythe <strong>Ministry</strong> <strong>of</strong> <strong>Textiles</strong>, Government <strong>of</strong>India. IJIRA is governed by a Council,headed by the Chairman, assisted by theVice Chairman and 24 members, drawnfrom the Industry, the Government,Eminent Pr<strong>of</strong>essionals and others. TheDirector is appointed by the Council andis the Principal Executive Officer <strong>of</strong> theAssociation exercising general power <strong>of</strong>supervision and coordination <strong>of</strong> overallactivities <strong>of</strong> the Association and is assistedby a Secretary-cum-Financial Controller.There are nine technical divisions andeach division is supervised by a Head orGroup Leader.The objectives <strong>of</strong> IJIRA are:(i) To promote research and otherscientific work connected with thejute trade and industries allied withor accessory thereto;(ii) To establish and maintainlaboratories and faster education <strong>of</strong>people engaged in or likely to beengaged in the said trade andindustry; and(iii) To examine and publish informationregarding the nature and merits <strong>of</strong>inventions, improvements materialsand designs connected with the saidtrades <strong>of</strong> industries.The R&D activities and technology transferprogrammes <strong>of</strong> IJIRA have helpedimprove the productivity, product qualityand cost viability <strong>of</strong> the organized jute millsand also the SMEs in the jute sector.Besides taking care <strong>of</strong> the persistentproblems <strong>of</strong> organised and decentralizedjute sectors, IJIRA is currently engagedin R&D projects such as (i) E-Library onJute, (ii) Wet Spinning TechnologyServices and (iii) Development <strong>of</strong> RamiebasedProducts etc.IJIRA has also set up its North EasternRegional Centre in Assam at Guwahati.The <strong>Ministry</strong> <strong>of</strong> <strong>Textiles</strong> has sanctioned thenecessary budgetary provision for NorthEastern Regional Centre & Promotion <strong>of</strong>Natural Fibres (Jute, Ramie etc.) basedIndustries in North Eastern Region. IJIRAPowerloom Service Centre (PSC) isrendering services to decentralizedPowerloom Units <strong>of</strong> Assam for169

m i n i s t r y o f t e x t i l e simprovement in productivity. TheHandicraft sector is also getting benefitthrough R&D works <strong>of</strong> IJIRA.IJIRA has three Regional Centres atShantipur (West Bengal), Guwahati(Assam) and Vizianagram (AndhraPradesh).WOOL<strong>RESEARCH</strong>ASSOCIATION, THANE (WRA)The Wool Research Association, Thanewas established and registered under theSocieties Registration Act 1860 inOctober 1963. It is engaged in variousactivities, necessary for the technologicalupgradation <strong>of</strong> the Indian WoollenIndustry, which include research anddevelopment work, special trainingprogramme, educational activities,foreign delegations’ visits, workshops andpaper presentations at national andinternational level. It has become anAssociate Member <strong>of</strong> International WoolTextile Organization (IWTO), Brussels,Belgium.Wool Research Association has thefollowing five departments – (i) QualityTest House - ISO 9001-2000 certified, (ii)Chemical Processing Laboratory, (iii) EcoTesting & Analytical Labotatory, (iv) TextileDesigning (CAD-CAM)-Woven & Knitted,and (v) Yarn & Fabric Manufacturing labs.Sponsored Projectsi) During 2003-04, the Khadi & VillageIndustries Commission, Mumbaisanctioned a ‘Science &Technology’ Project entitled“Introduction <strong>of</strong> Indian CrossbreedFine Wools for Woollen KhadiProducts like Shawls, Lohies, etc.”ii) The <strong>Ministry</strong> <strong>of</strong> <strong>Textiles</strong>,Government <strong>of</strong> India sponsored thefollowing two projects to beundertaken by the Wool ResearchAssociation in collaboration with theCentral Silk Board, Bangalore:(a) Optimise Yarn ProcessingParameters for spun Yarn <strong>of</strong>Eri, Silk/Wool blends and todevelop value addedproducts; and(b) To design and fabricatesuitable machinery forprocessing silk and silk/woolblends upto yarn stage fordecentralized sector andcottage industry.Industrial Consultancy & TechnicalServicesThe Association provided variousindustrial consultancy and technicalservices to the Indian Woollen Industrythrough its established infrastructureduring 2003-04, which included thefollowing:●●Consultancy to M/s SiddharthColourchem in application &improved properties <strong>of</strong> metal freereactive dyes on wool;Consultancy to M/s BhutticoWeavers Society (Kullu) to set upa Dyeing & Finishing facility Centrefor shawls and other woollensmade from Wool/Angora &Pashmina;170

a n n u a l r e p o r t 0 4 - 0 5●●●Training programmes for dyeing inthe carpet, shawl and namda belts<strong>of</strong> the country;Consultancy in setting up miniscouringfacilities for wool producingareas in different States likeRajasthan, Himachal Pradesh,Jammu & Kashmir; andConsultancy to Dharamsi MorarjiChemicals in developing dyeingauxiliaries.1. Computer Aided Textile Designing2. Instrumental Chemical Analysis3. Textile Testing and Quality ControlOther Activities● Wool Research Associationconducted a dyeing trainingprogramme in Tonk, Jaipur(Rajasthan) to boost the growth <strong>of</strong>the Namada industry through bettervalue addition.Short Term CoursesWRA conducted short term courses byimparting training in textile testing andresearch in the field <strong>of</strong> textile technology,specifically wool technology, and alsoconducted the following tailor-made shortduration courses for the benefits <strong>of</strong> cottageand organized woollen industry:●The in-plant training for degreestudents <strong>of</strong> Textile and EngineeringInstitute, Ichalkaranji was arrangedat WRA. The students benefitedfrom different aspects like ComputerAided Textile Designing, Tie & DyeTechniques for wool, wool testingand mechanical processing etc.171