Nitrogen Gas Springs and Accessories - Electronic Fasteners Inc

Nitrogen Gas Springs and Accessories - Electronic Fasteners Inc Nitrogen Gas Springs and Accessories - Electronic Fasteners Inc

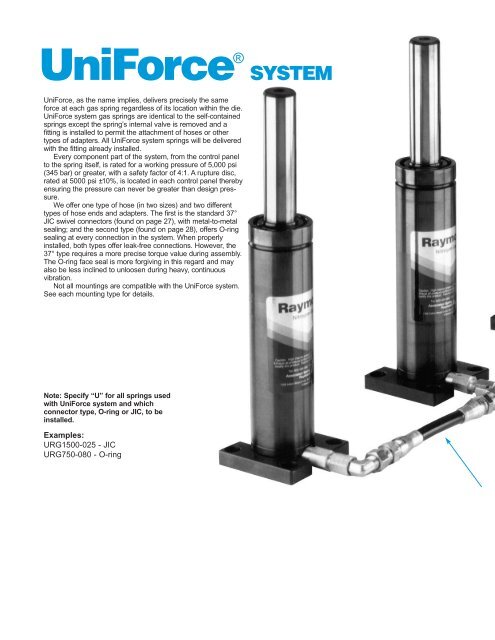

UniForce ® SYSTEMUniForce, as the name implies, delivers precisely the sameforce at each gas spring regardless of its location within the die.UniForce system gas springs are identical to the self-containedsprings except the spring’s internal valve is removed and afitting is installed to permit the attachment of hoses or othertypes of adapters. All UniForce system springs will be deliveredwith the fitting already installed.Every component part of the system, from the control panelto the spring itself, is rated for a working pressure of 5,000 psi(345 bar) or greater, with a safety factor of 4:1. A rupture disc,rated at 5000 psi ±10%, is located in each control panel therebyensuring the pressure can never be greater than design pressure.We offer one type of hose (in two sizes) and two differenttypes of hose ends and adapters. The first is the standard 37°JIC swivel connectors (found on page 27), with metal-to-metalsealing; and the second type (found on page 28), offers O-ringsealing at every connection in the system. When properlyinstalled, both types offer leak-free connections. However, the37° type requires a more precise torque value during assembly.The O-ring face seal is more forgiving in this regard and mayalso be less inclined to unloosen during heavy, continuousvibration.Not all mountings are compatible with the UniForce system.See each mounting type for details.Note: Specify “U” for all springs usedwith UniForce system and whichconnector type, O-ring or JIC, to beinstalled.Examples:URG1500-025 - JICURG750-080 - O-ring

Raymond ®Control PanelOrder No. SP4Mounting Holes are for3⁄8" Socket Head ScrewsPort on sidePortPortHigh Pressure Hose5,000 psi (345 bar) pressure ratingAramid Braided FiberPerforated outer coverfor pneumatic serviceMaximum working pressure—5,000 psi (345 bar)Minimum burst pressure—20,000 psi (1380 bar)The system pressure can be adjusted easily at the controlpanel. To lower pressure, simply open drain valve until thepressure drops to desired level. To raise pressure, hook upthe charging assembly’s female quick disconnect to themale nipple of the control panel. Open the valve on thenitrogen bottle and open the valve of the charging assemblyuntil desired pressure is reached. We do not however,recommend leaving the charging assembly hooked upwhen the die is running in the press.Aramid Braided Fiber• Meets or exceeds SAE 100R8 specificationsAramid reinforcement for compact strength and flexibility• Temperature range: -40°F to +200°F (-40°C to +93°C)• Couplings: 55 series, swaged or crimped• Hoses have permanently attached hose ends andcannot be assembled with normal hand tools.• Minimum hose length from end of fitting to end of fittingis 150 mm / 6 inches.• When ordering, specify length of hose in inches.Hose Support ClampOrder No. SP3• Prevents damage to hose• Provides support where long lengths are used• Minimizes hose chafing problems• Avoids twisting of hose lines• Keeps hose away from other moving objects

- Page 1: Raymond®Nitrogen Gas Springs and A

- Page 5 and 6: Raymond ®RD-19Disposable Mini Spri

- Page 7 and 8: Raymond ®RD-150Disposable Mini Spr

- Page 9 and 10: Raymond ®REStripper Springs — Se

- Page 11 and 12: Ordering Information — RCT 300 th

- Page 13 and 14: Mounting plate “J” for Models R

- Page 15 and 16: Model TRaymond ®All Threaded (Also

- Page 17 and 18: Ordering Information — RG-750 thr

- Page 19 and 20: Mounting plate “J” for Models R

- Page 21 and 22: Mounting Arrangements for RG 750 th

- Page 23 and 24: Ordering Information — RS-1000 th

- Page 25: RH 500 through RH 2200 cont.Flange

- Page 29 and 30: Hose Fittings — 9/16"-18" — O-R

- Page 31 and 32: Flange Stripper Top MountRaymond ®

- Page 33 and 34: RW-R Roller Cam Wedge UnitRaymond

- Page 35 and 36: RW-A Roller Cam Wedge UnitRaymond

- Page 37 and 38: Raymond ®RRRoller CamRaymond Rolle

- Page 39 and 40: Model RR 15 Roller CamRaymond ®Ord

- Page 41 and 42: Raymond ®Ordering Information —

- Page 43 and 44: Raymond ®RPPneumatic Pin Extractor

- Page 45 and 46: Spare Parts and AccessoriesRaymond

- Page 47 and 48: Typical Applications for Nitrogen G

- Page 49 and 50: How to OrderNitrogen Gas SpringsOrd

- Page 51 and 52: NotesRaymond ®

UniForce ® SYSTEMUniForce, as the name implies, delivers precisely the sameforce at each gas spring regardless of its location within the die.UniForce system gas springs are identical to the self-containedsprings except the spring’s internal valve is removed <strong>and</strong> afitting is installed to permit the attachment of hoses or othertypes of adapters. All UniForce system springs will be deliveredwith the fitting already installed.Every component part of the system, from the control panelto the spring itself, is rated for a working pressure of 5,000 psi(345 bar) or greater, with a safety factor of 4:1. A rupture disc,rated at 5000 psi ±10%, is located in each control panel therebyensuring the pressure can never be greater than design pressure.We offer one type of hose (in two sizes) <strong>and</strong> two differenttypes of hose ends <strong>and</strong> adapters. The first is the st<strong>and</strong>ard 37°JIC swivel connectors (found on page 27), with metal-to-metalsealing; <strong>and</strong> the second type (found on page 28), offers O-ringsealing at every connection in the system. When properlyinstalled, both types offer leak-free connections. However, the37° type requires a more precise torque value during assembly.The O-ring face seal is more forgiving in this regard <strong>and</strong> mayalso be less inclined to unloosen during heavy, continuousvibration.Not all mountings are compatible with the UniForce system.See each mounting type for details.Note: Specify “U” for all springs usedwith UniForce system <strong>and</strong> whichconnector type, O-ring or JIC, to beinstalled.Examples:URG1500-025 - JICURG750-080 - O-ring