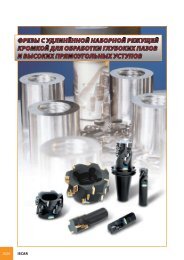

ÐнÑÑÑÑÐ¼ÐµÐ½Ñ Ð´Ð»Ñ ÑÑезеÑованиÑ

ÐнÑÑÑÑÐ¼ÐµÐ½Ñ Ð´Ð»Ñ ÑÑезеÑованиÑ

ÐнÑÑÑÑÐ¼ÐµÐ½Ñ Ð´Ð»Ñ ÑÑезеÑованиÑ

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

DIXI 7222 - 7223 - 7224DIXI 7222 DIXI 7223 - 7224CUTTING CONDITIONSapap HM TiALNaeaeap ae ap aeMaterials to be machined Vc [m/min]Vc [m/min] [mm] [mm] [mm] [mm] / P< 600 2 45 50 50 60 3 x ØD1 < 0.30 x ØD13 x ØD1 < 0.20 x ØD1Unalloyed steel / Low alloyed steel / P600 – 1500 235 45 3 x ØD1 < 0.20 x ØD13 x ØD1 < 0.10 x ØD1Unalloyed steel / Low alloyed steel45 50 3 x ØD1 < 0.30 x ØD13 x ØD1 < 0.20 x ØD1PLead alloyed cutting steel700 – 1500 230 45 3 x ØD1 < 0.15 x ØD13 x ØD1 < 0.07 x ØD1PHigh alloyed steel400 – 700 235 45 3 x ØD1 < 0.20 x ØD13 x ØD1 < 0.10 x ØD1MStainless steel / < 250 HB 25 35 35 45 3 x ØD1 < 0.30 x ØD13 x ØD1 < 0.20 x ØD1KGrey cast iron / Nodular iron pearlitic / > 250 HB 25 35 35 45 3 x ØD1 < 0.15 x ØD13 x ØD1 < 0.07 x ØD1KAlloyed cast iron / Nodular iron pearlitic / 25 35 35 45 3 x ØD1 < 0.30 x ØD13 x ØD1 < 0.20 x ØD1KNodular iron pearlitic / Malleable cast iron / InconelNimonic15 25 3 x ØD1 < 0.10 x ØD13 x ØD1 < 0.05 x ØD1SSpecial alloys / Heat resisting stainless steel Hastelloy / 15 25 3 x ØD1 < 0.15 x ØD13 x ØD1 < 0.07 x ØD1STitanium / Titanium alloy - ( - )80 100 3 x ØD1 < 0.30 x ØD13 x ØD1 < 0.20 x ØD1NCopper alloy - easy to machine (brass – bronze) - (. - )(CuAlFe) 60 80 80 100 3 x ØD1 < 0.30 x ØD13 x ØD1 < 0.20 x ØD1NCopper alloy - difficult to machine / Aluminium bronze (Ampco) / 80 100 100 120 3 x ØD1 < 0.40 x ØD13 x ØD1 < 0.30 x ØD1NAluminium alloy / Magnesium alloySi < 8% 90 110 110 130 3 x ØD1 < 0.40 x ØD13 x ØD1 < 0.30 x ØD1NAluminium cast ironSi > 8% 80 100 100 120 3 x ØD1 < 0.40 x ØD13 x ØD1 < 0.30 x ØD1NAluminium cast iron90 110 110 130 3 x ØD1 < 0.40 x ØD13 x ØD1 < 0.30 x ØD1NPlastic, 80 100 100 120 3 x ØD1 < 0.40 x ØD13 x ØD1 < 0.30 x ØD1NGold, silver (Vfp) , Z=2 40% - 80 % - .The plunging feed (Vfp) of an end mill Z = 2 (drilling) must be reduced from 40 to 80 % depending on the materialto be machined.186