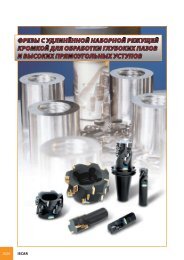

ÐнÑÑÑÑÐ¼ÐµÐ½Ñ Ð´Ð»Ñ ÑÑезеÑованиÑ

ÐнÑÑÑÑÐ¼ÐµÐ½Ñ Ð´Ð»Ñ ÑÑезеÑованиÑ

ÐнÑÑÑÑÐ¼ÐµÐ½Ñ Ð´Ð»Ñ ÑÑезеÑованиÑ

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TABLE OF END MILLSn HM n DICUT n CUTINOXn TiN n TiALN n DIAMANTPPPPMHKKKSSNNNNNNNNN / Unalloyed steel / Low alloyed steel / Unalloyed steel / Low alloyed steel Lead alloyed cutting steel High alloyed steel Stainless steelCutting materialCBN PCD CVD ND / MDCs l z On request< 600 / 2600 – 1500 / 2700 – 1500 / 2400 – 700 / 2 > 1500 / 2 (50-65 HRC)Tool steel and cast iron / < 250 HBGrey cast iron / Nodular iron pearlitic / > 250 HBAlloyed cast iron / Nodular iron pearlitic / Nodular iron pearlitic / Malleable cast iron / InconelNimonicSpecial alloys / Heat resisting stainless steelHastelloy / Titanium / Titanium alloy - ( - )Copper alloy - easy to machine (brass – bronze) - ( - ) (CuAlFe)Copper alloy - difficult to machine / Aluminium bronze(Ampco) / Aluminium alloy / Magnesium alloy Si < 8%Aluminium cast iron Si > 8%Aluminium cast ironGraphitePlastic Kevlar®Or, argentGold, silver94Diamondtools> . 311slzlllllzlzll. 124nnnnnnnnDIXI 7060Ø 0.50 -

DIXI 7202Ø 1.50 -DIXI 7203Ø 2.00 -DIXI 7204Ø 2.00 -DIXI 7210Ø 3.00 -DIXI 7213Ø 4.00 -DIXI 7214Ø 6.00 -. 129 . 130 . 131. 132 . 133. 13466nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn95 .96 Continued on page 96

TABLE OF END MILLS. 135DIXI 7222Ø 3.00 -. 136DIXI 7223Ø 3.00 -n HM n DICUT n XIDURn TiN n TiALN n DIAMANTP / Unalloyed steel / Low alloyed steel< 600 / 2nnnnP / Unalloyed steel / Low alloyed steel600 – 1500 / 2nnP Lead alloyed cutting steelnnP High alloyed steel700 – 1500 / 2nnM Stainless steel400 – 700 / 2nnH Tool steel and cast iron> 1500 / 2 (50-65 HRC)K / Grey cast iron / Nodular iron pearlitic < 250 HBnnnnK / Alloyed cast iron / Nodular iron pearlitic > 250 HBnnnnK / Nodular iron pearlitic / Malleable cast ironnnnnS / Special alloys / Heat resisting stainless steelInconelNimonicHastelloynnS / Titanium / Titanium alloynnN - ( - )Copper alloy - easy to machine (brass – bronze)nnN - ( - ) (CuAlFe)Copper alloy - difficult to machine / Aluminium bronze(Ampco)nnnnN / Aluminium alloy / Magnesium alloynnnnN Si < 8%Aluminium cast ironnnnnN Si > 8%Aluminium cast ironnnnnNGraphitennNPlasticnnnnNN Kevlar®Or, argentGold, silvernnnn96

DIXI 7224Ø 3.00 -DIXI 7232Ø 2.00 -DIXI 7237 +7237-10DIXI 7238Ø 0.30- 3.00DIXI 7239Ø 0.40- 3.00DIXI 7240Ø 0.05- 5.50. 137 . 138. 139. 140. 141. 14266nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn97.98 Continued on page 98

DIXI 7244Ø 0.40 -DIXI 7263Ø 2.00 -DIXI 7273Ø 3.00 -DIXI 7301Ø 2.00 - 8.00DIXI 7302Ø 3.00 -DIXI 7303Ø 2.00 - 5.00. 146. 147. 148. 149. 149. 1506 652712nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn99.100 Continued on page 100

TABLE OF END MILLSn HM n DICUT n XIDURn TiN n TiALN n DIAMANT. 150DIXI 7304Ø 3.00 -. 151DIXI 7520Ø 0.40 -6Z = 3 -PPPPMHKKKS / < 600 / 2Unalloyed steel / Low alloyed steel / 600 – 1500 / 2Unalloyed steel / Low alloyed steel Lead alloyed cutting steel 700 – 1500 / 2High alloyed steel 400 – 700 / 2Stainless steel > 1500 / 2 (50-65 HRC)Tool steel and cast iron / < 250 HBGrey cast iron / Nodular iron pearlitic / > 250 HBAlloyed cast iron / Nodular iron pearlitic / Nodular iron pearlitic / Malleable cast iron / InconelNimonicSpecial alloys / Heat resisting stainless steelHastelloynSNNNNNNNNN / Titanium / Titanium alloy - ( - )Copper alloy - easy to machine (brass – bronze) - ( - ) (CuAlFe)Copper alloy - difficult to machine / Aluminium bronze(Ampco) / Aluminium alloy / Magnesium alloy Si < 8%Aluminium cast iron Si > 8%Aluminium cast ironGraphitePlastic Kevlar®Or, argentGold, silver100n

DIXI 7543Ø 1.00 -DIXI 7560Ø 0.35 -DIXI 7561Ø 2.00 -DIXI 7562Ø 6.00 -DIXI 7572Ø 3.00 -DIXI 7582Ø 1.00 - 5.50. 154. 157. 158. 159. 160. 161Z =6D 1>2.8nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn n nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn101.102 Continued on page 102

TABLE OF END MILLSn HM n DICUT n XIDURn TiN n TiALN n DIAMANT. 162DIXI 7583Ø 0.5 - 3.00. 163DIXI 7593Ø 6.00 -Z = 3 -P / Unalloyed steel / Low alloyed steel< 600 / 2P / Unalloyed steel / Low alloyed steel600 – 1500 / 2P Lead alloyed cutting steelP High alloyed steel700 – 1500 / 2nM Stainless steel400 – 700 / 2nH Tool steel and cast iron> 1500 / 2 (50-65 HRC)K / Grey cast iron / Nodular iron pearlitic < 250 HBK / Alloyed cast iron / Nodular iron pearlitic > 250 HBK / Nodular iron pearlitic / Malleable cast ironS / Special alloys / Heat resisting stainless steelInconelNimonicHastelloyS / Titanium / Titanium alloynN - ( - )Copper alloy - easy to machine (brass – bronze)nN - ( - ) (CuAlFe)Copper alloy - difficult to machine / Aluminium bronze(Ampco)N / Aluminium alloy / Magnesium alloynnnN Si < 8%Aluminium cast ironnnnN Si > 8%Aluminium cast ironnnnNGraphiteNPlasticNN Kevlar®Or, argentGold, silvernn102

103

-DIXI 7032Ø 0.06 -Diamondtools. 116TABLE OF BALL-NOSE AND TORIC FLUTEEND MILLSn HM n DICUT n XIDURCBN PCD CVD ND / MDCs l z > . 311n TiN n TiALN n DIAMANTOn requestP / Unalloyed steel / Low alloyed steel< 600 / 2nnP / Unalloyed steel / Low alloyed steel600 – 1500 / 2nP Lead alloyed cutting steelnP High alloyed steel700 – 1500 / 2nM Stainless steel400 – 700 / 2nH Tool steel and cast iron> 1500 / 2 (50-65 HRC)sK / Grey cast iron / Nodular iron pearlitic < 250 HBnnK / Alloyed cast iron / Nodular iron pearlitic > 250 HBnnK / Nodular iron pearlitic / Malleable cast ironnnS / Special alloys / Heat resisting stainless steelInconelNimonicHastelloynS / Titanium / Titanium alloylznN - ( - )Copper alloy - easy to machine (brass – bronze)lnN - ( - ) (CuAlFe)Copper alloy - difficult to machine / Aluminium bronze(Ampco)ln n nN / Aluminium alloy / Magnesium alloylnnN Si < 8%Aluminium cast ironlnnN Si > 8%Aluminium cast ironlznnNGraphitelznNPlasticlnnNN Kevlar®Or, argentGold, silverlnn104

DIXI 7033Ø 1.00 -DIXI 7034Ø 6.00 -DIXI 7042Ø 2.00 -DIXI 7045Ø 0.20 -DIXI 7046Ø 0.20 -DIXI 7047Ø 0.20 -. 117 . 118 . 119. 120. 121. 122nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn n nn n nn n nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn105 .106 Continued on page 106

-. 123DIXI 7050Ø 2.00 -. 125DIXI 7070Ø 3.00 -TABLE OF BALL-NOSE AND TORIC FLUTEEND MILLSn HM n DICUT n XIDURn TiN n TiALN n DIAMANTP / Unalloyed steel / Low alloyed steel< 600 / 2nP / Unalloyed steel / Low alloyed steel600 – 1500 / 2nP Lead alloyed cutting steelnPM High alloyed steel Stainless steel700 – 1500 / 2400 – 700 / 2nnnH Tool steel and cast iron> 1500 / 2 (50-65 HRC)nK / Grey cast iron / Nodular iron pearlitic < 250 HBnK / Alloyed cast iron / Nodular iron pearlitic > 250 HBnK / Nodular iron pearlitic / Malleable cast ironnS / Special alloys / Heat resisting stainless steelInconelNimonicHastelloynS / Titanium / Titanium alloynN - ( - )Copper alloy - easy to machine (brass – bronze)nN - ( - ) (CuAlFe)Copper alloy - difficult to machine / Aluminium bronze(Ampco)nN / Aluminium alloy / Magnesium alloynN Si < 8%Aluminium cast ironnN Si > 8%Aluminium cast ironnNGraphiteNPlasticnNN Kevlar®Or, argentGold, silvern106

DIXI 7090Ø 2.00 -DIXI 7532Ø 1.00 -DIXI 7542Ø 1.00 -DIXI 7552Ø 3.00 -DIXI 7554Ø 2.00 -. 126. 152 . 153. 155. 156nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn n nnnnnnnnnnnnnn107

, . > 45 HRCTABLE OF HSC END MILLSAND STEEL MACHINING > 45 HRCn HM n DICUT n XIDURn TiN n TiALN n DIAMANTPPPPMHKKKS / Unalloyed steel / Low alloyed steel / Unalloyed steel / Low alloyed steel Lead alloyed cutting steel High alloyed steel Stainless steel Tool steel and cast iron / Grey cast iron / Nodular iron pearlitic / Alloyed cast iron / Nodular iron pearlitic / Nodular iron pearlitic / Malleable cast iron / Special alloys / Heat resisting stainless steel Cutting materialCBN PCD CVD ND / MDCs l z On request< 600 / 2600 – 1500 / 2700 – 1500 / 2400 – 700 / 2> 1500 / 2 (50-65 HRC) < 250 HB > 250 HBInconelNimonicHastelloyDiamondtools> . 311s. 116nnnnnDIXI 7032Ø 0.06 -nnnnnnnnS / Titanium / Titanium alloylznN - ( - )Copper alloy - easy to machine (brass – bronze)lnN - ( - ) (CuAlFe)Copper alloy - difficult to machine / Aluminium bronze(Ampco)ln n nN / Aluminium alloy / Magnesium alloylnnN Si < 8%Aluminium cast ironlnnN Si > 8%Aluminium cast ironlznnNGraphitelznNPlasticlnnNN Kevlar®Or, argentGold, silverlnn108

DIXI 7042Ø 2.00 -DIXI 7045Ø 0.20 -DIXI 7046Ø 0.20 -DIXI 7047Ø 0.20 -DIXI 7050Ø 2.00 -DIXI 7070Ø 3.00 -. 119. 120. 121. 122. 123. 125nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn n nn n nn n nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn109 .110 Continued on page 110

, . > 45 HRC. 126DIXI 7090Ø 2.00 -. 151DIXI 7520Ø 0.40 -TABLE OF HSC END MILLSAND STEEL MACHINING > 45 HRCn HM n DICUT n XIDURn TiN n TiALN n DIAMANT6P / Unalloyed steel / Low alloyed steel< 600 / 2nnP / Unalloyed steel / Low alloyed steel600 – 1500 / 2nP Lead alloyed cutting steelnP High alloyed steel700 – 1500 / 2nM Stainless steel400 – 700 / 2nH Tool steel and cast iron> 1500 / 2 (50-65 HRC)nK / Grey cast iron / Nodular iron pearlitic < 250 HBnnK / Alloyed cast iron / Nodular iron pearlitic > 250 HBnnK / Nodular iron pearlitic / Malleable cast ironnnS / Special alloys / Heat resisting stainless steelInconelNimonicHastelloynSNNNNNNNNN / Titanium / Titanium alloy - ( - )Copper alloy - easy to machine (brass – bronze) - ( - ) (CuAlFe)Copper alloy - difficult to machine / Aluminium bronze(Ampco) / Aluminium alloy / Magnesium alloy Si < 8%Aluminium cast iron Si > 8%Aluminium cast ironGraphitePlastic Kevlar®Or, argentGold, silver110nnn nn nn nn n nnn nn n

DIXI 7532Ø 1.00 -DIXI 7542Ø 1.00 -DIXI 7543Ø 1.00 - 12.00DIXI 7552Ø 3.00 - 20.00DIXI 7554Ø 2.00 -DIXI 7560Ø 0.35 - 20.00. 152. 153. 154. 155. 156. 1576nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn111.112 Continued on page 112

, . > 45 HRCDIXI 7561Ø 2.00 - 12.00. 158. 159DIXI 7562Ø 6.00 -TABLE OF HSC END MILLSAND STEEL MACHINING > 45 HRCn HM n DICUT n XIDURn TiN n TiALN n DIAMANTP / Unalloyed steel / Low alloyed steel< 600 / 2P / Unalloyed steel / Low alloyed steel600 – 1500 / 2P Lead alloyed cutting steelnP High alloyed steel700 – 1500 / 2M Stainless steel400 – 700 / 2H Tool steel and cast iron> 1500 / 2 (50-65 HRC)K / Grey cast iron / Nodular iron pearlitic < 250 HBK / Alloyed cast iron / Nodular iron pearlitic > 250 HBK / Nodular iron pearlitic / Malleable cast ironS / Special alloys / Heat resisting stainless steelInconelNimonicHastelloyS / Titanium / Titanium alloynN - ( - )Copper alloy - easy to machine (brass – bronze)nnN - ( - ) (CuAlFe)Copper alloy - difficult to machine / Aluminium bronze(Ampco)N / Aluminium alloy / Magnesium alloynnnN Si < 8%Aluminium cast ironnnnN Si > 8%Aluminium cast ironnnnNGraphiteNPlasticnnnNN Kevlar®Or, argentGold, silver112

DIXI 7572Ø 3.00 - 20.00DIXI 7582Ø 1.00 -DIXI 7583Ø 1.00 -DIXI 7593Ø 6.00 -. 160. 161. 162. 1632.8nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn113

KEVLAR ®KEVLAR ®TABLE OF CHAMFERING END MILLSAND END MILLS FOR KEVLAR ®n HM n DICUT n XIDURDIXI 7623Ø 0.80 -. 164 . 127DIXI 7112Ø 5.00 -n TiN n TiALN n DIAMANTP / Unalloyed steel / Low alloyed steel< 600 / 2nnP / Unalloyed steel / Low alloyed steel600 – 1500 / 2nP Lead alloyed cutting steelnP High alloyed steel700 – 1500 / 2nM Stainless steel400 – 700 / 2nH Tool steel and cast iron> 1500 / 2 (50-65 HRC)K / Grey cast iron / Nodular iron pearlitic < 250 HBnnK / Alloyed cast iron / Nodular iron pearlitic > 250 HBnnK / Nodular iron pearlitic / Malleable cast ironnnS / Special alloys / Heat resisting stainless steelInconelNimonicHastelloynS / Titanium / Titanium alloynN - ( - )Copper alloy - easy to machine (brass – bronze)nN - ( - ) (CuAlFe)Copper alloy - difficult to machine / Aluminium bronze(Ampco)nnN / Aluminium alloy / Magnesium alloynnN Si < 8%Aluminium cast ironnnN Si > 8%Aluminium cast ironnnNGraphitennNNNPlastic Kevlar®Or, argentGold, silvernnnnn114

DIXI 7113Ø 4.76 -. 128n115

DIXI 7032Z = 2BALL-NOSE END MILLS. 166 . 168ISO 513: P M KD 1 L 1 D h6 L HM DICUT TiALN DIAMANTØ

DIXI 7033Z = 3BALL-NOSE END MILLS. 170 . 166ISO 513: P M KD 1 L 1 D h6 L HM TiALNØ

DIXI 7034Z = 4BALL-NOSE END MILLS. 166 . 170ISO 513: P M KD 1 e8 L 1 D h6 L HM TiALN6 9 6 578 12 8 6310 15 10 7312 18 12 7314 21 14 7516 24 16 8220 30 20 104•= Weldon DIN 6535-HB - .•= WELDON-Spannfläche nach DIN 6535-HB auf Anfrage.•=118

DIXI 7042Z = 2. 174. 207. 166ISO 513: P M KBALL-NOSE END MILLSD 1 e8 L 1 D h6 L HM TiALN DIAMANT2 10 2 613 10 3 614 12 4 755 14 5 86• 6 16 6 93• 8 20 8 100•10 24 10 100•12 28 12 110•14 32 14 120•16 36 16 120•20 45 20 150•= Weldon DIN 6535-HB - .•= WELDON-Spannfläche nach DIN 6535-HB auf Anfrage.•=119

DIXI 7045Z = 2BALL-NOSE END MILLS. 166 . 172ISO 513: P M KD 1 L 1 D 2 D h6 L 2 L HM DICUT TiALNØ

DIXI 7046Z = 2BALL-NOSE END MILLS. 172 . 166ISO 513: P M KD 1 L 1 D 2 D h6 L 2 L HM DICUT TiALNØ

DIXI 7047Z = 2BALL-NOSE END MILLS. 166 . 172ISO 513: P M KD 1 L 1 D 2 D h6 L 2 L HM DICUT TiALNØ

DIXI 7050 . 174 . 166BALL-NOSE END MILLSISO 513: P M K -The tapered shank of these end mills enablesmachining of deep forms without vibration.D 1 L 1 D h6 L L 2 Z TiALNØ

DIXI 7060 Z = 1STRAIGHT FLUTE SLOT DRILLS. 188ISO 513: P K ND 1 ± 0.01 L 1 D h6 L HM0.50 1.0 4 350.60 1.2 4 350.70 1.5 4 350.80 1.5 4 350.90 1.5 4 351.00 1.5 4 351.10 2.0 4 351.20 2.0 4 351.30 2.0 4 351.40 2.0 4 351.50 2.0 4 351.60 2.0 4 351.70 2.5 4 351.80 2.5 4 351.90 2.5 4 352.00 2.5 4 352.50 3.0 4 353.00 3.5 4 423.50 4.0 4 424.00 5.0 4 42• 4.50 6.0 6 50• 5.00 7.0 6 50• 6.00 7.0 8 50•= Weldon DIN 6535-HB - .•= WELDON-Spannfläche nach DIN 6535-HB auf Anfrage.•=124

DIXI 7070 XIDUR. 206MULTI-TOOTH END MILLSWITH CORNER RADIUSISO 513: P HD 1 e8 L 1 D 2 L 2 D h6 L R Z XIDUR3 4.5 2.75 12.0 6 57 0.5 44 6.0 3.70 13.5 6 57 0.5 45 7.5 4.60 17.5 6 57 0.5 46 9.0 5.50 24.0 6 66 0.5 46 9.0 5.50 24.0 6 66 0.8 46 9.0 5.50 24.0 6 66 1.0 46 9.0 5.50 24.0 6 66 1.5 48 10.0 7.50 28.0 8 75 0.5 68 10.0 7.50 28.0 8 75 1.0 68 10.0 7.50 28.0 8 75 1.5 68 10.0 7.50 28.0 8 75 2.0 610 12.0 9.25 30.0 10 75 0.5 610 12.0 9.25 30.0 10 75 1.0 610 12.0 9.25 30.0 10 75 1.5 610 12.0 9.25 30.0 10 75 2.0 610 12.0 9.25 30.0 10 75 2.5 612 12.0 11.00 32.0 12 83 1.0 612 12.0 11.00 32.0 12 83 1.5 612 12.0 11.00 32.0 12 83 2.0 612 12.0 11.00 32.0 12 83 3.0 6•= Weldon DIN 6535-HB - .•= WELDON-Spannfläche nach DIN 6535-HB auf Anfrage.•=125

DIXI 7090MULTI-TOOTH END MILLSWITH CORNER RADIUS. 184ISO 513: P M KD 1 L 1 D 2 L 2 D h6 L R Z HM TiALN DIAMANTØ

DIXI 7112Z = 2 ROUTERS FOR COMPOSITESISO 513:N : Vc = 250 - 500 [/.] Vf = 500 - 2000 [/.] .-.SCHNITTBEDINGUNGEN:FräsenVc = 250 - 500 [m/min.]Vf = 500 - 2000 [mm/min.]Die Stärke der zu bearbeitendenFaserverbundplatte hat einen direkten Einflussauf die Steigung der Fräswerkzeuge.In manchen Fällen kann ein Spezialwerkzeugnotwendig werden.D 1 L 1 L HM5.00 20 756.00 25 756.35 1/4" 25 758.00 25 759.52 3/8" 25 7510.00 25 7512.00 25 7512.70 1/2" 27 75 :- , .- , -, . 60°C(140°F), .CUTTING CONDITIONS :Routing[mm/min.]Vc = 250 - 500 [m/min.]Vf = 500 - 2000Depending on the thickness of the materialto be machined, the router pitch can vary.Therefore,a special tool is necessary in some cases.The two main conditions are :- Fibres must be cut without producing any fuzz, delamination andburr.- The heat produced during machining must be removed through thetool and, if possible, with compressed air.Furthermore, the work temperature must not exceed 60°C (140°F) inorder to avoid the resin melting.127

DIXI 7113- “COMBI” Z = 2BORING ROUTERS “COMBI”FOR COMPOSITESISO 513:N : Vc = 100 - 150 [/.] f = 0.05 - 0.15 [/]D 1 inches L 1 L HM4.76 3/16" 25 755.00 25 756.00 30 756.35 1/4" 30 758.00 30 759.52 3/8" 30 7510.00 30 7512.00 30 7512.70 1/2" 30 75 :- , -.- , -, . 60°C(140°F), . Vc = 250 - 500 [/.] Vf = 500 - 2000 [/.] -. -.SCHNITTBEDINGUNGEN:BohrenFräsenVc = 100 - 150 [m/min.]f = 0.05 - 0.15 [mm/U.]Vc = 250 - 500 [m/min.]Vf = 500 - 2000 [mm/min.]Die Stärke der zu bearbeitenden Faserverbundplattehat einen direkten Einfluss auf die Steigung derFräswerkzeuge.In manchen Fällen kann ein Spezialwerkzeugnotwendig werden.CUTTING CONDITIONS :Drilling Vc = 100 - 150 [m/min.]f = 0.05 - 0.15 [mm/rev.]The two main conditions are:- Fibres must be cut without producing any fuzz, delamination andburr.- The heat produced during machining must be removed through thetool and, if possible, with compressed air.Furthermore, the work temperature must not exceed 60°C (140°F)in order to avoid the resin melting.Routing Vc = 250 - 500 [m/min.]Vf = 500 - 2000 [mm/min.]Depending on the thickness of the material to bemachined, the router pitch can vary. Therefore,a special tool is necessary in some cases.128

DIXI 7202Z = 2- SLOT DRILLS - CENTRE CUTTING. 176. 165ISO 513: P M KD 1 L 1 D h6 L HM TiALNØ

DIXI 7203Z = 3SLOT DRILLS - CENTRE CUTTING. 165 . 180ISO 513: P M KD 1 e8 L 1 D h6 L HM TiALN2.00 8.0 2.0 322.50 8.0 2.5 323.00 10.0 3.0 383.50 12.0 3.5 384.00 12.0 4.0 505.00 15.0 5.0 50• 6.00 18.0 6.0 507.00 20.0 7.0 60• 8.00 25.0 8.0 639.00 25.0 9.0 67•10.00 30.0 10.0 7211.00 30.0 11.0 73•12.00 30.0 12.0 7313.00 30.0 13.0 75•14.00 30.0 14.0 7515.00 30.0 15.0 75•16.00 30.0 16.0 92•18.00 40.0 18.0 125•20.00 40.0 20.0 130•= Weldon DIN 6535-HB - .•= WELDON-Spannfläche nach DIN 6535-HB auf Anfrage.•=130

DIXI 7204Z = 46. 182 . 165SLOT DRILLS - CENTRE CUTTINGISO 513: P M KD 1 e8 L 1 D h6 L HM TiALN2.00 8 2.0 322.50 8 2.5 323.00 10 3.0 384.00 12 4.0 505.00 14 5.0 50• 6.00 16 6.0 50•= Weldon DIN 6535-HB - .•= WELDON-Spannfläche nach DIN 6535-HB auf Anfrage.•=131

DIXI 7210 WZ = 3ROUGHING END MILLS. 165 . 1900.20x45°ISO 513: P M KD 1 d12 L 1 D h6 L HM CUTINOX3.00 8.0 6 574.00 10.0 6 575.00 13.0 6 576.00 13.0 8 637.00 16.0 8 638.00 16.0 8 639.00 18.0 10 7210.00 22.0 10 72 Weldon DIN 6535-HB.Mit WELDON-Spannfläche nach DIN 6535-HB.With WELDON configuration according to DIN 6535-HB.132

DIXI 7213 WZ = 3- ""0.20x45°. 192. 165"PIRANHA" ROUGHING END MILLSISO 513: P K N” .--, . . DIXI 7213 “” .D 1 d12 L 1 D h6 L HM TiALN4.00 10.0 6 575.00 13.0 6 576.00 13.0 8 637.00 16.0 8 638.00 16.0 10 7210.00 22.0 10 7211.00 22.0 12 8312.00 25.0 12 8314.00 27.0 14 8316.00 36.0 16 10020.00 40.0 20 104 Weldon DIN 6535-HB.Mit WELDON-Spannfläche nach DIN 6535-HB.With WELDON configuration according to DIN 6535-HB.Developed for rough milling, these end mills haveteeth especially designed for maximum chip removal.The particular shape of the radial relief with constantprofile guarantees improved chip breakage andreduces the cutting forces, permitting higher metalremoval rates.These end mills can be sharpened by regrinding theend face in the usual manner, while regrinding theflute will restore the cutting edge on the diameter.133

DIXI 7214 W- ""Z = 46"PIRANHA" ROUGHING END MILLS. 165. 192ISO 513: P K ND 1 d12 L 1 D h6 L HM TiALN6.00 15.0 6 578.00 16.0 10 7210.00 22.0 10 7212.00 25.0 12 8314.00 30.0 14 8316.00 36.0 16 10020.00 40.0 20 104” .-, . . Weldon DIN 6535-HB.Mit WELDON-Spannfläche nach DIN 6535-HB.With WELDON configuration according to DIN 6535-HB. Developed for rough milling, these end mills haveteeth especially designed for maximum chip removal.The particular shape of the radial relief with constantprofile guarantees improved chipbreakage and reduces the cutting forces,permitting higher metal removal rates.These end mills can be sharpened by regrinding theend face in the usual manner, whileregrinding the flute will restore the cuttingedge on the diameter.134

DIXI 7222Z = 2- END MILLS CENTRE CUTTING. 186 . 165ISO 513: P M KD 1 e8 L 1 D h6 L HM TiALN DIAMANT3.00 30.0 3 604.00 30.0 4 605.00 35.0 5 75• 6.00 40.0 6 100• 8.00 40.0 8 100•10.00 40.0 10 100•12.00 45.0 12 100•14.00 65.0 14 150•16.00 65.0 16 150•20.00 65.0 20 150•= Weldon DIN 6535-HB - .•= WELDON-Spannfläche nach DIN 6535-HB auf Anfrage.•=135

DIXI 7223- Z = 3END MILLS CENTRE CUTTING. 165. 186ISO 513: P M KD 1 e8 L 1 D h6 L HM TiALN DIAMANT3.00 30.0 3 604.00 30.0 4 605.00 35.0 5 75• 6.00 40.0 6 100• 8.00 40.0 8 100•10.00 40.0 10 100•12.00 45.0 12 100•14.00 65.0 14 150•16.00 65.0 16 150•18.00 65.0 18 150•20.00 65.0 20 150•= Weldon DIN 6535-HB - .•= WELDON-Spannfläche nach DIN 6535-HB auf Anfrage.•=136

DIXI 7224Z = 46. 186. 165END MILLS CENTRE CUTTINGISO 513: P M KD 1 e8 L 1 D h6 L HM TiALN DIAMANT3.00 30.0 3 604.00 30.0 4 605.00 35.0 5 75• 6.00 40.0 6 100• 8.00 40.0 8 100•10.00 40.0 10 100•12.00 45.0 12 100•14.00 65.0 14 150•16.00 65.0 16 150•20.00 65.0 20 150•= Weldon DIN 6535-HB - .•= WELDON-Spannfläche nach DIN 6535-HB auf Anfrage.•=137

DIXI 7232 Z = 2STRAIGHT FLUTE SLOT DRILLS. 165 . 188ISO 513: P K N6528D 1 e8 L 1 D h6 L HM2.00 6.0 2 383.00 7.0 3 384.00 8.0 4 505.00 10.0 5 50• 6.00 10.0 6 57• 8.00 16.0 8 63•10.00 19.0 10 72 -.”, . .327 -. •= Weldon DIN 6535-HB - .•= WELDON-Spannfläche nach DIN 6535-HB auf Anfrage.•=The straight flute slot drills can be used whenthe clamping force is relatively low (vacuum)or when the overhang is considerable.Similar tools are also available in diamond.Please refer to our catalogue for ourcomprehensive range of diamond tools page327.138

DIXI 7237 DIXI 7237-10Z = 2-, , L 2 =3xD 1orD 1 0.40 . 176 . 165ISO 513: P M KSLOT DRILLS EXTRA SHORT,NECKED DOWN, L2=3xD1DIXI 72377237-D 1 L 1 D 2 L 2 D h6 L HM TiALN RØ

DIXI 7238-, , L 2 =5xD 1Z = 2SLOT DRILLS EXTRA SHORT,NECKED DOWN, L2 = 5 x D1. 165. 178ISO 513: P M KD 1 L 1 D 2 L 2 D h6 L HM TiALNØ

DIXI 7239Z = 2-, , L 2 =8xD 1. 178. 165ISO 513: P M KSLOT DRILLS EXTRA SHORT,NECKED DOWN, L2 = 8 x D1D 1 L 1 D 2 L 2 D h6 L HM TiALNØ

DIXI 7240-Z = 2SLOT DRILLS EXTRA SHORT. 165. 176ISO 513: P M KD 1 L 1 D h6 L Z HM TiALNØ

DIXI 7242Z = 2- 6527D 1 > 6. 176 . 165ISO 513: P M KSLOT DRILLS, CENTRE CUTTINGREINFORCED SHANKD 1 L 1 D h6 L HM TiALNØ 2.0 3 380.45 1.0 3 380.50 1.0 3 380.50 > 2.5 3 380.55 1.2 3 380.60 1.2 3 380.60 > 3.0 3 380.65 1.4 3 380.70 1.4 3 380.70 > 3.5 3 380.75 1.6 3 380.80 1.6 3 380.80 > 4.0 3 380.85 1.8 3 380.90 1.8 3 380.90 > 4.5 3 380.95 2.0 3 381.00 2.0 3 381.00 > 5.0 3 381.05 2.2 3 381.10 2.2 3 381.15 2.4 3 381.20 2.4 3 381.20 > 6.0 3 381.25 2.6 3 381.30 2.6 3 381.35 2.8 3 381.40 2.8 3 381.45 3.0 3 381.50 3.0 3 381.50 > 7.0 3 38Dimensions in inches on request.143 .144 Continued on page 144

DIXI 7242. 165 . 176D 1 > 66527ISO 513: P M KD 1 L 1 D h6 L HM TiALNØ

DIXI 7243Z = 3- 6527D 1 6. 180 . 165ISO 513: P M KSLOT DRILLS, CENTRE CUTTINGREINFORCED SHANKD 1 L 1 D h6 L HM TiALNØ 15.0 10 63• 8.50 16.0 10 72• 9.00 16.0 10 72• 9.50 19.0 10 72•10.00 19.0 10 72•12.00 22.0 12 83•14.00 22.0 14 83•16.00 26.0 16 92•18.00 26.0 18 92•20.00 32.0 20 104145

DIXI 7244- Z = 46SLOT DRILLS, CENTRE CUTTINGREINFORCED SHANK. 165. 182ISO 513: P M K6527D 1 L 1 D h6 L HM TiALNØ

DIXI 7263 TiALNZ = 3 . 194. 165HPC END MILLSISO 513: P K SD 1 L 1 D h6 L TiALNØ

DIXI 7273Z = 3FINISHING END MILLS. 165 . 180D 1 12ISO 513: P M KD 1 e8 L 1 D h6 L HM3.00 10.0 3 384.00 12.0 4 505.00 14.0 5 50• 6.00 16.0 6 57• 8.00 20.0 8 63•10.00 22.0 10 72•12.00 22.0 12 73•14.00 25.0 14 75•16.00 27.0 16 82•20.00 35.0 20 104 (45°) - -.-., , ,, -.•= Weldon DIN 6535-HB - .•= WELDON-Spannfläche nach DIN 6535-HB aufAnfrage.•= End mills with fast helix reduce vibration andimprove surface finish.These end mills are recommended for finishingoperations when machining hard materials.Nevertheless they can be used for milling lightmaterials such as aluminium, plexiglas and othersynthetics.148

DIXI 7301Z = 1 . 190END MILLS FOR PLASTICSISO 513:ND 1 e8 L 1 D h6 L HM2.00 6.0 3 383.00 11.0 3 504.00 16.0 4 505.00 16.0 5 50• 6.00 16.0 6 50• 8.00 23.0 8 50•= Weldon DIN6535-HB .•= WELDON-Spannfläche nach DIN 6535-HB auf Anfrage.•=DIXI 7302Z = 1 END MILLS FOR PLASTICSD 1 e8 L 1 D h6 L HM3.00 17.0 3 614.00 23.0 4 615.00 23.0 5 61• 6.00 23.0 6 75• 8.00 32.0 8 75•10.00 33.0 10 75•12.00 33.0 12 100•= Weldon DIN6535-HB .•= WELDON-Spannfläche nach DIN 6535-HB auf Anfrage.•=149

DIXI 7303 Z = 1END MILLS FOR PLASTICS. 190ISO 513:ND 1 e8 L 1 D h6 L HM2.00 8.0 6 503.00 17.0 6 754.00 23.0 6 755.00 23.0 6 75DIXI 7304 ,, Z = 1END MILLS FOR PLASTICSLEFT HAND SPIRAL, RIGHT HAND CUTTINGD 1 e8 L 1 D h6 L HM3.00 17.0 6 614.00 23.0 6 755.00 23.0 6 75• 6.00 23.0 6 75• 8.00 32.0 8 75•10.00 33.0 10 75•= Weldon - DIN 6535-HB .•= WELDON-Spannfläche nach DIN 6535-HB auf Anfrage.•=150

DIXI 7520 XIDUR D 1 6. 204 . 165MULTI-TOOTH END MILLSISO 513:HD 1 L 1 D h6 L Z XIDURØ

DIXI 7532 XIDUR Z = 2BALL NOSE END MILLS. 166 . 202ISO 513: P HD 1 L 1 D h6 L XIDURØ

DIXI 7542 XIDURZ = 2. 203 . 166BALL NOSE END MILLSISO 513: P HD 1 L 1 D 2 L 2 D h6 L XIDURØ

DIXI 7543 XIDURZ = 3END MILLS. 165 . 2000.05 -0.15x45°ISO 513: P M K , .D 1 L 1 D h6 L XIDURØ

DIXI 7552Z = 2. 196. 198 .165END MILLS WITH CORNER RADIUSISO 513: S N--.Also intended for machining thin walls.D 1 e8 L 1 D 2 L 2 D h6 L R HM DICUT3.00 4.0 2.75 10 6 57 0.54.00 5.0 3.70 12 6 57 0.55.00 6.0 4.60 15 6 57 0.56.00 7.0 5.50 18 6 57 1.08.00 9.0 7.50 23 8 63 1.010.00 11.0 9.25 30 10 75 1.512.00 13.0 11.00 35 12 83 1.512.00 > 13.0 11.00 35 12 83 2.012.00 13.0 11.00 35 12 83 2.516.00 17.0 15.00 44 16 92 2.016.00> 17.0 15.00 44 16 92 2.516.00 > 17.0 15.00 44 16 92 4.020.00 21.0 19.00 54 20 104 2.020.00 > 21.0 19.00 54 20 104 2.520.00 > 21.0 19.00 54 20 104 4.0•= Weldon DIN 6535-HB .•= WELDON-Spannfläche nach DIN 6535-HB auf Anfrage.•=155

DIXI 7554Z = 46END MILLS WITH CORNER RADIUS. 165 . 182ISO 513: P M KD 1 L 1 D 2 L 2 D h6 L R HM TiALNØ

DIXI 7560, 40°, 40°MULTI-TOOTH END MILLS, 40°0.10 - 0.20x45°D 1> 6. 188 . 165ISO 513: P M KD 1 e8 L 1 D h6 L Z HM TiALN DLCD 1>6•= Weldon DIN 6535-HB - .•= WELDON-Spannfläche nach DIN 6535-HB auf Anfrage.•=0.35 0.90 3.0 38 30.40 1.00 3.0 38 30.45 1.10 3.0 38 30.50 1.25 3.0 38 30.55 1.40 3.0 38 30.60 1.50 3.0 38 30.65 1.70 3.0 38 30.70 1.75 3.0 38 30.75 1.90 3.0 38 30.80 2.00 3.0 38 30.85 2.15 3.0 38 30.90 2.40 3.0 38 30.95 2.40 3.0 38 31.00 2.50 3.0 38 31.10 2.75 3.0 38 31.20 3.00 3.0 38 31.30 3.25 3.0 38 31.40 3.50 3.0 38 31.50 3.75 3.0 38 31.60 4.00 3.0 38 31.70 4.25 3.0 38 31.80 4.50 3.0 38 31.90 4.75 3.0 38 32.00 8.00 3.0 38 52.10 5.25 3.0 38 52.20 5.50 3.0 38 52.30 5.75 3.0 38 52.40 6.00 3.0 38 52.50 8.00 3.0 38 52.60 6.50 3.0 38 52.70 6.75 3.0 38 52.80 7.00 3.0 38 52.90 7.00 3.0 38 53.00 10.00 3.0 38 54.00 12.00 4.0 50 55.00 14.00 5.0 50 5• 6.00 16.00 6.0 57 5• 8.00 19.00 8.0 63 59.00 22.00 9.0 67 5•10.00 22.00 10.0 72 6•12.00 26.00 12.0 83 6•14.00 26.00 14.0 83 6•16.00 32.00 16.0 92 6•20.00 38.00 20.0 104 8157

DIXI 7561 Z = 1SINGLE TOOTH END MILLS FOR ALUMINIUM. 196ISO 513: P ND 1 e8 L 1 D h6 L HM2.00 0.10 x 45° 4.0 3 383.00 0.15 x 45° 6.0 3 384.00 0.15 x 45° 12.0 4 505.00 0.15 x 45° 14.0 5 50• 6.00 0.20 x 45° 16.0 6 50• 8.00 0.20 x 45° 20.0 8 60•10.00 0.20 x 45° 22.0 10 70•12.00 0.20 x 45° 25.0 12 70•= Weldon DIN 6535-HB .•= WELDON-Spannfläche nach DIN 6535-HB auf Anfrage.•=158

DIXI 7562Z = 2END MILLS0.20 x 45°. 196. 198 .165ISO 513: S N, Z=2 .Also intended for machining thin walls.D 1 e8 L 1 D h6 L HM TiALN6.00 10.0 6 508.00 15.0 8 6010.00 18.0 10 6612.00 20.0 12 7314.00 22.0 14 7516.00 25.0 16 8220.00 35.0 20 104 Weldon DIN 6535-HB .WELDON-Spannfläche nach DIN 6535-HB auf Anfrage.159

DIXI 7572Z = 2END MILLS0.15 - 0.20x 45°.165 . 196.199-.207ISO 513: S ND 1 e8 L 1 D h6 L HM TiALN DIAMANT3.00 14.0 3 504.00 16.0 4 505.00 18.0 5 60• 6.00 20.0 6 75• 8.00 25.0 8 759.00 27.0 9 90•10.00 30.0 10 90•12.00 36.0 12 100•14.00 42.0 14 100•16.00 50.0 16 120•20.00 60.0 20 130•= Weldon DIN 6535-HB - .•= WELDON-Spannfläche nach DIN 6535-HB auf Anfrage.•=160

Z = 2DIXI 7582 0.10 - 0.20x 45°D 1> 2.8. 196END MILLS, REINFORCED SHANKISO 513: P M S. 198 .165 Ø

DIXI 7583 Z = 3END MILLS, REINFORCED SHANK.165.180ISO 513: P M SD 1 L 1 D h6 L HM TiALNØ

DIXI 7593 END MILLS.199ISO 513:ND 1 h6 L 1 D 2 D h6 L 2 L Z HM6.00 6.0 5.6 6 30 66 38.00 8.0 7.6 8 45 81 310.00 10.0 9.6 10 50 90 312.00 12.0 11.6 12 55 100 316.00 16.0 15.6 16 72 120 320.00 20.0 19.6 20 80 130 4 Weldon DIN 6535-HB - .WELDON-Spannfläche nach DIN 6535-HB auf Anfrage. DIXI 7593 --.The superior rigidity of this DIXI 7593 end millenables the machining of deep pockets and therouting of “high faces”.163

DIXI 7623Z = 3CHAMFERING TOOLS.180ISO 513: P M KD 1 e8 L 1 D 2Ø

CHOOSING THE NUMBER OF TEETH1SlottingZ 22RampingZ 2 - Z 3 3SlottingZ 2 - Z 3 Routing (roughing)Z 3 - Z 4 Routing (finishing)Multi-tooth165

HELP IN USING BALL-NOSE END MILLS.Checking for run out..Finishing operation.max. 0.005 , -.If possible, incline the tool..Correction of radial feed and rotation. .Correction of plunging feed. /.(Vf)=80% . (n)=100% ./.(Vf)=100% . (n)=60% ./. (Vf)=60%166

D 1 Ø D Ø D = 2 ap (D 1 - ap), - ØapCALCULATION OF Ø DOF BALL-NOSE END MILLSap [mm] 0.02 0.03 0.04 0.05 0.10 0.15 0.20 0.25 0.30 0.400.2 0.120 0.143 0.160 0.173 0.2000.3 0.150 0.180 0.204 0.224 0.283 0.3000.4 0.174 0.211 0.240 0.265 0.346 0.387 0.4000.5 0.196 0.237 0.271 0.300 0.400 0.458 0.490 0.5000.6 0.22 0.26 0.30 0.33 0.45 0.52 0.57 0.59 0.600.8 0.25 0.30 0.35 0.39 0.53 0.62 0.69 0.74 0.77 0.801 0.28 0.34 0.39 0.44 0.60 0.71 0.80 0.87 0.92 0.981.2 0.31 0.37 0.43 0.48 0.66 0.79 0.89 0.97 1.04 1.131.5 0.34 0.42 0.48 0.54 0.75 0.90 1.02 1.12 1.20 1.332 0.40 0.49 0.56 0.62 0.87 1.05 1.20 1.32 1.43 1.602.5 0.45 0.54 0.63 0.70 0.98 1.19 1.36 1.50 1.62 1.833 0.49 0.60 0.69 0.77 1.08 1.31 1.50 1.66 1.80 2.043.5 0.53 0.65 0.74 0.83 1.17 1.42 1.62 1.80 1.96 2.234 0.56 0.69 0.80 0.89 1.25 1.52 1.74 1.94 2.11 2.405 0.63 0.77 0.89 0.99 1.40 1.71 1.96 2.18 2.37 2.716 0.69 0.85 0.98 1.09 1.54 1.87 2.15 2.40 2.62 2.998 0.80 0.98 1.13 1.26 1.78 2.17 2.50 2.78 3.04 3.4910 0.89 1.09 1.26 1.41 1.99 2.43 2.80 3.12 3.41 3.9212 0.98 1.20 1.38 1.55 2.18 2.67 3.07 3.43 3.75 4.3114 1.06 1.29 1.49 1.67 2.36 2.88 3.32 3.71 4.05 4.6616 1.13 1.38 1.60 1.79 2.52 3.08 3.56 3.97 4.34 5.0020 1.26 1.55 1.79 2.00 2.82 3.45 3.98 4.44 4.86 5.60ap [mm] 0.50 0.60 0.70 0.80 0.90 1.00 1.50 2.00 2.50 3.001 1.001.2 1.18 1.201.5 1.41 1.47 1.502 1.73 1.83 1.91 1.962.5 2.00 2.14 2.24 2.33 2.403 2.24 2.40 2.54 2.65 2.75 2.83 3.003.5 2.45 2.64 2.80 2.94 3.06 3.16 3.464 2.65 2.86 3.04 3.20 3.34 3.46 3.87 4.005 3.00 3.25 3.47 3.67 3.84 4.00 4.58 4.90 5.006 3.32 3.60 3.85 4.08 4.28 4.47 5.20 5.66 5.92 6.008 3.87 4.21 4.52 4.80 5.06 5.29 6.24 6.93 7.42 7.7510 4.36 4.75 5.10 5.43 5.72 6.00 7.14 8.00 8.66 9.1712 4.80 5.23 5.62 5.99 6.32 6.63 7.94 8.94 9.75 10.3914 5.20 5.67 6.10 6.50 6.87 7.21 8.66 9.80 10.72 11.4916 5.57 6.08 6.55 6.97 7.37 7.75 9.33 10.58 11.62 12.4920 6.24 6.82 7.35 7.84 8.29 8.72 10.54 12.00 13.23 14.28167

DIXI 7032DIXI 7032apCUTTING CONDITIONS HM DICUT TIALN DIAMANTapaeaeMaterials to be machined Vc [m/min]Vc [m/min]Vc [m/min]Vc [m/min] [mm] [mm] / P< 600 2Unalloyed steel / Low alloyed steel / P600 – 1500 2Unalloyed steel / Low alloyed steelPPMKKKSSNNNNNNNNLead alloyed cutting steel700 – 1500 2High alloyed steel400 – 700 2Stainless steel / < 250 HBGrey cast iron / Nodular iron pearlitic / > 250 HBAlloyed cast iron / Nodular iron pearlitic / Nodular iron pearlitic / Malleable cast iron / Special alloys / Heat resisting stainless steel / InconelNimonicHastelloyTitanium / Titanium alloy - ( - )Copper alloy - easy to machine (brass – bronze) - (. - )(CuAlFe)Copper alloy - difficult to machine / Aluminium bronze (Ampco) / Aluminium alloy / Magnesium alloySi < 8%Aluminium cast ironSi > 8%Aluminium cast ironGraphitePlastic, Gold, silver168

Vc [/.] x 1000n [/.] = xD[]DIXI 7032 Z = 2 Vf [/.] = n [/.] x [] x Feed per toothfz []Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1169

DIXI 7033 - 7034DIXI 7033 - 7034CUTTING CONDITIONSap HM TiALNapaeaeMaterials to be machined Vc [m/min]Vc [m/min] [mm] [mm]PPPPMKKKSSNNNNNNN / < 600 2Unalloyed steel / Low alloyed steel / 600 – 1500 2Unalloyed steel / Low alloyed steelLead alloyed cutting steel700 – 1500 2High alloyed steel400 – 700 2Stainless steel / < 250 HBGrey cast iron / Nodular iron pearlitic / > 250 HBAlloyed cast iron / Nodular iron pearlitic / Nodular iron pearlitic / Malleable cast iron / Special alloys / Heat resisting stainless steel / InconelNimonicHastelloyTitanium / Titanium alloy - ( - )Copper alloy - easy to machine (brass – bronze) - (. - )(CuAlFe)Copper alloy - difficult to machine / Aluminium bronze (Ampco) / Aluminium alloy / Magnesium alloySi < 8%Aluminium cast ironSi > 8%Aluminium cast ironPlastic, Gold, silver170

DIXI 7033 Z = 3Vc [/.] x 1000 DIXI 7034 Z = 4n [/.] = xD[] Vf [/.] = n [/.] x [] x Feed per toothfz []Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1171

CUTTING CONDITIONSapae HM DICUT TiALN DIAMANTMaterials to be machinedapVc [m/min]Vc [m/min]Vc [m/min]Vc [m/min] [mm]ae[mm] / P< 600 2Unalloyed steel / Low alloyed steel / P600 – 1500 2Unalloyed steel / Low alloyed steelPPMKKKSSNNNNNNNNLead alloyed cutting steel700 – 1500 2High alloyed steel400 – 700 2Stainless steel / < 250 HBGrey cast iron / Nodular iron pearlitic / > 250 HBAlloyed cast iron / Nodular iron pearlitic / Nodular iron pearlitic / Malleable cast iron / Special alloys / Heat resisting stainless steel / InconelNimonicHastelloyTitanium / Titanium alloy - ( - )Copper alloy - easy to machine (brass – bronze) - (. - )(CuAlFe)Copper alloy - difficult to machine / Aluminium bronze (Ampco) / Aluminium alloy / Magnesium alloySi < 8%Aluminium cast ironSi > 8%Aluminium cast ironGraphitePlastic, Gold, silver172

DIXI 7045 Z = 2Vc [/.] x 1000 DIXI 7046 Z = 2n [/.] =DIXI 7047 Z = 2 xD[] Vf [/.] = n [/.] x [] x Feed per toothfz [mm]Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1173

DIXI 7042 - 7050 CUTTING CONDITIONSapae HM TiALN DIAMANTMaterials to be machined Vc [m/min]Vc [m/min]Vc [m/min]ap[mm]ae[mm] / P< 600 2 60 90 80 100

Vc [/.] x 1000n [/.] = xD[]DIXI 7042 Z = 2DIXI 7050 Z = 2D 1 10 Z = 3 Vf [/.] = n [/.] x [] x Feed per toothfz []Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 10.010 -0.021 0.012 -0.03 0.014 -0.03 0.019 -0.04 0.024 -0.05 0.029 -0.07 0.038 -0.08 0.05 - 0.12 0.07 -0.13 0.08 - 0.170.007 -0.015 0.009 -0.02 0.011 -0.02 0.014 -0.03 0.018 -0.04 0.022 -0.05 0.029 -0.06 0.04 - 0.08 0.05 -0.10 0.06 - 0.120.012 -0.030 0.015 -0.04 0.018 -0.05 0.024 -0.06 0.030 -0.07 0.036 -0.10 0.048 -0.12 0.06 - 0.17 0.08 -0.19 0.10 - 0.240.007 -0.015 0.009 -0.02 0.011 -0.02 0.014 -0.03 0.018 -0.04 0.022 -0.05 0.029 -0.06 0.04 - 0.08 0.05 -0.10 0.06 - 0.120.007 -0.015 0.009 -0.02 0.011 -0.02 0.014 -0.03 0.018 -0.04 0.022 -0.05 0.029 -0.06 0.04 - 0.08 0.05 -0.10 0.06 - 0.120.010 -0.021 0.012 -0.03 0.014 -0.03 0.019 -0.04 0.024 -0.05 0.029 -0.07 0.038 -0.08 0.05 - 0.12 0.07 -0.13 0.08 - 0.170.007 -0.015 0.009 -0.02 0.011 -0.02 0.014 -0.03 0.018 -0.04 0.022 -0.05 0.029 -0.06 0.04 - 0.08 0.05 -0.10 0.06 - 0.120.010 -0.021 0.012 -0.03 0.014 -0.03 0.019 -0.04 0.024 -0.05 0.029 -0.07 0.038 -0.08 0.05 - 0.12 0.07 -0.13 0.08 - 0.170.007 -0.015 0.009 -0.02 0.011 -0.02 0.014 -0.03 0.018 -0.04 0.022 -0.05 0.029 -0.06 0.04 - 0.08 0.05 -0.10 0.06 - 0.120.007 -0.015 0.009 -0.02 0.011 -0.02 0.014 -0.03 0.018 -0.04 0.022 -0.05 0.029 -0.06 0.04 - 0.08 0.05 -0.10 0.06 - 0.120.012 -0.030 0.015 -0.04 0.018 -0.05 0.024 -0.06 0.030 -0.07 0.036 -0.10 0.048 -0.12 0.06 - 0.17 0.08 -0.19 0.10 - 0.240.007 -0.015 0.009 -0.02 0.011 -0.02 0.014 -0.03 0.018 -0.04 0.022 -0.05 0.029 -0.06 0.04 - 0.08 0.05 -0.10 0.06 - 0.120.012 -0.030 0.015 -0.04 0.018 -0.05 0.024 -0.06 0.030 -0.07 0.036 -0.10 0.048 -0.12 0.06 - 0.17 0.08 -0.19 0.10 - 0.240.012 -0.030 0.015 -0.04 0.018 -0.05 0.024 -0.06 0.030 -0.07 0.036 -0.10 0.048 -0.12 0.06 - 0.17 0.08 -0.19 0.10 - 0.240.012 -0.030 0.015 -0.04 0.018 -0.05 0.024 -0.06 0.030 -0.07 0.036 -0.10 0.048 -0.12 0.06 - 0.17 0.08 -0.19 0.10 - 0.240.017 -0.045 0.021 -0.05 0.025 -0.07 0.034 -0.09 0.042 -0.11 0.050 -0.14 0.067 -0.18 0.08 - 0.25 0.12 -0.29 0.13 - 0.360.017 -0.045 0.021 -0.05 0.025 -0.07 0.034 -0.09 0.042 -0.11 0.050 -0.14 0.067 -0.18 0.08 - 0.25 0.12 -0.29 0.13 - 0.360.012 -0.030 0.015 -0.04 0.018 -0.05 0.024 -0.06 0.030 -0.07 0.036 -0.10 0.048 -0.12 0.06 - 0.17 0.08 -0.19 0.10 - 0.24175

DIXI 7202 -7237 - 7240 -7242Ø < 0.50 Ø > 0.50 CUTTING CONDITIONSapapaeae HM TiALNap ae ap aeMaterials to be machined Vc [m/min]Vc [m/min] [mm] [mm] [mm] [mm] / P< 600 2 70 100 90 110 < 0.5 x ØD1 1 x ØD1 < 1.0 x ØD1 1 x ØD1Unalloyed steel / Low alloyed steel / P600 – 1500 2 70 90 < 0.3 x ØD1 1 x ØD1 < 0.6 x ØD1 1 x ØD1Unalloyed steel / Low alloyed steel70 100 < 0.5 x ØD1 1 x ØD1 < 1 x ØD1 1 x ØD1PLead alloyed cutting steel700 – 1500 2 40 55 < 0.2 x ØD1 1 x ØD1 < 0.5 x ØD1 1 x ØD1PHigh alloyed steel400 – 700 270 90 < 0.5 x ØD1 1 x ØD1 < 0.8 x ØD1 1 x ØD1MStainless steel / < 250 HB 70 100 90 110 < 0.5 x ØD1 1 x ØD1 < 1 x ØD1 1 x ØD1KGrey cast iron / Nodular iron pearlitic / > 250 HB 40 70 70 90 < 0.3 x ØD1 1 x ØD1 < 0.6 x ØD1 1 x ØD1KAlloyed cast iron / Nodular iron pearlitic / 70 100 90 110 < 0.3 x ØD1 1 x ØD1 < 0.6 x ØD1 1 x ØD1KNodular iron pearlitic / Malleable cast iron / InconelNimonic25 35 < 0.4 x ØD1 1 x ØD1SSpecial alloys / Heat resisting stainless steel Hastelloy / 30 45 < 0.30 x ØD1 1 x ØD1 < 0.5 x ØD1 1 x ØD1STitanium / Titanium alloy - ( - )140 160 < 0.5 x ØD1 1 x ØD1 < 1 x ØD1 1 x ØD1NCopper alloy - easy to machine (brass – bronze) - (. - )(CuAlFe) 120 140 170 190 < 0.3 x ØD1 1 x ØD1 < 0.7 x ØD1 1 x ØD1NCopper alloy - difficult to machine / Aluminium bronze (Ampco) / 180 220 230 270 < 0.6 x ØD1 1 x ØD1 < 1.2 x ØD1 1 x ØD1NAluminium alloy / Magnesium alloySi < 8% 240 260 300 340 < 0.6 x ØD1 1 x ØD1 < 1.2 x ØD1 1 x ØD1NAluminium cast ironSi > 8% 140 160 210 230 < 0.4 x ØD1 1 x ØD1 < 0.9 x ØD1 1 x ØD1NAluminium cast iron240 260 300 340 < 0.6 x ØD1 1 x ØD1 < 1.2 x ØD1 1 x ØD1NPlastic, 140 160 200 220 < 0.6 x ØD1 1 x ØD1 < 0.9 x ØD1 1 x ØD1NGold, silver (Vfp) , Z=2 40% - 80 % - .The plunging feed (Vfp) of an end mill Z = 2 (drilling) must be reduced from 40 to 80 % depending on the materialto be machined.176

Vc [/.] x 1000n [/.] = xD 1 []DIXI 7202 Z = 2DIXI 7237 Z = 2DIXI 7240 Z = 1-2DIXI 7242 Z = 2 Vf [/.] = n [/.] x [] x Feed per toothfz []Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 10.003 - 0.01 0.006 -0.015 0.012 -0.020 0.016 - 0.04 0.02 -0.06 0.03 - 0.09 0.04 - 0.11 0.05 -0.12 0.06 -0.13 0.07 - 0.140.003 - 0.01 0.006 -0.015 0.012 -0.020 0.016 - 0.04 0.02 -0.06 0.03 - 0.09 0.04 - 0.11 0.05 -0.12 0.06 -0.13 0.07 - 0.140.003 - 0.01 0.006 -0.015 0.012 -0.020 0.016 - 0.04 0.02 -0.06 0.03 - 0.09 0.04 - 0.11 0.05 -0.14 0.07 -0.16 0.08 - 0.200.002 - 0.01 0.006 -0.015 0.012 -0.020 0.016 - 0.04 0.02 -0.06 0.03 - 0.09 0.04 - 0.11 0.05 -0.12 0.06 -0.13 0.07 - 0.140.002 - 0.01 0.006 -0.015 0.012 -0.020 0.016 - 0.04 0.02 -0.06 0.03 - 0.09 0.04 - 0.11 0.05 -0.12 0.06 -0.13 0.07 - 0.140.003 - 0.01 0.006 -0.015 0.012 -0.020 0.016 - 0.04 0.02 -0.06 0.03 - 0.09 0.04 - 0.11 0.05 -0.12 0.06 -0.13 0.07 - 0.140.003 - 0.01 0.006 -0.015 0.012 -0.020 0.016 - 0.04 0.02 -0.06 0.03 - 0.09 0.04 - 0.11 0.05 -0.12 0.06 -0.13 0.07 - 0.140.003 - 0.01 0.006 -0.015 0.012 -0.020 0.016 - 0.04 0.02 -0.06 0.03 - 0.09 0.04 - 0.11 0.05 -0.12 0.06 -0.13 0.07 - 0.140.012 -0.020 0.016 - 0.04 0.02 -0.06 0.03 - 0.09 0.04 - 0.11 0.05 -0.12 0.06 -0.13 0.07 - 0.140.002 - 0.01 0.006 -0.015 0.012 -0.020 0.016 - 0.04 0.02 -0.06 0.03 - 0.09 0.04 - 0.11 0.05 -0.12 0.06 -0.13 0.07 - 0.140.003 - 0.01 0.006 -0.015 0.012 -0.020 0.016 - 0.04 0.02 - 0.06 0.03 - 0.09 0.04 - 0.11 0.05 -0.14 0.07 -0.16 0.08 - 0.200.003 - 0.01 0.006 -0.015 0.012 -0.020 0.016 - 0.04 0.02 -0.06 0.03 - 0.09 0.04 - 0.11 0.05 -0.12 0.06 -0.13 0.07 - 0.140.003 - 0.01 0.006 -0.015 0.012 -0.020 0.016 - 0.04 0.02 -0.06 0.03 - 0.09 0.04 - 0.11 0.05 -0.14 0.07 -0.16 0.08 - 0.200.003 - 0.01 0.006 -0.015 0.012 -0.020 0.016 - 0.04 0.02 -0.06 0.03 - 0.09 0.04 - 0.11 0.05 -0.14 0.07 -0.16 0.08 - 0.200.003 -0.01 0.006 -0.015 0.012 -0.020 0.016 -0.04 0.02 -0.06 0.03 - 0.09 0.04 - 0.11 0.05 -0.14 0.07 -0.16 0.08 - 0.200.003 -0.01 0.006 -0.015 0.012 -0.020 0.016 -0.04 0.02 -0.06 0.03 - 0.09 0.04 - 0.11 0.05 -0.21 0.10 -0.24 0.11 - 0.300.003 -0.01 0.006 -0.015 0.012 -0.020 0.016 -0.04 0.02 -0.06 0.03 - 0.09 0.04 - 0.11 0.06 -0.14 0.07 -0.16 0.08 - 0.20177

DIXI 7238 - 72397237 7238 - 7239CUTTING CONDITIONSapapaeae HM TiALNap ae ap aeMaterials to be machined Vc [m/min]Vc [m/min] [mm] [mm] [mm] [mm] / 70 100 90 110 < 0.10 x ØD1 1 x ØD1 < 0.04 x ØD1 1 x ØD1P< 600 2Unalloyed steel / Low alloyed steel / 70 90 < 0.10 x ØD1 1 x ØD1 < 0.04 x ØD1 1 x ØD1P600 – 1500 2Unalloyed steel / Low alloyed steel70 100 < 0.12x ØD1 1 x ØD1 < 0.06 x ØD1 1 x ØD1PLead alloyed cutting steel700 – 1500 240 55 < 0.10 x ØD1 1 x ØD1 < 0.04 x ØD1 1 x ØD1PHigh alloyed steel400 – 700 2MStainless steel70 90 < 0.10x ØD1 1 x ØD1 < 0.04 x ØD1 1 x ØD1 / < 250 HBKGrey cast iron / Nodular iron pearlitic70 100 90 110 < 0.10 x ØD1 1 x ØD1 < 0.04 x ØD1 1 x ØD1 / > 250 HB 40 70 70 90 < 0.10 x ØD1 1 x ØD1 < 0.04 x ØD1 1 x ØD1KAlloyed cast iron / Nodular iron pearlitic / 70 100 90 110 < 0.10 x ØD1 1 x ØD1 < 0.04 x ØD1 1 x ØD1KNodular iron pearlitic / Malleable cast iron / InconelNimonic25 35 < 0.10 x ØD1 1 x ØD1 < 0.04 x ØD1 1 x ØD1SSpecial alloys / Heat resisting stainless steel Hastelloy / 30 45 < 0.10 x ØD1 1 x ØD1 < 0.04 x ØD1 1 x ØD1STitanium / Titanium alloy - ( - )140 160 < 0.12 x ØD1 1 x ØD1 < 0.06 x ØD1 1 x ØD1NCopper alloy - easy to machine (brass – bronze) - (. - )(CuAlFe) 120 140 170 190 < 0.10 x ØD1 1 x ØD1 < 0.04 x ØD1 1 x ØD1NCopper alloy - difficult to machine / Aluminium bronze (Ampco) / 180 220 230 270 < 0.12 x ØD1 1 x ØD1 < 0.06 x ØD1 1 x ØD1NAluminium alloy / Magnesium alloySi < 8% 240 260 300 340 < 0.12 x ØD1 1 x ØD1 < 0.06 x ØD1 1 x ØD1NAluminium cast ironSi > 8% 140 160 210 230 < 0.12 x ØD1 1 x ØD1 < 0.06 x ØD1 1 x ØD1NAluminium cast iron240 260 300 340 < 0.15 x ØD1 1 x ØD1 < 0.10 x ØD1 1 x ØD1NPlastic, 140 160 200 220 < 0.12 x ØD1 1 x ØD1 < 0.06 x ØD1 1 x ØD1NGold, silver (Vfp) , Z=2 40% - 80% - .The plunging feed (Vfp) of an end mill Z = 2 (drilling) must be reduced from 40 to 80 % depending on the materialto be machined.178

n [/.] = Vc [/.] x 1000 xD 1 []DIXI 7238 Z = 2DIXI 7239 Z = 2 Vf [/.] = n [/.] x [] x Feed per toothfz []Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 10.002 - 0.003 0.002 - 0.004 0.003 - 0.01 0.008 - 0.012 0.010 - 0.015 0.012 - 0.016 0.013 - 0.02 0.015 - 0.022 0.02 - 0.025 0.022 - 0.040.002 - 0.003 0.002 - 0.004 0.003 - 0.01 0.008 - 0.012 0.010 - 0.015 0.012 - 0.016 0.013 - 0.02 0.015 - 0.022 0.02 - 0.025 0.022 - 0.040.002 - 0.003 0.002 - 0.004 0.003 - 0.01 0.008 - 0.012 0.010 - 0.015 0.012 - 0.016 0.013 - 0.02 0.015 - 0.022 0.02 - 0.025 0.022 - 0.040.0003-0.0010 0.002 - 0.003 0.002 - 0.004 0.003 - 0.01 0.008 - 0.012 0.010 - 0.015 0.012 - 0.0160.013 - 0.02 0.015 - 0.022 0.02 - 0.0250.002 - 0.003 0.002 - 0.004 0.003 - 0.01 0.008 - 0.012 0.010 - 0.015 0.012 - 0.016 0.013 - 0.02 0.015 - 0.022 0.02 - 0.025 0.022 - 0.040.002 - 0.003 0.002 - 0.004 0.003 - 0.01 0.008 - 0.012 0.010 - 0.015 0.012 - 0.016 0.013 - 0.02 0.015 - 0.022 0.02 - 0.025 0.022 - 0.040.002 - 0.003 0.002 - 0.004 0.003 - 0.01 0.008 - 0.012 0.010 - 0.015 0.012 - 0.016 0.013 - 0.02 0.015 - 0.022 0.02 - 0.025 0.022 - 0.040.002 - 0.003 0.002 - 0.004 0.003 - 0.01 0.008 - 0.012 0.010 - 0.015 0.012 - 0.016 0.013 - 0.02 0.015 - 0.022 0.02 - 0.025 0.022 - 0.040.003 - 0.01 0.008 - 0.012 0.010 - 0.015 0.012 - 0.016 0.013 - 0.02 0.015 - 0.022 0.02 - 0.025 0.022 - 0.040.002 - 0.003 0.002 - 0.004 0.003 - 0.01 0.008 - 0.012 0.010 - 0.015 0.012 - 0.016 0.013 - 0.02 0.015 - 0.022 0.02 - 0.025 0.022 - 0.040.002 - 0.003 0.002 - 0.004 0.003 - 0.01 0.008 - 0.012 0.010 - 0.015 0.012 - 0.016 0.013 - 0.02 0.015 - 0.022 0.02 - 0.025 0.022 - 0.040.002 - 0.003 0.002 - 0.004 0.003 - 0.01 0.008 - 0.012 0.010 - 0.015 0.012 - 0.016 0.013 - 0.02 0.015 - 0.022 0.02 - 0.025 0.022 - 0.040.002 - 0.003 0.002 - 0.004 0.003 - 0.01 0.008 - 0.012 0.010 - 0.015 0.012 - 0.016 0.013 - 0.02 0.015 - 0.022 0.02 - 0.025 0.022 - 0.040.002 - 0.003 0.002 - 0.004 0.003 - 0.01 0.008 - 0.012 0.010 - 0.015 0.012 - 0.016 0.013 - 0.02 0.015 - 0.022 0.02 - 0.025 0.022 - 0.040.002 - 0.003 0.002 - 0.004 0.003 - 0.01 0.008 - 0.012 0.010 - 0.015 0.012 - 0.016 0.013 - 0.02 0.015 - 0.022 0.02 - 0.025 0.022 - 0.040.002 - 0.003 0.002 - 0.004 0.003 - 0.01 0.008 - 0.012 0.010 - 0.015 0.012 - 0.016 0.013 - 0.02 0.015 - 0.022 0.02 - 0.025 0.022 - 0.040.002 - 0.003 0.002 - 0.004 0.003 - 0.01 0.008 - 0.012 0.010 - 0.015 0.012 - 0.016 0.013 - 0.02 0.015 - 0.022 0.02 - 0.025 0.022 - 0.04179

DIXI 7203 - 7243 - 7273 - 7583 - 7623 Ø < 1 mmØ > 1 mmCUTTING CONDITIONSapapaeae HM TiALNap ae ap aeMaterials to be machined Vc [m/min]Vc [m/min] [mm] [mm] [mm] [mm]PPPPMKKKSSNNNNNNNN / < 600 2Unalloyed steel / Low alloyed steel / 600 – 1500 2Unalloyed steel / Low alloyed steelLead alloyed cutting steel700 – 1500 2High alloyed steel400 – 700 2Stainless steel / < 250 HBGrey cast iron / Nodular iron pearlitic / > 250 HBAlloyed cast iron / Nodular iron pearlitic / Nodular iron pearlitic / Malleable cast iron / Special alloys / Heat resisting stainless steel / InconelNimonicHastelloyTitanium / Titanium alloy - ( - )Copper alloy - easy to machine (brass – bronze) - (. - )(CuAlFe)Copper alloy - difficult to machine / Aluminium bronze (Ampco) / Aluminium alloy / Magnesium alloySi < 8%Aluminium cast ironSi > 8%Aluminium cast ironGraphitePlastic, Gold, silver70 100 90 110 < 0.5 x ØD1 1 x ØD1 < 1.0 x ØD11 x ØD10.00650 80 70 90 < 0.3 x ØD11 x ØD1< 0.6 x ØD11 x ØD10.00670 100 < 0.5 x ØD11 x ØD1 < 1 x ØD1 1 x ØD10.00640 55 < 0.2 x ØD11 x ØD1< 0.5 x ØD11 x ØD10.00640 60 70 90 < 0.5 x ØD11 x ØD1< 0.8 x ØD11 x ØD10.006 -70 100 90 110 < 0.5 x ØD11 x ØD1 < 1 x ØD1 1 x ØD10.00640 70 70 90 < 0.3 x ØD11 x ØD1< 0.6 x ØD11 x ØD10.00670 100 90 110 < 0.3 x ØD11 x ØD1< 0.6 x ØD11 x ØD10.00625 35 < 0.4 x ØD11 x ØD130 45 < 0.30 x ØD11 x ØD1 < 0.5 x ØD11 x ØD10.006140 160 < 0.5 x ØD11 x ØD1 < 1 x ØD1 1 x ØD10.006120 140 170 190 < 0.3 x ØD11 x ØD1< 0.7 x ØD1 1 x ØD10.006180 220 230 270 < 0.6 x ØD11 x ØD1< 1.2 x ØD11 x ØD10.006240 260 300 340 < 0.6 x ØD11 x ØD1< 1.2 x ØD11 x ØD10.006140 160 210 230 < 0.4 x ØD11 x ØD1< 0.9 x ØD11 x ØD10.006140 160 200 220 < 0.6 x ØD11 x ØD1< 0.9 x ØD11 x ØD10.006240 260 300 340 < 0.6 x ØD11 x ØD1< 1.2 x ØD11 x ØD10.006140 160 200 220 < 0.6 x ØD11 x ØD1< 0.9 x ØD11 x ØD10.006180

Vc [/.] x 1000n [/.] = xD 1 []DIXI 7203 Z = 3DIXI 7243 Z = 3DIXI 7273 Z = 3DIXI 7583 Z = 3 Vf [/.] = n [/.] x [] x Feed per toothfz []Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1- 0.0150.012 -0.020 0.016 - 0.040.02 - 0.060.03 - 0.090.04 - 0.110.05 - 0.110.06 - 0.120.07 - 0.14- 0.0150.012 -0.020 0.016 - 0.040.02 - 0.060.03 - 0.090.04 - 0.110.05 - 0.110.06 - 0.120.07 - 0.13- 0.0150.012 -0.020 0.016 - 0.040.02 - 0.060.03 - 0.090.04 - 0.120.05 - 0.140.07 - 0.160.08 - 0.20- 0.0150.012 -0.020 0.016 - 0.040.02 - 0.060.03 - 0.090.04 - 0.110.05 - 0.110.06 - 0.120.07 - 0.0.0150.012 -0.020 0.016 - 0.040.02 - 0.060.03 - 0.090.04 - 0.110.05 - 0.110.06 - 0.120.07 - 0.13- 0.0150.012 -0.020 0.016 - 0.040.02 - 0.060.03 - 0.090.04 - 0.110.05 - 0.110.06 - 0.120.07 - 0.13- 0.0150.012 -0.020 0.016 - 0.040.02 - 0.060.03 - 0.090.04 - 0.110.05 - 0.110.06 - 0.120.07 - 0.13- 0.0150.012 -0.020 0.016 - 0.040.02 - 0.060.03 - 0.090.04 - 0.110.05 - 0.110.06 - 0.120.07 - 0.130.012 -0.020 0.016 - 0.040.02 - 0.060.03 - 0.090.04 - 0.110.05 - 0.110.06 - 0.120.07 - 0.13- 0.0150.012 -0.020 0.016 - 0.040.02 - 0.060.03 - 0.090.04 - 0.110.05 - 0.110.06 - 0.120.07 - 0.13- 0.0150.012 -0.020 0.016 - 0.040.02 - 0.060.03 - 0.090.04 - 0.110.05 - 0.140.07 - 0.160.08 - 0.20- 0.0150.012 -0.020 0.016 - 0.040.02 - 0.060.03 - 0.090.04 - 0.110.05 - 0.110.06 - 0.120.07 - 0.13- 0.0150.012 -0.020 0.016 - 0.040.02 - 0.060.03 - 0.090.04 - 0.120.05 - 0.140.07 - 0.160.08 - 0.20- 0.0150.012 -0.020 0.016 - 0.040.02 - 0.060.03 - 0.090.04 - 0.120.05 - 0.140.07 - 0.160.08 - 0.20- 0.0150.012 -0.020 0.016 - 0.040.02 - 0.060.03 - 0.090.04 - 0.120.05 - 0.140.07 - 0.160.08 - 0.20- 0.0150.005 -0.020 0.016 - 0.040.02 - 0.060.03 - 0.090.04 - 0.120.05 - 0.140.07 - 0.160.08 - 0.20- 0.0150.012 -0.020 0.016 - 0.040.02 - 0.060.03 - 0.090.04 - 0.120.05 - 0.210.10 - 0.240.11 - 0.30- 0.0150.005 -0.020 0.016 - 0.040.02 - 0.060.03 - 0.090.04 - 0.120.05 - 0.140.07 - 0.160.08 - 0.20181

CUTTING CONDITIONSDIXI 7204 - 7244 - 7554Ø < 1 mmapØ > 1 mmap HM TiALNaeaeap ae ap aeMaterials to be machined Vc [m/min]Vc [m/min] [mm] [mm] [mm] [mm] / P< 600 2 70 100 90 110 < 1 x ØD1 < 0.2 x ØD1< 1 x ØD1 < 0.3 x ØD1Unalloyed steel / Low alloyed steel / P600 – 1500 270 90 < 1 x ØD1 < 0.10 x ØD1< 1 x ØD1< 0.2 x ØD1Unalloyed steel / Low alloyed steel70 100 < 1.5 x ØD1< 0.2 x ØD1< 1.5 x ØD1< 0.3 x ØD1PLead alloyed cutting steel700 – 1500 240 55 < 1 x ØD1 < 0.10 x ØD1< 1 x ØD1< 0.2 x ØD1PHigh alloyed steel400 – 700 270 90 < 1 x ØD1 < 0.1 x ØD1< 1 x ØD1 < 0.3 x ØD1MStainless steel / < 250 HB 70 100 90 110 < 1 x ØD1 < 0.2 x ØD1< 1 x ØD1 < 0.3 x ØD1KGrey cast iron / Nodular iron pearlitic / > 250 HB 40 70 70 90 < 1 x ØD1 < 0.1 x ØD1< 1 x ØD1 < 0.3 x ØD1KAlloyed cast iron / Nodular iron pearlitic / 70 100 90 110 < 1 x ØD1 < 0.1 x ØD1< 1 x ØD1 < 0.3 x ØD1KNodular iron pearlitic / Malleable cast iron / InconelNimonic25 35 < 1 x ØD1 < 0.1 x ØD1SSpecial alloys / Heat resisting stainless steel Hastelloy / 30 45 < 1 x ØD1 < 0.1 x ØD1< 1 x ØD1 < 0.3 x ØD1STitanium / Titanium alloy - ( - )140 160 < 1.5 x ØD1< 0.2 x ØD1< 1.5 x ØD1< 0.3 x ØD1NCopper alloy - easy to machine (brass – bronze) - (. - )(CuAlFe) 120 140 170 190 < 1 x ØD1 < 0.1 x ØD1< 1 x ØD1 < 0.2 x ØD1NCopper alloy - difficult to machine / Aluminium bronze (Ampco) / 180 220 230 270 < 1.5 x ØD1< 0.2 x ØD1< 1.5 x ØD1< 0.3 x ØD1NAluminium alloy / Magnesium alloySi < 8% 240 260 300 340 < 1.5 x ØD1< 0.2 x ØD1< 1.5 x ØD1< 0.3 x ØD1NAluminium cast ironSi > 8% 140 160 210 230 < 1.5 x ØD1< 0.2 x ØD1< 1.5 x ØD1< 0.3 x ØD1NAluminium cast iron240 260 300 340 < 1.5 x ØD1< 0.2 x ØD1< 1.5 x ØD1< 0.3 x ØD1NPlastic, 140 160 200 220 < 1.5 x ØD1< 0.2 x ØD1< 1.5 x ØD1< 0.3 x ØD1NGold, silver182

DIXI 7204 Z = 4Vc [/.] x 1000DIXI 7244 Z = 4n [/.] =DIXI 7554 Z = 4 xD 1 [] Vf [/.] = n [/.] x [] x Feed per toothfz []Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 10.006 - 0.015 0.012 -0.020 0.016 - 0.04 0.02 - 0.06 0.03 -0.09 0.04 - 0.12 0.05 - 0.10 0.06 -0.11 0.07 -0.140.006 - 0.015 0.012 -0.020 0.016 -0.04 0.02 - 0.06 0.03 -0.09 0.04 - 0.12 0.05 - 0.07 0.06 -0.08 0.07 -0.100.006 - 0.015 0.012 -0.020 0.016 - 0.04 0.02 - 0.06 0.03 -0.09 0.04 - 0.12 0.05 - 0.14 0.07 -0.16 0.08 -0.200.006 - 0.015 0.012 -0.020 0.016 - 0.04 0.02 - 0.06 0.03 -0.09 0.04 - 0.12 0.05 - 0.13 0.06 -0.14 0.07 -0.150.006 - 0.015 0.012 -0.020 0.016 - 0.04 0.02 - 0.06 0.03 -0.09 0.04 - 0.12 0.05 - 0.13 0.06 -0.14 0.07 -0.150.006 - 0.015 0.012 -0.020 0.016 - 0.04 0.02 - 0.06 0.03 -0.09 0.04 - 0.12 0.05 - 0.13 0.06 -0.14 0.07 -0.150.006 - 0.015 0.012 -0.020 0.016 - 0.04 0.02 - 0.06 0.03 -0.09 0.04 - 0.12 0.05 - 0.13 0.06 -0.14 0.07 -0.150.012 -0.020 0.016 - 0.04 0.02 - 0.06 0.03 -0.09 0.04 - 0.12 0.05 - 0.13 0.06 -0.14 0.07 -0.150.006 - 0.015 0.012 -0.020 0.016 - 0.04 0.02 - 0.06 0.03 -0.09 0.04 - 0.12 0.05 - 0.13 0.06 -0.14 0.07 -0.150.006 - 0.015 0.012 -0.020 0.016 - 0.04 0.02 - 0.06 0.03 -0.09 0.04 - 0.12 0.05 - 0.07 0.06 -0.08 0.07 -0.100.006 - 0.015 0.012 -0.020 0.016 - 0.04 0.02 - 0.06 0.03 -0.09 0.04 - 0.12 0.05 - 0.14 0.07 -0.16 0.08 -0.200.006 - 0.015 0.012 -0.020 0.016 - 0.04 0.02 - 0.06 0.03 -0.09 0.04 - 0.12 0.05 - 0.07 0.06 -0.08 0.07 -0.100.006 - 0.015 0.012 -0.020 0.016 - 0.04 0.02 - 0.06 0.03 -0.09 0.04 - 0.12 0.05 - 0.14 0.07 -0.16 0.08 -0.20.006 - 0.015 0.012 -0.020 0.016 - 0.04 0.02 - 0.06 0.03 -0.09 0.04 - 0.12 0.05 - 0.14 0.07 -0.16 0.08 -0.200.006 - 0.015 0.012 -0.020 0.016 - 0.04 0.02 - 0.06 0.03 -0.09 0.04 - 0.12 0.05 - 0.14 0.07 -0.16 0.08 -0.200.006 - 0.015 0.012 -0.020 0.016 - 0.04 0.02 - 0.06 0.03 -0.09 0.04 - 0.12 0.05 - 0.21 0.10 -0.24 0.11 -0.300.006 - 0.015 0.005 -0.020 0.016 - 0.04 0.02 - 0.06 0.03 -0.09 0.04 - 0.12 0.05 - 0.14 0.07 -0.16 0.08 -0.20183

DIXI 7090 CUTTING CONDITIONS HM TiALN DIAMANTapaeMaterials to be machined Vc [m/min]Vc [m/min]Vc [m/min]ap[mm]ae[mm] / P< 600 2Unalloyed steel / Low alloyed steel70 100 90 110 < 1 x ØD1 < 0.2 x ØD1 / P600 – 1500 2Unalloyed steel / Low alloyed steel70 90 < 1 x ØD1 < 0.2 x ØD1PLead alloyed cutting steel70 100 < 1.5 x ØD1< 0.2 x ØD1700 – 1500 2PHigh alloyed steel40 55 < 1 x ØD1 < 0.1 x ØD1400 – 700 2MStainless steel70 90 < 1 x ØD1 < 0.1 x ØD1 / < 250 HBKGrey cast iron / Nodular iron pearlitic70 100 90 110 < 1 x ØD1 < 0.2 x ØD1 / > 250 HBKAlloyed cast iron / Nodular iron pearlitic40 70 70 90 < 1 x ØD1 < 0.2 x ØD1 / KNodular iron pearlitic / Malleable cast iron70 100 90 110 < 1 x ØD1 < 0.2 x ØD1 / InconelNimonicSSpecial alloys / Heat resisting stainless steel Hastelloy25 35 < 1 x ØD1 < 0.1 x ØD1 / STitanium / Titanium alloy30 45 < 1 x ØD1 < 0.2 x ØD1 - ( - )NCopper alloy - easy to machine (brass – bronze)140 160 < 1.5 x ØD1< 0.2 x ØD1 - (. - )(CuAlFe)NCopper alloy - difficult to machine / Aluminium bronze (Ampco)120 140 170 190 < 1 x ØD1 < 0.15x ØD1 / NAluminium alloy / Magnesium alloy180 220 230 270 < 1.5 x ØD1< 0.2 x ØD1Si < 8%NAluminium cast iron240 260 300 340 < 1.5 x ØD1< 0.2 x ØD1Si > 8%NAluminium cast iron140 160 210 230 200 300 < 1.5 x ØD1< 0.2 x ØD1NGraphite200 300 < 1.5 x ØD1< 0.2 x ØD1NPlastic240 260 300 340 < 1.5 x ØD1< 0.2 x ØD1, NGold, silver140 160 200 220 < 1.5 x ØD1< 0.2 x ØD1184

Vc [/.] x 1000n [/.] = xD 1 []DIXI 7090Z = 2Ø >4 Z = 4 Vf [/.] = n [/.] x [] x Feed per toothfz []Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 10.016 - 0.04 0.02 - 0.06 0.03 - 0.09 0.04 - 0.12 0.06 -0.140.016 - 0.04 0.02 - 0.06 0.03 - 0.09 0.04 - 0.12 0.06 -0.140.016 - 0.04 0.02 - 0.06 0.03 - 0.09 0.04 - 0.12 0.06 -0.140.016 - 0.04 0.02 - 0.06 0.03 - 0.09 0.04 - 0.12 0.06 -0.140.016 - 0.04 0.02 - 0.06 0.03 - 0.09 0.04 - 0.12 0.06 -0.140.016 - 0.04 0.02 - 0.06 0.03 - 0.09 0.04 - 0.12 0.06 -0.140.016 - 0.04 0.02 - 0.06 0.03 - 0.09 0.04 - 0.12 0.06 -0.140.016 - 0.04 0.02 - 0.06 0.03 - 0.09 0.04 - 0.12 0.06 -0.140.016 - 0.04 0.02 - 0.06 0.03 - 0.09 0.04 - 0.12 0.06 -0.140.016 - 0.04 0.02 - 0.06 0.03 - 0.09 0.04 - 0.12 0.06 -0.140.016 - 0.04 0.02 - 0.06 0.03 - 0.09 0.04 - 0.12 0.06 -0.140.016 - 0.04 0.02 - 0.06 0.03 - 0.09 0.04 - 0.12 0.06 -0.140.016 - 0.04 0.02 - 0.06 0.03 - 0.09 0.04 - 0.12 0.06 -0.140.016 - 0.04 0.02 - 0.06 0.03 - 0.09 0.04 - 0.12 0.06 -0.140.016 - 0.04 0.02 - 0.06 0.03 - 0.09 0.04 - 0.12 0.06 -0.140.005 - 0.02 0.011 - 0.04 0.018 - 0.05 0.025 - 0.08 0.04 - 0.140.016 - 0.04 0.02 - 0.06 0.03 - 0.09 0.04 - 0.12 0.06 -0.210.016 - 0.04 0.02 - 0.06 0.03 - 0.09 0.04 - 0.12 0.06 -0.14185

DIXI 7222 - 7223 - 7224DIXI 7222 DIXI 7223 - 7224CUTTING CONDITIONSapap HM TiALNaeaeap ae ap aeMaterials to be machined Vc [m/min]Vc [m/min] [mm] [mm] [mm] [mm] / P< 600 2 45 50 50 60 3 x ØD1 < 0.30 x ØD13 x ØD1 < 0.20 x ØD1Unalloyed steel / Low alloyed steel / P600 – 1500 235 45 3 x ØD1 < 0.20 x ØD13 x ØD1 < 0.10 x ØD1Unalloyed steel / Low alloyed steel45 50 3 x ØD1 < 0.30 x ØD13 x ØD1 < 0.20 x ØD1PLead alloyed cutting steel700 – 1500 230 45 3 x ØD1 < 0.15 x ØD13 x ØD1 < 0.07 x ØD1PHigh alloyed steel400 – 700 235 45 3 x ØD1 < 0.20 x ØD13 x ØD1 < 0.10 x ØD1MStainless steel / < 250 HB 25 35 35 45 3 x ØD1 < 0.30 x ØD13 x ØD1 < 0.20 x ØD1KGrey cast iron / Nodular iron pearlitic / > 250 HB 25 35 35 45 3 x ØD1 < 0.15 x ØD13 x ØD1 < 0.07 x ØD1KAlloyed cast iron / Nodular iron pearlitic / 25 35 35 45 3 x ØD1 < 0.30 x ØD13 x ØD1 < 0.20 x ØD1KNodular iron pearlitic / Malleable cast iron / InconelNimonic15 25 3 x ØD1 < 0.10 x ØD13 x ØD1 < 0.05 x ØD1SSpecial alloys / Heat resisting stainless steel Hastelloy / 15 25 3 x ØD1 < 0.15 x ØD13 x ØD1 < 0.07 x ØD1STitanium / Titanium alloy - ( - )80 100 3 x ØD1 < 0.30 x ØD13 x ØD1 < 0.20 x ØD1NCopper alloy - easy to machine (brass – bronze) - (. - )(CuAlFe) 60 80 80 100 3 x ØD1 < 0.30 x ØD13 x ØD1 < 0.20 x ØD1NCopper alloy - difficult to machine / Aluminium bronze (Ampco) / 80 100 100 120 3 x ØD1 < 0.40 x ØD13 x ØD1 < 0.30 x ØD1NAluminium alloy / Magnesium alloySi < 8% 90 110 110 130 3 x ØD1 < 0.40 x ØD13 x ØD1 < 0.30 x ØD1NAluminium cast ironSi > 8% 80 100 100 120 3 x ØD1 < 0.40 x ØD13 x ØD1 < 0.30 x ØD1NAluminium cast iron90 110 110 130 3 x ØD1 < 0.40 x ØD13 x ØD1 < 0.30 x ØD1NPlastic, 80 100 100 120 3 x ØD1 < 0.40 x ØD13 x ØD1 < 0.30 x ØD1NGold, silver (Vfp) , Z=2 40% - 80 % - .The plunging feed (Vfp) of an end mill Z = 2 (drilling) must be reduced from 40 to 80 % depending on the materialto be machined.186

Vc [/.] x 1000n [/.] = xD 1 []DIXI 7222 Z = 2DIXI 7223 Z = 3DIXI 7224 Z = 4 Vf [/.] = n [/.] x [] x Feed per toothfz []Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 10.006 - 0.01 0.008 -0.02 0.010 - 0.02 0.012 - 0.02 0.014 -0.03 0.018 - 0.04 0.02 - 0.04 0.02 -0.05 0.03 -0.06 0.03 - 0.070.005 - 0.01 0.006 -0.01 0.008 - 0.02 0.009 - 0.02 0.011 -0.02 0.014 - 0.03 0.02 - 0.03 0.02 -0.04 0.02 -0.04 0.02 - 0.050.008 - 0.02 0.010 -0.03 0.013 - 0.03 0.015 - 0.04 0.018 -0.04 0.023 - 0.05 0.03 - 0.06 0.03 -0.07 0.04 -0.08 0.04 - 0.100.005 - 0.01 0.006 -0.01 0.008 - 0.02 0.009 - 0.02 0.011 -0.02 0.014 - 0.03 0.02 - 0.03 0.02 -0.04 0.02 -0.04 0.02 - 0.050.005 - 0.01 0.006 -0.01 0.008 - 0.02 0.009 - 0.02 0.011 -0.02 0.014 - 0.03 0.02 - 0.03 0.02 -0.04 0.02 -0.04 0.02 - 0.050.006 - 0.01 0.008 -0.02 0.010 - 0.02 0.012 - 0.02 0.014 -0.03 0.018 - 0.04 0.02 - 0.04 0.02 -0.05 0.03 -0.06 0.03 - 0.070.005 - 0.01 0.006 -0.01 0.008 - 0.02 0.009 - 0.02 0.011 -0.02 0.014 - 0.03 0.02 - 0.03 0.02 -0.04 0.02 -0.04 0.02 - 0.050.006 - 0.01 0.008 -0.02 0.010 - 0.02 0.012 - 0.02 0.014 -0.03 0.018 - 0.04 0.02 - 0.04 0.02 -0.05 0.03 -0.06 0.03 - 0.070.005 - 0.01 0.006 -0.01 0.008 - 0.02 0.009 - 0.02 0.011 -0.02 0.014 - 0.03 0.02 - 0.03 0.02 -0.04 0.02 -0.04 0.02 - 0.050.005 - 0.01 0.006 -0.01 0.008 - 0.02 0.009 - 0.02 0.011 -0.02 0.014 - 0.03 0.02 - 0.03 0.02 -0.04 0.02 -0.04 0.02 - 0.050.008 - 0.02 0.010 -0.03 0.013 - 0.03 0.015 - 0.04 0.018 -0.04 0.023 - 0.05 0.03 - 0.06 0.03 -0.07 0.04 -0.08 0.04 - 0.100.005 - 0.01 0.006 -0.01 0.008 - 0.02 0.009 - 0.02 0.011 -0.02 0.014 - 0.03 0.02 - 0.03 0.02 -0.04 0.02 -0.04 0.02 - 0.050.008 - 0.02 0.010 -0.03 0.013 - 0.03 0.015 - 0.04 0.018 -0.04 0.023 - 0.05 0.03 - 0.06 0.03 -0.07 0.04 -0.08 0.04 - 0.100.008 - 0.02 0.010 -0.03 0.013 - 0.03 0.015 - 0.04 0.018 -0.04 0.023 - 0.05 0.03 - 0.06 0.03 -0.07 0.04 -0.08 0.04 - 0.100.008 - 0.02 0.010 -0.03 0.013 - 0.03 0.015 -0.04 0.018 -0.04 0.023 -0.05 0.03 - 0.06 0.03 -0.07 0.04 -0.08 0.04 - 0.100.011 - 0.03 0.014 -0.04 0.018 - 0.05 0.021 -0.05 0.025 -0.06 0.032 -0.08 0.04 - 0.09 0.04 -0.11 0.05 -0.12 0.06 - 0.150.008 - 0.02 0.010 -0.03 0.013 - 0.03 0.015 -0.04 0.018 -0.04 0.023 -0.05 0.03 - 0.06 0.03 -0.07 0.04 -0.08 0.04 - 0.10187

DIXI 7560DIXI 7560apCUTTING CONDITIONS HM TiALNap aeMaterials to be machined Vc [m/min]Vc [m/min] [mm] [mm] / P< 600 2 90 110 110 130 1.50 x ØD1 < 0.10 x ØD1Unalloyed steel / Low alloyed steel / P600 – 1500 280 100 1.50 x ØD1 < 0.10 x ØD1Unalloyed steel / Low alloyed steel80 110 1.50 x ØD1 < 0.30 x ØD1PLead alloyed cutting steel700 – 1500 260 80 1.50 x ØD1 < 0.05 x ØD1PHigh alloyed steel400 – 700 280 100 1.50 x ØD1 < 0.05 x ØD1MStainless steel / < 250 HB 80 110 110 140 1.50 x ØD1 < 0.20 x ØD1KGrey cast iron / Nodular iron pearlitic / > 250 HB 50 70 80 100 1.50 x ØD1 < 0.05 x ØD1KAlloyed cast iron / Nodular iron pearlitic / 80 110 110 130 1.50 x ØD1 < 0.10 x ØD1KNodular iron pearlitic / Malleable cast iron / InconelNimonic35 50 1.50 x ØD1 < 0.05 x ØD1SSpecial alloys / Heat resisting stainless steel Hastelloy / 40 55 1.50 x ØD1 < 0.10 x ØD1STitanium / Titanium alloy - ( - )160 200 1.50 x ØD1 < 0.30 x ØD1NCopper alloy - easy to machine (brass – bronze) - (. - )(CuAlFe) 140 160 170 220 1.50 x ØD1 < 0.10 x ØD1NCopper alloy - difficult to machine / Aluminium bronze (Ampco)aeDIXI 7060 - 7232apHMaeap aeMaterials to be machined Vc [m/min] [mm] [mm]PPNNN / < 600 2Unalloyed steel / Low alloyed steelLead alloyed cutting steel - ( - )Copper alloy - easy to machine (brass – bronze)Plastic, Gold, silver70 100 < 1.0 x ØD11 x ØD10.00370 100 < 1 x ØD1 1 x ØD1140 160 < 1 x ØD1 1 x ØD1240 260 < 1.2 x ØD11 x ØD10.003140 160 < 0.9 x ØD11 x ØD10.003188

n [/.] = Vc [/] x 1000 xD 1 []DIXI 7560 Z = 5-8 Vf [/.] = n [/.] x [] x Feed per toothØ D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 12.00 - 3.00 3.00 - 5.00 5.00 - 8.00 8.00 - 10.0010.00 - 14.0014.00 - 16.0016.00 - 20.00(Z = 5) (Z = 5) (Z = 5) (Z = 6) (Z = 6) (Z = 6) (Z = 6)0.016 - 0.04 0.02 - 0.06 0.03 - 0.07 0.04 - 0.08 0.05 -0.09 0.06 - 0.10 0.07 - 0.11fz []0.016 - 0.04 0.02 - 0.06 0.03 - 0.07 0.04 - 0.08 0.05 -0.09 0.06 - 0.10 0.07 - 0.110.016 - 0.04 0.02 - 0.06 0.03 - 0.07 0.04 - 0.08 0.05 -0.09 0.07 - 0.10 0.08 - 0.110.016 - 0.04 0.02 - 0.06 0.03 - 0.07 0.04 - 0.08 0.05 -0.09 0.06 - 0.10 0.07 - 0.110.016 - 0.04 0.02 - 0.06 0.03 - 0.07 0.04 - 0.08 0.05 -0.09 0.06 - 0.10 0.07 - 0.110.016 - 0.04 0.02 - 0.06 0.03 - 0.07 0.04 - 0.08 0.05 -0.09 0.06 - 0.10 0.07 - 0.110.016 - 0.04 0.02 - 0.06 0.03 - 0.07 0.04 - 0.08 0.05 -0.09 0.06 - 0.10 0.07 - 0.110.016 - 0.04 0.02 - 0.06 0.03 - 0.07 0.04 - 0.08 0.05 -0.09 0.06 - 0.10 0.07 - 0.110.016 - 0.04 0.02 - 0.06 0.03 - 0.07 0.04 - 0.08 0.05 -0.09 0.06 - 0.10 0.07 - 0.110.016 - 0.04 0.02 - 0.06 0.03 - 0.07 0.04 - 0.08 0.05 -0.09 0.06 - 0.10 0.07 - 0.110.016 - 0.04 0.02 - 0.06 0.03 - 0.07 0.04 - 0.08 0.05 -0.09 0.07 - 0.10 0.08 - 0.110.016 - 0.04 0.02 - 0.06 0.03 - 0.07 0.04 - 0.08 0.05 -0.09 0.06 - 0.10 0.07 - 0.11DIXI 7060 Z = 1DIXI 7202 Z = 2 Feed per toothfz []Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1- 0.010.006 -0.015 0.012 - 0.020 0.016 - 0.04 0.02 -0.06 0.03 - 0.09 0.04 - 0.110.003 - 0.01 0.006 -0.015 0.012 -0.020 0.016 - 0.04 0.02 -0.06 0.03 - 0.09 0.04 - 0.110.003 - 0.01 0.006 -0.015 0.012 -0.020 0.016 - 0.04 0.02 - 0.06 0.03 - 0.09 0.04 - 0.11- 0.010.006 -0.015 0.012 - 0.020 0.016 - 0.04 0.02 -0.06 0.03 - 0.09 0.04 - 0.11- 0.010.006 -0.015 0.012 - 0.020 0.016 - 0.04 0.02 -0.06 0.03 - 0.09 0.04 - 0.11189

DIXI 7210DIXI 7210DIXI 7210CUTTING CONDITIONSapap HM CUTINOXaeaeap ae ap aeMaterials to be machined Vc [m/min]Vc [m/min] [mm] [mm] [mm] [mm] / P< 600 2 70 100 100 120 1.5 x ØD1 0.5 x ØD1 < 1.3 x ØD1 1 x ØD1Unalloyed steel / Low alloyed steel / P600 – 1500 280 100 1.5 x ØD1 0.5 x ØD1 < 1.0 x ØD1 1 x ØD1Unalloyed steel / Low alloyed steel70 100 1.5 x ØD1 0.5 x ØD1 < 1.0 x ØD1 1 x ØD1PLead alloyed cutting steel700 – 1500 250 70 1.5 x ØD1 0.5 x ØD1 < 1.0 x ØD1 1 x ØD1PHigh alloyed steel400 – 700 280 100 1.5 x ØD1 0.5 x ØD1 < 1.0 x ØD1 1 x ØD1MStainless steel / < 250 HB 70 100 100 120 1.5 x ØD1 0.5 x ØD1 < 1.0 x ØD1 1 x ØD1KGrey cast iron / Nodular iron pearlitic / > 250 HB 40 70 80 100 1.5 x ØD1 0.5 x ØD1 < 1.0 x ØD1 1 x ØD1KAlloyed cast iron / Nodular iron pearlitic / 70 100 100 120 1.5 x ØD1 0.5 x ØD1 < 1.0 x ØD1 1 x ØD1KNodular iron pearlitic / Malleable cast iron / S30 45 1.5 x ØD1 0.5 x ØD1 < 1.0 x ØD1 1 x ØD1Titanium / Titanium alloyDIXI 7301 - 7302 - 7303 - 7304ap HMaeapaeMaterials to be machined Vc [m/min] [mm] [mm]N130 200 < 1.5 x ØD1 1 x ØD1Plastic (Vfp) , Z=1 40% - 80% - .The plunging feed (Vfp) of an end mill Z = 1 (drilling) must be reduced by 40 to 80 % depending on the material tobe machined.190

Vc [/.] x 1000n [/.] = xD 1 []DIXI 7210 Z = 3 Vf [/.] = n [/.] x [] x Feed per toothfz []Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 10.02 - 0.03 0.025 -0.04 0.028 - 0.045 0.032 - 0.05 0.035 - 0.06 0.04 - 0.08 0.06 - 0.100.02 - 0.03 0.025 -0.04 0.028 - 0.045 0.032 - 0.05 0.035 - 0.06 0.04 - 0.08 0.06 - 0.100.02 - 0.03 0.025 -0.04 0.028 - 0.045 0.032 - 0.05 0.035 - 0.06 0.04 - 0.08 0.06 - 0.100.02 - 0.03 0.025 -0.04 0.028 - 0.045 0.032 - 0.05 0.035 - 0.06 0.04 - 0.08 0.06 - 0.100.02 - 0.03 0.025 -0.04 0.028 - 0.045 0.032 - 0.05 0.035 - 0.06 0.04 - 0.08 0.06 - 0.100.02 - 0.03 0.025 -0.04 0.028 - 0.045 0.032 - 0.05 0.035 - 0.06 0.04 - 0.08 0.06 - 0.100.02 - 0.03 0.025 -0.04 0.028 - 0.045 0.032 - 0.05 0.035 - 0.06 0.04 - 0.08 0.06 - 0.100.02 - 0.03 0.025 -0.04 0.028 - 0.045 0.032 - 0.05 0.035 - 0.06 0.04 - 0.08 0.06 - 0.100.02 - 0.03 0.025 -0.04 0.028 - 0.045 0.032 - 0.05 0.035 - 0.06 0.04 - 0.08 0.06 - 0.10DIXI 7301 Z = 1DIXI 7302 Z = 1DIXI 7303 Z = 1DIXI 7304 Z = 1 Feed per toothfz []Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 10.020 - 0.05 0.025 -0.06 0.03 - 0.08 0.04 - 0.10 0.05 - 0.12 0.06 - 0.16 0.08 - 0.20 0.10 - 0.28191

DIXI 7213 - 7214DIXI 7213 DIXI 7214 apapCUTTING CONDITIONSaeae HM TiALNap ae ap aeMaterials to be machined Vc [m/min]Vc [m/min] [mm] [mm] [mm] [mm] / P< 600 2 70 100 90 110 < 1.0 x ØD1 1 x ØD1 < 1 x ØD1 < 0.5 x ØD1Unalloyed steel / Low alloyed steel / P600 – 1500 270 90 < 0.5 x ØD1 1 x ØD1 < 1 x ØD1 < 0.3 x ØD1Unalloyed steel / Low alloyed steel70 100 < 1.0 x ØD1 1 x ØD1 < 1.5 x ØD1< 0.5 x ØD1PLead alloyed cutting steel / < 250 HB 70 100 90 110 < 1.0 x ØD1 1 x ØD1 < 1 x ØD1 < 0.5 x ØD1KGrey cast iron / Nodular iron pearlitic / > 250 HB 40 70 70 90 < 0.4 x ØD1 1 x ØD1 < 1 x ØD1 < 0.4 x ØD1KAlloyed cast iron / Nodular iron pearlitic / 70 100 90 110 < 0.4 x ØD1 1 x ØD1 < 1 x ØD1 < 0.4 x ØD1KNodular iron pearlitic / Malleable cast iron - ( - )140 160 < 2.0 x ØD1 1 x ØD1 < 1.5 x ØD1< 0.5 x ØD1NCopper alloy - easy to machine (brass – bronze) - (. - )(CuAlFe) 120 140 170 190 < 1.0 x ØD1 1 x ØD1 < 1 x ØD1 < 0.3 x ØD1NCopper alloy - difficult to machine / Aluminium bronze (Ampco) / 180 220 230 270 < 2.0 x ØD1 1 x ØD1 < 1.5 x ØD1< 0.5 x ØD1NAluminium alloy / Magnesium alloySi < 8% 240 260 300 340 < 2.0 x ØD1 1 x ØD1 < 1.5 x ØD1< 0.5 x ØD1NAluminium cast ironSi > 8% 140 160 210 230 < 2.0 x ØD1 1 x ØD1 < 1.5 x ØD1< 0.5 x ØD1NAluminium cast iron240 260 300 340 < 2.0 x ØD1 1 x ØD1 < 1.5 x ØD1< 0.5 x ØD1NPlastic, 140 160 200 220 < 1.0 x ØD1 1 x ØD1 < 1.5 x ØD1< 0.5 x ØD1NGold, silver192

DIXI 7213 Z = 3Vc [/.] x 1000 DIXI 7214 Z = 4n [/.] = xD 1 [] Vf [/.] = n [/.] x [] x Feed per toothfz []Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 10.008 - 0.02 0.010 -0.02 0.012 - 0.02 0.014 - 0.03 0.016 -0.03 0.018 - 0.04 0.020 -0.04 0.02 -0.05 0.03 -0.06 0.03 - 0.070.006 - 0.01 0.008 -0.02 0.009 - 0.02 0.011 - 0.02 0.012 -0.02 0.014 - 0.03 0.015 -0.03 0.02 -0.04 0.02 -0.04 0.02 - 0.050.010 - 0.03 0.013 -0.03 0.015 - 0.04 0.018 - 0.04 0.020 -0.05 0.023 - 0.05 0.025 -0.06 0.03 -0.07 0.04 -0.08 0.04 - 0.100.008 - 0.02 0.010 -0.02 0.012 - 0.02 0.014 - 0.03 0.016 -0.03 0.018 - 0.04 0.020 -0.04 0.02 -0.05 0.03 -0.06 0.03 - 0.070.006 - 0.01 0.008 -0.02 0.009 - 0.02 0.011 - 0.02 0.012 -0.02 0.014 - 0.03 0.015 -0.03 0.02 -0.04 0.02 -0.04 0.02 - 0.050.008 - 0.02 0.010 -0.02 0.012 - 0.02 0.014 - 0.03 0.016 -0.03 0.018 - 0.04 0.020 -0.04 0.02 -0.05 0.03 -0.06 0.03 - 0.070.010 - 0.03 0.013 -0.03 0.015 - 0.04 0.018 - 0.04 0.020 -0.05 0.023 - 0.05 0.025 -0.06 0.03 -0.07 0.04 -0.08 0.04 - 0.100.006 - 0.01 0.008 -0.02 0.009 - 0.02 0.011 - 0.02 0.012 -0.02 0.014 - 0.03 0.015 -0.03 0.02 -0.04 0.02 -0.04 0.02 - 0.050.010 - 0.03 0.013 -0.03 0.015 - 0.04 0.018 - 0.04 0.020 -0.05 0.023 - 0.05 0.025 -0.06 0.03 -0.07 0.04 -0.08 0.04 - 0.100.010 - 0.03 0.013 -0.03 0.015 - 0.04 0.018 - 0.04 0.020 -0.05 0.023 - 0.05 0.025 -0.06 0.03 -0.07 0.04 -0.08 0.04 - 0.100.010 - 0.03 0.013 -0.03 0.015 - 0.04 0.018 -0.04 0.020 -0.05 0.023 -0.05 0.025 -0.06 0.03 -0.07 0.04 -0.08 0.04 - 0.100.014 - 0.04 0.018 -0.05 0.021 - 0.05 0.025 -0.06 0.028 -0.07 0.032 -0.08 0.035 -0.09 0.04 -0.11 0.05 -0.12 0.06 - 0.150.010 - 0.03 0.013 -0.03 0.015 - 0.04 0.018 - 0.04 0.020 -0.05 0.023 - 0.05 0.025 -0.06 0.03 -0.07 0.04 -0.08 0.04 - 0.10193

DIXI 7263Ø > 1 mmCUTTING CONDITIONSapTiALNaeap aeMaterials to be machined Vc [m/min] [mm] [mm]PPPKKKSS / < 600 2Unalloyed steel / Low alloyed steel / 600 – 1500 2Unalloyed steel / Low alloyed steelLead alloyed cutting steel / < 250 HBGrey cast iron / Nodular iron pearlitic / > 250 HBAlloyed cast iron / Nodular iron pearlitic / Nodular iron pearlitic / Malleable cast iron / Special alloys / Heat resisting stainless steel / Titanium / Titanium alloyInconelNimonicHastelloy194

DIXI 7263 Z = 3Vc [/.] x 1000n [/.] = xD 1 []Ø D 1 Ø D 1 Ø D 1 Ø D 1 Vf [/.] = n [/.] x [] x Feed per toothfz []195

DIXI 7561DIXI 7561CUTTING CONDITIONSapaeHMapaeMaterials to be machined Vc [m/min] [mm] [mm]P80 100 < 0.7 x ØD1 1 x ØD1Lead alloyed cutting steel - ( - )N100 130 < 1 x ØD1 1 x ØD1Copper alloy - easy to machine (brass – bronze) / 120 160 < 1 x ØD1 1 x ØD1NAluminium alloy / Magnesium alloySi < 8% 120 160 < 1 x ØD1 1 x ØD1NAluminium cast ironSi > 8% 100 130 < 1 x ØD1 1 x ØD1NAluminium cast iron (Vfp) , Z=1 40% - 80% - .The plunging feed (Vfp) of an end mill Z = 1 (drilling) must be reduced by 40 to 80 % depending on the material tobe machined.DIXI 7552 - 7562 - 7572 - 7582ae HM TiALN DICUTMaterials to be machined Vc [m/min] Vc [m/min] Vc [m/min]ap[mm]ae[mm]PMSNNNNHigh alloyed steelStainless steel / 700 – 1500 2400 – 700 2Titanium / Titanium alloy - ( - )Copper alloy - easy to machine (brass – bronze) - (. - )(CuAlFe)Copper alloy - difficult to machine / Aluminium bronze (Ampco)Plastic, Gold, silverap196

Vc [/.] x 1000n [/.] = xD 1 []DIXI 7561 Z = 1 Vf [/.] = n [/.] x [] x Feed per toothfz []Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 10.010 - 0.03 0.013 -0.04 0.02 - 0.05 0.02 - 0.06 0.03 - 0.07 0.03 - 0.10 0.04 - 0.12 0.05 - 0.170.014 - 0.04 0.018 -0.05 0.02 - 0.06 0.03 - 0.08 0.04 - 0.09 0.04 - 0.12 0.06 - 0.15 0.07 - 0.210.014 - 0.04 0.018 -0.05 0.02 - 0.06 0.03 - 0.08 0.04 - 0.09 0.04 - 0.12 0.06 - 0.15 0.07 - 0.210.014 - 0.04 0.018 -0.05 0.02 - 0.06 0.03 - 0.08 0.04 - 0.09 0.04 - 0.12 0.06 - 0.15 0.07 - 0.210.014 - 0.04 0.018 -0.05 0.02 - 0.06 0.03 - 0.08 0.04 - 0.09 0.04 - 0.12 0.06 - 0.15 0.07 - 0.21DIXI 7552 Z = 2DIXI 7562 Z = 2DIXI 7582 Z = 2 Feed per toothfz []Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1197

DIXI 7552 - 7562 - 7582CUTTING CONDITIONSapaeDIXI 7552 - 7562 - 7582 Z = 2 Alluminium Aluminium ( Vc 400 - 600 /. )- . . . D 1 Z Vc n Vf ap ae fz/.] [. -1] [/.] [] [] []1 2 90000 900 0.2 1 0.0051.5 2 400 84890 1270 0.45 1.5 0.0082 2 400 63660 1270 0.6 2 0.0102.5 2 400 50930 1270 0.75 2.5 0.0133 2 400 42440 1270 1.5 3 0.0154 2 400 31830 1270 2 4 0.0205 2 400 25470 1270 2.5 5 0.0306 2 400 21220 1270 3 6 0.0308 2 400 15920 1270 4 8 0.04010 2 400 12730 1270 5 10 0.05012 2 400 10610 1270 6 12 0.06014 2 400 9090 1270 7 14 0.07016 2 400 7960 1270 8 16 0.08018 2 400 7070 1270 9 18 0.09020 2 400 6370 1270 10 20 0.100apaeDIXI 7552 - 7562 - 7582 Z = 2 Aluminium ( Vc 700 - 1200 /. )- . . . D 1 Z Vc n Vf ap ae fz/.] [. -1] [/.] [] [] []1 2 90000 1800 0.3 0.7 0.0101.5 2 90000 2700 0.45 1.1 0.0152 2 90000 3600 0.6 1.4 0.0202.5 2 700 89130 4460 0.75 1.8 0.0253 2 700 74270 4460 0.9 2.1 0.0304 2 700 55710 4460 1.2 2.8 0.0405 2 700 44560 4460 1.5 3.5 0.0506 2 700 37140 4460 1.8 4.2 0.0608 2 700 27850 4460 2.4 5.6 0.08010 2 700 22280 4460 3 7 0.10012 2 700 18570 4460 3.6 8 0.12014 2 700 15920 4460 4.2 10 0.14016 2 700 13930 4460 4.8 11 0.16018 2 700 12380 4460 5.4 13 0.18020 2 700 11140 4460 6 14 0.200 (Vfp) , Z=2 40%-80% .The plunging feed (Vfp) of an end mill Z = 2 (drilling) must be reduced by 40-80 % depending on the material to be machined. , Vf () -.If the spindle does not allow the recommended rpm, Vf must be reduced proportionally.198

DIXI 7572 - 7593ap CUTTING CONDITIONSaeDIXI 7572 Z = 2 Allunimium Alluminum (Vc) 180 - 250 /.- . . . D 1 Z Vc n Vf ap ae fz/.] [. -1] [/.] [] [] []3 2 180 19100 570 9 0.1 0.0154 2 180 14320 570 12 0.1 0.025 2 180 11460 920 15 0.1 0.046 2 180 9550 1150 18 0.15 0.067 2 180 8190 1150 20 0.15 0.078 2 180 7160 1150 22 0.15 0.089 2 180 6370 1150 24 0.15 0.0910 2 180 5730 1150 26 0.2 0.1012 2 180 4770 1140 30 0.2 0.1214 2 180 4090 1150 35 0.2 0.1416 2 180 3580 1150 45 0.25 0.1620 2 180 2860 1140 55 0.25 0.20 (Vfp) , Z=2 40% - 80% - .The plunging feed (Vfp) of an end mill Z = 2 (drilling) must be reduced by 40 to 80 % depending on the material tobe machined.apDIXI 7593 Z = 3-4 Alluminium ( Vc 400 - 600 /. )- . . . D 1 Z Vc n Vf ap ae fz/.] [. -1] [/.] [] [] []6 3 400 21220 570 3 6 0.0098 3 400 15920 570 4 8 0.01210 3 400 12730 760 5 10 0.0212 3 400 10610 760 6 12 0.02416 3 400 7960 760 8 16 0.03218 3 400 7070 760 9 18 0.03620 4 400 6370 1020 10 20 0.04199

DIXI 7543Ø < 1 mmØ > 1 mm CUTTING CONDITIONSapapaeaeXIDURap ae ap aeMaterials to be machined Vc [m/min] [mm] [mm] [mm] [mm]PPPPMKKKSS / < 600 2Unalloyed steel / Low alloyed steel / 600 – 1500 2Unalloyed steel / Low alloyed steelLead alloyed cutting steel700 – 1500 2High alloyed steel400 – 700 2Stainless steel / < 250 HBGrey cast iron / Nodular iron pearlitic / > 250 HBAlloyed cast iron / Nodular iron pearlitic / Nodular iron pearlitic / Malleable cast iron / Special alloys / Heat resisting stainless steel / Titanium / Titanium alloyInconelNimonicHastelloy90 110 < 0.5 x ØD1 1 x ØD1 < 1.0 x ØD1 1 x ØD10.002 - 0.01 0.00370 90 < 0.3 x ØD1 1 x ØD1 < 0.6 x ØD1 1 x ØD190 110 < 0.5 x ØD1 1 x ØD1 < 1.0 x ØD1 1 x ØD140 55 < 0.15 x ØD1 1 x ØD1 < 0.3 x ØD1 1 x ØD170 90 < 0.5 x ØD1 1 x ØD1 < 0.8 x ØD1 1 x ØD190 110 < 0.3 x ØD1 1 x ØD1 < 0.7 x ØD1 1 x ØD170 90 < 0.2 x ØD1 1 x ØD1 < 0.4 x ØD1 1 x ØD190 110 < 0.2 x ØD1 1 x ØD1 < 0.4 x ØD1 1 x ØD125 35 < 0.3 x ØD1 1 x ØD140 60 < 0.2 x ØD1 1 x ØD1 < 0.3 x ØD1 1 x ØD1 HSC conditionsapaeDIXI 7543 XIDUR Z = 3 . AISI 316L. 904L .(Vc) 200-250 /.Stainless steel- . . . D 1 Z Vc n Vf ap ae fz/.] [. -1] [/.] [] [] []1 3 200 64000 480 0.15 1.00 0.0042 3 200 31830 760 0.30 2.00 0.0083 3 200 21220 1150 0.75 3.00 0.0184 3 200 15920 1150 1.00 4.00 0.0245 3 200 12730 1150 1.25 5.00 0.0306 3 200 10610 1150 1.50 6.00 0.0368 3 200 7960 1340 2.00 8.00 0.05610 3 200 6370 1340 2.50 10.00 0.07012 3 200 5310 1340 3.00 12.00 0.084200

Vc [/.] x 1000 DIXI 7543 Z = 3n [/.] = xD 1 [] Vf [/.] = n [/.] x [] x Feed per toothfz []Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 1 Ø D 13 - 0.01 0.006 - 0.02 0.010 - 0.020.014 - 0.040.02 - 0.050.002 - 0.01 0.002 - 0.01 0.005 - 0.01 0.008 - 0.02 0.011 - 0.03 0.02 - 0.040.003 - 0.01 0.004 - 0.01 0.008 - 0.03 0.013 - 0.04 0.018 - 0.05 0.03 - 0.070.002 - 0.01 0.002 - 0.01 0.005 - 0.01 0.008 - 0.02 0.011 - 0.03 0.02 - 0.040.002 - 0.01 0.002 - 0.01 0.005 - 0.01 0.008 -0.02 0.011 - 0.03 0.02 - 0.040.002 - 0.01 0.003 - 0.01 0.006 - 0.02 0.010 - 0.02 0.014 - 0.04 0.02 - 0.050.002 - 0.01 0.002 - 0.01 0.005 - 0.01 0.008 - 0.02 0.011 - 0.03 0.02 - 0.040.002 - 0.01 0.003 - 0.01 0.006 - 0.02 0.010 - 0.02 0.014 - 0.04 0.02 - 0.050.002 - 0.01 0.002 - 0.01 0.005 - 0.01 0.008 - 0.02 0.011 - 0.03 0.02 - 0.040.002 - 0.01 0.002 - 0.01 0.005 - 0.01 0.008 - 0.02 0.011 - 0.03 0.02 - 0.04 apHSC conditionsae.DIXI 7543 XIDUR Z = 3 AISI 316L. 904L .(Vc 250-300 /.)- . . . D 1 Z Vc n Vf ap ae fz/.] [. -1] [/.] [] [] []1 3 250 80000 480 0.60 0.15 0.0042 3 250 39790 950 1.20 0.30 0.0083 3 250 26530 1430 1.80 0.45 0.0184 3 250 19890 1430 2.40 0.60 0.0245 3 250 15920 1430 3.00 0.75 0.0306 3 250 13260 1430 3.60 0.90 0.0368 3 250 9950 1670 4.80 1.20 0.05610 3 250 7960 1670 6.00 1.50 0.07012 3 250 6630 1670 7.20 1.80 0.084201

DIXI 7532 apCUTTING CONDITIONSae DIXI 7532 XIDUR Z = 230-45 .Vc 400-500 /.Tool steel and cast ironHRC . . . D Vc n Vf ap ae Deff. fz/.] [. -1] [/.] [] [] [] []1 90000 1800 0.02 0.05 0.28 0.011.5 400 84890 3400 0.04 0.06 0.48 0.022 400 63660 3820 0.05 0.09 0.62 0.033 400 42440 3400 0.07 0.13 1.08 0.044 400 31830 3180 0.09 0.15 1.20 0.055 400 25470 3570 0.15 0.25 1.71 0.076 400 21220 3400 0.20 0.30 2.15 0.088 400 15920 3180 0.25 0.35 2.78 0.1010 400 12730 3820 0.30 0.50 3.41 0.1512 400 10610 4240 0.40 0.60 4.31 0.20 DIXI 7532 XIDUR Z = 2 Tool steel and cast iron 45 - 55 .Vc 250-350 /. . . . D Vc n Vf ap ae Deff. fz/.] [. -1] [/.] [] [] [] []1 250 79580 1110 0.02 0.05 0.28 0.0071.5 250 53050 2120 0.03 0.07 0.42 0.022 250 39790 2390 0.04 0.09 0.56 0.033 250 26530 2120 0.05 0.11 0.77 0.044 250 19890 1990 0.07 0.15 1.04 0.055 250 15920 1910 0.12 0.20 1.53 0.066 250 13260 1860 0.15 0.25 1.87 0.078 250 9950 1790 0.20 0.30 2.50 0.0910 250 7960 1750 0.25 0.40 3.12 0.1112 250 6630 1720 0.30 0.50 3.75 0.13DIXI 7532 XIDUR Z = 2 55 - 65 . Vc 100-200 /.Tool steel and cast ironHRC . . . D Vc n Vf ap ae Deff. fz/.] [. -1] [/.] [] [] [] []1 130 41380 330 0.02 0.04 0.28 0.0041.5 130 27590 390 0.03 0.05 0.42 0.0072 130 20690 410 0.04 0.06 0.56 0.0103 130 13790 410 0.05 0.07 0.77 0.0154 130 10350 520 0.06 0.10 0.97 0.0255 130 8280 500 0.08 0.16 1.25 0.0306 130 6900 550 0.10 0.18 1.54 0.0408 130 5170 520 0.15 0.20 2.17 0.05010 130 4140 500 0.18 0.22 2.65 0.06012 130 3450 550 0.20 0.25 3.07 0.080 + Luft + Öl empfohlen Air + oil recommended (n) (Vf) . - (.) , -. , Vf () . ().The indicated n and Vf values should be considered as starting points. Depending on the quality of shape to machine (precisionand surface finish) these values can be increased or reduced.If the spindle does not allow the recommended rpm, Vf must be reduced proportionnally.Down milling is recommended when possible.202

DIXI 7542ap CUTTING CONDITIONSaeDIXI 7542 XIDUR Z = 230-45 . Vc 400-500 /.Tool steel and cast ironHRC . . . D Vc n Vf ap ae Deff. fz/.] [. -1] [/.] [] [] [] []1 90000 1800 0.02 0.05 0.28 0.011.5 320 67910 2720 0.04 0.06 0.48 0.022 320 50930 3060 0.05 0.09 0.62 0.033 320 33950 2720 0.07 0.13 1.08 0.044 320 25470 2550 0.09 0.15 1.20 0.055 320 20370 2850 0.15 0.25 1.71 0.076 320 16980 2720 0.20 0.30 2.15 0.088 320 12730 2550 0.25 0.35 2.78 0.1010 320 10190 3060 0.30 0.50 3.41 0.1512 320 8490 3400 0.40 0.60 4.31 0.20 DIXI 7542 XIDUR Z = 245 - 55 .Vc 250-350 /.Tool steel and cast ironHRC . . . D Vc n Vf ap ae Deff. fz/.] [. -1] [/.] [] [] [] []1 200 63660 890 0.02 0.05 0.28 0.0071.5 200 42440 1700 0.03 0.07 0.42 0.0202 200 31830 1910 0.04 0.09 0.56 0.0303 200 21220 1700 0.05 0.11 0.77 0.0404 200 15920 1590 0.07 0.15 1.04 0.0505 200 12730 1530 0.12 0.20 1.53 0.0606 200 10610 1490 0.15 0.25 1.87 0.0708 200 7960 1430 0.20 0.30 2.50 0.09010 200 6370 1400 0.25 0.40 3.12 0.11012 200 5310 1380 0.30 0.50 3.75 0.130 DIXI 7542 XIDUR Z = 255 - 65 . Vc 100-200 /.Tool steel and cast ironHRC . . . D Vc n Vf ap ae Deff. fz/.] [. -1] [/.] [] [] [] []1 100 31830 250 0.02 0.04 0.28 0.0041.5 100 21220 300 0.03 0.05 0.42 0.0072 100 15920 320 0.04 0.06 0.56 0.0103 100 10610 320 0.05 0.07 0.77 0.0154 100 7960 400 0.06 0.10 0.97 0.0255 100 6370 380 0.08 0.16 1.25 0.0306 100 5310 420 0.10 0.18 1.54 0.0408 100 3980 400 0.15 0.20 2.17 0.05010 100 3180 380 0.18 0.22 2.65 0.06012 100 2650 420 0.20 0.25 3.07 0.080 + Luft + Öl empfohlen Air + oil recommended (n) (Vf) . - (.) , -. , Vf () . ().The indicated n and Vf values should be considered as starting points. Depending on the quality of shape to machine (precisionand surface finish) these values can be increased or reduced.If the spindle does not allow the recommended rpm, Vf must be reduced proportionnally.Down milling is recommended when possible.203