Table of Contents - TG Drives

Table of Contents - TG Drives

Table of Contents - TG Drives

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

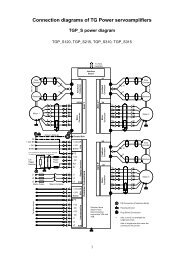

SOFTWARE SYSTEM<br />

Function<br />

block<br />

Digital<br />

inputs<br />

Digital<br />

outputs<br />

Pr<strong>of</strong>ile<br />

generator<br />

Register<br />

set<br />

Input/<br />

Trigger<br />

In Physical<br />

input<br />

Out PL2<br />

statement<br />

Pg PL2<br />

statement<br />

Regulator Reg Speed and<br />

position set<br />

points and<br />

resolver<br />

input<br />

Motor<br />

control<br />

System<br />

inputs<br />

System<br />

outputs<br />

Analog<br />

inputs<br />

Analog<br />

outputs<br />

Resolver RD1,<br />

RD2<br />

Motor Register<br />

values<br />

SysIo Alarm and<br />

safety<br />

SysIo PL2<br />

statement<br />

Ana Analog<br />

signals<br />

Ana PL2<br />

statement<br />

Physical<br />

resolver<br />

input<br />

Gear box Gear Auxiliary<br />

resolver<br />

Output/<br />

Affecting<br />

PL2 code<br />

execution<br />

flow.<br />

Physical<br />

outputs.<br />

Speed and<br />

position set<br />

commands.<br />

Current set<br />

point,<br />

(momentary<br />

demanded<br />

torque).<br />

Motor drive<br />

adaptation.<br />

PL2 code<br />

execution.<br />

HW<br />

affected in<br />

the unit<br />

PL2<br />

accessible<br />

values<br />

Value on<br />

analog<br />

output pins<br />

Velocity and<br />

position <strong>of</strong><br />

motor or<br />

auxiliary<br />

resolver<br />

Set<br />

position<br />

Pdata acc None Timer ticks Set<br />

acceleration<br />

Function Block Diagram<br />

Description<br />

Input handling to the DMC 2 .<br />

Digital output handling from<br />

the DMC 2 unit.<br />

Calculates the momentary<br />

desired values <strong>of</strong> speed and<br />

position.<br />

Controls the motor speed and<br />

position according to the<br />

momentary set points and the<br />

measured speed and<br />

position. Compensates for any<br />

speed or position error.<br />

Adapts the motor drive to the<br />

electrical characteristics <strong>of</strong> the<br />

motor.<br />

Allows the PL2 code to detect<br />

and respond to alarm and<br />

safety signals generated in<br />

hardware protection systems.<br />

Allows certain hardware<br />

functions (i.e. enabling the<br />

power stage or activating<br />

brake relay or LEDs) to be<br />

controlled by the PL2 code.<br />

Allows the PL2 code to<br />

monitor analog signals either<br />

by direct reading or by<br />

”connecting” it to an internal<br />

variable.<br />

Allows the PL2 code to set<br />

analog outputs to specific<br />

values or ”connect” it to an<br />

internal variable.<br />

Allows the FW system and the<br />

PL2 code to access<br />

position and velocity, not only<br />

<strong>of</strong> the controlled motor but<br />

also <strong>of</strong> one auxiliary resolver.<br />

Allows the motor set position<br />

to be controlled by the<br />

auxiliary resolver speed and<br />

position, in such a way that an<br />

electronic gearing is achieved.<br />

Pdata acc is a data array that<br />

allows the PL2 programmer to<br />

User's Manual 5.1 Inmotion Technologies AB<br />

Doc. No.9032 0027 01 (B), Rev. 11.07.2001<br />

19