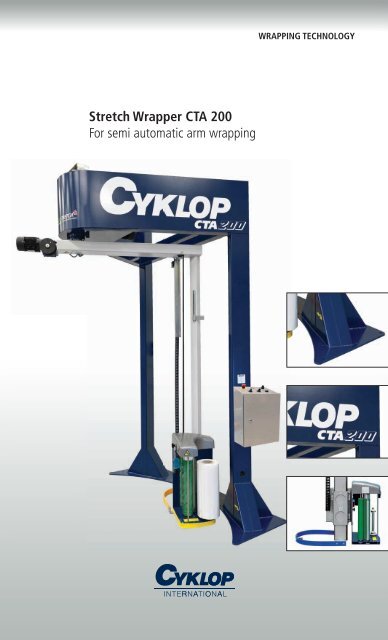

Stretch Wrapper CTA 200 For semi automatic arm wrapping

Stretch Wrapper CTA 200 For semi automatic arm wrapping

Stretch Wrapper CTA 200 For semi automatic arm wrapping

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Stretch</strong> <strong>Wrapper</strong> <strong>CTA</strong> <strong>200</strong><strong>For</strong> <strong>semi</strong> <strong>automatic</strong> <strong>arm</strong> <strong>wrapping</strong>WRAPPING TECHNOLOGY

<strong>Stretch</strong> <strong>Wrapper</strong> <strong>CTA</strong> <strong>200</strong>Overview and dimensionsQuiet operationExtremely rigid chassisAir supply not neededDBCADim (mm) A B C DStandard 3573 Ø2800 2397 2459Weight, standard: 690 kg (Weight can vary depending on options).

<strong>Stretch</strong> <strong>Wrapper</strong> <strong>CTA</strong> <strong>200</strong>SpecificationMachine Rotation speed max 10,5 r/minPowerSupply3 x 400 V + N + PE, 50 HzProtectionIP51Pallet Goods<strong>Stretch</strong> FilmMax size (length x width)Highest goods height incl palletCore diameterOuter diameter, maxFilm width, maxFilm thicknessFloor mounting Min. concrete thickness 150 mm1<strong>200</strong> x 1<strong>200</strong> mm2400 mm (standard machine)76 mm250 mm500 mm15-35 my<strong>Stretch</strong> <strong>wrapping</strong> programs5 standard, 1 for manual operationBottom/top <strong>wrapping</strong>s Prog 1 2 bottom 1 top Stops in topProg 2 3 bottom 2 top Stops in topProg 3 2 bottom 1 top Up/downProg 4 3 bottom 2 top Up/downProg 5 4 bottom 3 top Up/downProg 6Manual settingFilm carriage speedVariable film overlapping top and bottomPre stretch / Film tensionAdjustable, friction brakeControllerSiemens PLCCE-mark (EN 60204)<strong>Stretch</strong> <strong>Wrapper</strong> <strong>CTA</strong> <strong>200</strong>Options Galvanized chassi Extended chassi - height, length or both.

<strong>Stretch</strong> <strong>Wrapper</strong> <strong>CTA</strong> <strong>200</strong>Cyklop´s <strong>CTA</strong> <strong>200</strong> rotary <strong>arm</strong> machine is a floor mounted stretch wrapper. <strong>For</strong> low volume users in lines of businesses.Wraps irregular shaped loads. Uses pallet truck to load stretch wrapper. Operator starts wrap cycle at machine andmanually cuts/attach the film.Levels of automation based on long experience, extension possibilities and a large number of settings give this newseries of stretch wrappers a high profitability through optimal adaptation to every need. These properties guarantee agood protection and transport packaging as well as the lowest possible material cost.Easy to operate Controls are easy to find andunderstand. Film roll change fast and simple. Automatic load height sensor. No air supply needed.Saves money The chosen prestretch ratio staysconstant, which guarantees aconsistent low film, consumption,load after load. Film carriage speed is individuallyadjustable to minimize film overlap.Consistent packaging result Flexible setting possibilitiesenable optimum packaging for avariety of goods. 5 programs are factory presetwith one additional for manualoperation.Key features: Floor mounted model Easy change of all programparameters and settings. The <strong>CTA</strong> <strong>200</strong> allowing bothlow pre-stretched filmsand pre-stretched film rollsto be used. Quiet operation Extremely rigid chassis Unlimited load weight capacityThis folder may not be copied or the content in any way be changed. All rights reserved. © Copyright by Cyklop Teknik – Burseryd 2011 - PBE - <strong>CTA</strong> <strong>200</strong>

![[1.4 CONTROL MOTOR] (drC-)](https://img.yumpu.com/50024176/1/184x260/14-control-motor-drc.jpg?quality=85)

![[1.5 in-/utgångskonfig.] (io-)](https://img.yumpu.com/32675802/1/184x260/15-in-utgaangskonfig-io.jpg?quality=85)