New Autoform Bladders – AP 2, AP 4 & AP 6

New Autoform Bladders – AP 2, AP 4 & AP 6

New Autoform Bladders – AP 2, AP 4 & AP 6

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>New</strong> <strong>Autoform</strong> <strong>Bladders</strong> <strong>–</strong> <strong>AP</strong> 2, <strong>AP</strong> 4 & <strong>AP</strong> 6<br />

In the past, Continental was using many<br />

different <strong>Autoform</strong> bladders for a wide range<br />

tire sizes. The most recent <strong>AP</strong> 2, <strong>AP</strong> 4 and<br />

<strong>AP</strong> 6 range of <strong>Autoform</strong> bladders is designed<br />

using the latest Continental mold design<br />

guidelines. It also allows you to produce<br />

a wider range of tires with a single bladder<br />

size.<br />

As noted in the chart on next page, these<br />

bladders can be ordered with the industry<br />

standard 112 mm cone diameter or the 63 mm<br />

cone diameter, as well as for the „Kobe“<br />

system of clamping.<br />

Our new <strong>AP</strong> 4 and <strong>AP</strong> 6 line of bladders are<br />

also available to fit press mechanisms with<br />

273 mm or 329 mm clamping diameters.<br />

Continental-standard-cone<br />

The bladder contour is designed to fit the<br />

green tire contour. The groove design and<br />

advanced pebble surface structure are<br />

developed to optimize venting, thus helping to<br />

avoid trapped air between bladder and inside<br />

of the tire. The design also helps to<br />

significantly improve visual recognition of<br />

“tire findings” on the inside. The advanced<br />

pebble surface also helps to minimize<br />

consumption of innerliner compound.<br />

Kobe-system-cone<br />

Industry-standard-cone

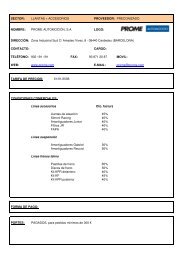

Specifications for <strong>AP</strong> 2, <strong>AP</strong> 4 and <strong>AP</strong> 6 <strong>Autoform</strong> <strong>Bladders</strong><br />

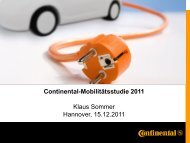

Simulated shaping process<br />

0 kPa <strong>–</strong> before<br />

shaping<br />

EUROPE<br />

Sales Office Hannover (Germany)<br />

Phone: +49 511 976 33 66<br />

Fax: +49 511 976 36 54<br />

Email: torsten.rupp@conti.de<br />

NORTH & SOUTH AMERICA<br />

Sales Office Ft. Mill, SC (USA)<br />

Phone: +1 704 583 8772<br />

Fax: +1 704 583 8738<br />

Email rick.scott@conti-na.com<br />

60 kPa <strong>–</strong> shaping<br />

pressure<br />

ASIA PACIFIC<br />

Sales Office Petaling Jaya (Malaysia)<br />

Phone: +603 7787 88 34<br />

Fax: +603 7781 97 66<br />

Email: angel.tan@conti-sime.com