Circular Flap Gate Specs.pdf - Plasti-Fab, Inc.

Circular Flap Gate Specs.pdf - Plasti-Fab, Inc.

Circular Flap Gate Specs.pdf - Plasti-Fab, Inc.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

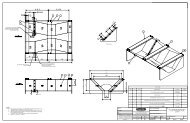

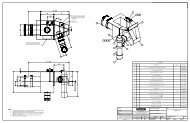

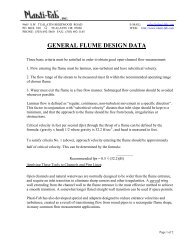

SECTION ____________CIRCULAR FLAP GATES UP TO 48” (1219MM)PART 1GENERAL1.01 SUMMARYA. This Section includes all <strong>Flap</strong> <strong>Gate</strong>s required for the complete installation ofthe work.1.02 REFERENCESA. Design, fabricate and test valves and materials in accordance withmanufacturers' recommended procedures and the following codes andstandards:1. ASTM A193 - Stainless Steel Anchor Bolts2. ASTM A276 - Stainless Steel Bars3. ASTM B584 - Alloy 865 Manganese Bronze4. ASTM D256 - Izod Impact Strength5. ASTM D570 - Water Absorption Rate6. ASTM D638 - Tensile Strength7. ASTM D695 - Compressive Properties of Rigid <strong>Plasti</strong>c8. ASTM D696 - Coefficient of Linear Expansion9. ASTM D790 - Flexural Properties10. ASTM D792 - Density and Specific Gravity at 23 0 C11. ASTM D1056 - Polymer Grade12. ASTM D2583 - Indentation Hardness13. ASTM D2563-0 - Visual Defects14. ASTM D2584 - Resin, Glass & Filler Content15. AWWA C-563 - Leakage Rate16. NSF-61 - Potable WaterB. Composition of the flap gate laminate shall be in accordance with therecommendations shown in the Quality Assurance Report for ReinforcedThermoset <strong>Plasti</strong>c (RTP) Corrosion Resistant Equipment prepared underthe sponsorship of the Society of the <strong>Plasti</strong>cs Industry, <strong>Inc</strong>. (SPI), and theMaterial Technology Institute (MTI) of the Chemical Process Industry for“Hand Lay-UP Laminates,” and shall meet the specifications for Type I,Grade 10 laminates shown in Appendix M-1 of said report.C. Manufacturers shall be experienced in the design and manufacture ofspecific flap gates and accessories for a minimum period of 20 years.1.03 SUBMITTALSA. Submit the following for acceptance:1. Approval Drawings1

a. Showing all critical dimensionsb. Showing principal parts and materials2. Spare parts list, when applicable1.04 DELIVERY, STORAGE AND HANDLINGA. Ship all valves with suitable packaging to protect products from damage.B. Protect valve threads, flanges, stems and operators from damage.PART 2PRODUCTS2.01 MATERIALSA. <strong>Gate</strong> Body shall be:1. Engineered composite FRP materialB. <strong>Flap</strong> shall be:1. A Neoprene lip seal shall be integral to the flap2. <strong>Flap</strong> material shall be one piece hinge/seal assembly of moldedNeoprene rubber. The neoprene flap shall have a steel platevulcanized into it and a raised rounded 1/8” (3mm) wide seatingsurface.C. Hinge shall be:1. Hinge material shall be one piece hinge/seal assembly of molded(Neoprene / EPDM) rubber.D. Anchor Bolts1. Shall be type (T-304L / T316L / Super Duplex) Stainless Steel.2.02 FLAP GATESA. Acceptable Manufacturers:1. <strong>Plasti</strong>-<strong>Fab</strong> <strong>Inc</strong>2. Shall be Model No. FG______ (diameter, or WxL)B. Or approved equal. Pre-approved by Engineer at least 10 business daysprior to bid date.C. Manufacturer must have a qualified Engineer on staff with at least 10 yearsof experience with <strong>Flap</strong> <strong>Gate</strong>s.2.03 DESIGN CRITERIAA. Composition of the laminate shall be in accordance with therecommendations shown in the Quality Assurance Report for ReinforcedThermostat <strong>Plasti</strong>c (RTP) Corrosion Resistance Equipment preparedunder the sponsorship of the Society of the <strong>Plasti</strong>cs Industry, <strong>Inc</strong>. (SF1),and the Material Technology Institute (MTI) of the Chemical ProcessIndustry for “Hand Lay-up Laminates”, and shall meet the specificationsfor Type I, Grade 10 Laminates shown in Appendix. M-1 of said report.DEFECTSCracksCrazingBlistersChipsPitsDry SpotsFish EyesBurned AreasEntrapped AirWrinkles and solid blisters, not toexceed 1/8”Surface porosity (pinholes orALLOWABLE TOLERANCENoneMaximum Deviation: 10% ofthicknessNone2

pores in the laminate surface)Exposed GlassExposure of cut edgesScratchesForeign MatterNoneNone more than .002” deep(.05mm)NoneB. Maximum Fiber Stress1. Ultimate or yield, whichever applies, does not exceed 2.5 times theworking stress.C. Deflection1. Deflection across the gate width shall be limited to: L/360 or ¼”(6mm), whichever is less, at the maximum operating head.D. Head Pressure1. <strong>Gate</strong> shall be designed for a maximum head pressure of: _________E. <strong>Gate</strong> Size1. <strong>Gate</strong> diameter: ____________, or ___________ W x ___________L2.04 CONSTRUCTIONA. Body1. Each gate shall be molded individually to the exact dimensionsspecified2. <strong>Flap</strong> gate bodies shall be manufactured of gray fiberglass reinforcedpolyester (FRP) containing ultraviolet absorbers.3. The surfaces shall be resin rich to a depth of 0.010-0.020 inches (0.3-.05mm) and reinforced with C-glass or polymeric fiber surfacingmaterial.4. The surface shall be free of exposed reinforcing fibers5. The composition of these layers shall be approximately 95% (byweight) resin.6. The remaining laminate shall be made up of resin and reinforcingfibers in a form, orientation, and position in the laminate to meetthe mechanical requirementsB. Body Flange1. Body flange shall be drilled for mounting directly to a (flat wall surface/ flat face flange with 125lb bolting pattern) using ½” (13mm)diameter (T-304L / T316L / Super Duplex) stainless steel mountingboltsC. <strong>Flap</strong>/Seal/Hinge1. Elastomeric flap/seal/hinge shall be made of molded or extruded(Neoprene / EPDM) having a hardness range of 45 - 65 shore Adurometer and conforming to ASTM Specification D-2000, havinga maximum compression set of 25%, and low temperaturebrittleness to meet suffix F-17 (- 40°).2.05 PHYSICAL PROPERTIESA. Structural characteristics for a 1/8" (3mm) glass mat laminate shall meet thefollowing minimum physical properties.Tensile strengthFlexural ModulusFlexural StrengthCompressive StrengthImpact StrengthWater absorption15,000 psi (1034 ksc)1,000,000 psi (70307 ksc)20,000 psi (1406 ksc)22,000 psi (1547 ksc)9.0 ft-lbs/in.(1.24 kgf.m/25mm)0.13% (in 24 hours)3

B. <strong>Flap</strong>/seal/hinge: Extruded Virgin Neoprene / EPDM shall have the followingphysical characteristics.Specific Gravity 1.25Hardness55 - 65 Shore A DurometerTensile Strength1500 psi min. (0.07 ksc)Elongation 300%Low temperature brittleness - 40PART 3EXECUTION3.01 INSTALLATIONA. Thoroughly clean and remove all shipping materials prior to setting.B. Install <strong>Gate</strong>s per Manufacturer’s recommendations.3.02 FIELD TESTING (OPTIONAL)A. Qualified Factory representative shall provide ___ hours of training for facilityemployeesB. Representative shall complete a Certification of Proper Installation andprovide copies to the Owner, Engineer, and Contractor.END OF SECTION4