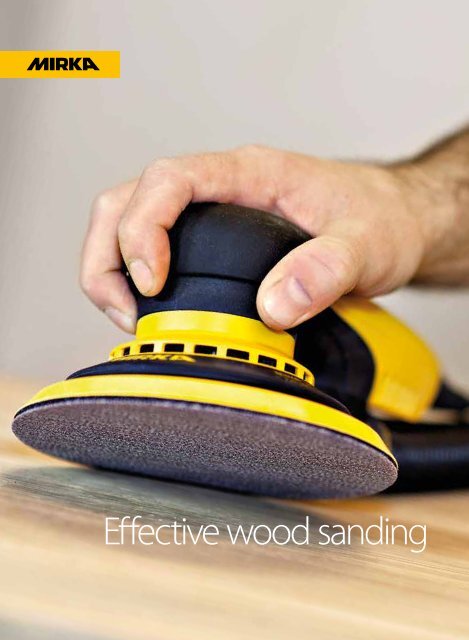

Effective wood sanding - Mirka

Effective wood sanding - Mirka

Effective wood sanding - Mirka

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Effective</strong> <strong>wood</strong> <strong>sanding</strong>

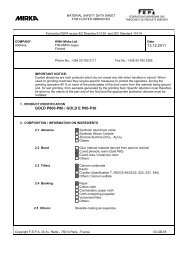

ContentsKWH <strong>Mirka</strong> Ltd is part of the KWH Group and the biggest manufacturerof coated abrasives in Scandinavia. Through its innovative research anddevelopment program, <strong>Mirka</strong> has become a specialist in flexible abrasives, aswell as revolutionary, patented abrasives which allow customers to enjoy atruly dust-free surface finishing process.<strong>Mirka</strong> has invested heavily in product development and the companyhas expanded from a leading abrasive producer into a developer andmanufacturer of complete <strong>sanding</strong> systems.These innovations are further backed by the creation of ground-breakingnew coatings production processes. The wide range includes advancedproducts designed to efficiently tackle specialised applications for bothprofessionals and DIY, as well as products that have been specially developedfor the most demanding operations.<strong>Mirka</strong>’s Power Tools unit develops and manufactures advanced <strong>sanding</strong>and polishing machines providing outstanding benefits to users. Theseinnovatively designed tools combined with a range of effective, high qualityaccessories, give <strong>Mirka</strong>’s customers unmatched access to a complete <strong>sanding</strong>solution to meet their individual needs.<strong>Mirka</strong> is a globally expanding company with subsidiaries located in Europe,North and South America and Asia. Head quarters and production are locatedin Finland. More than 90% of our products are exported and sold in more than80 countries.<strong>Mirka</strong> is the first company in its sector to obtain the three mostimportant quality standards. The production process guaranteesreliable quality by following the ISO 9001 quality assurancesystem. The OHSAS 18001 occupational health and safetymanagement system ensures a high level of work safety.The ISO 14001 environmental management system provesthat we consider the environment in all our activities.Products for <strong>wood</strong> <strong>sanding</strong>Machine and hand <strong>sanding</strong> 6Belt <strong>sanding</strong> 24Narrow belt <strong>sanding</strong> 30Guide for effective <strong>wood</strong> <strong>sanding</strong><strong>Effective</strong> <strong>wood</strong> <strong>sanding</strong> 34Sanding material construction 35Backing material 35Make coat and size coat 38Grains and coatings 39Additional treatments 43Fastening systems 45Sanding with portable machines and hand tools 46User recommendations 46Net <strong>sanding</strong> 48<strong>Mirka</strong> <strong>sanding</strong> and polishing tools 50Polishing compounds 55Belt <strong>sanding</strong> 56Optimising belt lifespan 56Grit size and sequence 57Stock removal per unit 58Belt <strong>sanding</strong> speed 59Belt joints 60Problem solving 62Wide belt storage 66© 2013 KWH <strong>Mirka</strong> Ltd. All rights reserved.2 3

Products for<strong>wood</strong> <strong>sanding</strong>_06Machine and hand <strong>sanding</strong>Abranet®Abranet® HDAbralon®Q.Silver®Polarstar®Microstar®Mirlon®Mirlon Total®Coarse CutUltimax®GoldGold Soft GripGoldflex-SoftSoft <strong>sanding</strong> padHand padsCaratflexWPFP16P24P36P40P50P60Symbols_24Belt <strong>sanding</strong>Ultimax®Unimax®Avomax PlusSica OpenJepuflex PlusSica ClosedSica FineSica Fine StearateSica CoarseCalitexStalitP80P100P120DiscSheetRoll_30Narrow belt <strong>sanding</strong>Microstar®Hiolit XHiolit JHiolit FOraflexP150Abranet®Abranet®Abranet®P180P220Wide beltNarrow beltPad4 5

PRODUCTS FOR OTHER MACHINE AND SANDING HAND SANDING PRODUCTSPRODUCTS FOR MACHINE AND HAND SANDINGAbranet ®Abranet ® HDABRANET AND ABRANET HDThe range of innovative abrasivesthat use <strong>Mirka</strong>’s revolutionaryand patented ‘Net Sanding’construction is continuouslybeing expanded as new productsand accessories are added toprovide effective solutions tochanging market needs.BENEFITS: Abranet combines highperformance and a longer lifespan thantraditional abrasives, making it a costeffective solution in a vast range ofapplications. It is user-friendly whetherbeing used by machine or by hand andits true dust-free <strong>sanding</strong> characteristicsresult in a cleaner work environment,as well as a better surface finish.Technical specificationsGrain Aluminium oxideBonding Resin over resinBacking Polyamide fabricCoating ClosedColour BrownishGrit range P80–P180, P240, P320–P1000BENEFITS: Abranet HD was specificallydeveloped to achieve outstanding resultson the most challenging applications.It delivers optimum performance andsuperior stock removal, while its strongconstruction gives it exceptional resistanceto edge wear that allows it to retain its high<strong>sanding</strong> efficiency for far longer, especiallyin demanding situations.Technical specificationsGrain Special aluminium oxide grainBonding Resin over resinBacking Nylon meshCoating Semi-openColour BrownishGrit range P40, P60, P80, P120–P180application: Sanding of both soft andhard <strong>wood</strong>, intermediate <strong>sanding</strong> of paintand lacquer, <strong>sanding</strong> of putty and filler.application: General use for high stockremoval with minimal clogging on <strong>wood</strong>and old paint. Abranet HD is the idealchoice where conventional abrasives fail!6 7

PRODUCTS FOR OTHER MACHINE AND SANDING HAND SANDING PRODUCTSPRODUCTS FOR MACHINE AND HAND SANDINGAbralon ®Q. Silver ®BENEFITS: This multifunctional <strong>sanding</strong>material features a unique, three-layerflexible construction that allows it tocreate an ultra-fine surface finish on flatand profiled surfaces. The flexible weaveconstruction also makes it suitable forboth dry and wet <strong>sanding</strong>, either bymachine or by hand.application: Suitable for wet <strong>sanding</strong>of high gloss paints and lacquers priorto polishing.Technical specificationsGrainBondingBackingCoatingColourSilicon carbideSpecial resinKnitted fabric on foamSpecial Abralon® methodGreyGrit range 180, 360, 500, 600,1000, 2000, 3000, 4000BENEFITS: Developed specially totackle the more demanding surfacesin the <strong>wood</strong> industry, Q.Silver featuresextra hardened aluminium oxide grainsto produce excellent cut, especially onharder <strong>wood</strong> types, paints and lacquers.In addition, a stearate coating minimisesdust loading and maximises productlifespan.application: For <strong>sanding</strong> of soft andhard <strong>wood</strong>, fillers, paints and lacquersby machine or by hand.Technical specificationsGrainBondingBackingCoatingColourAluminium oxide P80–P500Silicon carbide 600–1500Resin over resinD-paper P80–P150, C-paperP180–P500, B-paper 600–1500Semi-openBlueishGrit range P80–P320, P400–P500, 600–15008 9

PRODUCTS FOR OTHER MACHINE AND SANDING HAND SANDING PRODUCTSPRODUCTS FOR MACHINE AND HAND SANDINGPolarstar ®Microstar ®BENEFITS: The polyester film backingmaterial gives Polarstar a more flexible andmuch smoother abrasive surface, comparedto conventional paper backed abrasives.This allows it to quickly produce a fine,consistent surface finish and the stearatecoating ensures superb durability due toan excellent resistance to clogging. It is alsomanufactured using an environmentallyfriendly, solvent-free coating.application: Suitable for wet and dry<strong>sanding</strong> , especially <strong>sanding</strong> of harder highgloss paints and lacquers prior to polishing.Technical specificationsGrainBondingBackingCoatingColourGrit rangeAluminium oxide P320–P600Silicon carbide P800–P1500Resin over resinPolyester filmSemi-openGreen / whiteP320–P1500BENEFITS: This new film product is designedfor mattening and paint rectification of topandclear coat applications. Microstar hasa special stearate layer and a smooth filmbacking. This product has a high quality finishand lasts longer as it does not clog as easilyas traditional products. Microstar produces afine scratch pattern that is easy to polish out.application: Suitable for dry <strong>sanding</strong>,especially <strong>sanding</strong> of harder high gloss paintsand lacquers prior to polishing.Technical specificationsGrain Aluminium oxideBonding Low VOC resin systemBacking Polyester filmCoating Semi-openColour WhiteGrit range P800–P150010 11

PRODUCTS FOR OTHER MACHINE AND SANDING HAND SANDING PRODUCTSPRODUCTS FOR MACHINE AND HAND SANDINGMirlon ® Mirlon Total ®BENEFITS: Thanks to its specialstructure, Mirlon is a highly flexible,three-dimensional, non-woven abrasivethat’s easy to use on profiled and flatsurfaces to produce an excellent surfacefinish. In particular, it is ideal for creatingan excellent base for the next lacquer layer.application: Fine <strong>sanding</strong> of <strong>wood</strong>,paint and lacquers by hand or machine.Technical specificationsGrainBondingBackingCoatingColourGrit rangeAluminium oxide (GP, VF)Silicon carbide (UF, MF)ResinNon-wovenThree-dimensionalGreen (GP), red (VF),dark grey (UF), brownish (MF)320 (GP), 360 (VF),1500 (UF), 2000 (MF)BENEFITS: Developed using <strong>Mirka</strong>’sinnovative Total Coating Technology,Mirlon Total has a flexible structure whichmakes it ideal for <strong>sanding</strong> profiles anddifficult to reach areas by hand. Thanksto its open structure and Total CoatingTechnology it rapidly produces a finesurface finish.application: Fine <strong>sanding</strong> of <strong>wood</strong>,paint and lacquers by hand.Technical specificationsGrainBondingBackingCoatingColourGrit rangeAluminium oxide (VF)Silicon carbide (UF, MF)ResinNon-wovenThree-dimensional Total CoatingRed (VF), grey (UF), beige (MF)360 (VF), 1500 (UF), 2500 (MF)12 13

PRODUCTS FOR OTHER MACHINE AND SANDING HAND SANDING PRODUCTSPRODUCTS FOR MACHINE AND HAND SANDINGCoarse CutUltimax ®BENEFITS: A specially reinforced backingmaterial and <strong>Mirka</strong>’s Progressive Bonddust binding technology, make Coarse Cutideal for challenging <strong>sanding</strong> applications.Features include high stock removal,excellent edge wear resistance, superiorgrain adhesion and minimal clogging.application: Coarse <strong>sanding</strong> of bothsoft and hard <strong>wood</strong>.Technical specificationsGrainBondingBackingCoatingColourGrit rangeAluminium oxideResin over resin,Progressive BondSpecial reinforced F-paperSemi-openMaroonP36–P40, P60–P150BENEFITS: Manufactured using <strong>Mirka</strong>’s‘Selective Coating Technology’, Ultimaxfeatures a series of tiny cavities designedinto the abrasive material which efficientlyand effectively prevents clogging. Inaddition, the extra hardened aluminiumabrasive grains ensure a longer lifespanand reduced material usage per job.The result is maximum performanceand efficiency along with minimised cost.Technical specificationsGrainBondingBackingCoatingAluminium oxideResin over resinAntistatic F-paperClosed with Selective CoatingColour BrownGrit range Belts: P80-P180, P240–P320Grip discs: P40, P60–P180, P240, P320application: Recommended forhard<strong>wood</strong> surfaces.14 15

PRODUCTS FOR OTHER MACHINE AND SANDING HAND SANDING PRODUCTSPRODUCTS FOR MACHINE AND HAND SANDINGGoldGolf Soft GripBENEFITS: This durable, all-round <strong>sanding</strong>material is well suited to a wide variety of<strong>sanding</strong> applications in the <strong>wood</strong> process.It features a strong and flexible backingmaterial which makes it ideal for hand andmachine <strong>sanding</strong> and a stearate coatingthat minimises clogging and maximisesits lifespan.application: For <strong>sanding</strong> of soft andhard <strong>wood</strong>, fillers, paints and lacquersby hand or by machine.Technical specificationsGrainBondingBackingCoatingColourGrit rangeAluminium oxideResin over resin,Progressive BondD-weight latex paper P80–P150C-weight latex paper P180–P800Semi-openGoldP80–P800BENEFITS: Gold Soft is a <strong>sanding</strong> disc withoptimal foam thickness. The semi-opengrain coating gives less dust clogging anda better cutting performance. The softbacking gives an excellent paint finish. Asofter disc edge eliminates damages onprofile <strong>sanding</strong>.application: Recommended forintermediate and fine <strong>sanding</strong> of paintand primer.Technical specificationsGrain Aluminium oxideBonding Resin over resinBacking C-paper with PE-foamCoating Semi-openColour GoldGrit range P320, P500, P80016 17

PRODUCTS FOR OTHER MACHINE AND SANDING HAND SANDING PRODUCTSPRODUCTS FOR MACHINE AND HAND SANDINGGoldflex-SoftSoft <strong>sanding</strong> padBENEFITS: With its soft, flexiblecharacteristics, Goldflex-Soft wasdeveloped for hand <strong>sanding</strong> profiledsurfaces and irregular, difficult-to-reachdetails. The special stearate coatingprevents clogging and the foam baseis ‘grip friendly’ and applies pressureevenly to reduce the risk of producing‘finger marks’ on the surface.application: Fine <strong>sanding</strong> of <strong>wood</strong> andintermediate <strong>sanding</strong> of paint and lacquers.Technical specificationsGrain Aluminium oxideBonding Resin over resinBacking A-weight latex paper, PE-foamCoating Semi-openColour GoldGrit range P150–P320, P400–P1000BENEFITS: The Soft Sanding Pad is idealfor <strong>sanding</strong> profiled and flat surfaces byhand. Its soft backing material applieseven pressure which reduces the riskof producing ‘finger marks’ or <strong>sanding</strong>through paint. It is suitable for use inboth wet and dry modes.application: For <strong>sanding</strong> <strong>wood</strong>, fillers,paints and lacquers by hand.Technical specificationsGrit range Medium 60Fine 120Super Fine 220Ultra Fine 400Micro Fine 600115 x 140 mm18 19

PRODUCTS FOR OTHER MACHINE AND SANDING HAND SANDING PRODUCTSPRODUCTS FOR MACHINE AND HAND SANDINGHand padHand padBENEFITS: Designed for <strong>sanding</strong> profiledand contoured surfaces by hand, theSanding Sponge features a soft and flexibleconstruction which makes it ideal for hardto reach areas and edges. It is suitable foruse in both wet and dry modes.Technical specificationsGrit range Coarse / Coarse 36 / 36Medium / Medium 60 / 60Medium / Fine 60 / 100Fine / Fine 100 / 100Super Fine / Super Fine 180 / 180BENEFITS: The four sided Sanding Sponge(it has abrasive material on four sides) hasthe significant advantage of being ableto sand hard to reach inside edges andprofiles, as well as flat surfaces. It is suitablefor use in both wet and dry modes.Technical specificationsGrit range Coarse / Coarse 36 / 36Medium / Medium 60 / 60Medium / Fine 60 / 100Fine / Fine 100 / 100application: For <strong>sanding</strong> of <strong>wood</strong>,fillers, paints and lacquers by hand.application: For <strong>sanding</strong> of <strong>wood</strong>,fillers, paints and lacquers by hand.100 x 70 x 28 mm120 x 98 x 13 mm20 21

PRODUCTS FOR OTHER MACHINE AND SANDING HAND SANDING PRODUCTSPRODUCTS FOR MACHINE AND HAND SANDINGCaratflexWPFBENEFITS: This stearate coated abrasivefor dry <strong>sanding</strong> applications features finestock removal, a uniformed scratch pattern,a long lifespan and extremely good grainadherence. The backing consists of aflexible, impregnated latex paper whichis ideal for profile <strong>sanding</strong>.application: For <strong>sanding</strong> of <strong>wood</strong>,sealers, paint and lacquers by hand.Technical specificationsGrainBondingBackingCoatingColourGrit rangeSilicon carbideResin over resin,Progressive BondB-paper P80–P120A-paper P150–P400Semi-openGreyP80–P320, P400BENEFITS: WPF is ideal for matteningof paints and lacquers prior to the finaltop coat. The product is also well suitedfor fixing defects in lacquers or <strong>sanding</strong>away dirt layers. The use of a <strong>sanding</strong>block is recommended, in order to obtaina smooth surface with a smooth <strong>sanding</strong>pattern.application: For wet <strong>sanding</strong> of paintsand lacquers.Technical specificationsGrainBondingBackingCoatingColourGrit rangeAluminium oxide P80–P360Silicon carbide P400–P2000Resin over resinC-weight paper P80–P120B-weight paper P150–P2000ClosedBlackP80–P200022 23

PRODUCTS FOR BELT SANDINGPRODUCTS FOR BELT SANDINGUltimax ®Avomax PlusBenefits: Manufactured using <strong>Mirka</strong>’s‘Selective Coating Technology’, Ultimaxfeatures a series of tiny cavities designedinto the abrasive material which efficientlyand effectively prevent clogging. Inaddition, the extra hardened aluminiumabrasive grains ensure a longer lifespan andreduced material usage per job. The resultis maximum performance and efficiencyalong with minimised cost.Technical specificationsGrain Aluminium oxideBonding Resin over resinBacking Antistatic F-paperCoating Closed with Selective CoatingColour BrownGrit range P80-P180, P240–P320Benefits: The extra open abrasive coatingand aluminium oxide grains make AvomaxPlus ideally suited for the <strong>sanding</strong> of softand resinous materials. It is a high quality,long lasting and cost effective product thatdelivers excellent performance even whenused on materials that clog easily.Application: For soft and resinous <strong>wood</strong>types such as pine.Technical specificationsGrainBondingBackingCoatingColourGrit rangeAluminium oxideResin over resinT-paper P40, P60, F-PaperP80–P320, antistatic paperOpenMaroonP40, P60–P240, P320Application: Recommended for solid<strong>wood</strong> and demanding applicationsUnimax ®Sica OpenBenefits: A semi-open abrasive coatingmakes Unimax suitable for <strong>sanding</strong> of alltypes of <strong>wood</strong>. The aluminium oxide grainsproduce efficient cutting on both soft andhard <strong>wood</strong>, while the anti-static propertiesmake it dust repellent. This reduces the beltdust load and minimises clogging whichhelps the machine stay cleaner and improveswork safety while increasing belt lifespan.Application: Recommended for bothsoft and hard <strong>wood</strong> types.Technical specificationsGrain Aluminium oxideBonding Resin over resin, antistaticBacking Antistatic F-paperCoating Semi-openColour BlackGrit range P80–P220Benefits: The ideal choice for efficientlycreating a fine surface finish on both softand hard materials. The open coating andsilicon carbide grains used on Sica Openprevent clogging and improve the lifespanof the product. It is also completely anti-staticwhich limits dust loading and reduces dustduring the <strong>sanding</strong> process.Application: Recommended for softand hard <strong>wood</strong>.Technical specificationsGrain Silicon carbideBonding Resin over resin, antistaticBacking Antistatic F-paperCoating OpenColour BlackGrit range P80–P18024 25

PRODUCTS FOR BELT SANDINGPRODUCTS FOR BELT SANDINGJepuflex PlusSica FineBenefits: This high quality, cost effectiveproduct features a closed coating thatensures it delivers aggressive performanceand an efficient cut on hard <strong>wood</strong> types.Application: Recommended for hard<strong>wood</strong> types, such as oak.Technical specificationsGrainBondingBackingCoatingColourSilicon carbide P36Aluminium oxide P40–P400Resin over resinT-paper P36–P60, F-paperP80–P400, antistatic paperClosedMaroonBenefits: Developed for the fine <strong>sanding</strong>of paint and lacquer, Sica Fine features siliconcarbide grains and a semi-open coatingwhich makes it ideal for producing a highqualitysurface finish prior to applying thefinal coat. In addition, its fully anti-staticcharacteristics minimize the dust load.Technical specificationsGrain Silicon carbideBonding Resin over resin, antistaticBacking Antistatic E-paperCoating Semi-openColour BlackGrit range P240–P320, P400–P800Grit rangeP36–320, P400Application: Recommended forintermediate and fine <strong>sanding</strong> of paintand lacquers.Sica ClosedSica Fine StearateBenefits: Silicon carbide grains, incombination with a closed coating, ensurethat Sica Closed performs efficiently onhard materials to create a smooth, finesurface finish. The fully anti-static propertiesminimise dust in the <strong>sanding</strong> process andcontribute to the product’s long lifespan.Application: Recommended for hard<strong>wood</strong> and MDF.Technical specificationsGrain Silicon carbideBonding Resin over resin, antistaticBacking Antistatic F-paperCoating ClosedColour BlackGrit range P80–P220Benefits: Developed for the fine <strong>sanding</strong>of paint and lacquer, Sica Fine Stearate includesa stearate coating which minimises cloggingto prolong its lifespan. In addition, its fully antistaticcharacteristics minimize the dust load,while the silicon carbide grains and semi-opencoating make this product ideal for producinga high-quality surface finish prior to applyingthe final coat.Application: Recommended for intermediateand fine <strong>sanding</strong> of paint and lacquers.Technical specificationsGrainBondingBackingCoatingColourGrit rangeSilicon carbideStearate coated resin over resin,antistaticAntistatic E-paperSemi-openGreyP240–P320, P400–P150026 27

PRODUCTS FOR BELT SANDINGPRODUCTS FOR BELT SANDINGSica CoarseCalitexBenefits: Sica Coarse is ideal for coarse<strong>sanding</strong> and calibration <strong>sanding</strong> of hardmaterials. It features silicon carbide grains,in combination with an open coating,to provide long lasting performance ontough <strong>sanding</strong> applications. In addition, theproduct’s anti-static characteristics minimisedust load and help prevent clogging.Technical specificationsGrain Silicon carbideBonding Resin over resin, antistaticBacking Antistatic F-paperCoating OpenColour BlackGrit range P40–P60Benefits: This is a very strong and durableproduct designed for tough <strong>sanding</strong>applications, particularly calibration <strong>sanding</strong>and other applications where a large amountof material needs to be removed. Thepolyester cloth backing and open coatinghelp it maintain its shape and achievea long lifespan.Technical specificationsGrainBondingBackingCoatingColourGrit rangeSilicon carbide P16–P24Aluminium oxide P36–P80Resin over resinPolyester clothSemi-openMaroonP16–P40, P60, P80Application: Recommended for coarse<strong>sanding</strong> and calibration of hard <strong>wood</strong>and MDF.Application: Recommended for rough<strong>sanding</strong> and calibration of soft <strong>wood</strong> types.StalitBenefits: This is a tough <strong>sanding</strong>material specially developed for demandingapplications. It features high durability,stability and resistance to wear and tearthanks to the strong polyester backing.It is particularly suited to applications suchas calibration <strong>sanding</strong> where the removalof large amounts of material is required.Technical specificationsGrainBondingBackingCoatingColourGrit rangeAluminium oxideP40–P180, P240Resin over resinPolyester clothClosedMaroonP40, P60–P180, P240Application: Recommended for rough<strong>sanding</strong> and calibration of hard <strong>wood</strong> types.28 29

PRODUCTS FOR NARROW BELT SANDINGPRODUCTS FOR NARROW BELT SANDINGMicrostar ®Hiolit XBenefits: This new film product is designedfor mattening and paint rectification of topandclear coat applications. Microstar has aspecial stearate layer and a smooth filmbacking. This product has a high quality finishand lasts longer as it does not clog as easily astraditional products. Microstar produces a finescratch pattern that is easy to polish out.Application: Suitable for dry <strong>sanding</strong> ofhigh gloss paints and lacquers prior topolishing.Technical specificationsGrainBondingBackingCoatingColourGrit rangeAluminium oxideLow VOC resin systemPolyesterfilm with Grip backingPolyesterfilm with Antislip backingSemi-openWhiteP800–P1500Benefits: The stiff cotton-cloth backingensures this is a strong product that is ideallysuited to challenging <strong>sanding</strong> operations.It features excellent edge wear resistance,which extends its lifespan, and aluminiumoxide grains that produce efficient cuttingproperties on various <strong>wood</strong> types.Application: Recommended for softand hard <strong>wood</strong> where product stiffnessis important.Technical specificationsGrain Aluminium oxideBonding Resin over resinBacking X-weight cotton clothCoating ClosedColour MaroonGrit range P36–P180, P240Hiolit JBenefits: Suitable for a variety of <strong>wood</strong><strong>sanding</strong> applications, Hiolit J features a strong,durable backing material that delivers excellentedge wear, as well as flexibility. The aluminiumoxide grains ensure it produces efficient cuttingproperties on various <strong>wood</strong> types.Technical specificationsGrain Aluminium oxideBonding Resin over resinBacking J-weight cotton clothCoating ClosedColour MaroonApplication: Recommended for edgeand profile <strong>sanding</strong> applicationsGrit rangeP60–P240, P320, P40030 31

PRODUCTS FOR NARROW BELT SANDINGHiolit FBenefits: Hiolit F is a flexible and durable<strong>sanding</strong> material that is particularly effectivefor <strong>sanding</strong> profiles and other contouredsurfaces where flexibility is required. It offersefficient cutting properties on a variety of<strong>wood</strong> types and produces a high qualitysurface finish.Application: Recommended for edgeand profile <strong>sanding</strong> applications wherehigh flexibility is requiredTechnical specificationsGrainBondingBackingCoatingColourGrit rangeAluminium oxideResin over resinFlexible F-cotton clothClosedMaroonP80–P320, P400 Hiolit FP180, P240, P320 Hiolit F StearateGuidefor effective<strong>wood</strong> <strong>sanding</strong>OraflexBenefits: Oraflex is an ultra-flexible<strong>sanding</strong> material that is ideally suited toproducing a high quality surface finish onall kinds of profile <strong>sanding</strong> tasks. Its softcotton cloth construction makes it possibleto sand even difficult to reach places.Technical specificationsGrain Aluminium oxideBonding Resin over resinBacking Extra flexible F-clothCoating Semi-openColour MaroonApplication: Recommended for edgeand profile <strong>sanding</strong> applications whereultra high flexibility is required.Grit rangeP80–P180, P240, P32032 33

<strong>Effective</strong> <strong>wood</strong> <strong>sanding</strong>Achieving the desired final result with any surface treatment is affected bya wide variety of factors. For example, the choice of <strong>sanding</strong> material playsa vital part in the overall process.By choosing the correct type of <strong>sanding</strong> material and handling it correctly,you can ensure that you achieve an optimal <strong>sanding</strong> result, as well as the bestpossible lifespan for the <strong>sanding</strong> material itself.The aim of this guide is to outline the construction of various <strong>sanding</strong>materials and to highlight the differences between products in an effort tohelp you achieve the easiest and most effective <strong>sanding</strong> procedure for eachapplication.When <strong>sanding</strong> is performed correctly, it will ensure:• an even, smooth surface finish• an accurate thickness and flatness• minimal problems due to fibre rising• a better result due to less dust on the surface• cost savings, both on <strong>sanding</strong> products, as well as coatings and lacquersSanding materialconstruction1. Backing2. Make coat3. Grains4. Size coat5. Supersize6. Fastening system1Backing material23 41. Backing 2. Make coat 3. Grains 4. Size coat 5. Supersize 6. Fastening systemThe backing material not only carries the abrasive layers, it must also transferthe <strong>sanding</strong> power through to the surface. This means that larger abrasivegrains demand more power and, therefore, also need a stronger backingmaterial. For example, a backing material made of cloth-woven thread is oftenstronger and more stable than a backing material made of paper. Cloth can beeither rigid or flexible depending on the construction and, nowadays, thereare also strong paper backings specially developed for challenging <strong>sanding</strong>applications.563435

Cloth backingsType Weight Application Example productF (JJ) Flexible cotton cloth Profile <strong>sanding</strong> Hiolit F/OraflexJ Soft cotton cloth Edge <strong>sanding</strong> Hiolit JX Stiff cotton cloth Coarse <strong>sanding</strong> Hiolit XPES Polyester cloth Extra coarse <strong>sanding</strong> Stalit, CalitexWhen <strong>sanding</strong> between coats or around profiles, it is important to usea material that is both light and has a flexible backing. Flexibility enables the<strong>sanding</strong> material to follow edges and profiles, while the light paper providesa smooth surface for the abrasive grains which, in turn, results in a finer surfacefinish. For paper, the weight of the backing material is in direct proportion toits strength and stiffness.Paper backingsType Weight Application Example productA-paper 90 g/m 2 Manual profile <strong>sanding</strong> Gold FlexB-paper 110 g/m 2 Manual or light machine <strong>sanding</strong> Carat Flex P80–120C-paper 125 g/m 2 Machine disc <strong>sanding</strong> Q.Silver® P180–>D-paper 150–180 g/m 2 Coarse disc <strong>sanding</strong> DeflexE-paper 220–250 g/m 2 Intermediate belt <strong>sanding</strong> Sica FineF-paper 270 g/m 2 Belt <strong>sanding</strong>, coarse disc <strong>sanding</strong> Jepuflex Plus P80–P400Avomax Plus P80–P320Ultimax®An anti-static backing paper is used for wide belt <strong>sanding</strong> applications whereit helps to keep the machine and the <strong>sanding</strong> units clean of dust.When a superior surface finish is demanded, film backing can providea good alternative. The advantage of a film backing is the same as for premiumlight paper backings – it provides a very even surface for the abrasive grains.For non-conventional products there are unique backing materials. Forexample, the revolutionary material found on <strong>Mirka</strong>’s family of Net Sandingproducts which enables dust-free <strong>sanding</strong> and features integrated loopsfor easy fastening. For other products a combination of backing materialsis used, such as for Abralon and Goldflex-Soft. Coarse Cut is another example– it is made of a special paper backing reinforced with non-woven fibres.Unique/Special backingsType Special features Application Example productNet-backingNon-wovenbackingKnitted fabricon foamPaper on foamFiber reinforcedpaperFilm backingDust-freeThree-dimensionalstructureFoam layerfor damp <strong>sanding</strong>ErgonomicstructureStrong and durableEven constructionSuitable for most<strong>wood</strong> applicationsSanding of profiles,fine <strong>sanding</strong>Superior finish<strong>sanding</strong>Manual profile<strong>sanding</strong>Coarse <strong>sanding</strong>,edge <strong>sanding</strong>Superior finish<strong>sanding</strong>Abranet®Mirlon®, Mirlon Total®Abralon®Goldflex-SoftCoarse CutPolarstar®36 37

Make coat and size coatGrains and coatingsThe ‘make coat’ and ‘size coat’ are layers of resin. The make coat is the first layeron which the abrasive grains are applied, while the size coat is added to keepthe grains firmly in place. All products in the <strong>wood</strong> <strong>sanding</strong> range are made withsynthetic resins (R/R, resin over resin). The benefits of using synthetic resins,instead of natural glue, include greater product durability and more consistantquality.A key factor in producing flexible abrasives is the amount of resin thatis applied. A low amount of resin results in an aggressive product but withrestricted working lifespan. Increasing the amount of resin increases theproducts working lifespan.A constant research and development program has enabled <strong>Mirka</strong> tocontinually enhance the performance of its products. By optimising theconstruction of our products we have been able to provide innovative andcost effective solutions that meet the demanding requirements of moderncustomers.When it comes to <strong>sanding</strong> <strong>wood</strong> the choice of abrasive grain is vital, bothfor the final result and to achieve the best possible lifespan from the product.Choosing a sharp grain will achieve a good cut, however if a finer surface finishis essential then another type of grain may be chosen. The grain selectionprocess is also affected by the strength required.Aluminium oxideThe most common abrasive grain for <strong>sanding</strong> <strong>wood</strong> is aluminium oxide– the grains are sharp and tough enough for most applications.Silicon carbideCompared to aluminium oxide, silicon carbide is more regular in shape andis not as brittle. The strength of these grains makes it perform well on hardsurfaces. It would typically be used to sand materials such as oak and MDF,since fibre boards usually contain hard impurities. In addition, the shapeof the silicon carbide grains produces a better surface finish compared toaluminium oxide, which makes them more suitable for intermediate <strong>sanding</strong>.121. Make coat 2. Size coatAluminium oxide grains plough intosoft <strong>wood</strong> types.Silicon carbide grains cut throughhard <strong>wood</strong>.Wooden surface after <strong>sanding</strong> withaluminium oxide.Wooden surface after <strong>sanding</strong> withsilicon carbide.38 39

Closed coatingAluminium oxide grains.Silicon carbide grains.Standard grain: Qualities and useSemi-open coatingGrainAluminium oxide• White• Semi-friable• HardenedSilicon carbideZirkonium oxideUsePaint, lacquer, <strong>wood</strong>Allround (<strong>wood</strong>, light metals, all types of <strong>sanding</strong> machines)Metal, hard <strong>wood</strong> and hard coatingsPaint, lacquer, polishing, MDF, veneer, hard <strong>wood</strong>Demanding/aggressive metal <strong>sanding</strong>Open coatingAmount of grainswhitealuminium oxidesilicon carbideHardnessblue toughenedaluminium oxideThe performance is greatly affected by the amount of abrasive grains used.For example, less grains results in an open coating which is highly resistantto clogging, whereas more grains produce a closed coating with good stockremoval and a smooth surface finish.Brittlenesshalf noblealuminium oxidezirkonium oxideToughnessIt is important to note that both the surface structure and surface finish isaffected by the choice of grains. This means that the colour of the treatedsurface might vary. The minerals used for <strong>Mirka</strong> products are synthetic,making them harder and more durable compared to natural sand.Grit sizesDifferent grit sizes are used for different purposes. Therefore, grit sizes aresorted during manufacture. Abrasive products can be made with differentgrit size standards such as FEPA, ANSI and GOST (See next page). <strong>Mirka</strong> usesgrains according to the FEPA standards – Federation of European Producersof Abrasives. Products produced according to this standard are recognisedby the ‘P’ mark – for example P80.Grain size is determined by passing them through sieves that are measuredin ‘threads-per-inch’. When it comes to micro-grains, the threads-per-inchmeasurement is a theoretical amount.40 41

Grit standardsFEPA ANSI GOSTFEPA P Grain size (microns)Macro grain sizesP12 1815 12 160P16 1324 16 125P20 1000 20 100P24 764 24 80P30 642 30 63P36 538 36 50P40 425 40 40P50 336 50 32P60 269 60 25P80 201 80 16P100 162 100 12P120 125 120 10P150 100 150 8P180 82 180 6P220 68 220 5Micro grain sizesP240 58,5 ± 2,0 M63P280 52,2 ± 2,0 240 M50P320 46,2 ± 1,5 M40P360 40,5 ± 1,5 280P400 35,0 ± 1,5 320 M28P500 30,2 ± 1,5 M20P600 25,8 ± 1,0 360 M10P800 21,8 ± 1,0 400 M7P1000 18,3 ± 1,0 500 M5P1200 15,3 ± 1,0 600P1500 12,6 ± 1,0 800P2000 10,3 ± 0,8 1000P2500 8,4 ± 0,5 1200Additional treatmentsStearate coatingSome products receive a special stearate coating treatment which is designedto prolong lifespan. Usually the stearate is based on zinc or calcium and is likesmall flakes applied on top of the abrasive.Advantages:• As the stearate coating is worn off during use it prevents cloggingand gives the product a longer lifespan.• The stearate reduces the initial cut and, therefore, produces a moreconsistant surface finish over the lifetime of the product.Typical <strong>Mirka</strong> stearated products include Gold, Q.Silver, Abranet and SicaFine Stearate. Stearated products achieve best results when <strong>sanding</strong> paint,lacquer and similar surfaces. For coarse <strong>sanding</strong> with high <strong>sanding</strong> pressure(for example, <strong>wood</strong> <strong>sanding</strong> with wide belts), stearate provides no advantagebecause it is very quickly worn off.Stock removal g/m 2stearate coated beltsconventional beltsStanding time = lifetimeStandards are not directly comparable to each other.42 43

Anti-static treatmentStatic electricity load can cause significant dust problems when <strong>sanding</strong> with awide belt. However, using anti-static belts prevents dust problems and providesa better work environment. Indeed, reducing the static load of <strong>sanding</strong> machinebelts brings a variety of positive benefits:• A clean, dust-free <strong>sanding</strong> surface provides a better surfacetreatment result.• The machine stays cleaner which makes maintenance easier.• A low dust load ensures a better work environment.It is also worth noting that abrasives can have various degrees of antistaticeffect. Some products only have an antistatic backing material, while othersalso include an antistatic bonding system. Dust problems can also be furtherprevented through the use of an efficient dust extraction system.Fastening systemsGenerally there are two types of fastening systems – ‘PSA’ (Pressure SensitiveAdhesives) and ‘Grip’.PSA uses an adhesive that is permanently tacky in dry form. With only lightcontact or hand pressure, PSA’s adhere firmly to a variety of different surfaceswhich makes them ideally suited for fastening of discs and similar products toan even backing pad.The Grip fastening system is a Velcro material attached to the backing ofthe abrasive. The Velcro loops on the abrasive backing joins with the Velcrohooks on the backing pad to fasten the two together. For example, <strong>Mirka</strong>’sNet Sanding products are constructed with loops integrated into the backingmaterial.44 45

Sanding with portablemachines and hand toolsUser recommendationsCoarse <strong>wood</strong> <strong>sanding</strong>. When a lot of material needs to be removed P24–P80is used and, typically, these products have a thick paper backing. However,there are also special products, such as Coarse Cut, with reinforced paper, orAbranet HD, with a high strength version of <strong>Mirka</strong>’s unique ‘net’ construction.These products are well suited to <strong>sanding</strong> using orbital machines with forcedpad rotation (gear driven machines).Bare <strong>wood</strong> <strong>sanding</strong>.Bare <strong>wood</strong> <strong>sanding</strong>. P100–P220 is used to make the surface smooth and evenand also to ensure good adhesion for paint or lacquer. Q.Silver and Abranet aretypical products used for these purposes. Sanding with grits that are too finewill not give any advantages, normal paints and lacquers will cover the surfaceafter sanded with grit P180 (even P150). Decreased adhesion, longer <strong>sanding</strong>time and higher consumption of discs and <strong>sanding</strong> material.Intermediate <strong>sanding</strong> of paint or lacquer. Using P240–P600 is the typicalstep to make the surface even prior to final coating. A <strong>sanding</strong> grit that is toocoarse will easily cut through the first coating, while if it is too fine it will notmake the surface even and will be too time consuming. Flexible paper productswith stearate are recommended, while <strong>Mirka</strong>’s Net products are also very wellsuited for this type of <strong>sanding</strong>. When you need to manually sand profiles thereare several specialty products available, such as Mirlon Total, Goldflex-Soft and<strong>sanding</strong> sponges.Intermediate <strong>sanding</strong> of paint or lacquer.Sanding of top coat before polishing (P800–P4000). The initial step is tocut away defects and level up the surface. The following steps are only thereto remove scratches in order to achieve a high gloss finish with polishingcompounds. Recommended products are those with thin paper backing,Net Sanding technology or film backing. For example, <strong>Mirka</strong> Abralon is anexcellent choice for this stage.Sanding of top coat prior to polishing.46 47

Net <strong>sanding</strong>AdvantagesSanding dust is a major healthproblem in many industrial sectorssince dust from paint, lacquersand hard <strong>wood</strong> can contain a lot ofharmful particles. By developing itspatented Net Sanding technology,<strong>Mirka</strong> has solved the dust problemwith a simple, yet very clever solution.Now it is finally possible to use atrue dust-free <strong>sanding</strong> system thatminimises the risk of breathing inharmful <strong>sanding</strong> dust while deliveringa whole host of added advantages.Net Sanding technology virtuallyeliminates dust which gives theoperator better control over thejob and also improves the qualityof the end finish by removing therisk of dust problems affecting thesurface. Whether you are using<strong>sanding</strong> sheets or discs, another keyNet Sanding advantage is that it hasa longer lifespan than traditional<strong>sanding</strong> materials. <strong>Mirka</strong>’s NetSanding familyis being continuously expandedwith innovative new products andaccessories.ApplicationsNet Sanding products can be used for machine <strong>sanding</strong> with discs or strips,or they can be used by hand with a hand <strong>sanding</strong> block, and are well suitedfor most types of <strong>wood</strong>.On soft <strong>wood</strong> types, the product lifespan is increased thanks to theunique ‘Net’ construction which prevents clogging. In addition, its aggressivecharacteristics also make it ideal for <strong>sanding</strong> hard <strong>wood</strong>. Net Sanding productsare particularly effective when <strong>sanding</strong> MDF and similar materials where asubstantial volume of dust is often created. Now, Net Sanding technologysolves this problem by allowing dust to be efficiently removed from the worksurface. Net Sanding products are also excellent for denibbing putty, paintand lacquer.In many cases, it is recommended to use a grit size that is finer than younormally use because Net Sanding delivers more aggressive performancethan conventional products.Net <strong>sanding</strong> equipment and accessories<strong>Mirka</strong> offers a wide selection of tools and accessories. The range consistsof pneumatic and electric sanders designed to provide dust-free <strong>sanding</strong>when used together with <strong>Mirka</strong>’s Net Sanding products. Dust-free <strong>sanding</strong>with Net Sanding products requires special equipment – a well-functioningdust extraction system must be available. It can be a central dust extractionsystem or a separate industrial vacuum cleaner.NO DUST48 49

<strong>Mirka</strong> <strong>sanding</strong>and polishing toolsElectric toolsCompact Electric Random Orbital Sander (CEROS)Benefits: A unique design offers superior versatility and performance ina compact, lightweight package. Being electric makes it practical to useanywhere a power source is available – even in remote locations or wherespace is severely restricted. The optimized ergonomics ensure it is comfortableto grip, while the low profile design and very light weight allow easymanoeuvrability and greater control over the end finish. The ultra-reliablehermetic brushless motor is powerful enough to maintain a constant speedunder load and it is also virtually silent in operation and cheap to run. With fewwearing components, the need for maintenance is minimized and its lifespan islong.DIRECT ELECTRIC RANDOM ORBITAL SANDER (DEROS)Benefits: The first ever electric <strong>sanding</strong> machine with a brushless motor andno external power supply. It is also the lightest electric machine on the market.The machine has a soft start function, a built in electronic motor brake anda smooth, easy to operate lever to control motor speed. Thanks to its highefficiency brushless motor, DEROS also has plenty of power to get the job donequickly. Its performance is comparable to a conventional 500W electric machineand that ensures it maintains a constant speed even under heavy load. Theunique symmetrical design makes it just as comfortable whether it’s being usedin the left hand or the right hand and the longer body provides the option of atwo-hand grip. DEROS is equipped with a new type of backing pad, which hasa central air inlet. This results in improved air flow and helps extract dust awayfrom the center of the tool even faster.Application: Ideal for a multitude of <strong>sanding</strong> tasks, from <strong>wood</strong>en surfacesto paints and lacquers. Best results are achieved by using <strong>Mirka</strong> Net Sandingproducts.Application: Ideal for a multitude of <strong>sanding</strong> tasks, from <strong>wood</strong>en surfacesto paints and lacquers. Best results are achieved by using <strong>Mirka</strong> Net Sandingproducts.50 51

Pneumatic toolsRandom Orbital Sanders (ROS, PROS)Benefits: <strong>Mirka</strong> random orbital sanders are effective and durable tools forthe professional user. They are ergonomically designed machines which arebuilt for maximum dust extraction even at a low suction power. Made fromlightweight, hi-tech materials, they combine optimal strength and excellentuser comfort.Application: Recommended for various applications, from <strong>wood</strong> and filler,to primer and lacquer <strong>sanding</strong>. Best results are achieved by using <strong>Mirka</strong> NetSanding products.Models:Available in various models with different pad sizes, orbits and dust systems.Orbital Sanders (OS)Benefits: <strong>Mirka</strong> orbital sanders areeffective and durable tools for professional<strong>sanding</strong> operations. Made from lightweight,hi-tech materials, they combine optimal strengthand excellent user comfort. These orbital sanderswere developed specially for use with Net Sandingproducts and their rectangular shape is ideal for <strong>sanding</strong>edges and hard-to-reach areas.Application: Recommended for various applications, from <strong>wood</strong> and filler, toprimer and lacquer <strong>sanding</strong>. Best results are achieved by using <strong>Mirka</strong> Net Sandingproducts.Models: Available in different sizes.Random Orbital Polishers and Rotary Polisher (ROP2 and RP2)Benefits: Powerful performance and a compact, streamlined design that allowsoperators to polish even difficult to reach areas, make <strong>Mirka</strong>’s Two-HandedPolishers the fast way to achieve a glossy surface finish. There are two optionsto choose from depending on your needs.Two-handed Random Orbital Sanders (ROS2)Benefits: These two-handed pneumatic sanders combine heavy dutyperformance and durability with low profile, light weight and ergonomic stylingthat makes them easy to handle and control. These tools are comfortableenough to use all day long to produce consistent, high quality results.Application: The ideal tool for tackling a wide variety of polishing tasks withminimum fuss and maximum efficiency. The best result will be achieved togetherwith <strong>Mirka</strong> compounds and pads.Models: Available in different sizes and orbits.Application: Recommended for heavyduty applications together with AbranetHeavy Duty or Coarse Cut.Models: Available in various models withdifferent pad sizes and orbits.52 53

Pneumatic tools och Electric tools– Electric Polishers and Dust ExtractorPolishing compoundsPolishersBenefits: These are high qualityelectric polishers for professionalusers and come in two sizes to suitdifferent applications. Due to itslight weight and ergonomic design,the smaller polisher is very easy andconvenient to use, while the biggerpolisher provides a fast and efficienttool for tackling larger surfaces.Application: The smaller polisher issuitable for small-scale polishing tasksand vertical surfaces, while the biggerpolisher is ideal for larger surfaces.Compound gradesModels: Available in two models:150 mm PS1437 and 180 mm PS1524Coarse35 1510 Fine83DUST EXTRACTORBenefits: Specifically designed for dustfree<strong>sanding</strong>, in combination with <strong>Mirka</strong>tools and accessories, this dust extractoris an effective, high quality tool. Theautomatic electric start saves the usertime and the adjustable suction makes itideal for a variety of different tasks.Application: Recommended for allkinds of applications in both wet and drymodes.Models: <strong>Mirka</strong>® Dust Extractor 915and 915M54 55

Belt <strong>sanding</strong>In order to achieve the desired result and the best possible efficiency when<strong>sanding</strong> with a wide belt, many factors need to be taken into consideration.For example, the choice of <strong>sanding</strong> material is very important but other factors,such as the adjustment of <strong>sanding</strong> units, the choice of <strong>sanding</strong> speed and thehandling, are also essential.Optimising belt lifespanThe abrasive qualities of any <strong>sanding</strong> belt are reduced as it becomes slowlyclogged while in use. After a <strong>sanding</strong> belt has been used for a certain periodof time, clogging becomes so severe that the risk of causing geometric faultsin the sanded material rapidly increases. Further clogging will make the sandedmaterial overheated due to the high friction that occurs when greater pressureis applied to a clogged belt in order to continue achieving stock removal.Overall <strong>sanding</strong> costs can be minimised simply by choosing the mostsuitable product for each <strong>sanding</strong> operation. That means:• choosing the right type of grit• choosing the right type of coating• using the optimal grit sequence• avoiding <strong>sanding</strong> with finer grits than necessaryGrit size and sequenceIn general, the first <strong>sanding</strong> belt is used for stock removal, while the followingbelts are only used for creating an even surface finish. Typically, the first <strong>sanding</strong>unit consists of a drum made of materials such as steel or hard rubber. Thedrum, in combination with coarse grit (P36–P100) belts, is ideal for efficientstock removal.When it comes to producing an even surface finish, <strong>sanding</strong> units thatincorporate soft rubber drums or <strong>sanding</strong> pads are normally used. In these unitsthe grit range varies from P120–P320.For <strong>sanding</strong> between coats or intermediate <strong>sanding</strong>, grits P320–P800 aremost commonly used along with a very soft rubber drum or a soft <strong>sanding</strong> pad.When choosing a grit size the recommendation is to select belts that areonly one step from each other in grit sizes. For example, P80–P120–P180 areappropriate steps, whereas P60–P120–P220 often results in problems with thesurface finish and product lifespan.Recommended grit size useGrit sizeUseP24–P80Coarse <strong>sanding</strong>, calibrationP100–P320Medium <strong>sanding</strong>, <strong>wood</strong> <strong>sanding</strong>P320–P1200Fine <strong>sanding</strong>, intermediate <strong>sanding</strong>The lifespan of the belt can be further increased by ensuring that the <strong>sanding</strong>equipment is correct and used properly:• choose the right type of <strong>sanding</strong> machine for each sandi ng operation• adjust the <strong>sanding</strong> machine correctly• ensure the machine is properly maintained• check that the dust extraction is adequate56 57

Stock removal per unitWith a three belt machine, the starting point for stock removalper unit can be divided according to the following:• Station 1 ~ 60%• Station 2 ~ 30%• Station 3 ~ 10%With a two belt machine, the division can be as follows:• Station 1 ~ 75%• Station 2 ~ 25%A good way of controlling whether the adjustments are correct is to checkhow the belts are used in comparison to each other. If adjustments are madeaccording to the requirements given by the grit sequence and machine, thenthe belts are used at the same rate.Belt <strong>sanding</strong> speedThe general rule is that higher belt speeds result in larger stock removal.A higher belt speed means that both friction heat and load increase on thebelt which, in turn, reduces its lifespan. Different types of material requiredifferent <strong>sanding</strong> speeds.Material and recommendation for <strong>sanding</strong> belt speedMaterial Lowest <strong>sanding</strong> speed Highest <strong>sanding</strong> speedHard <strong>wood</strong> 15 m/s 24 m/sMDF 15 m/s 21 m/sSoft, resinous <strong>wood</strong> 12 m/s 18 m/sHigh gloss lacquer 2 m/s 8 m/sSynthetic material 9 m/s 21 m/sVeneer 18 m/s 27 m/sThe values indicate the <strong>sanding</strong> speed.Maximum removalContact drum unitSanding pad unitGrit Removal (mm / inches) Grit Removal (mm / inches)P36 Steel/hard rubber roller < 1.00 / 0.04 P36 –P40 Steel/hard rubber roller < 0.80 / 0.03 P40 –P60 Steel/hard rubber roller < 0.60 / 0.02 P60 –P80 Medium rubber roller < 0.50 / 0.019 P80 < 0.30 / 0.012P100 Medium rubber roller < 0.30 / 0.012 P100 < 0.20 / 0.008P120 Soft rubber roller < 0.20 / 0.008 P120 < 0.15 / 0.006P150 Soft rubber roller < 0.10 / 0.004 P150 < 0.08 / 0.003P180 – P180 < 0.05 / 0.002P220 – P220 < 0.03 / 0.001finer – finer < 0.03 / 0.00158 59

Belt jointsBelt joint performance is a key factor for <strong>sanding</strong> belts. The joints must be as strongas the actual <strong>sanding</strong> material and should not be too thick or too thin comparedto the <strong>sanding</strong> material. The belt should also have the right shape and dimension.TS-jointTypes of belt jointsA-jointMostly used for <strong>sanding</strong> belts made from paper, an A-joint is an overlapping jointwithout compensation on the sand side, e.g. without interruption in the coating.It produces a uniform <strong>sanding</strong> belt thickness, even across the joint, and results inan even <strong>sanding</strong> finish without chatter marks.A TS-joint is similar to a T-joint but is different in the way the connecting endsare cut. By using a TS-joint the hinge effect can be avoided. This joint type ismost suitable for belts in medium grit sizes and it is most common on clothbackedbelts, although TS-joints can also be found on paper-backed belts.B-jointTT-jointThe most common joint for <strong>sanding</strong> belts with cloth backing, the B-joint is anoverlapping joint with compensation on the sand side. This means that the jointarea is free of abrasive material which allows the cloth to overlap without thejoint having to be thicker than the rest of the belt. The B-joint is also suitablefor special paper products, such as <strong>Mirka</strong>’s Ultimax.This is a special joint where the tape is applied on the <strong>sanding</strong> side makingit suited to profile <strong>sanding</strong> with a <strong>sanding</strong> pad.T-jointTypically used for small cloth belts that require strength and flexibility, a T-jointis cut through the <strong>sanding</strong> belt without an overlap and the joint is attached withtape on the backing side.60 61

Problem solvingTypical problems when <strong>sanding</strong>with hand tools or by handHere we look at common problems in the <strong>sanding</strong> process when usinghand tools or <strong>sanding</strong> by hand. It is essential to understand where a problemoriginates from in order to correct the process.Potential problemsThe product is clogging• Check that the paint, lacquer or putty is properly cured.• A stearated product is usually the best choice for paint or lacquer.• Use machines with dust extraction and ensure the hole combinationon the backing pad is compatible with the <strong>sanding</strong> product.• Avoid <strong>sanding</strong> with grits that are too fine.The product is breaking up• Use a product with rigid backing material (e.g. Coarse Cut).• Ensure the machine and <strong>sanding</strong> material match.• A worn <strong>sanding</strong> pad often causes problems.Problems with profile <strong>sanding</strong>• Use a flexible <strong>sanding</strong> product (e.g. Carat Flex).• Use a product specially designed for <strong>sanding</strong> of profiles(e.g. Mirlon or Goldflex-Soft).• Try an orbital sander instead of a random orbital sander.Visible finger marks after hand <strong>sanding</strong>• Use a hand <strong>sanding</strong> tool when <strong>sanding</strong> plain surfaces.• Use specialty products, such as Goldflex-Soft, for <strong>sanding</strong> profiledsurfaces as they distribute the <strong>sanding</strong> pressure evenly.Visible scratches• Avoid too big a step between grits.• Silicon carbide products will usually give a better surface finish.• Use a random orbital sander.Not enough stock removal• Aluminium oxide products tend to have a better cut.• Start with coarse grits and work towards finer grits.Dust problems• Use Net Sanding products with suitable machines and accessories.62 63

Typical problems with belt <strong>sanding</strong>This section describes typical problems that might occur when using wide belts.It is essential to understand where a problem originates from in order to correctthe process.Potential problemsChatter marks in cross direction• Check the condition of the belt joint.• Is the machine working as it should?Chatter marksChatter marksIn particular, a malfunctioning drum cancause chatter marks.• Wrong type of <strong>sanding</strong> unit? A hard drumChatter markswith a short <strong>sanding</strong> contact patch is morelikely to result in chatter marks, compared to a soft <strong>sanding</strong> pad.Positive stripesBelt breakages: The belt is broken?• Check the oscillation of the machine and clean inside the machine.• Check the storage of the belts (see page ‘Wide belt storage’).• Avoid too much stock removal. Avoid using clogged belts.• Check the condition of the belt joint.Short belt lifespan: Is the belt clogging?• Avoid too much stock removal per <strong>sanding</strong> unit – check machineadjustments.• Make sure you are using the correct product and grit sequence.• Make sure the cleaning system and the dust extraction is operatingcorrectly.• Use the whole belt width when <strong>sanding</strong>.Positive stripes (stripes coming out of the <strong>wood</strong> piece)Positive stripes• Narrow stripes in a pattern followingthe belt oscillation? These are normallycaused by sharp objects in the workPositive stripespiece which destroy the abrasive.Change the belt and examine the work Negative stripespieces for sharp objects.• Wide straight stripes? Typically a problem with <strong>sanding</strong> drums or pads.Negative stripesClean the pad and have the drum calibrated.Uneven surface: The surface feels uneven?• Steps too big in grit sequence.• Stock removal with <strong>sanding</strong> unit which has a <strong>sanding</strong> contact thatis too soft.Negative stripes• Wide straight stripes? The mostcommon problem is dust on the<strong>sanding</strong> pad. Clean the pad or, ifnecessary, change the graphite cloth.• Narrow straight stripes? It is possiblethat small <strong>wood</strong> pieces or dust are stuckto the pressure shoe. Clean the machine.Negative stripes64 65

Wide belt storageBy simply following some basic recommendations on wide belt storage, youcan ensure that the belts remain undamaged and maintain their full workingpotential.• Store belts in their unopened packages until they are to be used.• The belts can be hung horizontally prior to use in orderto make handling easier.• The correct storage temperature is 15–25°C.• The relative humidity is recommended to be 35–60 per cent in orderfor the belts to maintain their shape.• Wide belts should have even moisture over the whole width.Avoid keeping belts hanging close to a cold wall or a heating source.Do not expose the belts to direct sunlight66

HeadquartersSubsidiaryBranch officeGraphic design: Studio PAP. Print: Fram 4/2013. 200401.For contact information,please visit www.mirka.comQuality from start to finish