protocol implementation conformance statement - WindowMaster

protocol implementation conformance statement - WindowMaster

protocol implementation conformance statement - WindowMaster

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

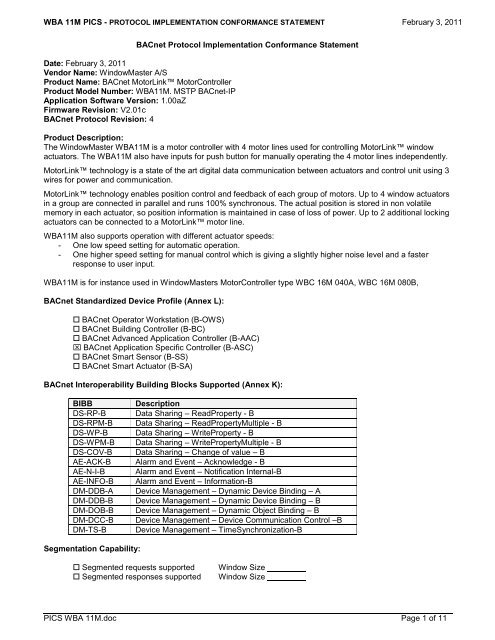

WBA 11M PICS - PROTOCOL IMPLEMENTATION CONFORMANCE STATEMENT February 3, 2011BACnet Protocol Implementation Conformance StatementDate: February 3, 2011Vendor Name: <strong>WindowMaster</strong> A/SProduct Name: BACnet MotorLink MotorControllerProduct Model Number: WBA11M. MSTP BACnet-IPApplication Software Version: 1.00aZFirmware Revision: V2.01cBACnet Protocol Revision: 4Product Description:The <strong>WindowMaster</strong> WBA11M is a motor controller with 4 motor lines used for controlling MotorLink windowactuators. The WBA11M also have inputs for push button for manually operating the 4 motor lines independently.MotorLink technology is a state of the art digital data communication between actuators and control unit using 3wires for power and communication.MotorLink technology enables position control and feedback of each group of motors. Up to 4 window actuatorsin a group are connected in parallel and runs 100% synchronous. The actual position is stored in non volatilememory in each actuator, so position information is maintained in case of loss of power. Up to 2 additional lockingactuators can be connected to a MotorLink motor line.WBA11M also supports operation with different actuator speeds:- One low speed setting for automatic operation.- One higher speed setting for manual control which is giving a slightly higher noise level and a fasterresponse to user input.WBA11M is for instance used in <strong>WindowMaster</strong>s MotorController type WBC 16M 040A, WBC 16M 080B,BACnet Standardized Device Profile (Annex L): BACnet Operator Workstation (B-OWS) BACnet Building Controller (B-BC) BACnet Advanced Application Controller (B-AAC) BACnet Application Specific Controller (B-ASC) BACnet Smart Sensor (B-SS) BACnet Smart Actuator (B-SA)BACnet Interoperability Building Blocks Supported (Annex K):BIBBDescriptionDS-RP-B Data Sharing – ReadProperty - BDS-RPM-B Data Sharing – ReadPropertyMultiple - BDS-WP-B Data Sharing – WriteProperty - BDS-WPM-B Data Sharing – WritePropertyMultiple - BDS-COV-B Data Sharing – Change of value – BAE-ACK-B Alarm and Event – Acknowledge - BAE-N-I-B Alarm and Event – Notification Internal-BAE-INFO-B Alarm and Event – Information-BDM-DDB-A Device Management – Dynamic Device Binding – ADM-DDB-B Device Management – Dynamic Device Binding – BDM-DOB-B Device Management – Dynamic Object Binding – BDM-DCC-B Device Management – Device Communication Control –BDM-TS-B Device Management – TimeSynchronization-BSegmentation Capability: Segmented requests supported Segmented responses supportedWindow SizeWindow SizePICS WBA 11M.doc Page 1 of 11

WBA 11M PICS - PROTOCOL IMPLEMENTATION CONFORMANCE STATEMENT February 3, 2011Standard Object Types Supported:Object instantiation is static; i.e. objects cannot be created or deleted. Refer to table at end of this document forobject details.Object TypeDevice Binary Analog Multi-statePropertyIn Value Out In Value Out In ValueObject Identifier Object Name Object Type Description System StatusDevice Online StatusVendor NameVendor IdentifierModel NameFirmware Revision()Appl Software Revision()locationProtocol VersionProtocol RevisionProtocol Services SupportedProtocol Object Types Supported Object ListMax APDU LengthSegmentation SupportAPDU TimeoutNumber APDU RetriesMax MasterMSTPMax Info FramesMSTPDevice Address BindingDatabase RevisionActive cov subscriptions -Present Value Status Flags Event State Reliability Out-of-Service Inactive Text Active Text Number of states State text Units Priority Array * * *Relinquish Default * * *COV Increments *Time delay - - - - - -Notification Class - - - - - -High limit - - -Low limit - - -Limit Enable - - -Deadband - - -Alarm value - - -Alarm values - -Fault values - -Event Enable - - - - - -Notify Type - - - -PICS WBA 11M.doc Page 2 of 11

WBA 11M PICS - PROTOCOL IMPLEMENTATION CONFORMANCE STATEMENT February 3, 2011* For commandable values only() means Value not right,- means not implemented yetAnalog Output Objects Instance Summary:ID Objects Name Description Unit PresentValueAccessAO 1 Max_Position_Input_Line_1 Sets the maximum allowed position for motor line 1 Percent CAO 2 Max_Position_Input_Line_2 Sets the maximum allowed position for motor line 2 Percent CAO 3 Max_Position_Input_Line_3 Sets the maximum allowed position for motor line 3 Percent CAO 4 Max_Position_Input_Line_4 Sets the maximum allowed position for motor line 4 Percent CAO 5 Auto_Position_Line_1 Sets the target position with auto speed for motor line 1 Percent CAO 6 Auto_Position_Line_2 Sets the target position with auto speed for motor line 2 Percent CAO 7 Auto_Position_Line_3 Sets the target position with auto speed for motor line 3 Percent CAO 8 Auto_Position_Line_4 Sets the target position with auto speed for motor line 4 Percent CAO 9 Hand_Relative_Position_Line_1 Hand relative position for motor line 1 Percent CAO 10 Hand_Relative_Position_Line_2 Hand relative position for motor line 2 Percent CAO 11 Hand_Relative_Position_Line_3 Hand relative position for motor line 3 Percent CAO 12 Hand_Relative_Position_Line_4 Hand relative position for motor line 4 Percent CAO 13 Hand_Absolute_Position_Line_1 Set the target position of motor line 1 using Hand speed Percent CAO 14 Hand_Absolute_Position_Line_2 Set the target position of motor line 2 using Hand speed Percent CAO 15 Hand_Absolute_Position_Line_3 Set the target position of motor line 3 using Hand speed Percent CAO 16 Hand_Absolute_Position_Line_4 Set the target position of motor line 4 using Hand speed Percent CBinary Output Objects Instance Summary:ID Objects Name Description Active / inactive Text PresentValueAccessBO 1 Close_All Set that all motor lines must be closed Close all motor lines /CInactiveBO 2 Auto_Off Set whether automatic control is Automatic control disabled / CactiveAutomatic control enabledBO 3 Service Set to disable all actuator movements Movements not allowed / CMovements allowedBO 4 Close_Line_1 Set that motor line 1 must be closed Motor line must be closed / CNormal operationBO 5 Close_Line_2 Set that motor line 2 must be closed Motor line must be closed / CNormal operationBO 6 Close_Line_3 Set that motor line 3 must be closed Motor line must be closed / CNormal operationBO 7 Close_Line_4 Set that motor line 4 must be closed Motor line must be closed / CNormal operationBO 8 Disable_Hand_Line_1 Set to disable manual control for Disable manual contol / Cmotor line 1Enable manual controlBO 9 Disable_Hand_Line_2 Set to disable manual control for Disable manual contol / Cmotor line 2Enable manual controlBO 10 Disable_Hand_Line_3 Set to disable manual control for Disable manual contol / Cmotor line 3Enable manual controlBO 11 Disable_Hand_Line_4 Set to disable manual control for Disable manual contol / Cmotor line 4BO 12 Disable_Auto_Line_1 Set to disable automatic control formotor line 1BO 13 Disable_Auto_Line_2 Set to disable automatic control formotor line 2BO 14 Disable_Auto_Line_3 Set to disable automatic control formotor line 3BO 15 Disable_Auto_Line_4 Set to disable automatic control formotor line 4Enable manual controlDisable automatically control/ Enable automaticallycontrolDisable automatically control/ Enable automaticallycontrolDisable automatically control/ Enable automaticallycontrolDisable automatically control/ Enable automaticallycontrolCCCCPICS WBA 11M.doc Page 3 of 11

WBA 11M PICS - PROTOCOL IMPLEMENTATION CONFORMANCE STATEMENT February 3, 2011ID Objects Name Description Active / inactive Text PresentValueAccessBO 16 Clear_Hand_Timer_Line_1 Clears the timer for manual movementof motor line 1 When clearedautomatic control takes precedenceBO 17 Clear_Hand_Timer_Line_2 Clears the timer for manual movementof motor line 2 When clearedautomatic control takes precedenceBO 18 Clear_Hand_Timer_Line_3 Clears the timer for manual movementof motor line 3 When clearedautomatic control takes precedenceBO 19 Clear_Hand_Timer_Line_4 Clears the timer for manual movementof motor line 4 When clearedautomatic control takes precedenceAnalog Input Objects Instance Summary:Clear/expire timer / NoactionClear/expire timer / NoactionClear/expire timer / NoactionClear/expire timer / NoactionID Objects Name Description Unit PresentValueAccessAI 1 Hand_Position_Output_Line_1 Local hand command cascade output for motor line 1 Percent RAI 2 Hand_Position_Output_Line_2 Local hand command cascade output for motor line 2 Percent RAI 3 Hand_Position_Output_Line_3 Local hand command cascade output for motor line 3 Percent RAI 4 Hand_Position_Output_Line_4 Local hand command cascade output for motor line 4 Percent RAI 5 Actual_Position_Line_1 Contains the actual position for Line 1 Percent RAI 6 Actual_Position_Line_2 Contains the actual position for Line 2 Percent RAI 7 Actual_Position_Line_3 Contains the actual position for Line 3 Percent RAI 8 Actual_Position_Line_4 Contains the actual position for Line 4 Percent RAI 9 Actual_Max_Position_Line_1 Contains the maximum allowed position of Line 1 Percent RAI 10 Actual_Max_Position_Line_2 Contains the maximum allowed position of Line 1 Percent RAI 11 Actual_Max_Position_Line_3 Contains the maximum allowed position of Line 1 Percent RAI 12 Actual_Max_Position_Line_4 Contains the maximum allowed position of Line 1 Percent RAI 13 No_Of_Actuators_Detected_Line_1 Indicates no of actuators detected on Line 1 RAI 14 No_Of_Actuators_Detected_Line_2 Indicates no of actuators detected on Line 2 RAI 15 No_Of_Actuators_Detected_Line_3 Indicates no of actuators detected on Line 3 RAI 16 No_Of_Actuators_Detected_Line_4 Indicates no of actuators detected on Line 4 RCCCCPICS WBA 11M.doc Page 4 of 11

WBA 11M PICS - PROTOCOL IMPLEMENTATION CONFORMANCE STATEMENT February 3, 2011ID Objects Name Description PresentValueAccessMI 17 Heat_Smoke_Link_State This object contains information about the heat and smoke daisychained communication link.1 = No priority override.2 = Close.3 = Open.4 = Open (and Close).5 = Emergency Close.6 = Emergency Close (and close).7 = Emergency Close (and open).8 = Emergency Close (and open and close.9 = Emergency Open.10 = Emergency Open (and close).11 = Emergency Open (and open).12 = Emergency Open (and open and Close).13 = Emergency Open (and emg. close).14 = Emergency Open (and emg. close and close).15 = Emergency Open (and emg. close and open).16 = Emergency Open (and emg. close and open and close).RBinary Value Objects Instance Summary:ID Objects Name Description Active / inactive Text PresentValueAccessBV 1 Lock_Actuator_Blocked_Is_Closed_Line_1 This non-volatile parameter setswhether obstacles duringlocking situation must bejudged as a mal function or anormal situation on line 1BV 2 Use_Local_Input_Line_1 This non-volatile parameter setswhether local input must beactiveBV 3 Lock_Actuator_Blocked_Is_Closed_Line_2 This non-volatile parameter setswhether obstacles duringlocking situation must bejudged as a mal function or anormal situation on line 2BV 4 Use_Local_Input_Line_2 This non-volatile parameter setsweather local input must beactive for line 2BV 5 Lock_Actuator_Blocked_Is_Closed_Line_3 This non-volatile parameter setswhether obstacles duringlocking situation must bejudged as a mal function or anormal situation on line 3BV 6 Use_Local_Input_Line_3 This non-volatile parameter setsweather local input must beactive for line 3BV 7 Lock_Actuator_Blocked_Is_Closed_Line_4 This non-volatile parameter setswhether obstacles duringlocking situation must bejudged as a mal function or anormal situation on line 4BV 8 Use_Local_Input_Line_4 This non-volatile parameter setsweather local input must beactive for line 4Use overcurrent or switch /Use switchUse and transmit / TransmitonlyUse overcurrent or switch /Use switchUse and transmit / TransmitonlyUse overcurrent or switch /Use switchUse and transmit / TransmitonlyUse overcurrent or switch /Use switchUse and transmit / TransmitonlyPresent Value Access types Legend: R = Read-only, W (Note1)= Writeable, C=Commandable. Commandablevalues supports priority arrays 16 relinquish defaults.Note1: Object contains parameter/configuration data stored in flash memory. A data changes lead to all motorlines going into configuration mode for some seconds. Object should not be destination for any for anykind of cyclic write scheme.W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)PICS WBA 11M.doc Page 7 of 11

WBA 11M PICS - PROTOCOL IMPLEMENTATION CONFORMANCE STATEMENT February 3, 2011Analog Value Objects Instance Summary:ID Objects Name Description Unit PresentValueAccessAV 1 Hand_Speed_Line_1 This non-volatile parameter sets the speed ofthe actuators during hand operationPercentW(Note 1)AV 2 Automatic_Speed_Line_1 This non-volatile parameter sets the speed of PercentWthe actuators during automatic operationAV 3 Heat_Smoke_Speed_Line_1 This non-volatile parameter sets the speed ofthe actuators during Heat and SmokeoperationAV 4 Max_Position_Comfort_Line_1 This non-volatile parameter sets themaximum opening allowed during normal(comfort) operationAV 5 Max_Position_Heat_Smoke_Line_1 This non-volatile parameter sets themaximum opening allowed during Heat andSmoke operationAV 6 Lock_Actuator_Hand_Speed_Line_1 This non-volatile parameter sets the speed ofthe locking actuators during hand operationAV 7 Lock_Actuator_Auto_Speed_Line_1 This non-volatile parameter sets the speed ofthe locking actuators during automaticoperationAV 8 Lock_Actuator_Heat_Smoke_Speed_Line_1 This non-volatile parameter sets the speed ofthe locking actuators during Heat and SmokeoperationAV 9 Lock_Actuator_Service_Position_Line_1 This non-volatile parameter sets the serviceposition of the actuator when the lockingactuator is in service positionAV 10 Hand_Time_Out_Line_1 This non-volatile parameter sets the durationof time after hand operation, where automaticcommands are ignoredAV 11 Hand_Speed_Line_2 This non-volatile parameter sets the speed ofthe actuators during hand operationAV 12 Automatic_Speed_Line_2 This non-volatile parameter sets the speed ofthe actuators during automatic operationAV 13 Heat_Smoke_Speed_Line_2 This non-volatile parameter sets the speed ofthe actuators during Heat and SmokeoperationAV 14 Max_Position_Comfort_Line_2 This non-volatile parameter sets themaximum opening allowed during normal(comfort) operationAV 15 Max_Position_Heat_Smoke_Line_2 This non-volatile parameter sets themaximum opening allowed during Heat andSmoke operationAV 16 Lock_Actuator_Hand_Speed_Line_2 This non-volatile parameter sets the speed ofthe locking actuators during hand operationAV 17 Lock_Actuator_Auto_Speed_Line_2 This non-volatile parameter sets the speed ofthe locking actuators during automaticoperationAV 18 Lock_Actuator_Heat_Smoke_Speed_Line_2 This non-volatile parameter sets the speed ofthe locking actuators during Heat and SmokeoperationAV 19 Lock_Actuator_Service_Position_Line_2 This non-volatile parameter sets the serviceposition of the actuator when the lockingactuator is in service positionAV 20 Hand_Time_Out_Line_2 This non-volatile parameter sets the durationof time after hand operation, where automaticcommands are ignoredAV 21 Hand_Speed_Line_3 This non-volatile parameter sets the speed ofthe actuators during hand operationAV 22 Automatic_Speed_Line_3 This non-volatile parameter sets the speed ofthe actuators during automatic operationPercentPercentPercentPercentPercentPercentMinutesPercentPercentPercentPercentPercentPercentPercentPercentMinutesPercentPercent(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)PICS WBA 11M.doc Page 8 of 11

WBA 11M PICS - PROTOCOL IMPLEMENTATION CONFORMANCE STATEMENT February 3, 2011ID Objects Name Description Unit PresentValueAccessAV 23 Heat_Smoke_Speed_Line_3 This non-volatile parameter sets the speed ofthe actuators during Heat and SmokeoperationPercentAV 24 Max_Position_Comfort_Line_3 This non-volatile parameter sets thePercentmaximum opening allowed during normal(comfort) operationAV 25 Max_Position_Heat_Smoke_Line_3 This non-volatile parameter sets thePercentmaximum opening allowed during Heat andSmoke operationAV 26 Lock_Actuator_Hand_Speed_Line_3 This non-volatile parameter sets the speed of Percentthe locking actuators during hand operationAV 27 Lock_Actuator_Auto_Speed_Line_3 This non-volatile parameter sets the speed of Percentthe locking actuators during automaticoperationAV 28 Lock_Actuator_Heat_Smoke_Speed_Line_3 This non-volatile parameter sets the speed of Percentthe locking actuators during Heat and SmokeoperationAV 29 Lock_Actuator_Service_Position_Line_3 This non-volatile parameter sets the serviceposition of the actuator when the lockingactuator is in service positionAV 30 Hand_Time_Out_Line_3 This non-volatile parameter sets the duration Minutesof time after hand operation, where automaticcommands are ignoredAV 31 Hand_Speed_Line_4 This non-volatile parameter sets the speed of Percentthe actuators during hand operationAV 32 Automatic_Speed_Line_4 This non-volatile parameter sets the speed of Percentthe actuators during automatic operationAV 33 Heat_Smoke_Speed_Line_4 This non-volatile parameter sets the speed of Percentthe actuators during Heat and SmokeoperationAV 34 Max_Position_Comfort_Line_4 This non-volatile parameter sets thePercentmaximum opening allowed during normal(comfort) operationAV 35 Max_Position_Heat_Smoke_Line_4 This non-volatile parameter sets thePercentmaximum opening allowed during Heat andSmoke operationAV 36 Lock_Actuator_Hand_Speed_Line_4 This non-volatile parameter sets the speed of Percentthe locking actuators during hand operationAV 37 Lock_Actuator_Auto_Speed_Line_4 This non-volatile parameter sets the speed of Percentthe locking actuators during automaticoperationAV 38 Lock_Actuator_Heat_Smoke_Speed_Line_4 This non-volatile parameter sets the speed of Percentthe locking actuators during Heat and SmokeoperationAV 39 Lock_Actuator_Service_Position_Line_4 This non-volatile parameter sets the serviceposition of the actuator when the lockingactuator is in service positionAV 40 Hand_Time_Out_Line_4 This non-volatile parameter sets the duration Minutesof time after hand operation, where automaticcommands are ignoredAV 41 Actual_Position_Min_Transmit_Interval This non-volatile parameter sets the minimum Secondsretransmit interval of Actual Position for eachmotor lineAV 42 Objects_Receive_Monitor_Time_Out This non-volatile parameter determines how Minutesoften updates on monitored objects must bereceivedPresent Value Access types Legend: R = Read-only, W (Note1)= Writeable (Note1), C=Commandable.Commandable values supports priority arrays 16 relinquish defaults.Note1: Object contains parameter/configuration data stored in flash memory. A data changes lead to all motorlines going into configuration mode for some seconds. Object should not be destination for any for anykind of cyclic write scheme.W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)W(Note 1)PICS WBA 11M.doc Page 9 of 11

WBA 11M PICS - PROTOCOL IMPLEMENTATION CONFORMANCE STATEMENT February 3, 2011Multi-state Value Objects Instance Summary:ID Objects Name Description PresentValueAccessMV 1 Expected_No_Of_Actuators_Line_1 WBA11M examines the actual actuator configuration on themotor line. The controller in each MotorLink actuator includesinformation about how many fellow actuators that is needed inorder to have a valid configuration.This non-volatile parameter determines how to handlediscrepancies in the actuator configuration. Please note thatnormally actuators are exchanging actual position in order tokeep synchronised positions - independent of tolerances anddifferent loads. If position differs the actuators will automaticallywait for the slowest one. If one or more actuators fail to respond,the operation is stopped in order to avoid damage on thewindow. This synchronisation feature is used if more actuatorsare needed in order to operate a large or heavy window. If morewindows - each equipped with a single actuator (-1) areconnected to the same motor line, this synchronisation feature isdisabled. Depending on the demand for detection ofconfiguration or run time failures, non-volatile parameters mustbe selected in order to fit the expected number of actuators or adon’t care value, where no check of the number of actuators is inaction.Valid values are:1: Line disabled2: 1 single-actuator (-1)3: 2 not synchronised single-actuators (-1)4: 3 not synchronised single-actuators (-1)5: 4 not synchronised single-actuators (-1)6-13: Normal (use value in window actuators)14: Don't care 1 to 4 not synchronised single-actuators (-1)15-16: Normal (use value in window actuators)MV 2 Expected_No_Of_Lock_Actuators_Line_1 This non-volatile parameter determines the expectedconfiguration of locking actuators.Possible values are:1. None: No locking actuators are present.2. One locking actuator must be present.3. Two locking actuators must be present.W(Note 1)W(Note 1)4. Don’t care: One or two locking actuators can be present.MV 3 Expected_No_Of_Actuators_Line_2 See Expected_No_Of_Actuators_Line_1 W(Note 1)MV 4 Expected_No_Of_Lock_Actuators_Line_2 See Expected_No_Of_Lock_Actuators_Line_1 W(Note 1)MV 5 Expected_No_Of_Actuators_Line_3 See Expected_No_Of_Actuators_Line_1 W(Note 1)MV 6 Expected_No_Of_Lock_Actuators_Line_3 See Expected_No_Of_Lock_Actuators_Line_1 W(Note 1)MV 7 Expected_No_Of_Actuators_Line_4 See Expected_No_Of_Actuators_Line_1 W(Note 1)MV 8 Expected_No_Of_Lock_Actuators_Line_4 See Expected_No_Of_Lock_Actuators_Line_1 W(Note 1)MV 9 Objects_To_Monitor This non-volatile parameter determines which objects to monitorfor cyclic updates.1. None: No objects are monitored.2. Maximum position: The maximum position object for eachmotor line is monitored.3. Close: The close object for each motor line is monitored.4. Max. position and close: The maximum position object andthe close object for each motor line are monitored.W(Note 1)PICS WBA 11M.doc Page 10 of 11

WBA 11M PICS - PROTOCOL IMPLEMENTATION CONFORMANCE STATEMENT February 3, 2011ID Objects Name Description PresentValueAccessMV 10 Line_Communication_Error_Threshold Sporadic communication errors can appear in thecommunication between WEA11M and the MotorLinkactuators.This non-volatile parameter determines how tolerant theWBA11M must be before an error is transmitted.Range:1. Commissioning: Any disturbance is handled as an error.2. Normal: Normal tolerance towards sporadic errors.3. High: High tolerance towards sporadic errors – to be used innoisy environments.Present Value Access types Legend: R = Read-only, W (Note1)= Writeable, C= Commendable. Commendablevalues supports priority arrays 16 relinquish defaults.Note1: Object contains parameter/configuration data stored in flash memory. A data changes lead to all motorlines going into configuration mode for some seconds. Object should not be destination for any for anykind of cyclic write scheme.Data Link Layer Options: BACnet IP, (Annex J) BACnet IP, (Annex J), Foreign Device ISO 8802-3, Ethernet (Clause 7) ANSI/ATA 878.1, 2.5 Mb. ARCNET (Clause 8) ANSI/ATA 878.1, RS-485 ARCNET (Clause 8), baud rate(s) ____________ MS/TP master (Clause 9), baud rate(s): Auto, 2400, 4800, 9600,19200, 38400, 76800, 115200__ MS/TP slave (Clause 9), baud rate(s): Auto, 2400, 4800, 9600,19200, 38400, 76800, 115200__ Point-To-Point, EIA 232 (Clause 10), baud rate(s): Point-To-Point, modem, (Clause 10), baud rate(s): LonTalk, (Clause 11), medium: __________ Other:W(Note 1)Device Address Binding:Is static device binding supported? (This is currently necessary for two-way communication with MS/TP slavesand certain other devices.) Yes NoNetworking Options: Router, Clause 6 - List all routing configurations, e.g., ARCNET-Ethernet, Ethernet-MS/TP, etc. Annex H, BACnet Tunneling Router over IP BACnet/IP Broadcast Management Device (BBMD)Does the BBMD support registrations by Foreign Devices? Yes NoCharacter Sets Supported:Indicating support for multiple character sets does not imply that they can all be supported simultaneously. ANSI X3.4 IBM /Microsoft DBCS ISO 8859-1 ISO 10646 (UCS-2) ISO 10646 (UCS-4) JIS C 6226PICS WBA 11M.doc Page 11 of 11