RM /t - MYCRON Steel Berhad

RM /t - MYCRON Steel Berhad

RM /t - MYCRON Steel Berhad

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

INVESTOR PRESENTATION

PRESENTATION CONTENTS1. Corporate Information2. Operations3. Financials4. Business Outlook5. Share Valuation6. Summary

MAJOR SHAREHOLDERS(AS AT NOVEMBER 30, 2007)Shareholders3 0 -N o v -0 7N o .S h a re s S h a re(M illio n ) h o ld in gM e le w a r In d u stria l G ro u p B h d 97.50 54.5%M e le w a r E q u itie s (B V I) L td 9 .3 4 5 .2 %M a la ysia n A ssu ra n ce A llia n ce B h d 5.50 3.1%Melewar G roup 112.34 62.8%PNB 5.45 3.0%Group & Govt Funds 117.79 65.8%Foreign Shareholding 5.60 3.1%Balance Free Float 55.61 31.1%T o ta l P a id U p C a p ita l 179.00 100.0%

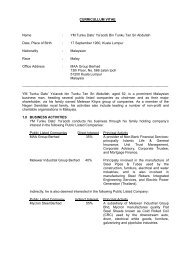

BOARD OF DIRECTORSSeated from left to right :Tunku Dato’ Ya’acob bin Tunku Abdullah(Non-Independent Non-Executive Director)Tunku Dato’ Seri Iskandar bin Tunku Abdullah(Non-Independent Non-Executive Chairman)Azlan bin Abdullah(Executive Director / Chief Executive Officer)Lim Kim Chuan(Non-Independent Non-Executive Director)Standing from right to left:Chan Sang Whye (Resigned, April 2007)(Executive Director / Chief Operating Officer)Dato’ Zulkifly @ Sofi bin Haji Mustapha(Non-Independent Non-Executive Director)Dato’ Abu Talib bin Mohamed(Independent Non-Executive Director)Dato’ Narendrakumar Jasani a/l Chunilai Rugnath(Independent Non-Executive Director)Paul Chan Wan Siew(Independent Non-Executive Director)

SENIOR MANAGEMENT STAFFAzlan bin AbdullahChief Executive OfficerKevin KokVP, OperationsWong Yeap MinVP, FinanceEducation :• BSc (Buss Admin) -Trinity Univ, USA• MBA – Morehead State Univ, USAExperience :• 13 years in senior banking positions withCitibank, United Asian Bank & Bank Of Commerce• 7 years as MD of Precision equipment manufacturer• 6 years in <strong>Steel</strong> IndustryEducation :• ICSA, AUSTRALIAExperience:• 25 years experience in the steel industry• Started in Maruichi in 1983, then was assigned toMycron in 1994.Education :• Fellow - CIMA, UK• Fellow - ACCA,UKExperience :• 8 years KPMG, 10 years Financial Management• 14 years Corporate Planning & General Mgt

OPERATIONS

COMPANY BACKGROUND‣ Attained SIRIM ISO 9001 in 1996.‣ Manufacturer of highest qualityMalaysian CRC.‣ Factory located in Shah Alam.LocationLandBuilt-upCapacityEquipment: Lot 717, Jalan Sungai Rasau,Section 16, 40200 Shah Alam, Selangor: 781,423 sg.ft. (17.94 acres): 307,507 sq.ft.: 15,000 t /mth180,000 t /year: Continuous Pickling LineHitachi 6-High Cold Reduction MillElectrolytic Cleaning LineBatch Annealing FurnaceRecoiling Line

WHAT IS CRC?HOT ROLLED COILS COLD ROLLED COILS DOWN STREAM INDUSTRIESVehicle Parts &BodiesConsumer GoodsElectronicsPipesThick & Rusty <strong>Steel</strong>Sheet (1.7mm to3.5mm thick)Thin & Clean <strong>Steel</strong>Sheet (0.2mm to2.5mm thick)<strong>MYCRON</strong> STEEL<strong>Steel</strong> DrumsOffice & Home Furniture

CRC CUSTOMERSPRODUCT MIX <strong>Steel</strong> Centers Auto & Electrical35% 49,900 t /yrDrum M akers23% 32,800 t /yrP a lm O il,Petroleum<strong>MYCRON</strong> STEELM e le w a r S te e l T u b e sRated Capacity: 180,000 t/yr 17% 24,200 t /yr Furniture &Operating Capacity (on currentElectricalCRC range): 165,000 t/yr Pipe Makers12% 17,100 t /yrC u rre n t P e rio d 17 m o n thProduction : 202,000 t <strong>Steel</strong> GalvanizersAnnual Production : 142,600 t /yr 5% 7,100 t /yrC apac ity U tiliz ation : 86%F u rn itu re M a ke rs4% 5,700 t /yrUnlike long-product steelmanufacturers, Mycron hasMINIMAL exposure to thedomestic Construction Sector.S te e l S tra p p in g s3% 4,300 t /yrOthers1% 1,400 t /yr

RAW MATERIAL SUPPLIERSManufacturing Cost Structure% CostRaw Materials - Hot Rolled Coil (HRC) 87%Manufacturing & Overheads Cost 12%Transportation Cost (Domestic) 1%Manufacturing & Delivery Cost 100%• HRC constitutes 87% of total production cost.• 40% HRC purchased from Mega<strong>Steel</strong> because of import restrictionsimposed by MITI. Mega<strong>Steel</strong> HRC is lower grade quality (i.e. madefrom scrap steel).• 60% HRC imported from JFE, Japan. Imported HRC is higher quality(i.e. made directly from smelted iron ore).• Mega<strong>Steel</strong>’s HRC prices (to CRC manufacturers) are ≈ 5% higherthan international prices. Used to cost substantially more.• Currently almost 100% of CRC output is sold in Malaysia.

CRC MANUFACTURING PROCESSINPUT – HOT ROLLED COILSFromSuppliersHRC steel sheetsarrive in coils.1Pickling BathOUTPUT – COLD ROLLED COILSToCustomers51. HRC rust scales removed in acidbasedContinuous Pickling Line.Cold Roll Mill (C<strong>RM</strong>)25. Finished CRC is inspected,oiled, recoiled & sealed (forrust protection).OUT –Rough orSmooth CRCIN - HRC orRough CRC3. CRC are stacked in aBatch AnnealingFurnace, and heated,for several days, toreturn the mechanicalproperties to the steel.4. Annealed CRC is passedthrough C<strong>RM</strong> again, toeven out any warps in thesteel (Skinpass Process).2. Sheets are passed throughthe Cold Roll Mill andcompressed into thinnersheets (CRC). Process isrepeated until the appropriatethickness is attained.

HOT ROLLED COILS (FROM SUPPLIERS)CONTINUOUS PICKLING LINE - ENTRYCONTINUOUS PICKLING LINE - EXITCOLD REDUCTION MILL (Sheet compression)

ELECTROLYTIC CLEANING LINEH 2 ANNEALING FURNACES (Loading)H 2 ANNEALING FURNACES (Heating)COLD REDUCTION MILL (Skinpass Process)

ELECTROSTATIC OIL COATERRECOILING LINE – Exit Tension ReelPACKINGCRC FINISHED GOODS STORE

FINANCIALS

STEEL PRICE CHART800CRC & HRC INTERNATIONAL PRICE700Since mid-2005 pricescorrected substantially(-US$ 170 /t) as Chinabecame steel exporter.US$ / M T600500400CRCHRCAsianfinancialcrisisSince 2002 pricesincreased sharply due todemand surge by China.Strongpricerecovery.3002001000Stable HRC:CRC spread ≈US$ 100/t19961 9 9 719981 9 9 920002 0 0 1200220032 0 0 420052 0 0 62007HRC manufacturers’ margins are significantly affected by market price fluctuations.CRC manufacturers’ margins are very stable, with HRC:CRC spread ≈ US$ 100/t.HRC price movements are always passed on to CRC customers.

INCOME STATEMENT2003<strong>RM</strong>'000y/e 31 January2004<strong>RM</strong>'0002005<strong>RM</strong>'0002006<strong>RM</strong>'000G ross Revenue ♥ 201, 085 2 6 9 , 577 357, 284 325, 461ΩC ost of Sales (162,743) (231,978) (309,877) (3 3 0 ,9 6 3 )G ross Profit 38,342 3 7 ,5 9 9 4 7 ,4 0 7 (5 ,5 0 2 )O t h er I ncome 1 , 226 796 672 349D istribution C ost (2,682) (1 ,8 9 3 ) (1 ,7 7 7 ) (1 ,3 4 8 )Admin C ost (2,992) (1 ,9 5 0 ) (8 ,7 2 0 ) (5 ,9 1 7 )F Y E 3 0 /6 /0 7<strong>RM</strong>'000482,335(4 3 7 ,5 5 9 )44,7761 ,4 28(2 ,8 4 5 )8,765Finance Cost - ( 1 , 895) ( 1 , 914) ( 3 , 141) ( 3 ,9 87)O ther Expenses - - - -P ro fit B e fo re T a x ♪ 3 3 ,8 9 4 3 2 ,6 5 7 35,668 (15,559)T ax (9, 949) (9, 0 7 9) (9,5 44) 3 , 3 5 9P ro fit Afte r T a x 2 3 ,9 4 5 2 3 ,5 7 8 2 6 ,1 2 4 (12,200)♥ Gross Revenue has grown strongly with the increase in HRC prices.Mycron has passed on the price increase of raw materials to customers.Ω Since mid-2005 (FY 2006), HRC & CRC prices have fallen.♪ PBT has been strong for the past 3 years (avg. <strong>RM</strong> 34 mil /year).♣(1 ,1 6 9 )29,4 37(7 ,6 64)21,773♣ PBT loss of <strong>RM</strong> 15.6 mil, due to write down in inventory values following the fall in internationalHRC prices. Mycron has reduced HRC cost to US$ 445 /MT. This is a one-time loss.

BALANCE SHEET31 JanuaryBALANCE SHEET 2003 2004 20052 0 0 6R M '0 0 0 R M '0 0 0 R M '0 0 0 <strong>RM</strong> '000Fixed Assets 128,304 126,879 127,491 185,334♥D e f erred T ax A sset 7 , 874 0 0 4 , 700D e fe r r e d T a x L ia b ilitie s 0 (1 ,0 0 7 ) (8 ,8 0 2 ) (2 0 ,0 1 0 )Current Assets 108,261 90,247 152,191 139,814Current Liabilities ilitie (9 , 889) (79 , 917) (4 8 , 704) (81 , 817)Net Current Assets 98,372 10,330 103,487 57,997Non Current Liabilities 0 0 0 0NET ASSETS 234, 550 136, 202 222, 176 228, 021Share capital 60,000 60,000 179,000 179,000Share Prem ium Account 14,919 14,919Revaluation Reserve 30, 575Retained Profits 174,550 76,202 28,257 3,527SHAREHOLDERS' FUNDS 234,550 136,202 222,176 228,021♪FYE 30/6/07<strong>RM</strong> '000259,4980(21,749)166,917(9 8 , 563)68,354(58,882)247, 221179,00014,91931, 13422,168247,221♥ Mycron has adopted international Financial Reporting Standards (FRS) for FY 2006,and this has resulted in a fixed asset revaluation surplus of <strong>RM</strong> 30.6mil.♪ Drop in Current Assets due to write-down in value of inventories.

OPERATING MARGINSy/e 31 JanuaryAverage y/e 31Jan2002 2003 2004 2005 2002-2005 2006<strong>RM</strong>'m <strong>RM</strong>'m <strong>RM</strong>'m <strong>RM</strong>'m <strong>RM</strong> mil <strong>RM</strong>'mSales 160. 2 201.11 269.66 357.33 247.0 325.4Operating C ost 131.2 158.0 226.0 308.2 205.8 311.7EB ITD A 29.0 43.1 43.6 49.2 41.2 13.7F YE 3 0 /6 /0 7<strong>RM</strong>'m482.3434.847.5TONNAGE ('0000 0 t) 121. 4 142.22 154.11 154.55 143.11 118.2202.00♣C a p a c ity U tilis a tio n 6 7 % 7 9 % 8 6 % 8 6 % 7 9 % 6 6 %79%Op.C ost (R M /t) 1,081 1,111 1,466 1,994 1,413 2,6372,153EBITDA (R M /t) 239 303 283 318 286 ♦116♥235E B IT D A / S a le s 1 8 .1 % 2 1 .4 % 1 6 .2 % 1 3 .8 % 1 6 .7 % 4 .2 %9.8%♣ Drop in sales tonnage, as customers withholding orders to reduce inventories,in anticipation of further CRC price falls in 2005. Customers inventory levels areat minimum levels, and orders have picked-up since Q1 2006.♥ Lower margin per tonne (<strong>RM</strong> 116 /t) due to Cost of Sales at historic price.With write down in values of inventories at year-end, FY 2007 margins willbetter reflect operating profitability (should be similar to pre-2006 margins).♦ If no major HRC price movements, profits for FY 2007 will return to pre-2006 levels.

DIVIDEND POLICY1.81.6(%) DIVIDEND PAIDas % of PUCPre-IPOpayout180%1 . 41.210.80.60.40.2FYE020% 20% 20% 20%7%DividendPolicyPayoutRatio =25% PAT3.5%0% 4%2000 2001 2002 2003 2004 2005 2006 2007FYE June30, 2007

BUSINESSOUTLOOK

STEEL CONSUMPTION (Long & Flat Products)kg1000900800700600500400300200100Per Capita <strong>Steel</strong> Consum ption - kg/per annum031 30IndoPhilThe Future for989Malaysian <strong>Steel</strong>is Bright.75Viet218Thai294584428pan61079INDONESIAPHILIPPINESVIETNAMTHAILANDM A L A Y S IASINGAPORETAIW ANKOREAJAP ANASEANSource : MISIF 2006• Malaysia consumes 294 kg of steel per capita annually.• As Malaysia’s development continues, demand for steel will grow.• MISIF forecasts long-term demand growth of 6.0% per year.JaAsean

DOMESTIC MARKETMarket Estimated Tonnage♫ Although AP’s are restricted, SUPPLY Share t/year t/monthMalaysia imports 62% of itsCRC needs (mostly high-end Mycron 28% 11% 150,000 12,500quality steel).Orna<strong>Steel</strong> 57% 21% 300,000 25,000Mega<strong>Steel</strong> ♠ 15% 6% 80,000 6,667♥ Of the 38% CRC producedlocally, Mycron supplies 28%,Local 100% 38% ♥ 530,000 44,167Orna 57% & Mega 15%.Imports 62% ♫870,000000 72,500100% 1,400,000 116,667♠ Mega<strong>Steel</strong> Started production Q1 2006Announced Capacity : 1,300,000 , t/yearExpected Production : 200,000 t/year (Mycron opinion)CRC Quality : Low-end CRC. Focused on pipe / tube use.Made from Mega<strong>Steel</strong> HRC (scrap based steel)<strong>MYCRON</strong>’s STRATEGYMycron already producer of high-end quality CRC (for drum, electrical, autocomponent quality). Will move further up-market (i.e. auto bodies, roofing, etc)using higher quality imported HRC, via upgraded facility (ready by April 2008).Mega<strong>Steel</strong> (with support from Orna<strong>Steel</strong> & Mycron) is lobbying MITI to protect thedomestic CRC market, by further restricting CRC imports.HRC is a protected market in Malaysia. CRC will be protected too.

PLANT UPGRADE & EXPANSION• Embarking on plant upgrade and expansion. Capex: <strong>RM</strong> 120m.• Installation of new facilities –Tension Leveller, Skinpass Mill andadditional Annealing equipment. Completion: April 2008.• Upgrade will raise quality of high-end CRC (=better margins).• Capacityincreases from180,000 t/yr to260,000 t/yr(+ 80,000 t /yr)or +45%• Profit After Taxincrease due tothe plantupgrade &expansion isestimated to be<strong>RM</strong> 16.6 mil /yry/e 31 JanuaryUPGRADE P&L2002 2003 2004 2005 2006 FYE 30/6/07TONNAGE ('000 t) 121.4 142.2 154.1 154.5 118.2 202.0EBITDA (<strong>RM</strong> m il) 29.0 43.1 43.6 49.2 13.7 47.5EBITDA (<strong>RM</strong> /t) 239 303 283 318 116 235Average EB ITD A 2002-2005 R M /t 286A v g O p .C o s t (R M /t) 1 ,4 1 3 S a v in g s 4 .0 % 5 7E B IT D A P la n t U pgra d e R M /t 3 4 2Plant Upgrade Additional Output t/yr 80,000Payback (yrs)EBITDA of Plant Upgrade <strong>RM</strong> mil/yr 27.4 4.4PAT after Depn. Interest t & Tax <strong>RM</strong> mil/yr 16.66 72 7.2

SITE PHOTOGRAPHS

SITE PHOTOGRAPHS

INVESTMENT IN PMP GALVANIZERS• Mycron purchased 20% in PMP Galvanizers Sdn Bhd.• PMP is subsidiary of Multi Resources Holdings Sdn Bhd, (inKuching, Sarawak) which manufactures roofing products likeroofing truss, colour coating and roofing profiles, for export toAustralia, New Zealand, Middle East and South East Asia.• PMP is in the midst of installing a <strong>RM</strong>85 million CRCgalvanizing plant (Capacity = 150,000 t/yr).• Commissioning done in late January 2007.• PMP has signed an off-take agreement to buy up to 75,000 t/yrof CRC upon completion of Mycron’s plant upgrade andexpansion (Expanded Plant capacity= 80,000 t/yr).• Win-win for both :PMP has a regular supply of high quality CRC.Mycron is guaranteed an off-take for the added capacity.

<strong>MYCRON</strong> STEELPMPG CONTINUOUS GALVANIZING LINEPayoff Reels with one coil finishing& another waiting to be fed in.Exit Looper

<strong>MYCRON</strong> STEELPMPG CONTINUOUS GALVANIZING LINEEntry Looper with coils being accumulated for continuous processing

OFFTAKE AGREEMENT WITHBLUESCOPE STEEL• Signed on July 31, 2007.• Bluescope will buy from Mycron up to60,000t 000t by the 3 rd year from the dateof the agreement.• HRC to be sourced from BluescopeAustralia.• Outside of the 60:40 ruling.

TECHNICAL SERVICE AGREEMENTS WITH JFEJAPAN• First one was signed in April 2006.• JFE to provide technical assistance in producing thin-gaugeCRC (

SHARE VALUATION

<strong>MYCRON</strong> SHARE PRICE MOVEMENT• Mycron’s share price has performed poorly compared to the CI.• Reasons :Fall in HRC prices.Poor construction sector performance negative out-look for steel sector.Post IPO stock over-hang after MIG 1:4 distribution in-specie of Mycron shares.

VALUATION OFLISTED STEEL COMPANIESComp a n ie sShareP EPrice(June 30 2007)<strong>RM</strong> psRatioAnn Joo R esources 3.78 11.0AISB 0.60 -Choo Bee Metal 2.38 7.7F A C B In d 0 .8 5 -H iap Teck 2.10 21.3K insteel 6 .2 5 1 .7Ornasteel 1.65 8.5M ycron <strong>Steel</strong> 0.80 5.8AVERAGE 10.04The PE ratio for listed steelcompanies is relatively low at10.04x compared to theIndustrial Sector PE of 17.8x.Valuations are slightly downbecause of fall in HRC prices(one-time effect).But main share pricesuppression caused by theslow down in the domesticconstruction sector.Under 9 th Malaysia Planconstruction industry willeventually pick-up.PE for steel sector shouldeventually go above 10.04x.

VALUE OF <strong>MYCRON</strong> SHARES<strong>Steel</strong> companies are affected by theslow down in the construction sector& have low PE ratios (10.04x).Mycron has a PE ratio (5.8x) lowerthan the steel industry.But Mycron has almost ZEROexposure to the construction sector.Mycron supplies to the electronic,auto, palm oil, petroleum & furnitureindustries.Mycron’s valuation should be similarto these industries (PE≈14x).Mycron’s fair value : <strong>RM</strong> 1.90 psWith expansion, value :<strong>RM</strong> 3.19 ps<strong>MYCRON</strong>y/e 31 JanuaryExpansionPROFITS 2003 2004 2005 2006 Profit<strong>RM</strong>'m <strong>RM</strong>'m <strong>RM</strong>'m <strong>RM</strong>'m <strong>RM</strong>'mProfit After Tax 23.9 23.6 26.1 -12.2 16.6Average PAT (maintainable) 24.5 24.541.1Paid Up Capital (mil shares) 179 179EPS (maintainable) 0.137 0.230<strong>RM</strong> ps PER <strong>RM</strong> ps4.4 0.605.7 0.78M a rk e t p ric e 0 .8 0 5 .8 0 .8 07.3 1.008.0 1.109.5 1.30N TA value 1.33 9.7 1.33IP O p ric e 1 .4 0 1 0 .2 1 .4 010.9 1 .5 012.0 1.6512.4 1.7013.1 1.80End U ser Sector ( PE 14x) 1 3 .9 1 .9 014.6 2 .0 015.3 2.1016.1 2.20Industrial Sector ( PE 17x) 1 6 .8 2 .3 017.5 2.40<strong>RM</strong> ps1.011.311.341.681.852.182.232.352 .5 22.772.853.023.193 .3 63.533.693.864.03

SUMMARY

SUMMARY• Mycron has been profitable since it started operations in 1990.• Mycron is manufacturer actu of highest grade CRC C in Malaysia.ays a• Malaysia imports 60% of its CRC needs.• International market price for HRC has been volatile. But spreadbetween CRC & HRC has always been stable (≈ US$ 100 /t).• CRC manufacturers always pass through HRC price changes toits customers. The profit margin for CRC manufacturers is stable.• In Malaysia, the spread between HRC and CRC is also veryhealthy (> US$ 100 /t).• Mycron enjoys good CRC:HRC spreads, because of:• Mycron’s 17 year client relations (1 st M’sian manufacturer).• Mycron’s premium high-end CRC steel output.• Mycron’s strong reputation for quality.

SUMMARY• Mega<strong>Steel</strong> entering CRC market with low-end quality steel.• Mycron is focused on high-end CRC C steel.• Technical Agreements with JFE will enable Mycron topenetrate the roofing and automobile sectors.• Mycron is upgrading facility to produce even higher-qualityh CRC. Expansion completion : April 2008.• Upgraded facility will also increase capacity by 45%(=80,000 000 t/yr).• PMP Galvanizers Sdn Bhd has signed off-take agreementfor up to 75,000 t/yr of the additional CRC.• The additional 80,000 t/yr capacity, will contribute <strong>RM</strong>27.4 mil EBITDA or <strong>RM</strong> 16.6 mil PAT.Thi t S b t ti l I i P fit Aft T• This represents a Substantial Increase in Profit After Tax,and should be a RE-RATING FACTOR for Mycron.

SUMMARY• Mycron’s share price (at <strong>RM</strong> 0.80 per share) is trading below itsbook value (NTA=<strong>RM</strong> 1.33 per share).• Wrongly classified with long-product <strong>Steel</strong> counters, which wereaffected by the slow down in the domestic construction sector.Mycron has almost zero exposure to construction sector.• Mycron’s PE ratio should be the same as its clients (electronics,auto, furniture, and drum for petroleum & palm oil industries)with PE=14x• Mycron’s share price should be:EPS = <strong>RM</strong> 0.137 x PE 14 = <strong>RM</strong> 1.90 ps (to match customers)EPS = <strong>RM</strong> 0.230 x PE 14 = <strong>RM</strong> 3.19 ps (with plant expansion)Once reclassified, the up-side for Mycron’sSTRONGshare price is tremendous…. + 299%BUY

THANK YOU