A6 Series Brochure

A6 Series Brochure

A6 Series Brochure

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

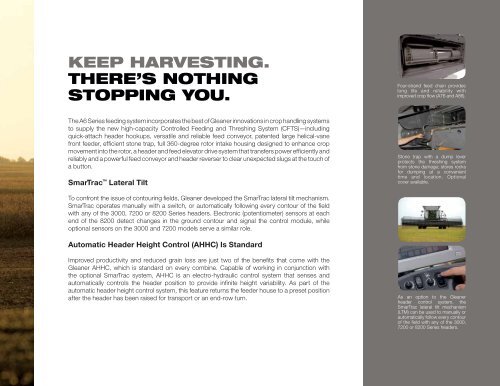

KEEP HARVESTING.THERE’S NOTHINGSTOPPING YOU.Four-strand feed chain provideslong life and reliability withimproved crop fl ow (A76 and A86).The <strong>A6</strong> <strong>Series</strong> feeding system incorporates the best of Gleaner innovations in crop handling systemsto supply the new high-capacity Controlled Feeding and Threshing System (CFTS)—includingquick-attach header hookups, versatile and reliable feed conveyor, patented large helical-vanefront feeder, effi cient stone trap, full 360-degree rotor intake housing designed to enhance cropmovement into the rotor, a header and feed elevator drive system that transfers power effi ciently andreliably and a powerful feed conveyor and header reverser to clear unexpected slugs at the touch ofa button.SmarTrac Lateral TiltStone trap with a dump leverprotects the threshing systemfrom stone damage; stores rocksfor dumping at a convenienttime and location. Optionalcover available.To confront the issue of contouring fi elds, Gleaner developed the SmarTrac lateral tilt mechanism.SmarTrac operates manually with a switch, or automatically following every contour of the fi eldwith any of the 3000, 7200 or 8200 <strong>Series</strong> headers. Electronic (potentiometer) sensors at eachend of the 8200 detect changes in the ground contour and signal the control module, whileoptional sensors on the 3000 and 7200 models serve a similar role.Automatic Header Height Control (AHHC) Is StandardImproved productivity and reduced grain loss are just two of the benefi ts that come with theGleaner AHHC, which is standard on every combine. Capable of working in conjunction withthe optional SmarTrac system, AHHC is an electro-hydraulic control system that senses andautomatically controls the header position to provide infi nite height variability. As part of theautomatic header height control system, this feature returns the feeder house to a preset positionafter the header has been raised for transport or an end-row turn.As an option to the Gleanerheader control system, theSmarTrac lateral tilt mechanism(LTM) can be used to manually orautomatically follow every contourof the fi eld with any of the 3000,7200 or 8200 <strong>Series</strong> headers.