A6 Series Brochure

A6 Series Brochure

A6 Series Brochure

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

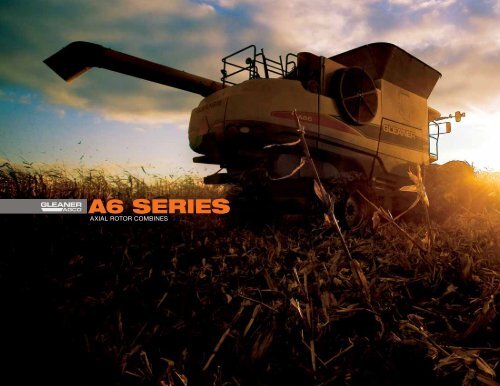

<strong>A6</strong> SERIESAXIAL ROTOR COMBINES

WE ARE• the last effort between a ready crop and hard work’s reward.• a friend, ally and partner no matter what.• the wisdom of decades and the bringer of new opportunities.BUILT WITH THE FARMER IN MIND.

BUILT WITHMEL IN MINDGossen Ag means business when it comes to combines.The Gossen fl eet of nine Gleaners will run up and downmiddle America custom harvesting wheat, milo, corn andsoybeans. They expect only the highest performance fromtheir combines. They push their machines to the very limit.They rely on no one but Gleaner.Mel GossenGossen Ag Custom HarvestersCORN, OKLAHOMA

BUILT WITH THESTRASSERS IN MINDThe Strassers are a family of farmers in western Kansas.They are a family that expects their machines to be goodpartners in farming. They rely on well-built machines,unmatched dealer service and the simplicity that only aGleaner can provide.The StrassersKALVESTA, KANSAS

BUILT WITHRICK IN MINDRick Hurley farms outside of Curlew, Iowa where he bringsin corn crops that are nearly unimaginable. Rick has highexpectations from his Gleaner. Rick and his dealer are bothup to every challenge the crop can throw at them.Rick HurleyCURLEW, IOWA

BUILT WITHYOU IN MINDSince inventing the fi rst self-propelled combine in 1923, wehave created the innovations and machines that farmerswant and need.Today, we produce the most innovative, best built andeasiest to maintain combines available. For farmers whocannot and will not tolerate lags in performance, downtimein the fi eld, less than optimal cleaning, slope sensitivityor anything less than the sheer design to keep you goingstrong each hour of every day, there is no better combinethan a Gleaner.

1BUILT WITH THEFARMER IN MINDMEANS KNOWINGWHAT’S ON THEFARMER’S MIND.23With every new series of combine we make, we try to make the improvementsthat help make your job easier and more profi table. The <strong>A6</strong> <strong>Series</strong> has several newupdates for more effi cient and enjoyable harvesting.New grain handling system on <strong>A6</strong>6 (Class VI) and A76 (Class VII) featuresDirect Flow unloading system. Utilizing only two augers, versus three oncompetitive models, reduces power requirement when unloading, machinerywear and cracking of grain.1 New 12” (305 mm) bin fi ll auger for increased grain handling capacity onall models.2 New optional 350 bushel (12,334 L) grain bin on A76 Model.New cab with ISOBUS electronics and virtual terminal with programmabilityupto 20 different crop settings can be stored.Automatic one-button recall of all crop setting functions.Reduced B pillar for improved visibility.3 New armrest controls with integrated command arm mounted C2000 virtualterminal with optional video capability.4 Optional leather heated seat (cloth seat standard).New handsome styling on <strong>A6</strong>6, A76 and A86 models.5 New cab roof lighting package for better night vision.6 New service lights for engine compartment, left and right side of combine.7 Easier servicing with integrated grease banks.New heavy duty adjustable axle and rear wheel assist (RWA) option on A76with larger steering tire options available.4567

THE HEART & SOULOF A GLEANERThe <strong>A6</strong> <strong>Series</strong> axial-rotor line of Gleaner combines come from our familiartradition of innovation and performance. Our <strong>A6</strong> line features some of thehighest capacity machines ever built coupled with powerful technology.When the heart of your operation is simply getting the most crop throughthe machine, Gleaner <strong>A6</strong> <strong>Series</strong> combines are up to every task.ModelEnginePowerhp (kW)PowerBulgehp (kW)Grain Tank bu(L)Unloadingbu/sec(L /s)<strong>A6</strong>6 300 (224) 321 (239) 300 (10,570) 4.5 (159)A76 350 (261) 375 (280) 300 (10,570) 4.5 (159)Optional 350 (12,334)A86 425 (317) 459 (342) 350 (12,334) 4.5 (159)Extended bar rotorCommand-arm mounted Console IIComforTech II cabRotor driveRotor gearboxResidue disposalChaff spreaderGrain panConcavesTransverse fanExclusive helical-vane front feederHeavy-duty final driveReverserStone trapVariable-speed header driveHeavy-duty adjustable or RWA rear axleFour-strand feed chain on all A76 and A86 ModelsWide feeder houseFactory-installed Auto-Lube optionFactory-installed Auto-Guideoption with remote antenna on all <strong>A6</strong> ModelsNew cab roof headliner123456789101112131415161718192021

2021345216171319157181412101189 16

KEEP HARVESTING.THERE’S NOTHINGSTOPPING YOU.Four-strand feed chain provideslong life and reliability withimproved crop fl ow (A76 and A86).The <strong>A6</strong> <strong>Series</strong> feeding system incorporates the best of Gleaner innovations in crop handling systemsto supply the new high-capacity Controlled Feeding and Threshing System (CFTS)—includingquick-attach header hookups, versatile and reliable feed conveyor, patented large helical-vanefront feeder, effi cient stone trap, full 360-degree rotor intake housing designed to enhance cropmovement into the rotor, a header and feed elevator drive system that transfers power effi ciently andreliably and a powerful feed conveyor and header reverser to clear unexpected slugs at the touch ofa button.SmarTrac Lateral TiltStone trap with a dump leverprotects the threshing systemfrom stone damage; stores rocksfor dumping at a convenienttime and location. Optionalcover available.To confront the issue of contouring fi elds, Gleaner developed the SmarTrac lateral tilt mechanism.SmarTrac operates manually with a switch, or automatically following every contour of the fi eldwith any of the 3000, 7200 or 8200 <strong>Series</strong> headers. Electronic (potentiometer) sensors at eachend of the 8200 detect changes in the ground contour and signal the control module, whileoptional sensors on the 3000 and 7200 models serve a similar role.Automatic Header Height Control (AHHC) Is StandardImproved productivity and reduced grain loss are just two of the benefi ts that come with theGleaner AHHC, which is standard on every combine. Capable of working in conjunction withthe optional SmarTrac system, AHHC is an electro-hydraulic control system that senses andautomatically controls the header position to provide infi nite height variability. As part of theautomatic header height control system, this feature returns the feeder house to a preset positionafter the header has been raised for transport or an end-row turn.As an option to the Gleanerheader control system, theSmarTrac lateral tilt mechanism(LTM) can be used to manually orautomatically follow every contourof the fi eld with any of the 3000,7200 or 8200 <strong>Series</strong> headers.

BETTER AND MOREEFFICIENT THRESHINGAND SEPARATINGThe Gleaner <strong>A6</strong> <strong>Series</strong> rotor applies a smart design to the critical intake, threshing, separation anddischarge tasks involved in the high-capacity rotary threshing system. By threshing in multiple, controlledpasses, gently permitting the grain to fall through the concaves in combination with centrifugal forceover the separator grates, the rotor’s harvesting action improves crop quality, reduces losses and lowersoperating costs.Perhaps the single biggest issue that faces axial combines is the bottleneck created when the materialshifts direction as it moves from the feeder house into the rotor. To solve this problem, a patented18-inch (457 mm) helical-vane feeder smoothly accelerates the crop off the feed chain and feedsthe rotor on a capacity-boosting full 360 degrees of intake. Extra heavy edge-hardened fl ightingfeeds the crop uniformly into the thresher. The result is Controlled Threshing and Feedingthat reduces the bottlenecks that plague so many of our competitor’s machines.The <strong>A6</strong> <strong>Series</strong> rotor is the longest in the industry at 140 inches (3,556 mm)and uses six rows of rasp bars in the threshing area and three rows in theseparator area. The rotor also features twenty-one rotor knives and anadditional three rows of fi ve separator paddles.The rotor is driven by a constant-speed hydrostatic system thatdraws its power from a hydraulic pump driven directly off the engine.Full-pressure hydrostatic rotor drive maintains speed even whenengine rpm drop. It reverses at the fl ip of an in-cab switch.

The rotor is powered by a hydrostatic systemfully regulated by electronic control of oil fl ow androtor speed. A three-speed heavy-duty planetarygearbox drives the rotor on the A86.160 degrees of concave wrap and exclusivepivoting clearance adjustment allow forbetter distribution on the A86.The <strong>A6</strong> rotor’s patented direct discharge throwsmaterial directly out of the thresher, eliminatingthe need for discharge beaters. The simple butadvanced design minimizes unnecessary strawdamage, as well as eliminating horsepowerrobbingdrives, shafts and belts.The patented intake uses edge-hardened fl ightingto feed crop into the threshing system positivelyyet nonaggressively. Material moves effi ciently withminimal damage to grain due to the new extendedbar design.THE GRAIN-CLEANING SYSTEMUnlike systems that push or pull material into therotor, the Controlled Feeding and Threshing System(CFTS) maintains full control of the crop mat fromthe wide feeder house through the crop-hungryrotor. Thanks to helical-vane feeding, there's nopinching, bunching or twisting that can negativelyaffect threshing performance.Grain pan with sloped cascade design takes advantage of the full cleaning area eliminating the use of augersfound on competitive machines.

CLEANER GRAIN. IT’S TIMEYOU GOT PAID WHAT YOURCROP IS WORTH.The Gleaner <strong>A6</strong> <strong>Series</strong> brings together a high-output transverse cleaning fan and closed pressurized shoe assembly to achieve the maximumairfl ow for maximum grain cleaning. Oriented transverse to the axis of the machine, the Transverse Flow fan brings air into the cleaningsystem straight-on, rather than at a right angle. Straight-through fan fl ow reduces cavitation and turbulence, increases uniformity of cleaningacross the entire cleaning shoe. 8,296 in 2 (5.35 m 2 ) of wire and vane-type chaffer and sieve cleaning area in the A76 and A86 models comeequipped with a single locking adjustment each. These adjustments create a versatile sieve confi guration that gives excellent capacity andcleaning characteristics, allowing the shoe to fi t a wide range of crops quickly and easily.1 Falling grain from the pan gets an initial cleaning by passing over a cascade chaffer pan supplied with a curtain of air from thecleaning fan.2 The cascade pan and fi ngers place crop on the chaffer front, ensuring the chaffer’s entire width is put to use, maximizing itsseparation capabilities.3 System-pressurizing air fl ows straight through the transverse cleaning fan, not at a right angle. The straight-through fl ow of thefan reduces cavitation and turbulence, resulting in even cleaning across the entire cleaning shoe.4 The fan drive can be placed into one of two different ranges allowing the operator to adjust infi nitely the cleaning fan speed fromthe cab console.5 Standard-equipment wire and vane-type chaffer and sieve accomplish fi nal cleaning. The chaffer and the lower sieve are equippedwith a single locking adjustment each.6 A large returns system delivers unthreshed crop back to the rotor for reprocessing to reduce grain loss and improve grain samplequality without a loss of throughput.

152436A large-capacity clean-grainelevator moves the grain to thegrain tank. Easy to service withthe bottom adjustment.The electric chaffer and sieve adjustment can becontrolled from the ground through the controlcenter on the left, rear side of combine or from theC2000 virtual terminal in the cab.Monitored by in-cab digital readout, fan speedcan be adjusted from the operator’s console viaelectric linear actuator for maximum performanceand productivity.Grain loss sensors keep track and alertthe operator.13-in. (330 mm) transverse fl owfan in A86 provides high volumeand low pressure air supply. 11-in.(279 mm) fan on <strong>A6</strong>6 and A76.

350 BUSHELSIN 88 SECONDSThe unique DirectFlow unloader on all Gleaner <strong>A6</strong> <strong>Series</strong> accomplishes thatmarvel by combining the convenience of a turret unloader with the inherentsimplicity of the Gleaner swivel design. What looks like a standard turret augerenters and crosses the entire tank width at a single, gentle angle, whereits discharge auger is fed by a large fl oor auger, driven by a close-coupledchain. No gearboxes. No open drives. No vertical augers. Its 171-inch (4.34 m)discharge height and 292-inch (7.40 m) reach from center means it swings outover carts—not into them—and forward into your view without worry of hittingthe tank. When done, it folds back like a grain cart auger, atop a grain-savingcatch basin.On the <strong>A6</strong>6 and A76, the unloading time is 75 seconds. The A76 with optional350 bushel (12,334 L) grain bin and the A86 unload in 88 seconds.Class VIII Unloading ComparisonHow much time do you invest to fi ll ten 1,000-bushel grain trucks?ModelGrainTank(bu)AverageUnloadingRate (bu/sec)Time PerUnloadingCycle (sec)UnloadingCyclesTotalTimeInvested(min)Gleaner A86 350 4.0 88 29 42.5JD 9870 STS 300 3.0 100 33 55.0CIH 8120 350 3.2 117 29 56.5NH CR9070 350 3.0 117 29 56.5Combined with the other design features of the renowned, reliable and effi cientGleaner grain-handling system—high-capacity clean-grain auger, large andheavy returns system and massive 300 bushel (10,570 L) on the <strong>A6</strong>6 and A76-and 350 bushel (12,334 L)-capacity tank optional on the A76 and standard onthe A86.Exclusive <strong>A6</strong> <strong>Series</strong> DirectFlow Unloading System15-inch (381 mm)Unloader Auger12-inch (305 mm) Cross Auger

BETTER RESIDUEMANAGEMENT.BECAUSE EVERY PARTOF THE CROP COUNTS.The straw chopper is mounted to the combineon a rail system which allows movementbackward for direct discharge with the use ofthe header latching wrench.Today’s cropping conditions have evolved toward no-till and minimum-till with increasedfocus on residue management and higher relative value of material other than grain (MOG)as a marketable cash crop in itself.Whether factory- or fi eld-installed, our residue-disposal choices will fi t a wide varietyof needs, from spreading the aftermath as thinly and uniformly as possible for betterrecapture of nutrients, to dropping it smoothly behind in a 50-inch (1,270 mm) windrow ofunchopped, undamaged material ideally suited to make the highest-quality baled bedding orfeed forage.For extra heavy chaff spreading, an optional chaff spreader is available with two hydraulicdrivenimpellers to provide extra wide distribution.No need to chop the straw? Use the dualdisc spreader to distribute material evenly onthe fi eld. The discs can be easily removed ifno spreading is required.The air-assisted chaff spreader on the <strong>A6</strong><strong>Series</strong> is integrated into the combine’s design,not added on. Gas-charged cylinders pivotthe entire assembly to the storage-serviceposition, allowing access to rear of combine.

EASY TO RUN.EASY TO KEEP RUNNING.The <strong>A6</strong>6, A76 and A86 not only use horsepower more effi ciently, but are easier and quickerto service and maintain. The cleaning fan uses the only variable-speed belt and pulley on theentire combine. As few as twelve main drive belts (thirteen on the A76 and A86) - that’s 36%fewer than the competition, and three drive chains are required to power the entire machine- which is 62% fewer than the competition, and only six augers - 50% fewer than some of ourcompetitors. This means less wear, service, expense and downtime.A rotary screen, which ishydraulically driven for improvedreliability, ensures constant andeven airfl ow to the cooling system.The screen and cooler bothswing out of the way for easy andquick cleaning.A single ladder provideseasy access to the engine,fi lters and grain tank.ModelWorkingBeltsDrive Chains Gearboxes AugersGleaner <strong>A6</strong>6 12 3 2 6Gleaner A76 & A86 13 3 2 6A switch is provided to easilydisconnect the batteries forcombine storage.The optional Auto-Lubesystem simplifi es evenmore tasks by automaticallylubricating 80% of all greaseservice areas.Wide concave and separatorgrate inspection door allow forAccessibility to quick service checkups. points isquick and easy thanks to springloadedidlers that automaticallytension drive belts.

MakeModelGENERALGleaner<strong>A6</strong>6GleanerA76GleanerA86Class size VI VII VIIIFEEDING SYSTEMChain size #557 #557 #557Variable speed drive Available Available AvailableFeed reverser Electro-hydraulic Electro-hydraulic Electro-hydraulicHousing width in. (mm) 44.1 (1,121) 55.4 (1,408) 55.4 (1,408)Lateral tilt Optional Optional OptionalTHRESHING /SEPARATION SYSTEMSystem Axial rotor Axial rotor Axial rotorConcave type Open, 7 sections Open, 7 sections Open, 9 sectionsRock protection Stone trap Stone trap Stone trapThreshing bars Hardened Hardened HardenedDiameter in. (mm) 27.5 (700) 27.5 (700) 31.5 (800)Length in. (mm) 140 (3,556) 140 (3,556) 140 (3,556)Drive / speed control Hydrostatic Hydrostatic HydrostaticSpeed, low-range rpm 175 - 746 175 - 746 200 - 440Speed, mid-range rpm NA NA 200 - 789Speed, high-range rpm 175 - 970 175 - 970 200 - 1,040Concave / grate area in 2 (m 2 ) 2,205 (1.42) 2,205 (1.42) 2,721 (1.75)Separating area in 2 (m 2 ) 2,241 (1.45) 2,241 (1.45) 2,400 (1.54)CLEANING SYSTEMCleaning stages 2 2 2Chaffer area in 2 (m 2 ) 3,636 (2.34) 4,426 (2.86) 4,426 (2.86)Sieve area in 2 (m 2 ) 3,054 (1.97) 3,783 (2.44) 3,783 (2.44)Total area in 2 (m 2 ) 6,768 (4.36) 8,296 (5.35) 8,296 (5.35)Cleaning fan Transverse Transverse TransverseSpeed rpm 590 - 1,350 590 - 1,350 500 - 1,350Diameter in. (mm) 11 (279) 11 (279) 13 (330)GRAIN-HANDLING SYSTEMTank capacity bu (L) 300 (10,570) 300 (10,570)Optional 350 (12,333)350 (12,333)Unloading AugerDiameter in. (mm) 15 (381) 15 (381) 15 (381)Unload rates bu / sec (L /s) 4.5 (159)* 4.5 (159)* 4.5 (159)*Length from centerline in. (m) 293 (7.40) 293 (7.40) 293 (7.40)Discharge height in. (m) 171 (4.34) 171 (4.34) 171 (4.34)Clearance height in. (m) 161 (4.07) 161 (4.07) 161 (4.07)MakeModelCROP RESIDUE DISPOSALGleaner<strong>A6</strong>6GleanerA76GleanerA86Chopper 2 speed 2 speed 2 speedStraw spreader 2 speed 2 speed 2 speedHydraulic chaff spreader Optional Optional OptionalENGINEModel AGCO 84CTA AGCO 84CTA CAT C13 ACERTDisplacement in 3 (L) 513 (8.4) 513 (8.4) 763 (12.5)No. of cylinders 6 / inline 6 / inline 6 / inlineHP @ 2,100 rpm SAE (kW) 300 (223) 350 (261) 425 (317)Fuel tank capacity gal (L) 160 (605) 160 (605) 230 (870)DRIVE /PROPULSION SYSTEMHydrostatic transmission 4 speed 4 speed 4 speedFinal drive type Spur gear S-41 Spur gear S-41 Spur gear S-41Tread width in. (m) 120 / 145 (3.05 / 3.68) 120 /145 (3.05 / 3.68) 120 /145 (3.05 / 3.68)Steering AxleTread width 2WD in. (m) 119 / 143 (3.02 / 3.65) 119 / 143 (3.02 / 3.65) 119 / 143 (3.02 / 3.65)Tread width RWA in. (m) 121 / 145 (3.07 / 3.68) 121 / 145 (3.07 / 3.68) 121 / 145 (3.07 / 3.68)Steering type Dual cylinder Dual cylinder Dual cylinderTurning radius in. (m) 253 (6.43) 253 (6.43) 253 (6.43)HYDRAULIC SYSTEMHydraulic pump Gear Gear GearControl valve Electro-hydraulic Electro-hydraulic Electro-hydraulicTank capacity gal (L) 9.9 (36.5) 9.9 (36.5) 24 (90.8)CAB AND CONTROLSSeat Luxury / air ride Luxury / air ride Luxury / air rideSteering wheel Tilt / telescope Tilt / telescope Tilt / telescopeControls Right hand console Right hand console Right hand consoleInterior volume ft 3 (m 3 ) 121.4 (3.44) 121.4 (3.44) 121.4 (3.44)Glass area ft 3 (m 3 ) 61.2 (5.69) 61.2 (5.69) 61.2 (5.69)Field lights 12 12 12DIMENSIONSTransport height in. (m) 147 (3.73) 147 (3.73) 147 (3.73)Length w/o header in. (m) 392 (9.95) 392 (9.95) 392 (9.95)Wheelbase in. (m) 146 (3.71) 146 (3.71) 146 (3.71)Weight with tires lb (kg) 28,000 (12,701) 29,597 (13,425) 37,700 (17,101)Ground clearance in. (mm) 18.6 (480) 18.6 (480) 18.6 (480)* Per ISO 5687

WORK THIS TOUGHNEVER SEEMED SO EASY.While harvest is an exciting time, it can also be a grueling effort. The Gleaner ComforTech II cab andcontrols put comfort and convenience to work to improve the effi ciency of every task and every operator.In the center is an adjustable air-ride seat with armrests that positions you within an easy-to-use and effi cientlayout of the control and monitoring system. An effective, automatic, climate-control system, rounded visorroof and tinted glass shield out the elements while still giving your full view. More than 120 ft 3 (3.4 m 3 ) of cabspace accessed by a 40.5-inch (1,028 mm) door, plus 61.2 in 2 (5.8 m 2 ) of glass. A large service door oppositethe entry makes access to the console quick and convenient, while a large rear cab window gives you acomplete view into the grain tank.Measure. Manage. Move Ahead. Fieldstar II SystemsSpoil yourself with our newoptional premium sound systemwhich includes AM/FM radio, CDplayer, satellite-ready, weatherband and MP3 player so you canlisten to your own music.Add-on performance-data analysis leaves too much to chance under today’s demanding farmingconditions. That’s why all Gleaner combines now come with integrated Fieldstar ® II yield-monitoringsystems as standard equipment. Fieldstar II uses yield and moisture sensors, global positioning and theAdvanced Technology Solutions Console II to track yield data across terrains.New instructor seat with foldablefeature with additional cup holdersand a storage area.The postage-stamp-sized SDcard slot incorporated into theConsole II with Fieldstar IImakes data transfer to theoffi ce system quick, unclutteredand easy.Advanced Technology Solutionssoftware allows the operatorto create maps of any georeferenceddata.The unique C2000 virtual terminalcolor display incorporatestouch-screen fl exibility. Fullyprogrammable, it is transferableto other Fieldstar II-compatibleequipment.The automatic climate controlallows the operator to select adesirable comfort temperatureand the system will maintainthis temperature no matter howcold or hot it's outside the cab.The system includes three highvolume fi lters and eleven outletsfor optimum comfort.

Advanced Technology Solutions Yield Sensor II features:• Low profi le. No need to remove the sensor when folding the tank extensions.• Temperature-compensated load cell and full-width impact target reduce recalibration demands.Single-point with excellent accuracy.• 4X+ resolution in the load cell increases accuracy in light and low-yield crops.• Horizontal mount for fewer slope-induced errors.• Corrosion-resistant stainless steel impact target on high-quality plastic add to long service life.Other ATS features that bring precision agriculture performance to your Gleaner combine include:• WAAS GPS antenna pinpoints fi eld location to submeter accuracy.• Unique slim-line Console II incorporates color-display touch-screen technology and a securedigital (SD) card slot for transferring data and console programs.• Available Advanced Technology Solutions software for farm offi ce personal computers allowsyou to make maps of yield data, moisture level, fuel consumption, wheel slippage and otherrecorded data.Satellite-Assisted SteeringThe AE50-award-winning YieldSensor II measures the massof grain flowing through thegrain elevator.Gleaner offers a satellite-assisted steering system which increases the productivity of your combine whilereducing unwanted overlaps or skips. The equipment is fully transferable to other AGCO Auto-GuideReady equipment and is easy to learn and use. Varying accuracy levels are available with the fee-freeWAAS correction signal with a dynamic accuracy of 10 inches (25 cm) or advance to the high-precisionlocal-base RTK system that delivers an amazing 0.8 inch (2 cm) of dynamic accuracy.The moisture sensor providesinstant crop moisture readings.Auto-Guide is easily controlled from the Console IItouch-screen color display.The Auto-Guide TopDock is a compact all-inoneunit with 6-axis gyro for increased accuracy. Aremote antenna is also included to receive signalsin extreme northern areas of North America.

Dual centrally supported wetcylinder liners endure lessliner vibration, eliminating linercavitation that typically shortenscylinder life.1235647123456724 valves (4 per cylinder)2 rocker arms per cylinderCentral injector with 8 holesElectric fuel pumpAutomatic electric preheaterin manifoldCommon-rail injectionCANBus electronics

BUILT WITH THE POWERTO GET IT DONE RIGHT.The Gleaner combine’s large high-torque, split hydrostatic drive unit coupled to a four-speed transmission and heavy-duty fi nal drivesprovides ultimate power and reliability. The rear adjustable steering axle and factory- or fi eld-installed rear wheel assist (RWA) keep thecombine moving through the soft fi eld conditions. Transmission and fi nal drives feature increased gear reduction for a total 28.5 percentincrease in tractive effort for performance on hilly terrain without sacrifi cing torque or transport speed.Pushing all Gleaner Class VI and VII combines, you’ll fi nd a dependable power and easy-to-service AGCO 84CTA liquid-cooled turbo dieselengine. Effi cient and high-torquing, the engine’s low maintenance and good fuel economy come in addition to deep power reserves: from300 hp (224 kW) in the <strong>A6</strong>6 up to 350 hp (261 kW) to drive the A76; with power bulge at 1,900 rpm, that jumps to 321 hp (238 kW) and 375hp (280 kW), respectively. The engine’s rear mount distributes weight better for less noise and vibration, plus better accessibility for serviceand maintenance.AGCO 84CTA Engine Features• Four-valve-per-cylinder cross-fl ow head permits our engineers to center the injector over the piston, improving fuel/air mixing tobetter control emissions and fuel consumption.• Bosch common-rail fuel injection system takes its commands from the EEM3 electronic engine management software for precise,faster response and more power per gallon of diesel.• Three-ring pistons seal tight for effi ciency and better oil control.• Lightweight, big-end connecting rods’ facture-split production process leaves a rough-edge at the face to improve holding powerand durability while minimizing vibration.• Intercooling and exhaust gas recirculation make the AGCO 84CTA fully Tier III-compliant.• Large polyethylene fuel tank, protected by in-line canister-style separators, ensures an adequate supply of clean fuel to feedthe system.• 20,000 psi (1,400 bar) common-rail pressure• Three-stage pilot injection• Reduced noise level• Automatic fuel temperature compensationModel Engine Rated Powerhp (kW)Power Bulgehp (kW)<strong>A6</strong>6 AGCO 84CTA 300 (224) 321 (238)A76 AGCO 84CTA 350 (261) 375 (280)A86 C13 ACERT 425 (317) 459 (342)

THE SYSTEM. WORK BETTER.WORK TOGETHER.We believe harvesting is a system, changing from farm to farm, region to region. With that philosophy, we’re not chainedto any particular technology. Our commitment is to give you and your dealer the choice of several header options to suityour needs while getting the job done right.Gleaner headers have been redesigned from the ground up with the specifi c purpose of starting the controlled fl ow of cropmaterial before it reaches the feed elevator. At the same time, while recognizing the importance of speed and convenience.Today’s Gleaner headers now feature single-lever, multi-coupler connections that get you on and off, quickly.3000 <strong>Series</strong> Corn HeadsAll electrical and hydraulicconnections are included in thesingle-point multicoupler forquick and clean hookup.The 3000 <strong>Series</strong> corn heads remain the industry’s lowest-angle cornheads, at only 21.5 degrees. Dividers slide under downed stalksand gently straighten for fast, easy harvesting, with less damage.Standard adjustable stripper plates are electrically controlled incab.All-new knife roll option is available for prebreakup of BT cornas a fi eld-installed option.SizeRow Spacing6 Rows 30" (762 mm) - 36" (914 mm)8 Rows 30" (762 mm) - 36" (914 mm) - 38" (965 mm)12 Rows 20" (508 mm) - 22" (559 mm) - 30" (762 mm)4200 <strong>Series</strong> HeadersThe Gleaner 4200 <strong>Series</strong> high-capacitypickup headers include a 13 ft.(4.0 m)- or 15 ft. (4.6 m) wide conveyorauger. Equipped with your choice of aSwathmaster or Rake-Up attachment,14 ft. (4.3 m)- wide for the 13-ft. headerand 16 ft. (4.9 m) wide for the 15-ft.header, it provides a direct, smooth cropfl ow through even the densest windrows.With radial pin clutch protection, the4200 <strong>Series</strong> comes with factory-installedadapter and pickup attachment.Gleaner Ultra-Float Suspensionuses a heavy spring and shocksystem to dampen rugged terrainand smooth out the rough spots.An advanced, hydraulicallypositioned windguard, whichcan be raised or lowered fromthe cab, improves feeding andreduces crop rolling.Electric, cab-adjusted stripperplates allow the operator to makeon-the-go adjustments to meetchanging crop conditions.A self-contained, modular gearboxand torque limiter oneach row unit provides greaterdurability and allows easier rowwidth adjustment.SizePickup13' (4.0 m) 14' (4.3 m)15' (4.6 m) 16' (4.9 m)

5100 <strong>Series</strong> Draper HeadersThe 5100 <strong>Series</strong> draper headers offer 41.5 in. (1,054 mm) widerubberized drapers to help reduce losses in easily threshed crops.Gap-free placement reduces grain loss. Available in 25-ft. (7.6 m),30-ft. (9.1 m) and 36-ft. (10.9 m) widths, with a choice of universalU2 pickup or polytine pickup reel to match your cropping needs.Four coil springs provide six degrees of lateral fl oat and 8 in.(203 mm) of vertical fl oat, independent of the combine.ModelSizes5100 25' (7.6 m) - 30' (9.1 m) - 36' (10.9 m)An independent hydraulic drivesystem contains its own reservoirpump and fi lter for reliable powerto the cutterbar and side drapers.Hydraulically driven SCH planetarygear sickle drive system movesthe sickle at 1,200 strokes/minwith a 3 1 /8-in. (80 mm) stroke forsmooth cutting and increasedperformance.The reinforced, rubberized canvasdrapers feature slats constructedof reinforced fiberglass forstrength and durability.7200/8200 <strong>Series</strong> HeadersThe 7200 <strong>Series</strong> rigid cutterbar headers begin with a solid-welded steel frame for a rock-rigid foundation. SCH epicyclic drive system assures a fasterlinear cut with less vibration. Plus, the precision factory-balanced conveyor with exclusive 7-in. (178 mm) auger fl ighting also reduces life-sappingvibration and ensures smooth crop fl ow. Available with new level-2, HCC pickup reel in widths up to 35 feet (10.6 m). Electric, in-cab fore-and-aft reeladjustment comes standard, so you can adjust to changing crop conditions on the fl y—even through lodged and weedy patches.SCH fully enclosed epicyclicsickle drive provides a smoothlinear movement that reducesstress, wear and vibration forbetter cutting performance.Optional SCH cutterbar kniveson the 8200 bolt to the bar inalternating pattern to cut onboth the top and bottom, vastlyincreasing cutting effi ciency andextending wear life.New optional orbit reel kit reducesthe amount of material buildupbehind the cutterbar for a bettercrop fl ow.Model Type Sizes7200 Rigid Cutterbar 25' (7.6 m), 30' (9.1 m), 35' (10.6 m)8200 Flex Cutterbar 20' (6.0 m), 25' (7.6 m), 30' (9.1 m),35' (10.6 m)The 8200 <strong>Series</strong> fl ex headers start with all the standard features of the 7200, then add a choice of two sickle options: standard sickle or SCH sickle andguards. Its full-fi ngered auger with 7-in. (178 mm) fl ighting ensures smooth crop fl ow out to its maximum 35-ft. (10.6 m) header width. New lightweightHCC reel design provides greater strength with increased visibility.

SERVICE WITH YOU IN MINDThe Gleaner combine is backed by the strength and reputation of one of the world’s largest farm equipmentmanufacturers–AGCO Corporation. Local AGCO Gleaner dealers support each combine with experienced, factorytrainedstaff and service personnel.The Gleaner Guard warranty is the best in the industry from header to spreader. Nonconsumable parts found tobe defective in workmanship or material as delivered will be repaired or replaced for two years from date of delivery tothe initial owner regardless of the number of hours the machine has been used.The AGCO parts supply network offers a complete line of high-quality replacement parts and accessories. The AGCOlive-on-net Electronic Parts & Service Information provides immediate online access for dealers worldwide to operatormanuals, service manuals and service bulletins, further improving their response time and knowledge base ensuringthat your combine is back and running quickly.Gleaner dealers can provide Gleaner owners with access to www.agcopartsbooks.com. This gives Gleaner owners24-hour access to online parts information for their Gleaner combines.FinancingAGCO Finance remains committed to agriculture and understanding its unique needs—like the need to offerfl exible programs such as seasonal payments, skip payments and waiver periods. We are proud to offer affordable,comprehensive equipment fi nancing options for all Gleaner combines. We have the expertise, systems and fl exibilityto design a fi nancing program that’s as tailored to your needs as your new Gleaner combine is.

LET’S GET STARTED.The best way to see if you’re ready for a new <strong>A6</strong> Gleaner combine is to see one in action. Contact your dealer or visitus at www.agcoiron.com to see video of the <strong>A6</strong> and even arrange to try one for yourself.We want your experiences with us to be pleasant, so please tell us what information and insight you may need whencomparing machines. After all, while the Gleaner is built with the farmer in mind, our company is too.

AGCO Corporation • 4205 River Green Parkway, Duluth, GA 30096 • Phone 800.767.3221 • Fax 770.813.6038 • www.agcoiron.comAGCO may at any time, and from time to time, for technical or other necessary reasons, modify any of the data, specifications or warranty of the productsdescribed herein. Some equipment shown may be optional. Attention: Photographs in this publication may show protective shields or guards open orremoved for the purposes of illustration. Be certain all shields and guards are in place during operation.MegaXbib ® is a Reg. TM of Michelin North America, Inc.AGCO & Gleaner are Reg. TM of AGCO Corporation • © 2009 AGCO Corporation • GL08553 RP 09 (01) 2.5 LCP