HAYNES ® 188 alloy - Haynes International, Inc.

HAYNES ® 188 alloy - Haynes International, Inc.

HAYNES ® 188 alloy - Haynes International, Inc.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

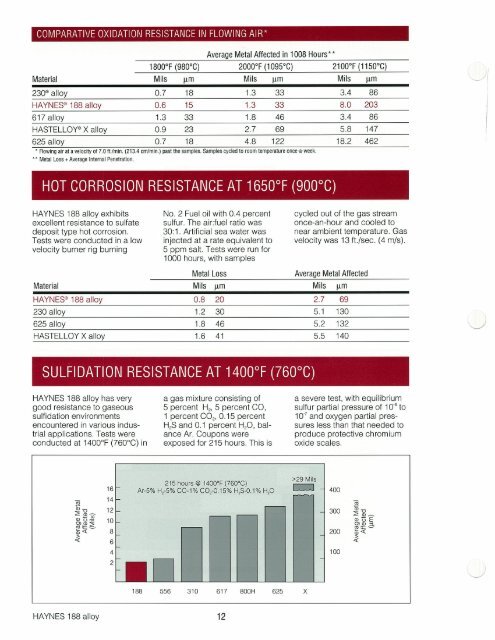

COMPARATIVE OXIDAT~ON RESISTANCE IN FLOWING A~R*Average Metal Affected in 1008 Hours”1800°F (980°C) 2000°F (1095°C) 2100°F (1150°C)Material Mils jim Mils jim Mils jim230<strong>®</strong><strong>alloy</strong> 0.7 18 1.3 33 3.4 86<strong>HAYNES</strong><strong>®</strong> <strong>188</strong> <strong>alloy</strong> 8.0 2036l7<strong>alloy</strong> 1.3 33 1.8 46 3.4 86HASTELLOY<strong>®</strong>X<strong>alloy</strong> 0.9 23 2.7 69 5.8 147625 <strong>alloy</strong> 0.7 18 4.8 122 18.2 462Flowing air at a velocity of 7.0 ftimin. (213.4 cnvmin.) past the samples. samples cycled to room temperature once-a-week.• * Metal Loss + Average Internal Penetration.HOT CORROSION RESISTANCE AT 1650°F (900°C)<strong>HAYNES</strong> <strong>188</strong> <strong>alloy</strong> exhibits No. 2 Fuel oil with 0.4 percent cycled out of the gas streamexcellent resistance to sulfate sulfur. The air:fuel ratio was once-an-hour and cooled todeposit type hot corrosion. 30:1. Artificial sea water was near ambient temperature. GasTests were conducted in a low injected at a rate equivalent to velocity was 13 ft/sec. (4 mIs).velocity burner rig burning5 ppm salt. Tests were run for1000 hours, with samplesMetal LossAverage Metal AffectedMaterial Mils j.tm Mils jim<strong>HAYNES</strong> <strong>188</strong> <strong>alloy</strong> 0.8 2023O<strong>alloy</strong> 1.2 30 5.1 130625 <strong>alloy</strong> 1.8 46 5.2 132HASTELLOYXaIIoy 1.6 41 5.5 140SULFIDATION RESISTANCE AT 1400°F (760°C)________<strong>HAYNES</strong> <strong>188</strong> al oy has very a gas mixture consisting of a severe test, with equilibriumgood resistance to gaseous 5 percent H2, 5 percent CO, su fur partial pressure of 106 tosulfidation envronments 1 percent CO , 0.15 percent 10 and oxygen partia presencountered in various indus- H2S and 0.1 percent H 0, bal- sures less than that needed totrial applications. Tests were ance Ar. Coupons were produce protective chromiumconducted at 1400°F (760°C) in exposed for 215 hours. This is oxide scales.1614°~o 120~~~ot=108642400300200 r100<strong>188</strong> 556 310 617 800H 625 x<strong>HAYNES</strong> <strong>188</strong> a oy 12