COANDA Grit Classifier RoSF 3 - brochure english

COANDA Grit Classifier RoSF 3 - brochure english

COANDA Grit Classifier RoSF 3 - brochure english

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

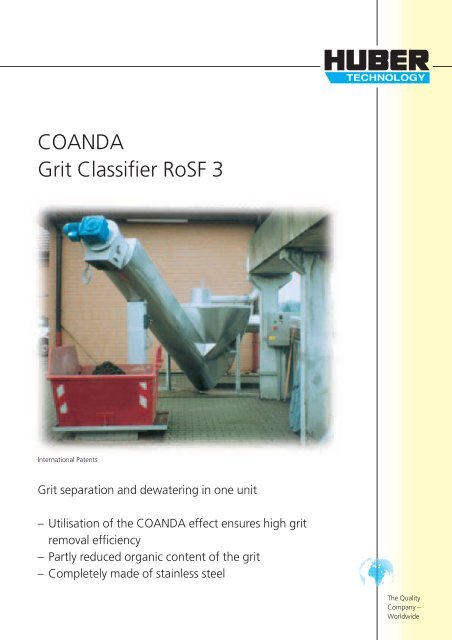

<strong>COANDA</strong><strong>Grit</strong> <strong>Classifier</strong> <strong>RoSF</strong> 3International Patents<strong>Grit</strong> separation and dewatering in one unit– Utilisation of the <strong>COANDA</strong> effect ensures high gritremoval efficiency– Partly reduced organic content of the grit– Completely made of stainless steelThe QualityCompany –Worldwide

➤➤➤ The Situation:<strong>Grit</strong> classifiers are widely used on sewage works for theremoval of grit. Flow conditions ideal for maximum gritremoval based on scientific definition have until nowbeen unobtainable.Previously designed plants based on past experiencehave often suffered from grit carry over due toinsufficient retention time caused by undersizing ofplant (consequence: deposits in digester, high wear rateof pumps) or conversely classified grit with a highorganic content due to oversizing of plant.Consequence: high disposal costs, and wet grit due toinsufficient dewatering.The heart of the <strong>COANDA</strong> <strong>Grit</strong> <strong>Classifier</strong> is the insertedCoanda Tulip. The organically laden water flowing infrom the top adheres to the tulip wall and is diverted tothe horizontal below water surface by the Coanda-Effect. Reduced radial and tangential flows assist theseparation process and the difference in densitybetween organic and mineral material is partly takeninto consideration.The classifier screw transports the clean grit up aninclined plane where it is dewatered under gravitybefore discharge into a skip. The mineral residue from aplant operating under optimum conditions is in excessof 90% (e.g. a plant with appropriate pre-screening andgrit collection facilities).➤➤➤ The Solution:The <strong>COANDA</strong> <strong>Grit</strong> <strong>Classifier</strong> was developed by HUBER incooperation with the University of Munich, hydraulicsdepartment. Based on the Coanda-Effect, the flow intothe tank can be defined exactly and simulatedmathematically. When operating at optimum flow, thegrit separation (grain size 0.2 mm) is up to 98 %.The difference in density between grit and otherorganic components can partly be taken intoconsideration to ensure reduced organic contaminationand thus static dewatering of the classified grit. Highefficiency has enabled the <strong>COANDA</strong> <strong>Grit</strong> <strong>Classifier</strong> to besignificantly smaller than conventional classifiers.gritaerationwastewater and organicmaterial➤➤➤ Design and function:Flow pattern in the <strong>COANDA</strong> <strong>Grit</strong> <strong>Classifier</strong>The grit / water mixture flows either by means of apump or by gravity into the vortex chamber where arotary motion is induced. An automatic air intake takesplace through the centrically located drilling hole on thevortex chamber.A classifying screw transports the grit from theseparation room into a skip.Hans Huber AGMaschinen- und AnlagenbauPostfach 63 · D-92332 BerchingTelephone: + 49 - 84 62 - 201 - 0Telefax: + 49 - 84 62 - 201 - 810e-mail: info@huber.deInternet: www.huber.deSubject to technical alteration<strong>COANDA</strong><strong>Grit</strong> <strong>Classifier</strong> <strong>RoSF</strong> 31,5 / 2 – 4.2005 – 9.2003