Australia's First Hot Sedimentary Aquifer Development - Geoscience ...

Australia's First Hot Sedimentary Aquifer Development - Geoscience ...

Australia's First Hot Sedimentary Aquifer Development - Geoscience ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

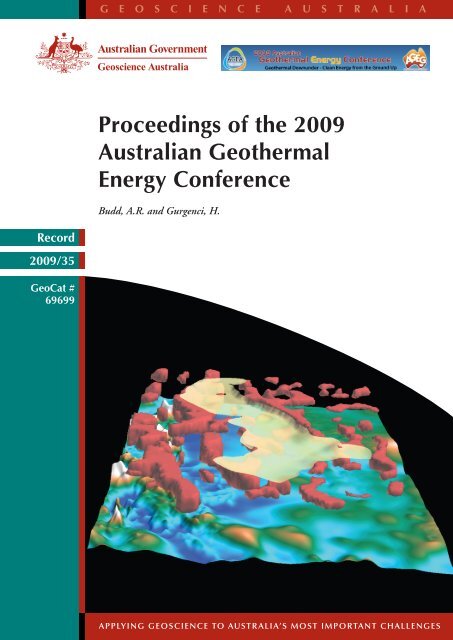

G E O S C I E N C E A U S T R A L I AProceedings of the 2009Australian GeothermalEnergy ConferenceBudd, A.R. and Gurgenci, H.Record2009/35GeoCat #69699APPLYING GEOSCIENCE TO AUSTRALIA’S MOST IMPORTANT CHALLENGES

Proceedings of the 2009 AustralianGeothermal Energy ConferenceGEOSCIENCE AUSTRALIARecord 2009/35Edited byAnthony Budd 1 and Hal Gurgenci 212<strong>Geoscience</strong> Australia, GPO Box 378, Canberra, ACT 2601Queensland Geothermal Energy Centre, The University of Queensland, St Lucia 4072

Department of Resources, Energy and TourismMinister for Resources and Energy: The Hon. Martin Ferguson, AM MPSecretary: Mr John Pierce<strong>Geoscience</strong> AustraliaChief Executive Officer: Dr Neil Williams PSM© Commonwealth of Australia, 2009This work is copyright. Apart from any fair dealings for the purpose of study, research,criticism, or review, as permitted under the Copyright Act 1968, no part may be reproducedby any process without written permission. Copyright is the responsibility of the ChiefExecutive Officer, <strong>Geoscience</strong> Australia. Requests and enquiries should be directed to theChief Executive Officer, <strong>Geoscience</strong> Australia, GPO Box 378 Canberra ACT 2601.<strong>Geoscience</strong> Australia has tried to make the information in this product as accurate aspossible. However, it does not guarantee that the information is totally accurate or complete.Therefore, you should not solely rely on this information when making a commercialdecision.ISSN 1448-2177ISBN 978-1-921672-28-6GeoCat # 69699Recommended bibliographic reference: Budd, A.R. and Gurgenci, H. (editors), 2009.Proceedings of the 2009 Australian Geothermal Energy Conference, <strong>Geoscience</strong> Australia,Record 2009/35.Recommended bibliographic citation: Chen, D. B. and Wong, G. 2009. Aims of a BasicEGS Model for the Cooper Basin, Australia, in: Budd and Gurgenci (editors), Proceedings ofthe 2009 Australian Geothermal Energy Conference, <strong>Geoscience</strong> Australia, Record 2009/35.Cover illustration: 3D image of gravity inversion modelling in the are between Mt Isa andthe Georgetown Inlier, Queensland, viewed obliquely from the south. The red bodies encloseregions of low density interpreted as granites located at depth beneath Millungera Basinsediments, the base of which is shown as the yellow surface. The interpreted granites areshown projected above an image of the Bouguer Gravity field, from which the inversionmodel was generated. Courtesy of Alison Kirkby, <strong>Geoscience</strong> Australia.

The Convenors would like to thank the following sponsors for their kind support:Platinum SponsorsGold SponsorsSilver SponsorsBronze SponsorsWednesday Happy Hour Conference Dinner Thursday Happy Hour

IntroductionThis volume is a compilation of Extended Abstracts presented at the 2009 AustralianGeothermal Energy Conference, 11-13 November 2009, Hilton <strong>Hot</strong>el, Brisbane, organised bythe Australian Geothermal Energy Association and the Australian Geothermal Energy Group.This Conference is the second dedicated conference organised by the geothermal energycommunity in Australia. The first conference in August 2008 was made possible by seedfunding from the Australian Government under the Sir Mark Oliphant International Frontiersof Science and Technology Conference funding scheme. This conference is made possible bythe sponsoring companies acknowledged earlier and paying delegates.This Conference is being held at a time of continuing rapid growth in all sectors of thegeothermal community, but also following a time of restricted financing availability due tothe Global Financial Crisis. The number of companies engaged in exploration stands at 48,the number of leases held or applied for is 386, and the value of the work program for thesecompanies exceeds $1.5 billion between 2002-2013. The Australian Geothermal EnergyAssociation serves as the peak industry representative body. The Australian Code forReporting Exploration Results, Geothermal Resources and Geothermal Reserves has been ineffect for over a year, and the second edition will be launched at this conference. TheUniversities of Queensland, West Australia, Adelaide and Newcastle have active establishedgeothermal research programs. The Australian Government has continued its strong supportof the sector through the international Partnership for Geothermal Technology, GeothermalIndustry <strong>Development</strong> Framework and Technology Roadmap, the Geothermal DrillingProgram, and the Onshore Energy Security Program.This volume of Extended Abstracts is organised under five headings:• Exploration• Underground Science and Technology• Power Conversion Technologies• Legislation, Policy and Infrastructure• Direct and Low-temperature UseAs editors of these proceedings, we first would like to thank the Technical Committee whohave been very generous with their time to review the submissions and to work with theauthors of the accepted submissions to improve the quality of the Abstracts and thepresentations.We also thank the Conference Chair Tony Hill and the rest of the Organising Committee whowere brave enough to take on the job organising this second event on behalf of the AustralianGeothermal Energy Association and the Australian Geothermal Energy Group. Jem Hansenand Impact Environment Conferences have done an excellent job in assisting theorganisation.We also thank again the sponsoring companies for their generous support.We thank <strong>Geoscience</strong> Australia for publishing the proceedings.Finally, we thank all delegates without whose participation none of this is worthwhile.Anthony BuddHal Gurgencii

Conference Organising CommitteeTony Hill (Chair), Primary Industries and Resources South AustraliaDr Andrew Barnicoat, <strong>Geoscience</strong> AustraliaDr Graeme Beardsmore, <strong>Hot</strong> Dry Rocks Pty LtdRod Bresnehan, Clean Energy AustraliasiaDr Anthony Budd, <strong>Geoscience</strong> AustraliaPeter Green, Geological Survey of QueenslandProfessor Hal Gurgenci, Queensland Geothermal Energy Centre of ExcellenceSusan Jeanes, Australian Geothermal Energy AssociationJohn King, Petratherm LtdAlan Knights, Green Rock Energy LtdKumar Thambar, Queensland Office of Clean EnergyProgram Technical PanelDr Anthony Budd (Chair), <strong>Geoscience</strong> AustraliaDr Bridget Ayling, <strong>Geoscience</strong> AustraliaDelton Chen, Geodynamics LtdGareth Cooper, <strong>Hot</strong> Dry Rocks Pty LtdNeal Evans, <strong>Geoscience</strong> AustraliaDes Fitzgerald, Intrepid GeophysicsEd Gerner, <strong>Geoscience</strong> AustraliaHelen Gibson, GeoIntrepidProfessor Hal Gurgenci, Queensland Geothermal Energy Centre of ExcellenceAlison Kirkby, <strong>Geoscience</strong> AustraliaAlan Knights, Green Rock Pty LtdChris Matthews, Torrens Energy LimitedTony Meixner, <strong>Geoscience</strong> AustraliaProfessor Behdad Moghtaderi, The University of NewcastleProfessor Klaus Regenauer-Lieb, The University of Western AustraliaPeter Reid, Petratherm LtdMichel Rosener, Geodynamics LtdDr Catherine Stafford, Granite Power LtdDr Adrian Williams, Geodynamics LtdDr Doone Wyborn, Geodynamics LtdConference OrganisersJem Hansen & Dawn HallinanImpact Environmental ConferencesPh: 02 6583 8118 Fax: 02 6583 8065ausgeothermal@impactenviro.com.auwww.ausgeothermal.comii

Contents Australian Geothermal Energy Conference 2009Meixner, T.J., Johnston, S., Kirkby, A.L., Gibson, H.J., Seikel, R., Stüwe, K., FitzGerald, D., Horspool, N.,Lane, R. and Budd, A.R.Establishing <strong>Hot</strong> Rock Exploration Models: From Synthetic Thermal Modelling to the CooperBasin 3D Geological Map ...........................................................................................................89Mortimer, L.Hydro-Mechanical Selection Criteria of Engineered Geothermal Systems ................................95Musson, A., Harrison, B., Gordon, K., Wright, S. and Sandiford, M.Thermal thinking: optimal targeting for Australian geothermal explorers ..................................101Taylor, D.H. and Harrison, B.C.Overview of Geothermal Resources and Exploration Activity in Victoria ..................................104Van Zyl, J.A.B., Uysal, I.T. and Gasparon, M.Mineralogy and Petrology of the Cooper Basin Basement Granites .........................................107Wellmann, J.F., Horowitz, F.G. and Regenauer-Lieb, K.Concept of an Integrated Workflow for Geothermal Exploration in <strong>Hot</strong> <strong>Sedimentary</strong> <strong>Aquifer</strong>s .111Underground Science and TechnologyAtrens, A.D., Gurgenci, H. and Rudolph, V.Exergetic performance and power conversion of a CO 2 thermosiphon.....................................117Battye, D.L. and Ashman, P.J.Radiation associated with <strong>Hot</strong> Rock geothermal power ............................................................120Bhuana, D.S., Ashman, P.J. and Nathan, G.J.Silica deposition in Enhanced Geothermal Systems.................................................................124Chen, D.B. and Wong, G.Aims of a Basic EGS Model for the Cooper Basin, Australia ....................................................128Espinoza-Ojeda, O.M., Santoyo, E. and Andaverde, J.Analysis of error sources for estimating geothermal stabilised formation temperatures usinganalytical and rigorous methods................................................................................................134Kaieda, H., Ueda, A., Kubota, K., Wakahama, H., Mito, S., Sugiyama, K., Ozawa, A., Kuroda, Y., Kaji,Y., Suzuki, H. and Sato, H.Field experiments for studying CO 2 mineral trap at high temperature at Ogachi, Japan ..........140Kuncoro, G.B., Ngothai, Y., O’Neill, B., Pring, A., Brugger, J.A Preliminary Study on Fluid-Rock Interactions of the <strong>Hot</strong> Fractured Rock GeothermalSystem in Cooper Basin, South Australia .................................................................................144Lawless, J.V., Clotworthy, A.W. and Ussher, G.The End Point of Geothermal <strong>Development</strong>s: Modelling Depletion of Geothermal Resources 150Leary, P. and Malin, P.EGS & "The Law of Averages"..................................................................................................153Long, A., Goldstein, B.A., Hill, T. and Malavazos, M.Summary of AGEG Technical Interest Groups Research Projects ...........................................158Lukas, A., Steinbrecher, T. and Uhde, J.Geothermal Applications: <strong>Development</strong> of new state of the art drilling rigs for geothermaluse.............................................................................................................................................164iv

Contents Australian Geothermal Energy Conference 2009Remoroza, A.I., Doroodchi, E., and Moghtaderi, B.Power Generation Potential of SC-CO 2 Thermosiphon for Engineered Geothermal Systems .169Shen, B.Modelling Reservoir Behaviour during Stimulation Tests at Habanero #1 ...............................175Thiel, S., Peacock, J., Heinson, G. and McAllister, L.Magnetotelluric Monitoring Of Geothermal Fluid Flow ..............................................................180Wyborn, D.Completion of Habanero Closed-loop Circulation Test .............................................................183Xing, H., Zhang, J., Liu, Y. and Mulhaus, H.Enhanced Geothermal Reservoir Simulation ............................................................................187Xu, C. and Dowd, P.A.Fracture Simulation for Deep Crystalline Rock .........................................................................191Yanagisawa, N., Rose, P. and Wyborn, D.Habanero Tracer Tests in the Cooper Basin, Australia: Key Results for EGS <strong>Development</strong> ...197Zhang, X., Jeffrey, R. and Wu, B.Two Basic Problems for <strong>Hot</strong> Dry Rock Reservoir Stimulation and Production..........................201Power ConversionBrimblecombe, J.S. and Vos, T.J.The Feasibility of a Nocturnal Radiative Heat Dissipation System for Remote GeothermalApplications...............................................................................................................................206Bryson, M., St Hill, S., Joshi, V. and Dixon, C.Low Temperature Difference Electricity Generation Using ORC ..............................................210Collins, R.Seasonal Storage of Air Cooled Water for Arid Zone Geothermal Power Plants......................216Dally, B., Nathan, G., Watson, S., Heath, A. and Howard, C.Feasibility Assessment of Underground Cooling for Geothermal Power Cycles ......................219Guan, Z. and Gurgenci, H.Dry Cooling Technology in Chinese Thermal Power Plants .....................................................224Gurgenci, H.How to Increase Geothermal Power Conversion Efficiencies ...................................................229Moghtaderi, B. and Doroodchi, E.An Overview of GRANEX Technology for Geothermal Power Generation and Waste HeatRecovery ...................................................................................................................................234Morgan, C. and Byers, S.PureCycle® Product <strong>Development</strong> and Applications Update....................................................239Murray, C.Natural Draft Dry Cooling Tower ...............................................................................................241Odabaee, M., Hooman, K. and Gurgenci, H.Comparing the Tube Fin Heat Exchangers to Metal Foam Heat Exchangers for GeothermalApplications...............................................................................................................................244v

Contents Australian Geothermal Energy Conference 2009Quinlivan, P.Assessment of Current Costs of Geothermal Power Generation in New Zealand (2007Basis) ........................................................................................................................................248Zhu, J. and Wang, K.Analysis of Reinjection Tests in a Bedrock Geothermal Reservoir, Tianjin, China ...................255Direct/Low-temperature UseGutiérrez, H. and Espíndola, S.Low and Moderate Enthalpy Geothermal Resources to Desalinate Sea Water and ElectricityProduction .................................................................................................................................259Payne, D.J.B., Hampson, G., Kiraly, D. and Davis, E.Direct GeoExchange Cooling for the Australian Square Kilometre Array Pathfinder ................265Swift, M. and Muhlhaus, J.Geothermal extraction from porous rocks - revisited ................................................................270Legislation/Policy/infrastructureBattye, D.L. and Ashman, P.J.Radiation associated with <strong>Hot</strong> Rock geothermal power ............................................................275Butler, T.R., Tissai-Krishna, S. and Morton, A.B.Bringing large scale geothermal electricity to the National Grid................................................279Dickinson, R.R., Battye, D.L., Linton, V., Ashman, P.J. Nathan, G.Alternative Energy Carriers for Remote Geothermal Sources ..................................................286Froome, C.W.What Contribution Can Geothermal Energy Make to Australia’s Renewable Energy Target ...290Knights, A.Levelised Unit Cost – A Calculation and Reporting methodology .............................................295Newson, J. and Brotheridge, J.Skills Issues and Training in the Geothermal Industry: A New Zealand perspective ................297Nguyen, M.H. and Saha, T.K.Power loss evaluations for long distance transmission lines.....................................................307Regenauer-Lieb, K. et al.The Western Australian Geothermal Centre of Excellence ......................................................313Ward, M., Beardsmore, G.R., Budd, A.R., Goldstein, B.A., Holgate, F.L., Jeffress, G., Larking, A.,Lawless, J.V., Reid, P.W. and Williams, A.The development, launch and implementation of the Australian Geothermal Reporting Codeand current developments.........................................................................................................317vi

Australian Geothermal Energy Conference 2009The Portable Electronic Divided Bar (PEDB): a Tool for MeasuringThermal Conductivity of Rock SamplesAnson M. Antriasian<strong>Hot</strong> Dry Rocks Pty. Ltd.Level 4, 141 Osborne Street, South Yarra, Victoria, 3141anson.antriasian@hotdryrocks.comThe thermal conductivity of a geological formationis an essential physical property to be determinedwhen attempting to understand and model heatflow. The Portable Electronic Divided Bar (PEDB)is an effective tool in measuring thermalconductivity, and is currently playing an importantrole in the development of heat flow modelling ofAustralian geothermal resources.The PEDB is an electronic apparatus thatproduces a temperature gradient across aspecially prepared rock sample; and with itsprecision heat flow monitoring system, it allowsthermal conductivity of a rock sample to bedetermined via the application of Fourier’s Law. Asimple spreadsheet allows direct temperaturemeasurements—utilizing thermocouples—to berecorded and interpreted to provide an absolutethermal conductivity value within ±3.5%.Measurements are rapid, taking from 5 to 15minutes per sample.In addition to uniaxial thermal conductivitymeasurements, biaxial and triaxial measurementscan be made with the PEDB, allowing for studiesof thermal conductivity anisotropy. Cylindrical coreas well as irregularly shaped rock samples can bemeasured.The Divided Bar was first described as a steadystatetool used to measure the thermalconductivity of materials by Benfield in 1939(Beardsmore and Cull, 2001). The PortableElectronic Divided Bar (PEDB) is a developmentof Benfield’s divided bar operating principal,utilizing advancements in technology to create ahigh accuracy (±3.5%), light-weight (less than 5kg), small size (260 mm x 310 mm x 450 mm) andlow power consumption (less than 200W), lownoise production device.In the field it is valuable for measuring the thermalconductivity of rock samples immediately afterrecovery from drilling, maintaining as closely aspossible the rock’s in-situ porosity and moisturecontent.For use in laboratory settings, the space that isrequired is the corner of an office desk, a singleAC power outlet, and a PC and logging device.Keywords: PEDB, portable electronic divided bar,thermal conductivity, heat flow, anisotropyThermal Conductivity and Heat FlowObserving Fourier’s Law:Q = (1)Q, , and are heat flow (W/m 2 ), thermalconductivity (W/mK), and thermal gradient (K/m),respectively.The heat flow of a site can be derived by utilisinga combination of: 1) thermal conductivitymeasurements to define ; and 2) down-holetemperature logging to define . Determining heatflow requires consideration of the geologicformations from which the thermal conductivitysamples came, and so rock samples that are tobe tested for thermal conductivity must becarefully chosen to ensure they are appropriatelyrepresentative of those geologic formations, withattention paid to characteristics such as lithologyand porosity.If thermal conductivity measurements fromseveral geological formations are taken, it ispossible to develop a down-hole profile of thermalconductivity.Calculation of Thermal ConductivityThermal conductivity of a rock sample, asmeasured by a PEDB, is determined by:d =(2)R = thermal conductivityd = thickness of the sample in mmR = (A (ΔT- c))/(a (diameter + b))A = surface area of sample in mm 2a, b, c, are calibration constants determinedduring the calibration process.ΔT is defined by:T2 T3 T =(3)T T T T 123T 1 , T 2 , T 3 , T 4 = temperatures of PEDB plates asshown on Figure 1.The thermal conductivity of each rock sample iscalculated using the measurements of the threevalues d, A, and ΔT, where ΔT is the ratio of thetemperature drop across the sample relative tothe sum of temperature drops across thepolycarbonate layers within each plate-pair—aunit-less quantity.411

Australian Geothermal Energy Conference 2009The measurements of d and A are made utilisingprecision callipers; the measurement of ΔT ismade utilising the PEDB, a PC, and a digitallogging device.Figure 1: Diagram showing principal components of theplates of the PEDB. Each brass plate is fitted with aseparate thermocouple; ΔT is the ratio of the temperature ofthe plates of the PEDB: ΔT = (T2-T3)/((T1 -T2)+(T3-T4)). Theheat source is above the top pair of brass plates, and thecold source is below the bottom pair; the consequence isthat heat flows across the rock sample.The PEDBPower supplyThe PEDB has a ‘universal’ power supply,capable of being powered by mains sources thatare within 100-250 VAC, 45-70 Hz. Portability ofthe PEDB can be achieved by using a sine-wavegenerator, a sine-wave inverter rated for 200 Wfrom a power source such as an automobile, orfrom a DC source.Plates of the PEDBTwo pairs of highly thermally conductive plates—brass in the case of the PEDB—are used, eachwith a layer of polycarbonate in between,comprising a brass-polycarbonate-brassassembly that resembles a sandwich, as shown inFigure 2. Each of these assemblies has athickness of approximately 7mm and a diameterof 65 mm. One of the assemblies is situated ontop of the rock sample—thermally connected to aheat source—and the other assembly is below thesample—thermally connected to a cold source.Such an orientation prevents: 1) convection fromoccurring between the plates and; 2) resultantintroduced uncertainties.Within each of the four brass plates is embeddeda thermocouple with its welded joint located in thecentre of the brass plate. Thus the temperaturesof each brass plate can independently bemeasured and used to determine .Figure 2: The plates of the PEDB. An HQ sized rock sampleis in place and ready for thermal conductivity measurement.Each pair of plates is brass, with a polycarbonate layer inbetween. Above the upper plate is a heat source, and belowthe lower plate is the cold source--a thermal gradient acrossthe sample is created; the ratio of the temperature dropsacross each of the polycarbonate layers and the sample isSample preparationThe PEDB measures the thermal conductivity ofconsolidated drill core. Samples measured forthermal conductivity can be any size up to adiameter of to 65 mm (approximate size of HQcore is 60mm). The samples should be cut so thatthe two faces of the sample produced areapproximately parallel, although preciseparallelism is not essential, owing to a swivelheadwhich allows for measurement of samplesthat are not perfectly parallel (Figure 3); samplepreparation is consequently easier than withsystems that do not allow for sub-parallel samplefaces.Figure 3: The swivel head (indicated by arrow) of the PEDBallows for thermal conductivity measurements of samples tobe made without necessitating perfect parallelism betweensample faces. Additionally, the black insulation shown iseffective in minimizing thermal loss from the sample.It is however essential that the faces of the rocksample are flat. This can be accomplished byusing a flat grinding wheel and lap-wheelcombination, which has been HDRPL’s preferred22

Australian Geothermal Energy Conference 2009method for processing thermal conductivitysamples thus far. The system of samplepreparation should be standardized. Generally,polishing to a fine grade up to 600-grit isrecommended.If the samples being measured for thermalconductivity were saturated with water in situ, allefforts should be made to preserve the inter-porewater within the core sample. If this is notpracticable, then the sample should be resaturatedbefore measurement via vacuumsaturation. In such cases the samples aresubjected to a vacuum for a standardized timebefore being submerged in water and returned toatmospheric pressure for a standardized time,whereafter they can be measured for thermalconductivity.Importance of sample preparation qualityIt has been observed that samples prepared withsub-flat faces or surface irregularities can returnsignificantly lower measured thermal conductivityvalues. Examples of surface irregularities thathave resulted in significant decrease in apparentthermal conductivity are:Convex sample faces resulting from worngrinding and polishing wheels.Grooved sample faces left over from therock-sawing process; chips that havefractured from the sample during cutting.Pitted surfaces resulting from preparationof weakly consolidated rocks susceptibleto “plucking” of grains.Sub horizontal fractures and/or joints.As zones of low thermal conductivity and highwater/air content that are created either within thesample itself or along the sample/plate contact,these irregularities effectively impede the heatflow across the sample. Careful efforts—implemented during sample selection,preparation, and measurement—are essential forproducing representative thermal conductivityresults. The overwhelming majority of coresamples that have been encountered by theauthor during conductivity measurement haveprovided useful samples for reliable thermalconductivity measurements, when carefullyprepared.Relevance of size and shape of samplestested in the PEDBIrregularly shaped rock samples can bemeasured. The accuracy of thermal conductivitymeasurements is independent of sample shapeso long as thermal loss around the perimeter ofthe sample is minimized. Generally, the thermalloss that may exist for a sample would increaseas its surface area increases, but this tendency iseffectively controlled with the use of thermalinsulation around the PEDB plates and rocksample (Figure ) which prevents environmental aircirculation from interfering with thermalconductivity measurements.Figure and Figure 5 show examples ofmeasurements that were made on differentlyshaped rock samples. In both cases, sampleswere ground flat, polished, and were of a variablesiltstone lithology. Variation in thermalconductivity was 5% or less from the mean in bothcases, consistent with normal inter-samplevariation.The dimensions of a rock sample that must bemeasured when calculating thermal conductivityare thickness and heat flux cross-section.Thickness is measured with precision calipers.Heat flux cross-section can found by measuringthe surface area of the rock sample’s face, eitherby calculating from core diameter, or by tracingthe sample and measuring the surface area of thetracing digitally (via scanner and digital graphicssoftware) or on to graph paper. Experiments haveshown that variations in results of measurementsmade via the tracing method and via thecalculation from diameter method are within 0.7%variation from the mean.Figure 4: Although varying significantly in size and shape,these samples—which were taken from the same rockspecimen—provide consistent results. Their conductivitiesare 2.04, 1.90, and 1.98 W/mK respectively, representing arange of 3.5% from the mean conductivity of 1.97 W/mK.33

Australian Geothermal Energy Conference 2009Figure 5: Although varying significantly in size and shape,these samples—taken from the same specimen—provideconsistent results. Their conductivities are 2.25, 2.11, and2.30 W/mK respectively, representing a range of 5% from themean conductivity of 2.22 W/mK.Mean Sample Temperature of the PEDBThe PEDB operates best when the mean sampletemperature is near the environmental airtemperature. To facilitate field operations, thePEDB is capable of operating at a range of meantemperatures, from approximately 10–35°C, andhas an indication system showing when the meantemperature approximates the environmentaltemperature.Thermal conductivity for rocks is dependent upontemperature, generally becoming less conductivewith increasing temperature, at a rate ofapproximately 0.16% per degree Celcius(Vosteen and Schellschmidt, 2003). This must bekept in mind when determining the thermalconductivity of geological formations, where thein-situ temperature is greater than that at whichthe laboratory tests were made.Equilibration ProcessOnce the sample is placed between the plates ofthe PEDB and slight pressure is applied to thesample via the hand-operated clamp, atemperature gradient is imposed across thesample and thermal equilibrium typically occurswithin 5–15 minutes. The time required isdependent upon sample thickness and surfacearea, and upon the thermal characteristics of therock sample—most importantly, thermaldiffusivity. A sample will equilibrate relativelyquickly if it is thin, and has a high surface areaand thermal diffusivity. Alternatively, a sample willtake longer to equilibrate if it is very thick, and hasa low surface area and thermal diffusivity. Figure6 and Figure 7 represent 1000 seconds ofrecorded data from the same thermal conductivitymeasurement.Figure 6: Example of data collected during thermalconductivity measurement; the horizontal axis is time,measured in seconds, and the vertical axis is temperaturemeasured in °C. Each plot represents the temperature of aplate of the PEDB, T1–T4, where the hot plate (T1) in this caseis approximately 35°C, the cold plate (T4) is approximately17°C, and the intermediate plates (T2 and T3), after having arock sample placed in between them, gradually increase intemperature until thermal equilibrium is reached.Figure 7: Example of data collected during thermalconductivity measurement; the horizontal axis is time,measured in seconds, and the vertical axis is ΔT. In thisexample, the sample measured for thermal conductivity isfully equilibrated after approximately 600s, to a ΔT value of1.44.Calibration of the PEDBThe PEDB is calibrated using a set of standardsof known thermal conductivity. These standardsare of differing thicknesses and surface areas,enabling the PEDB to be used for measuringdiversely shaped samples, and samples with arange of thicknesses and surface areas.During calibration, standards are placed in thePEDB individually and measurements are madeof the four plate temperatures T 1 –T 4 and thederived ΔT value once the standard has reachedthermal equilibrium.Measurement of thermal conductivityanisotropyAnisotropy is the characteristic of a material tobehave differently in one direction with respect toanother. Rocks can be thermally anisotropic, andin so being can exhibit different thermalconductivity in different directions.Typically, thermal conductivity measurements aremade along the long axis of a core specimen.During such testing, it is the expectation of theheat flow modeller that the core specimen was44

Australian Geothermal Energy Conference 2009taken from a bore that was drilled nearly vertically,and therefore was sufficiently parallel to Earth’sheat flow that the need for understanding howheat travels laterally across the core specimen isnegated.Testing for thermal conductivity anisotropy of arock sample involves biaxial or triaxialmeasurements. The preparation of cube-shapedsamples allows thermal conductivity to bemeasured along each axis of the same sample;thus, one sample can provide the minimum datarequired for the creation of an ellipsoidal thermalmodel. Alternatively, three orthogonally orientedsamples can be prepared from a commonspecimen, collectively providing data for thecreation of an ellipsoidal thermal model.For foliated meta-sedimentary specimens, thetendency has been observed (Figure 8) forthermal conductivity to be greater parallel to thefoliation, compared to perpendicular to thefoliation. In this paper, 1 is nominated as the axisof greatest thermal conductivity, while 2 isnominated the axis of least thermal conductivity,and it is assumed that there is an ellipticalgradation between 1 and 2 .Figure 8: Summary of thermal conductivity data from sixmeta-sedimentary rock specimens; the six differently shapedsymbols indicating the different specimens studied. Eachspecimen was measured for thermal conductivity at severalangles with respect to the specimen’s foliation. The verticalaxis is thermal conductivity (W/mK); the horizontal axis is theangle between the foliation of the rock sample, and thedirection of heat flow across the rock sample while within thePEDB, measured in degrees (°), where 0° indicates heatflow parallel to the planes of foliation, and 90° indicates heatflow perpendicular to the planes of foliation. A relationship isshown to exist between the magnitude of thermalconductivity and the direction of heat flow with respect to thespecimen’s foliation.Results of anisotropy testingThe results of two extreme cases of rock thermalconductivity anisotropy are shown in Figure 8 anddiscussed below.A foliated meta-sediment, Specimen A had amean conductivity of 4.26 W/mK parallel tofoliation, and a mean conductivity of 1.44 W/mKperpendicular to foliation. That is a variation of50% from the mean conductivity of 2.85 W/mK.The anisotropy factor for Specimen A expressedas 1 / 2 , is 2.96.Another foliated meta-sediment, Specimen B, hada mean conductivity of 5.37 W/mK parallel tofoliation, and a mean conductivity of 2.65 W/mKperpendicular to foliation. That is a variation of34% from the mean conductivity of 4.01 W/mK.The anisotropy factor for Specimen B expressedas 1 / 2 , is 2.03.In both cases, 1 was parallel to the rockspecimen’s foliation, while 2 was perpendicular tothe rock specimen’s foliation. In addition, 1 andthe foliation were within 5° of parallel to the borein both cases. Since the bores that these samplesoriginated from were vertical, the thermalconductivities that would be most relevant to theheat-flow modeller—for the location within thegeological formation from which the specimenscame—would be those that were parallel toEarth’s heat flow, and in these cases parallel to 1 . The conductivity values most relevant for heatflow modelling of geological formationsrepresented by specimens A and B, would be4.26 W/mK and 5.37 W/mK respectively.Calculation of variability in thermalconductivityBut what if the bores, foliation, and the direction of 1 discussed immediately above were NOTparallel to Earth’s heat flow, and happened to bedipping at 45° instead, as it might in a steeplydippingmineral exploration bore? In such a case,Earth’s heat flow is now no longer parallel with thebore, but is 45° to it; and consequently, thethermal conductivity vector of the rock specimenmost relevant to the heat flow modeller is thatwhich is parallel to the direction of Earth’s heatflow. Using an elliptical thermal conductivityblending model, where 1 and 2 are the vectorsrepresenting the greatest and lowest thermalconductivities respectively, the resultant thermalconductivity vector for 45° can be determined.The elliptical model is derived beginning with theequation for an ellipse:2 2x y1=(4)2 2a bx = cos θy = sin θa = 1b = 2 = resultant thermal conductivity when heat flowis at angle θ 1 = vector of greatest thermal conductivity55

Australian Geothermal Energy Conference 2009 2 = vector of least thermal conductivity = angle in (°) between the direction of Earth’sheat flow and 1Substituting variable into Equation (4) gives:2 2 2 2 cos sin 1= (5)1Solving for in Equation (5) gives:1 =22cos sin 122By applying the 1 and 2 data from the results ofanisotropy testing into Equation (6), the equivalentuniaxial thermal conductivity of the rock samplesA and B can be determined:Sample A:(6) 1 = 4.26 W/mK and 2 = 1.44 W/mKThe resultant when 1 is dipping at 45°is: 1.93 W/mKSample B: 1 = 5.37 W/mK and 2 = 2.65 W/mKThe resultant when 1 is dipping at 45°is: 3.36 W/mKSignificance of variability in thermalconductivityThe resultant of sample A and B at 45° is 1.93and 3.36 W/mK respectively. These values aresignificantly different than either of their respective 1 or 2 values.Sample ASample B55% variation from 1 (4.26 W/mK)34% variation from 2 (1.44W/mK)37% variation from 1 (5.37 W/mK)27% variation from 2 (2.65 W/mK)When entered into a heat flow model, thisvariation in measured thermal conductivity mayresult in significant variation of calculated heatflow.While bores drilled purposefully for geothermalenergy exploration may as a rule be vertical,bores such as those used for minerals explorationmay be significantly non-vertical owing to theefforts of the exploration program to maximize thelikelihood of hitting a target lode. Thus, careshould be taken when utilizing core from nonverticalbores for geothermal data, ensuring thatthermal conductivity anisotropy is accounted forwhen developing heat flow models.Limitations of the PEDBThe PEDB is not calibrated for measuringconductivities of samples larger than 65 mm indiameter. Larger core or hand specimens canhowever be accommodated by cutting them to asuitable size.The PEDB provides thermal conductivitymeasurements at mean temperatures from 15–35°C. Considerations of the geological formation’sin-situ temperature should be made, since thermalconductivity in rocks is a property that generallydecreases with increasing temperature.ConclusionsThe PEDB is effective in measuring thermalconductivity of rock specimens:Rapidly and on a production scaleIn remote locations and in the laboratoryUsing variable power suppliesThat have a non-standardized size andshape Triaxially for thermal conductivityanisotropy studiesReferencesIn parallel (two PEDB’s can be operatedsimultaneously)Vosteen, H.D. and Schellschmidt, R., 2003.Influence of temperature on thermal conductivity,thermal capacity and thermal diffusivity fordifferent types of rock. Physics and Chemistry ofthe Earth, 28, 499–509.Beardsmore, G.R. and Cull, J.P., 2001. CrustalHeat Flow, A Guide to Measurement andModelling, 108 pp.66

Modelling in Geothermal ExplorationGraeme R Beardsmore*<strong>Hot</strong> Dry Rocks Pty LtdLevel 4, 141 Osborne Street, South Yarra VIC 3141Australian Geothermal Energy Conference 2009In geothermal studies we often have to drawconclusions and make decisions using uncertainor incomplete data sets. In such circumstances,we are compelled to rely on ‘modelling’. Modellingtakes many forms and is used for many purposes,from temperature prediction to cash flowprediction.Equations typically modelled in geothermalstudies include the heat flow equation, phasechange equations, fluid dynamics equations,Rayleigh number equations, project valuationequations or hydro-geo-mechanical equations.Models of geothermal systems are oftenconstrained by geophysical measurements,observations of structural trends, geochemicalsignatures, flow rate observations, or temperaturemeasurements.Thermal modelling sheds light on probabletemperatures at depth prior to expensive drilling.Reservoir modelling, likewise, helps predict theperformance of future geothermal productionwells, with increasing confidence as reservoirproperties are constrained. Economic modelling,however uncertain, is essential to make informedinvestment and project development decisions.Keywords: Modelling, Inversion, Stored Heat,Numerical Simulation, Economic ModellingIntroductionIn geothermal studies we often have to drawconclusions and make decisions about complexsystems using uncertain or incomplete data sets.In such circumstances, we are compelled to relyon ‘modelling’ to make sense of the data. Butmodelling, itself, often presents us with anassortment of possible methods. This paperbriefly covers some of the common instanceswhere modelling is required in geothermal; thetype of data required; the range, strengths, andweaknesses of the different available modellingmethods; and what stages in the developmentprocess each might be appropriate.The authoritive online dictionary ‘wiktionary.com’defines a ‘model’ as “(1) A person who serves asa subject for artwork or fashion, usually in themedium of photography but also for painting ordrawing. (2) A miniature representation of aphysical object. (3) A simplified representation(usually mathematical) used to explain theworkings of a real world system or event.”Some individuals in the industry may fit definition(1), but the processes we use to make sense ofdisparate geothermal data fall into definition (3).The purpose of models is to assist predictionsabout variables that are beyond the current reachof measurements. Models might be used to helppredict the location of undiscovered heat sources,the temperature and reservoir conditions at undrilleddepths, or the income from a geothermaldevelopment at some time in the future.“Real world systems” that can be modelled ingeothermal studies include:Geological structuresUnderground temperatures (°C)Response of fracture networks to stressWell productivity (MWt)Generation capacity (MWe) Cash flow for a projectAll modelling should be based on observations ormeasured data. Models based on ‘estimated’ or‘assumed’ values do not add value to a projectbecause the outputs of any model are only asreliable as the inputs. If the inputs are poorlyconstrained, so are the outputs.Models must also conform to the laws of physics,such as conservation of mass and energy. Arobust model is a mathematical representation ofa system that honours all relevant governingequations, and is consistent with all observed ormeasured data. We say that these known data‘constrain’ the model.Models can be developed around many differentgoverning equations and be constrained by manydifferent types of data. Relevant governingequations in geothermal studies may include theheat flow equation, phase change equations, fluiddynamics equations, Rayleigh number equations,project valuation equations or hydro-geomechanicalequations. Models of geothermalsystems are often constrained by geophysicalmeasurements, observations of structural trends,geochemical signatures, flow rate observations, ortemperature measurements.Modelling terms that are commonly used, butrarely explained, include:1D, 2D, 3D, 4D, 2.5D etcForward modelling versus inversionStored heat versus numerical simulationHydro-geo-mechanical modellingEconomic modelling17

Australian Geothermal Energy Conference 2009The following sections explain each of theseterms and how they relate to “real world systems”.1D, 2D, 3D, 4D, 2.5D etcThe “D” in these terms means “dimension”—usually spatial dimension. The first threedimensions are the three orthogonal dimensionsof space (or ‘length’, ‘width’ and ‘depth’). Thefourth dimension is (usually) time. 1D modelling issufficient for processes that happen in a straightline. If a process intrinsically encompasses anarea or a vertical section, then a minimum of 2Dmodelling is required. Processes involvingvolumes of rock or space require 3D models,while 3D processes that change through timehave to be represented by 4D models.‘2.5D’ modelling refers to when a systemeffectively only varies in two dimensions, but isassumed to extend infinitely and unchanged intothe third dimension. Thus, for example, a threedimensional block can be entirely represented bya two dimensional cross-section.1D modellingAn example of 1D modelling is predicting thetemperature (T z ) at a particular depth (z) when weknow surface heat flow (Q) and assume verticalconductive heat transfer in the crust (Figure 1).divided by thermal conductivity) between thesurface and depth, z. All the energy transferoccurs vertically so the system can berepresented in a single dimension.1D models have the advantage that they are easyto comprehend, are computationally relativelysimple, do not require much computer memory orprocessing power, and deliver rapid results. Theyare appropriate for rapid regional reconnaissance,or in situations where data may only be availablefor a single location. Their disadvantages includethe fact that very few natural processes are trulyone-dimensional, so certain simplifications areinherent in the models.2D ModellingSome problems are too complex, or inherentlyareal or spatial in scope, to reduce to 1D. Anexample might be modelling the thermal effect ofconvection in a permeable layer. This requires atleast a 2D space to represent the vertical andhorizontal movement of water and heat (Figure 2).Figure 2. 2D model of temperature (°C) distribution wherecool water enters the bottom left of the model and exits at thetop left. The axes represent the physical dimensions, and theresult (temperature) is represented by cell colour. This couldnot be modelled in 1D. After Wang et al. (2009).Figure 1. 1D conductive heat flow model of temperatureincrease with depth. Only one dimension (‘depth’) ismodelled, with results (‘temperature’) plotted on the x-axis.Constraining temperature data shown in green.The governing equation for this is:T z = T 0 + Q.R Eq 1where T 0 is the surface temperature and R is thecumulative thermal resistance (physical thicknessHigher Dimensional ModellingThe real world is inherently four-dimensional.Everything exists in three-dimensional space andtime. The higher the dimension of modelling,therefore, the closer a model can approximate‘reality’. However, higher dimensional modellingcomes with significant challenges.It is usual to break each dimension of a model intosub-sections and to treat each subsection as adiscrete unit. In a 1D model, this may result inseveral tens or hundreds of discrete units makingup the total length of the model. In 2D, eachdimension might be divided into several tens orhundreds of units, resulting in hundreds to tens ofthousands of individual ‘cells’. For instance, theexample in Figure 2 shows the model areadivided into 20 units in each dimension, resulting28

Australian Geothermal Energy Conference 2009in 400 discrete cells. The number of cells ismultiplied further with 3D or 4D modelling, to thepoint where models (e.g. Figure 3) regularlyrequire millions of cells to adequately define themodel space.Figure 3. 3D representation of a geological layer. Threeorthogonal axes are displayed, with a particular variable(‘rock type’) represented by colour. There are over onemillion individual cells in this model.Storing and manipulating information aboutmillions of cells in a computational processrequires significant computing power and/or time.It is not unusual for a typical desktop computer totake several days, or even weeks, to solve asingle 3D model. In addition, the number ofboundary conditions and variables required tofully define a 3D model is typically higher thanlower dimensional problems.Boundary ConditionsSpatial-type models of any dimension needboundary conditions to constrain a solution.Boundary conditions provide a starting point forthe mathematical solution of the particulargoverning equation under investigation.Forward Modelling / InversionThe terms ‘forward modelling’ and ‘inversion’ referto fundamentally different ways of interpretingmeasured data. In ‘forward modelling’, anoperator builds a geological model and assignsproperties and boundary conditions that representa ‘best guess’ about the true nature of the piece ofcrust under investigation. The model is thensolved and the results are compared againstknown measurements of certain parameters. Ifthe results do not closely match the observations,the model is manually altered and the processrepeated until a good match is achieved.‘Inversion’ starts with the known measurements.The operator effectively tells the model what isknown, and the inversion process then derives theappropriate boundary conditions or particularvalues for variables to match the known data.3D conductive temperature modelling can beused to illustrate these two approaches.Conductive heat flow modelling typically relies ona geological model to represent the structure andlithological variation with the piece of crust underinvestigation. The different geological units of themodel are assigned properties including (as aminimum) thermal conductivity. Surfacetemperature is almost always used as one of thethermal boundary conditions, and there is anassumption of zero heat flow through the sides ofthe model. A second thermal boundary conditionis always required at either the top or base of themodel to fully constrain the solution to theconductive heat flow equation. The nature of thesecond boundary condition and how a solution isderived effectively distinguishes forward modellingfrom inversion modelling.Forward modelling of 3D conductive heat flow hasbeen practiced since the advent of digitalcomputers (e.g. Sams and Thomas-Betts, 1988;Gibson et al., 2008). Its strength lies in its relativesimplicity and ability to quickly reach a solution fortemperature distribution that satisfies a smallnumber of surface heat flow observations. It isappropriate in situations where very little is knownabout surface heat flow, or for conceptualmodelling to explore the effect of differentparameters on subsurface temperaturedistribution.Forward modelling inherently requires theoperator to assume a thermal boundary condition(typically ‘constant temperature’ or ‘constant heatflow’) at the base of the model. However, there isno geological reason to expect either heat flow ortemperature to be constant across any particulardepth surface. In fact, the whole premise ofgeothermal exploration is that heat flow andtemperature are not laterally constant at depth!Inversion modelling comes into its own when thenumber of surface observations increases beyondtwo or three. In this situation, it is unlikely that asimple basal condition will yield a solution thatclosely satisfies all the available data. But aninversion process inherently starts with thesurface data and derives the temperaturedistribution that best accounts for theobservations. This process results in conditions atthe base of the model that are rarely constanttemperature or constant heat flow (Figure 4).Stored Heat / Numerical SimulationTable 2 of the ‘Geothermal Lexicon’ (AGEG,2008) includes ‘stored heat’ and ‘numericalsimulation’ as options for estimating GeothermalResources and Geothermal Reserves. TheLexicon goes on to describe the two differentmethodologies in some detail. The methods aremutually independent and represent two verydifferent ways of assessing the potential of ageothermal play.39

Australian Geothermal Energy Conference 2009Figure 4. Inversion modelling of conductive heat flow. Thecolours represent modelled temperature at 5,000 m depthbeneath an area approximately 50 km x 40 km. The modelwas constrained by heat flow measurements at the sixlocations shown. Both heat flow and temperature varysignificantly across the model. After Torrens Energy (2008).A ‘stored heat’ evaluation is a technique forestimating the total heat energy contained within atarget volume of rock. The method requires theestimation of the volume, density, specific heatcapacity and temperature of the target reservoirformations. These parameters are sufficient toestimate the absolute amount of thermal energy inthe rock. The proportion of that energy that mightultimately be extracted depends on the lowesteconomically extractable temperature (‘cut-offtemperature’), the application to which the energywill be applied, and the efficiency with which theenergy can be extracted.The ‘stored heat’ approach quantifies theresource base—that is, it addresses the question,“How much thermal energy is in this geothermalplay?” It does not address any aspect ofextracting the energy, except for a considerationof the ultimate end use of the energy. It also doesnot address possible recharge of the thermalenergy during extraction. ‘Stored heat’ is a usefulconcept at the early stages of resource estimationand play evaluation, but is of limited use fordetailed project planning.‘Numerical simulation’ lets us investigate some ofthe practical issues surrounding the extraction ofthermal energy. Unlike ‘stored heat’ assessments,‘numerical simulation’ incorporates a timeelement. At the early stages of field development,it allows us to model the flow of fluid (liquid and/orgas) and heat for different extraction strategies,and investigate how they impact on the life of theresource in terms of achievable power output,reservoir temperature and pressure (Figure 5).Later in the life of the project, the models can berefined using actual production data like thermaldraw down to develop a predictive understandingof the response of the reservoir to production.Figure 5. Predicted temperature distribution in an EGSreservoir after 20 years of production using a hexagonal (top)and square (bottom) well pattern. Results from numericalsimulation. After Vörös et al. (2007).Numerical simulation is the best way toinvestigate parameters such as power outputthrough time, the effects of reinjection on reservoirtemperature and pressure, improvements inproductivity achievable through permeabilityenhancement, the impact of pumping on reservoirproductivity and lifetime, and similar issues.Numerical simulation, therefore, has a role to playat all stages of a project’s life.Hydro-geo-mechanical modellingCoupled hydro-geo-mechanical modelling is thefrontier of EGS numerical investigations. Thegrowth of an EGS reservoir during hydraulicstimulation and the geo-mechanical behaviour ofa reservoir during production are incrediblycomplex processes that currently defy realisticnumerical modelling. To get an idea of thecomplex systems at interplay during an EGSproject, consider the following:When water is injected into a fractured rock, manyprocesses take place. The pressured waterincreases the pore pressure in the fractures andeffectively jacks the fracture open. Eventually, thefriction on critically orientated fracture is reducedto the point where the two sides of the fracturecan slip against each other in response to thetectonic stress field. This slippage alters the local410

Australian Geothermal Energy Conference 2009stress field in the matrix in the vicinity of thefracture and the pressure within the pores. At thesame time, the thermal shock of the cool injectedwater on the hot fractured rocks causes thermalshrinking of the rock matrix, which in turn alsoaffects the local stress field. As the high-pressurewater near the borehole works its way into therock fabric, the volume of rock affected by thehydraulic stimulation increases, and the localstress field, pore pressures and temperaturescontinuously adjust and readjust to the hydraulicand thermal changes. As the injected fluidaccumulates in the fractured rock, even the bulkvolume of the rock increase.The exact reaction of the rock and fracture systemto the injected water depends on the density andorientation of all the fractures; the strength of therock; the thermal expansion coefficient, specificheat capacity, density and thermal conductivity ofthe rock; the pressure and temperature of theinjected fluid; the initial magnitude and orientationof the local stress field; the stiffness of thefractures; all of which are difficult to quantify.Developing code to explicitly model theoverwhelmingly complex system of interactingforces and flows is effectively impossible. It isphysically impossible to provide the computingpower and memory to store and process all theessential variables and governing equations onthe many different required scales. The problemmust be tackled in individual pieces, or by using a‘lumped variable’ approach.One example is ‘UDEC 1 ’ (Universal DistinctElement Code). UDEC models a rock mass as aseries of impermeable blocks separated bydiscontinuities (joints). The joints form boundariesbetween the blocks, and impose their ownboundary conditions. UDEC models the physicaldisplacement of the blocks in response to a stressfield. Solutions satisfy the laws of conservation ofmomentum and energy. UDEC simulations canprovide the following useful outcomes: Identification of the orientation of fracturesmost likely to shear during stimulation.An estimate of the pre-stimulation hydraulicconductivity and anisotropy of the fracturedrock (e.g. Figure 6).An indication of potential reservoir growth andfluid flooding directions.An estimate of stress magnitudes at the targetdepth and the injection pressures required forhydraulic stimulation.Results provide the basis for more complexmodels to simulate the lifetime performanceof an EGS project.1 UDEC is a Trademark of Itasca InternationalFigure 6. UDEC model results of the horizontal planarhydraulic conductivity (K) ellipse for a fracture network at aspecific depth (stress) level.Economic ModellingEconomic modelling aims to simplify the multitudeof factors that affect the ultimate profitability of aproject into a few basic assumptions. Unlike themodelling discussed earlier in this document,economic modelling is primarily about estimatingcash flow through time, with little reference tospatial or volumetric details.Many parameters can be estimated througheconomic modelling. Parameters such as the‘Levelised Cost of Power’, ‘Net Present Value’and ‘Expected Monetary Value’ allow the relativevalues of different geothermal plays, or differentstrategies for developing the same play, to beassessed. The sensitivity of project value tovariables such as discount rates, electricity price,operating costs, drilling costs, distance from thegrid, and so forth, can be explored througheconomic models. Likewise, the impact of policymeasures such as Renewable EnergyCertificates, Geothermal Drilling Program grants,and so forth, can also be explored.Economic modelling is a powerful tool forinforming investment decisions and for projectplanning, but the critical input variables oftenrelate to future economic conditions and are verydifficult to constrain. Regardless, economicmodelling should be used from very early in aproject’s life in order to identify the key drivers forthe economic success of each individual project.In some cases that may be low developmentcosts, while in others it may be high power saleprice.ConclusionsModelling in all its forms and guises is a vital andvaluable tool in making sense of the often scarceand uncertain data inherent in geothermal studies.Thermal modelling sheds light on probable511

Australian Geothermal Energy Conference 2009temperatures at depth prior to expensive drilling.Reservoir modelling, likewise, helps predict theperformance of future geothermal productionwells, with increasing confidence as reservoirproperties are constrained. Economic modelling,however uncertain, is essential to make informedinvestment and project development decisions.At each stage of development, the sophisticationof the modelling should refect the amount andreliability of the available data. Simple 1D modelsmay be appropriate when little information isavailable, while more complex, multi-dimensionalmodels are better for extracting the maximumvalue from larger, more reliable data sets.ReferencesAGEG (Australian Geothermal Energy Group)(2008). Geothermal lexicon for resources andreserves definition and reporting—Edition 1.AGEG Geothermal Code Committee, August2008. 105pp.Gibson, H., Stuwe, K., Seikel, R., FitzGerald, D.,Calcagno, P., Argast, D., McInerney, P. andBudd, A. (2008). Forward prediction of spatialtemperature variation from 3D geology models. In:Blevin, J.E., Bradshaw, B.E. and Uruski, C. (Eds),Eastern Australasian Basins Symposium III,Petroleum Exploration Society of Australia,Special Publication, 425-430.Sams, M.S. and Thomas-Betts, A. (1988). 3Dnumerical modelling of the conductive heat flow ofSW England. Geophysical Journal, 92, 323-334.Torrens Energy (2008). 780,000 PJ inferredresource, Parachilna Project, South Australia.Statement to the Australian Securities Exchange,20 August 2008. 4pp.Vörös, R., Weidler, R., de Graaf, L. and Wyborn,D. (2007). Thermal modelling of long termcirculation of multi-well development at theCooper Basin hot fractured rock (HFR) projectand current proposed scale-up program.Proceedings: Thirty-Second Workshop onGeothermal Reservoir Engineering, StanfordUniversity, Stanford, California, January 22–24.SGP-TR-183.Wang, Z., McClure, M.W. and Horne, R.N. (2009).A single-well EGS configuration using a thermosiphon.Proceedings: Thirty-Fourth Workshop onGeothermal Reservoir Engineering, StanfordUniversity, Stanford, California, February 9–11.SGP-TR-187.612

Australian Geothermal Energy Conference 2009A Geothermal Play Systems approach for explorationA.R. Budd, A.C. Barnicoat, B. F. Ayling, E.J. Gerner, A. J. Meixner, A. M. Kirkby.<strong>Geoscience</strong> Australia, GPO Box 378, Canberra 2601, ACT, Australia<strong>Hot</strong> Rock exploration and development hasprogressed rapidly in Australia in the last decade.A wealth of pre-competitive geological dataacquired by government surveys and mineral andpetroleum explorers is available in Australia, butheat flow data specific to geothermal explorationis sparse. A methodology is presented that setsout the key parameters required in <strong>Hot</strong> Rockexploration. Mappable practical proxiescorresponding to these parameters can utiliseexisting geological datasets. Australia has anenviable amount of geological data that is publiclyavailable, and this can be used to show that manyparts of the continent are attractive <strong>Hot</strong> Rockexploration areas.Keywords: <strong>Hot</strong> Rock, exploration, Australia,geothermal play systemsIntroductionMineral Systems Analysis or Petroleum PlaySystems are well established in their respectiveindustries. Exploration methods for conventionalgeothermal systems are likewise well established.To date, most EGS or <strong>Hot</strong> Rock projects (inAustralia at least) have used compilations ofbottom-hole temperatures to identify prospectivegeothermal systems. These data are mostlyrestricted to petroleum exploration areas. As aresult, with few exceptions only areas of historicalpetroleum potential in Australia have beenidentified as having geothermal potential, whether<strong>Hot</strong> Rock or hydrothermal. The other obvious datatype for temperature prediction (heat flow) ispoorly constrained in Australia with only ~150publicly-available measurements.<strong>Hot</strong> Rock systems are not restricted to thegeological settings favorable for oil and gasaccumulation and preservation. Therefore, it is tobe expected that there are areas of Australia withuntested <strong>Hot</strong> Rock geothermal potential.<strong>Geoscience</strong> Australia is deriving a GeothermalPlays System approach, modeled on the‘Exploration Science’ methodology of MineralSystems Analysis (Barnicoat 2008), to formulate aframework for <strong>Hot</strong> Rock exploration. Thisapproach links the key physical and/or chaemicalparameters of the geological system underconsideration, with mappable ‘practical proxies’ todefine exploration criteria. It is a scalableapproach that works for terrain selection, areaselection and drill target selection.To derive the key components necessary to forman accumulation of heat in a <strong>Hot</strong> Rock geothermalplay, a systematic approach is desirable. Fromthese key components, the geological,geophysical and geochemical data necessary forexploration should be identifiable. Importantly,‘practical proxies’ should be able to be developed,which utilize existing datasets to make informedassumptions regarding missing data. This wouldenable <strong>Hot</strong> Rock exploration in Australia toprogress.Method<strong>Hot</strong> Rock systems comprise a heat source, aninsulating layer, and sufficient permeability –either natural or enhanced - to enable sufficientflow of fluid through the heat reservoir.Temperature and flow rate are the two essentialparameters describing the potential output of ageothermal system.The steady-state equation for temperature (1)shows that the important determinants oftemperature are: thermal conductivity , depthintegratedheat generation A, mantle or basal heatflow Q m and the crustal thickness underconsideration Z.TAz Qmdz (1)In most areas of Australia, this temperatureequation cannot be solved by input of directmeasurements. Estimates must be used based oninference from other datasets that may have beenacquired for other purposes, and as such arepractical, proxy measurements. Further, some ofthese proxies translate readily to mappablefeatures that have concerned petroleum andmineral exploration geologists for many years.Increasingly in Australia, 3D geological maps arebeing made at various scales that already containmany of the mapped proxy data necessary for <strong>Hot</strong>Rock exploration, and these may be practicallyutilized for predicting the thermal structure of theupper crust.Thermal conductivityThe thermal conductivity of rocks varies accordingto composition, grainsize, porosity andtemperature. Basic geological mapping andlogging of drill core or chips will record lithology,and this information can be used to estimategrainsize, porosity and composition. Porosity maybe determined from density measurements andwell data. In a simplistic first-pass assessment,the effect of temperature may be ignored as itsinfluence is smaller than effects from composition,grainsize, or porosity. In more advanced problemsolvingmodels, it may be solved-for iteratively.113

Australian Geothermal Energy Conference 2009Heat GenerationHeat generation is a property that is dependent oncomposition. Uranium, thorium and potassium arethe main radiogenic elements that contribute toheat generation. The density of a rock is also animportant variable. The heat generation of a rockis given by the equation of Rybach (1988):A = 10 -5 ρ(9.52U + 2.56Th + 3.48K) (2)where ρ = density in kg m -3 and U, Th and K arethe concentration of uranium and thorium in partsper million and potassium in weight percent.Geochemical analyses of whole-rock samplesplus determination of density will fully solve theequation. In Australia, geochemical data is oftenanalyzed for a sample although density isgenerally not. In such case, density must beestimated based on lithology, the determination ofwhich will be aided by geochemistry. In detail, theheat production of a rock also depends on its age.In Australia, where recent active volcanism islacking, high-heat-producing granites aregenerally the only rocks capable of creating asufficient additional heat flow in the upper crust tocause significantly elevated temperaturenecessary for viable <strong>Hot</strong> Rock geothermalsystems, although low conductivity cover mayallow temperatures in radiogenic lithologies toreach economic values. High-heat productiongranites often occur as deeply (>3 km) buriedplutons and are not directly sampled. Graniteplutons, suites and supersuites share a geneticlineage that potentially enables some constraintsto be placed on unsampled plutons.Mappable practical proxies for heat production(from granites) can therefore be utilized frommapping geochemistry, geochronology andgeophysics (gravity, magnetic, radiometrics,seismic surveys) by: (1) mapping trends ofgranites from outcrop to beneath insulatingmaterials using geophysical interpretations; (2)using the chemistry (either measured or inferredfrom radiometrics) of outcropping granites tocalculate heat production; and (3) estimating thedepth and area (and therefore volume) of buriedgranites using constraints supplied by seismicsurveys and interpretation of gravity and magneticpotential field data (see Meixner et al. thisvolume).In Australia, the general nature of granites ingeological provinces is quite well known andcontinues to be refined. For example, it is knownthat late Archean granites in the Yilgarn Cratonare high-heat producing (Cassidy et al. 2002), asare the more felsic members of numeroussupersuites of the Paleozoic of eastern Australia(eg Chappell et al. 2000). Proterozoic granites inAustralia generally have high U, Th and Kcompared to granites of older and youngerperiods, and many Proterozoic supersuites arehigh heat producing (Budd et al. 2001, McLaren etal. 2003).At a national scale, the newly releasedRadiometric Map of Australia(http://www.ga.gov.au/minerals/research/national/radiometric/index.jsp) shows the surfacedistribution of K, U and Th for over 80 per cent ofthe continent (Figure 1). This new radiometricmap has been produced by leveling more than450 individual surveys collected over the past 40years and compiling them into a single seamlessimage. This dataset readily shows areas of highU, Th and K, some of which may correlate to highheat-producinggranites. Heat production mayalso be estimated from gamma logs or fromseismic velocity.Figure 1: A clip-out of the Radiometric Map of Australia, <strong>First</strong>Edition (Minty et al. 2008). The ternary radiometric imageshows the concentrations of the radioelements potassium(K), uranium (U) and thorium (Th) at the Earth’s surface asmeasured using the airborne gamma-ray spectrometricmethod. The image is a false color composite using thecolors red, blue and green to represent K, U and Threspectively.These various mappable proxies for heatproduction are supported by extensive publiclyavailabledatasets, and are readily incorporatedinto both 2D GIS and 3D maps.Mantle/Basal heat flow and section depthIn comparison to some other parts of the world,the broad thermal structure of the Australian crustis understood in great detail only in small areas.Sass and Lachenbruch (1979) and Cull (1982,1991) examined information on heat flow inAustralia, but with less than 150 heat flowmeasurements across the entire continent, thedata available are insufficient to be definitive.From this work, it was recognized that severalareas of Proterozoic crust have anomalously highheat flow (and include abundant high-heatproducinggranites). Several studies have214

Australian Geothermal Energy Conference 2009examined the occurrence of this high heat flow,heat production and implications for tectonicevolution, including (but not limited to): McLarenet al. (2006) in the Mount Painter Province, SouthAustralia; Neumann et al. (2000) in the area of theSouth Australian Heat Flow Anomaly; andSandiford et al (2001) in central Australia. Evenwith these studies, considerable further work isrequired to be done throughout Australia to betterunderstand the application of heat flow provinceunderstanding as outlined by Roy et al. (1968).Information on crustal structure is central tounderstanding the overall thermal structure of thecrust and for deriving mantle heat flow. Seismicreflection surveys directly map crustal structure,and provide information on the potential range oflithologies and hence heat generation and thermalconductivity. Seismic velocities derived from thedata also have implications for thermal structureincluding temperature and heat generation.Seismic velocity is a proxy for density, which mayassist in the mapping of granite volumes andtherefore potential heat production. Australia hasa good database of seismic reflection surveys,and surveys are being continually acquired.Other parametersOnce the temperature of a potential geothermal<strong>Hot</strong> Rock reservoir is constrained, the nextconcern is whether a fluid can pass through thereservoir at the necessary velocity and volume(flow rate) to extract the required energy from thereservoir and transport it to the surface. Darcy’slaw describes the flow of a fluid through a porousmedium: A( Pb Pa)q L(3)where q is the total discharge (units of volume pertime, e.g., m³/s) and is equal to the product of thepermeability (κ units of area, e.g. m²) of themedium, the cross-sectional area (A) to flow, andthe pressure drop (P b − P a ), all divided by thedynamic viscosity μ (in SI units e.g. kg/(m·s) orPa·s), and the length L the pressure drop is takingplace over.Of most interest during a resource evaluationphase is the permeability of the target reservoir orformation. Other than direct measurement,mappable practical proxies for this includepredicted lithology and seismic velocity.As <strong>Hot</strong> Rock developments usually includereservoir engineering to enhance reservoirpermeability, mapping the stress regime at thatcrustal level is of interest. This is mapped eitherdirectly through borehole measurement, mediumtolong-term passive seismic monitoring using anAustralia-wide seismic monitoring network, shorttermpassive seismic monitoring using temporaryarray deployments, or indirectly through surfaceneotectonic kinematic indicators. The AustralianStress Map (Hillis and Reynolds, 2000) showingthe crustal stress regime is available athttp://www.asprg.adelaide.edu.au/asm/ (Figure 2)and has provided useful information forgeothermal explorers in the early stages of theirdevelopments.Figure 2: Stress trajectories calculated from the AustralianStress Map (Hillis and Reynolds, 2000). The stresstrajectories indicate the orientation of the maximumhorizontal stress at each point along the trajectory, but theydo not imply information about magnitudes.ConclusionIn <strong>Hot</strong> Rock exploration in Australia, it is possibleto link the fundamental geothermal parameters tothe exploration process by means of thegeological expression of the fundamentalprocesses and the application of a scaledependentmapping of these into explorationdecision making.The most important step in the process istranslating the understanding of the process andthe key parameters controlling the process intofactors that can be determined spatially. <strong>Hot</strong> Rockgeothermal exploration in Australia is in its infancyand with some exceptions has been based on thedatabase of bottom-hole temperatures frompetroleum drilling. By incorporating national-scaledatasets into a Geographical Information System,a relatively rapid assessment of <strong>Hot</strong> Rockgeothermal plays can be done at a regional scale.This will inform both exploration programs (andtherefore lower risk) and pre-competitive dataacquisition programs.A companion paper (Meixner et al. this volume,Establishing <strong>Hot</strong> Rock Exploration Models - FromSynthetic Thermal Modeling to the Cooper Basin3D Geological Map) describes the use of thermalmodeling of 3D geological datasets as a moredetailed way of assessing geothermalprospectivity at a regional scale. Australia hasextensive publicly-available geological datasets,and with the understanding of how to practicallyapply these to geothermal exploration incombination with the tools to perform 3D thermalmodeling, the assessment of <strong>Hot</strong> Rock315

Australian Geothermal Energy Conference 2009geothermal play assessments will highlightAustralia as an attractive candidate forgeothermal investment.ReferencesBarnicoat A.C. 2008. The mineral systemsapproach of the pmd*CRC. <strong>Geoscience</strong> AustraliaRecord 2008/09, 1-6.Budd, A.R., Wyborn, L.A.I. & Bastrakova, I.V.2001. The metallogenic potential of AustralianProterozoic granites. <strong>Geoscience</strong> AustraliaRecord 2001/12, pp 154 + 2 CD-ROMs.Cassidy, K.F., Champion, D.C., McNaughton,N.J., Fletcher, I.R., Whitaker, A.J., Bastrakova,I.V. and Budd, A.R. 2002. Characterisation andmetallogenic significance of Archaean granitoidsof the Yilgarn Craton. AMIRA ProjectP482/Meriwa Project M281. Minerals and EnergyResearch Institute of Western Australia Report222.Chappell, B.W., White, A.J.R., Williams, I.S.,Wyborn, D. & Wyborn, L.A.I. 2000. Lachlan FoldBelt granites revisited: high- and low-temperaturegranites and their implications. Australian Journalof Earth Sciences, 47/1, 123-138.Cull, J.P. 1982. An appraisal of Australian heatflow data. Bureau of Mineral Resources Journal ofAustralian Geology and Geophysics, 7, 11-21.Cull, J.P. 1991. Heat flow and regionalgeophysics in Australia. In: Cermáck, V. andRybach, L. (eds.) Terrestrial Heat Flow and theLithosphere Structure, Springer-Verlag, Berlin,486-500.Hillis, R.R. and Reynolds, S.D. 2000. TheAustralian Stress Map. Journal of the GeologicalSociety (London), 157, 915-921McLaren, S., Sandiford, M., Hand, M., Neumann,N., Wyborn, L. and Bastrakova, I. 2003. The hotsouthern continent: heat flow and heat productionin Australian Proterozoic terranes. In: Hillis, R.R.and Muller, D. (eds.) Evolution and Dynamics ofthe Australian Plate. Geological Society ofAustralia Special Publication 22, 151-161.McLaren, S., Sandiford, M., Powell, R., Neumann,N. and Woodhead, J. 2006. Paleozoic intraplatecrustal anatexis in the Mount Painter Province,South Australia: timing, thermal budgets and therole of crustal heat production. Journal ofPetrology, 47/12, 2281-2302.Minty, B.R.S., Franklin, R., Milligan, P.R.,Richardson, L.M. and Wilford, J. 2008.Radiometric Map of Australia (<strong>First</strong> Edition), scale1:15 000 000, <strong>Geoscience</strong> Australia, Canberra.Neumann, N., Sandiford, M. and Foden, J. 2000.Regional geochemistry and continental heat flow:implications for the origin of the South Australiaheat flow anomaly. Earth and Planetary ScienceLetters, 183, 107-120.Roy, R.F., Blackwell, D.D. and Birch, F. 1968.Heat generation of plutonic rocks and continentalheat flow provinces. Earth and Planetary ScienceLetters, 5, 1-12.Rybach, L. 1988 Determination of heat productionrate, in: Haenel, R., Rybach, L. and Stegena, L.(eds.) Handbook of Terrestrial Heat-Flow DensityDetermination, Kluwer Academic Publishers, 125-142.Sandiford, M., Hand, M. and McLaren, S. 2001.Tectonic feedback, intraplate Orogeny and thegeochemical structure of the crust: a centralAustralian perspective. In: Miller, J.A.,Holdsworth, R.E., Buick, I. and Hand, M. (eds.)Continental Reactivation and Reworking.Geological Society, London, Special Publication184, 195-218.Sass, J.H. and Lachenbruch, A.H. 1979. Thethermal regime of the Australian continental crust.In: McElhinny, M.W. (ed.) The Earth – its Origin,Stucture and Evolution. Academic Press, NewYork, 301-352.416