Hydraulic ram pumps and Sling Pumps

Hydraulic ram pumps and Sling Pumps Hydraulic ram pumps and Sling Pumps

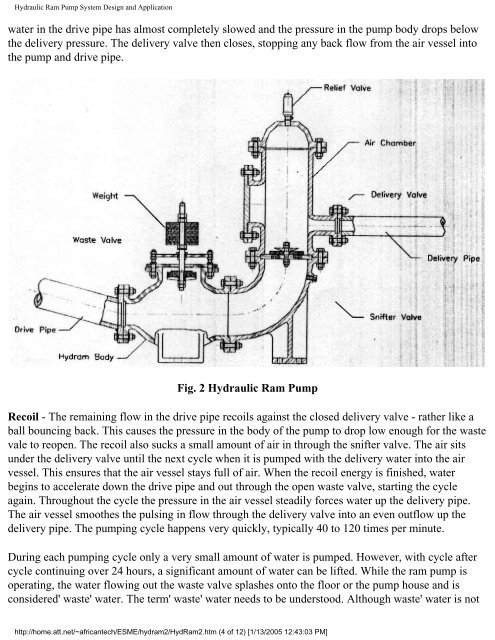

Hydraulic Ram Pump System Design and ApplicationFig. 1 Components of a Hydraulic Ram Pump StationWORKING PRINCIPLE OF HYDRAULIC RAM PUMPSAlthough hydraulic ram pumps come in a variety of shapes and sizes, they all have the same basiccomponents as shown in Fig. 2. The main parts of a ram pump are Hydram body, Waste value sniftervalve, delivery valve, air chamber and relief valve. Ram Pumps have a cyclic pumping action thatproduces their characteristic beat during operation. The cycle can be divided into three phases;acceleration, delivery and recoil.Acceleration - When the waste valve is open, water accelerates down the drive pipe and dischargesthrough the open valve. As the flow increases it reaches a speed where the drag force is sufficient tostart closing the valve. Once it has begun to move, the valve closes very quickly.Delivery - As the waste valve slams shut, it stops the flow of water through it. The water that has beenflowing in the drive pipe has considerable momentum which has to be dissipated. For a fraction of asecond, the water in the body of the pump is compressed causing a large~ surge in pressure. This typeof pressure rise is known as water hammer. As the pressure rises higher than that in the air chamber, itforces water through the delivery valve (a non-return valve). The delivery valve stays open until thehttp://home.att.net/~africantech/ESME/hydram2/HydRam2.htm (3 of 12) [1/13/2005 12:43:03 PM]

Hydraulic Ram Pump System Design and Applicationwater in the drive pipe has almost completely slowed and the pressure in the pump body drops belowthe delivery pressure. The delivery valve then closes, stopping any back flow from the air vessel intothe pump and drive pipe.Fig. 2 Hydraulic Ram PumpRecoil - The remaining flow in the drive pipe recoils against the closed delivery valve - rather like aball bouncing back. This causes the pressure in the body of the pump to drop low enough for the wastevale to reopen. The recoil also sucks a small amount of air in through the snifter valve. The air sitsunder the delivery valve until the next cycle when it is pumped with the delivery water into the airvessel. This ensures that the air vessel stays full of air. When the recoil energy is finished, waterbegins to accelerate down the drive pipe and out through the open waste valve, starting the cycleagain. Throughout the cycle the pressure in the air vessel steadily forces water up the delivery pipe.The air vessel smoothes the pulsing in flow through the delivery valve into an even outflow up thedelivery pipe. The pumping cycle happens very quickly, typically 40 to 120 times per minute.During each pumping cycle only a very small amount of water is pumped. However, with cycle aftercycle continuing over 24 hours, a significant amount of water can be lifted. While the ram pump isoperating, the water flowing out the waste valve splashes onto the floor or the pump house and isconsidered' waste' water. The term' waste' water needs to be understood. Although waste' water is nothttp://home.att.net/~africantech/ESME/hydram2/HydRam2.htm (4 of 12) [1/13/2005 12:43:03 PM]

- Page 1 and 2: Hydraulic ram pumps and Sling Pumps

- Page 3 and 4: Hydraulic ram pumps and Sling Pumps

- Page 5 and 6: Use a hydraulic ram pump to continu

- Page 7 and 8: Use a hydraulic ram pump to continu

- Page 9 and 10: Designing a Hydraulic Ram PumpL = T

- Page 11 and 12: Designing a Hydraulic Ram PumpTable

- Page 13 and 14: CAT Publications at www.ecobooks.co

- Page 16 and 17: Atlas Publications-inexpensive how-

- Page 18 and 19: The Development Technology UnitAnim

- Page 20 and 21: Home-made Hydraulic Ram PumpHome-ma

- Page 22 and 23: Home-made Hydraulic Ram Pumpturn it

- Page 24 and 25: Home-made Hydraulic Ram Pumpthe wat

- Page 26 and 27: Home-made Hydraulic Ram Pumphydraul

- Page 28 and 29: Hydraulic Ram Pump6. The length of

- Page 30 and 31: Hydraulic Ram PumpHydram Size 1 2 3

- Page 32 and 33: Hydraulic Ram PumpTable 3 can now b

- Page 34 and 35: Real Goods Catalog - Library & Offi

- Page 36 and 37: Hydraulic Ram Pumps EBAE 161-92Prin

- Page 38 and 39: Hydraulic Ram Pumps EBAE 161-92upon

- Page 40 and 41: Hydraulic Ram Pumps EBAE 161-92Hydr

- Page 42 and 43: Hydraulic Ram Pumps EBAE 161-923. D

- Page 44 and 45: Hydraulic Ram Pump System Design an

- Page 48 and 49: Hydraulic Ram Pump System Design an

- Page 50 and 51: Hydraulic Ram Pump System Design an

- Page 52 and 53: Hydraulic Ram Pump System Design an

- Page 54 and 55: Hydraulic Ram Pump System Design an

- Page 56 and 57: Picture GallerySearch the web with

- Page 58 and 59: Ram Pump (from Internet Glossary of

- Page 60 and 61: Ram Pump (from Internet Glossary of

- Page 62 and 63: Ram Pump (from Internet Glossary of

- Page 64 and 65: Motorless Water Pump--Gravi-Chekhtt

- Page 66 and 67: AEE Renewable Energy SupersourcePut

- Page 68 and 69: Aquatic Eco-Systems - Aquaculture S

- Page 70 and 71: Real Goods - Folk Ram Pumps

- Page 72 and 73: Sling Pump (from Internet Glossary

- Page 74 and 75: Sling Pump (from Internet Glossary

- Page 76 and 77: Table of ContentsIntroduction _____

- Page 78 and 79: and limited access configurations.F

- Page 80 and 81: Ram PumpsRam pumps are very simpleh

- Page 82 and 83: Nose Pumpsentire pump body.The pump

- Page 84 and 85: Table 2 - Installation Consideratio

- Page 86 and 87: Livestock WateringUSING STREAM-POWE

- Page 88 and 89: Figure 5 Sling PumpInstallation Opt

- Page 90 and 91: Real Goods - Pump water from stream

- Page 92 and 93: SlingpumpsRife Hydraulic Engine Mfg

- Page 94 and 95: Lifewater Canada: Sponsor a WellIf

<strong>Hydraulic</strong> Ram Pump System Design <strong>and</strong> Applicationwater in the drive pipe has almost completely slowed <strong>and</strong> the pressure in the pump body drops belowthe delivery pressure. The delivery valve then closes, stopping any back flow from the air vessel intothe pump <strong>and</strong> drive pipe.Fig. 2 <strong>Hydraulic</strong> Ram PumpRecoil - The remaining flow in the drive pipe recoils against the closed delivery valve - rather like aball bouncing back. This causes the pressure in the body of the pump to drop low enough for the wastevale to reopen. The recoil also sucks a small amount of air in through the snifter valve. The air sitsunder the delivery valve until the next cycle when it is pumped with the delivery water into the airvessel. This ensures that the air vessel stays full of air. When the recoil energy is finished, waterbegins to accelerate down the drive pipe <strong>and</strong> out through the open waste valve, starting the cycleagain. Throughout the cycle the pressure in the air vessel steadily forces water up the delivery pipe.The air vessel smoothes the pulsing in flow through the delivery valve into an even outflow up thedelivery pipe. The pumping cycle happens very quickly, typically 40 to 120 times per minute.During each pumping cycle only a very small amount of water is pumped. However, with cycle aftercycle continuing over 24 hours, a significant amount of water can be lifted. While the <strong>ram</strong> pump isoperating, the water flowing out the waste valve splashes onto the floor or the pump house <strong>and</strong> isconsidered' waste' water. The term' waste' water needs to be understood. Although waste' water is nothttp://home.att.net/~africantech/ESME/hyd<strong>ram</strong>2/HydRam2.htm (4 of 12) [1/13/2005 12:43:03 PM]