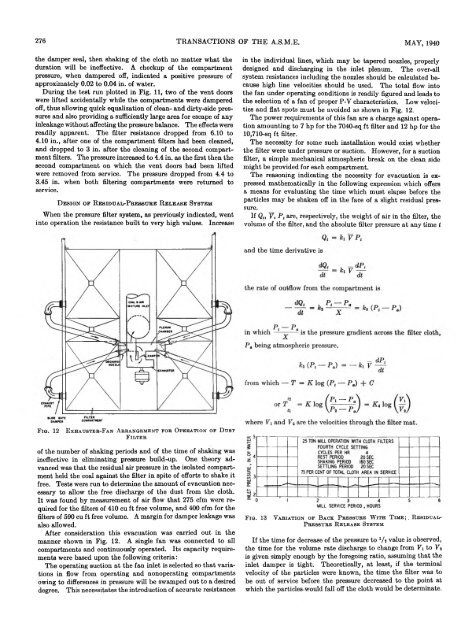

276 TRANSACTIONS OF THE A.S.M.E. MAY, 1940the damper seal, then shaking of the cloth no m atter what theduration will be ineffective. A checkup of the compartmentpressure, when dampered off, indicated a positive pressure ofapproximately 0.02 to 0.04 in. of water.During the test run plotted in Fig. 11, two of the vent doorswere lifted accidentally while the compartments were damperedoff, thus allowing quick equalization of clean- and dirty-side pressuresand also providing a sufficiently large area for escape of anyinleakage without affecting the pressure balance. The effects werereadily apparent. The filter resistance dropped from 6.10 to4.10 in., after one of the compartment filters had been cleaned,and dropped to 3 in. after the cleaning of the second compartmentfilters. The pressure increased to 4.4 in. as the first then thesecond compartment on which the vent doors had been liftedwere removed from service. The pressure dropped from 4.4 to3.45 in. when both filtering compartments were returned toservice.D e s ig n o f I I e s id u a l -P b e s s u b e R e l e a s e Sy st emWhen the pressure filter system, as previously indicated, wentinto operation the resistance built to very high values. Increasein the individual lines, which may be tapered nozzles, properlydesigned and discharging in the inlet plenum. The over-allsystem resistances including the nozzles should be calculated becausehigh line velocities should be used. The total flow intothe fan under operating conditions is readily figured and leads tothe selection of a fan of proper P-V characteristics. Low velocitiesand flat spots must be avoided as shown in Fig. 12.The power requirements of this fan are a charge against operationamounting to 7 hp for the 7040-sq ft filter and 12 hp for the10,710-sq ft filter.The necessity for some such installation would exist whetherthe filter were under pressure or suction. However, for a suctionfilter, a simple mechanical atmospheric break on the clean sidemight be provided for each compartment.The reasoning indicating the necessity for evacuation is expressedmathematically in the following expression which offersa means for evaluating the time which must elapse before theparticles may be shaken off in the face of a slight residual pressure.If Qtt V, P, are, respectively, the weight of air in the filter, thevolume of the filter, and the absolute filter pressure at any time tand the time derivative isF i g . 12E x h a u s t e b - F a n A b b a n g e m e n t f o b O f e b a t i o n o f D u s tF i l t e bof the number of shaking periods and of the time of shaking wasineffective in eliminating pressure build-up. One theory advancedwas that the residual air pressure in the isolated compartmentheld the coal against the filter in spite of efforts to shake itfree. Tests were run to determine the amount of evacuation necessaryto allow the free discharge of the dust from the cloth.It was found by measurement of air flow that 275 cfm were requiredfor the filters of 410 cu ft free volume, and 400 cfm for thefilters of 590 cu ft free volume. A margin for damper leakage wasalso allowed.After consideration this evacuation was carried out in themanner shown in Fig. 12. A single fan was connected to allcompartments and continuously operated. Its capacity requirementswere based upon the following criteria:The operating suction at the fan inlet is selected so that variationsin flow from operating and nonoperating compartmentsowing to differences in pressure will be swamped out to a desireddegree. This necessitates the introduction of accurate resistancesF i g . 13 V a b i a t i o n o f B a c k P b e s s u b e W i t h T i m e ; . R e s i d u a l -P b e s s u b e R e l e a s e S y s t e mIf the time for decrease of the pressure to 1/i value is observed,the time for the volume rate discharge to change from Vi to F sis given simply enough by the foregoing ratio, assuming that theinlet damper is tight. Theoretically, at least, if the terminalvelocity of the particles were known, the time the filter was tobe out of service before the pressure decreased to the point atwhich the particles would fall off the cloth would be determinate.

MUMFORD, MARKSON, RAVESE—CLOTH FILTERS ON COAL DUST-AIR MIXTURES 277A consideration of the terminal velocity of fine particles, asdiscussed by Croft,4 leads to the general conclusion that the airvelocities for the particles encountered here must be less thanabout 3.5 in. per sec and may have to be as low as 0.001 in.per sec before shaking can be effective. This consideration indicatesthe necessity for residual-pressure release.The effect of the residual-pressure release mechanism on theback pressure is clearly shown in Fig. 13 which should be comparedwith Figs. 8, 9, 10, and 11.I n s p e c t i o n a n d M a i n t e n a n c eOf particular interest in the operation of the dry dust filtersis the number of man-hours involved in inspection and maintenance.Inspections while the equipment is in service cover thefollowing:1 Lubrication of bearing surfaces of coal-conveyer valves,evacuating fans, and motors.2 Checking housing for leaks from dust side of collector.3 Observation of clean-air discharge for evidence of tom ordefective bags.4 Checking reclaimed-coal lines for free movement of coal.5 Checking operation of main exhauster damper control.6 Checking pressure balance of cloth filter with draft gage.Items 1 to 4 are covered by the regular millhouse operatingcrew and are made a routine m atter along with other duties atsimilar locations about every 2 hr. The inspection is primarilya precautionary measure. Items 5 and 6 are looked after bytest men in the technical department of the company. A monthlyinspection of the damper control is all that is generally necessaryand requires about 3 or 4 hr per month. Item 6 is included for thepurpose of checking the auxiliary-fan operation and is made aboutevery 3 or 4 months in about Vi hr.During the shutdown operation it is advisable to check thefollowing and do general internal cleaning:1 Shaker mechanism.2 Inspect damper gaskets.3 Inspect auxiliary-fan piping.It is good practice to make a general internal inspection of thecollector weekly.Maintenance data on the dust filters are not as complete asthey should be at this time because included in the maintenancefigures are design changes. These changes in design will undoubtedlylower maintenance charges and decrease outage periodsin the future. Figures subsequently cited are for the totaloperating hours given for each filter.The largest single item of maintenance in the dust filters is thefilter bag. Bag life is approximately 2 yr and the bags, withflameproofing applied, cost approximately $1 each. To removeand replace bags requires about 180 man-hr for the 25-tonmill and 275 man-hr for the 40-ton mill, assuming all bags are replaced.Defective bags are located from the clean side of thecollector and are replaced from the dust side of the collector.Since there are 552 bags in the 25-ton-mill installation and 840bags in the 40-ton-mill installation, this replacement is thereforean appreciable item and worthy of investigation.At the present time, tests are under way to confirm a proposeddecrease in shaking frequency and time. One other change hasbeen made which should improve the life of the bags. Formerlythe flow of clean air was downward but now the flow is upwardthrough the top, in order to prevent clean air with high vapor‘ “The Calculation of the Dispersion of Flue Dust and CindersFrom Chimneys,” by H. O. Croft, Trans. A.S.M.E., vol. 57, 1935,paper FSP-57-1, pp. 5-10.content passing from one collector to the other when one of thecollectors is out of service.The next largest item of maintenance is general cleaning andgasket repair. Approximately 400 man-hr have been spent inthis work but it is reasonably certain that this item will virtuallydisappear, because 90 per cent of the time devoted to cleaningwould not have been necessary if the collector were dust-tightinitially. For example, the access doors and coal-hopper casingleaked dust continually while the collectors were in service andrequired constant cleaning and patching, which otherwise wouldnot have been necessary. Dust-tight access doors were made toreplace the initial doors and the hopper casing was welded tomake it dust-tight. Gasket maintenance is a relatively smallitem and has approximated 50 man-hr, which time is spentabout once a year renewing gaskets on explosion vents, accessdoors, and damper frames.Reclaimed coal drive systems have bad approximately 330man-hr maintenance, a considerable portion of which can be consideredas due to the dusty atmosphere, resulting from leakagewhich in turn caused bearing maintenance and maintenance ofthe chain drive. Rotary valves which feed the coal into thescrew conveyer and return coal pipe have had no maintenance.Some trouble had been experienced in the early days with floodingof the conveyer screw, causing plugging of the return coalpipe at the point where it connects to the screw, but this has beenrectified by increasing the angle of inclination of the outlet coalpipe. At the present time the coal drive system runs continuously,but it is planned to try out intermittent operation of thedrive system which, if successful, will decrease maintenance.The shaker mechanism has needed 205 man-hr of maintenancewhich has been due largely to wear of the roll which fits in thecam groove of the rocker mechanism. The roll was worn eggshapedbecause it did not rotate with the cam but slid in the camgroove. Some of the rolls were worn down to the pin in a periodof 6 to 8 months but, when a grease-seal ball bearing was substitutedas a cam follower in place of the hardened steel roll, veryslight uniform wear resulted in a period of 18 months. Therehas been some loosening up and falling out of setscrews fastenedto the rocker shafts which have been replaced with a self-lockingtype of setscrew.Approximately 75 man-hr have been charged to resetting limitswitches. This is not excessive, since it is good practice to checkthe limit switches on the gate-damper motors about once every6 months. The purpose of the check is to insure a good seal ofthe damper against the door frame at all times so that the pressurebalance of the cloth will be proper for effective shaking.The 25-ton mill has been in service 6197 hr and the 40-ton mill5759 hr since the installation of the dry filters. During this timeit is estimated that 4400 tons of coal have been reclaimed by thedust filters. The operation of the filters has been normal and nomajor incidents in their operation have occurred.S a f e t y M e a s u r e sIt is recognized th at coal milling is a process which must becarefully handled to prevent fires during the operation. Protectiveequipment and safe procedures had been employed in themillhouse in line with best practice and this policy was extendedto the dry filters. Numerous tests on filter cloth, both treatedand untreated with flameproofing, indicated the desirability oftreating the cloth, although it was recognized that such treatmentwould increase the flow resistance of the cloth slightly andperhaps affect its life. The effect of the flameproofing was foundto be that of retarding the burning of the cloth and localizing it,although the time required for ignition of the treated and untreatedcloth seemed the same.Long horizontal runs of pipe are objectionable as are low pipe