FLSD flameproof TEFV induction motors - Source IEC

FLSD flameproof TEFV induction motors - Source IEC

FLSD flameproof TEFV induction motors - Source IEC

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

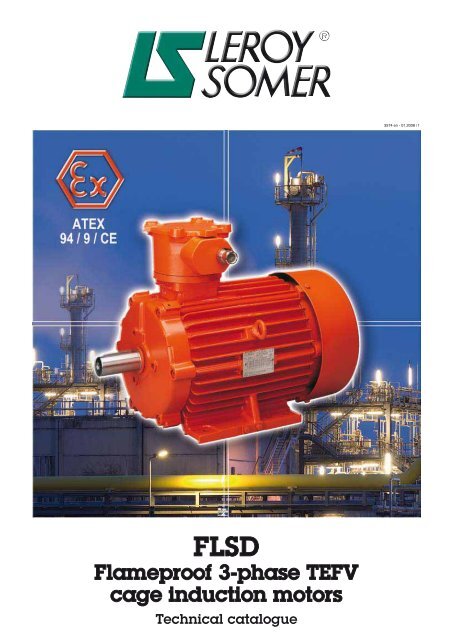

3574 en - 01.2008 / f<strong>FLSD</strong>Flameproof 3-phase <strong>TEFV</strong>cage <strong>induction</strong> <strong>motors</strong>Technical catalogue

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>II 2 GEEx d II B T41Use the complete motor designationas shown below when placing yourorder.Simply go through the completedesignation step by step.24P1500 min -1 <strong>FLSD</strong> 100 L 3 kWIM 1001IM B3230 /400 V50 Hz IP 55No. of pole(s)Speed(s)RangeidentificationFrame size<strong>IEC</strong> 60072-1For direct selection, see section : EPage 47FrametypeSection FP. 60 to 65RatedpowerSection EP. 48 to 57Mountingarrangements<strong>IEC</strong> 60034-7Section C1P. 21Supplyvoltage3Number and typeof cable glandSection C4P. 36Section C4P. 36Definitionof cablesMainsfrequencyDegree ofprotection<strong>IEC</strong> 60034-5Section A5P. 13This document has been translated from the French version (Ref. 3574F) which should be used for reference.Leroy-Somer reserves the right to modify the design, technical specifications and dimensions of the product shown in this catalogue.The descriptions cannot in any way be considered contractual.2

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>This catalogue describes LEROY-SOMER <strong>FLSD</strong> <strong>flameproof</strong> <strong>induction</strong> motorfrom 0.18 to 400 kW used in group II (surface industries)The range used by way of example is type :II 2 GEEx d II B T4 INERIS 01 ATEX 0001 XOther versions alsodescribed are :EEx d II B T5EEx d II C T5EEx d II B T6EEx d II C T6EEx de II B T4EEx de II B T5EEx de II C T5EEx de II B T6EEx de II C T6Example of marking :DistinctiveCommunity markSymbol for equipmentdesigned in accordancewith European standardsSymbol specifyingthe protection typeExplosion groupGas subdivisionTemperature classEC-type examinationcertificate numberEExd II B T4 INERIS 01 ATEX 0001XLEROY-SOMER offers various ranges of <strong>induction</strong> <strong>motors</strong> designed around a commonelectrical base. These <strong>motors</strong> conform to the latest European standards, and satisfy themajority of demanding applications in industrial and safety environments.References for LEROY-SOMER 3-phase <strong>induction</strong> motor ranges :FFF( )( F)( )F( )CDNEPXfrom 0.09 to 160 kW aluminium alloy frame.........................Catalogue ref. : 3676from 0.18 to 750 kW cast iron frame....................................Catalogue ref. : 3653from 0.18 to 400 kW cast iron frame, <strong>flameproof</strong> version.....Catalogue ref. : 3574from 0.18 to 400 kW aluminium alloy or cast iron frame,non-sparking version.............................Catalogue ref. : 3708from 0.75 to 55 kW aluminium alloy or cast iron frame,increased safety version........................Catalogue ref. : 3642from 0.18 to 400 kW aluminium alloy or cast iron frame,for dusty explosive atmospheres...........Catalogue ref. : 32153

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>ContentsPAGEPAGE- GENERAL INFORMATIONQuality assurance .............................................................. 8Product approval ................................................................ 9General standardization................................................... 10Tolerances on main performance parameters............... 12Definition of "Index of Protection" (IP/IK) ...................... 13- SPECIAL INFORMATIONDefinition of atmospheres and zones............................. 14Atmospheres at risk of explosion.............................................. 14Definition of zones at risk of explosion ..................................... 14Explosion group classification .................................................. 14Area levels................................................................................ 14Gas levels................................................................................. 14Temperature classes ................................................................ 14Classification of common gases (indicative values) .... 15Definition of equipment ................................................... 16Types of protection ................................................................... 16Electric <strong>motors</strong> protected by "d" <strong>flameproof</strong> enclosure(EN 50014 & EN 50018)........................................................... 16Electric <strong>motors</strong> protected by "e" increased safety enclosure(EN 50014 & EN 50019)........................................................... 16"n" non-sparking electric <strong>motors</strong> (EN 50014 & EN 50021) ....... 16Construction standards ............................................................ 17Comparison of USA/European standards ................................ 17Installation rules for surface industries ......................... 18Regulation relating to zones at risk of explosion caused bygas and vapours ....................................................................... 18Choice of equipment depending on the zone ........................... 18Installation technologies ........................................................... 18The cables and their method of installation .............................. 18- CONSTRUCTIONMounting arrangements .................................................. 21Components ..................................................................... 22Description of standard <strong>FLSD</strong> EEx d IIB T4 cast iron <strong>motors</strong> .. 22Other versions : <strong>FLSD</strong>E EEx de IIB cast iron <strong>motors</strong> ............... 23Other versions : <strong>FLSD</strong> EEx d IIC and <strong>FLSD</strong>E EEx de IICcast iron <strong>motors</strong> (for frame size ≤ 280)..................................... 23Special finishes ........................................................................ 23Bearings and lubrication ................................................. 24Bearings and bearing life ......................................................... 24Lubrication of bearings............................................................. 25Permanently greased bearings ................................................ 25Bearings with grease nipples ................................................... 25Grease life................................................................................ 25Types of bearing and standard bearing assemblies................. 26Bearing assembly diagrams..................................................... 27Permissible axial load (in daN) on main shaft extension forstandard bearing assembly ...................................................... 28Permissible radial load on main shaft extension ...................... 31Standard assembly .................................................................. 32Mains connection............................................................. 35Terminal box and cable gland positions ................................... 35Power supply cables (diameters to be supplied for selectionof the cable gland).................................................................... 36Cable gland for "d" <strong>flameproof</strong> terminal boxes ......................... 36Standard cable gland table (non-armoured cables) ..................36Number and type of adaptable cable glands on type "d"terminal box.............................................................................. 37Dimensions of standard cable glands on type "d" terminalbox............................................................................................ 37Table of optional "e" increased safety terminal boxes .............. 38Power supply terminals - direction of rotation .......................... 38Wiring diagrams ....................................................................... 38Earth terminals......................................................................... 38Operating conditions ....................................................... 19Normal operating conditions..................................................... 19Power correction....................................................................... 19Severe environment.................................................................. 19Heating when stationary........................................................... 19External finish................................................................... 20Copyright 2004: MOTEURS LEROY-SOMER4

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>ContentsPAGEPAGE- OPERATIONDuty cycle - Definitions.................................................... 39Weighted sound level [dB(A)] ......................................... 42Calculation of accelerating torque and starting time.... 43Vibration levels - Balancing............................................. 44- OPTIONAL FEATURESElectrical options ............................................................. 66Thermal protection ................................................................... 66Space heaters .......................................................................... 67A.C. injection ............................................................................ 67Mechanical options.......................................................... 68- ELECTRICAL CHARACTERISTICSSelection data: Single-speed........................................... 48Selection data: Two-speed............................................... 56Vibration sensor adaptations.................................................... 68Optional "e" increased safety terminal boxes - dimensions ..... 68Drip covers ............................................................................... 68Drain valves.............................................................................. 69Forced ventilation ..................................................................... 69Roller bearings ......................................................................... 69Flying leads (on request).......................................................... 69- DIMENSIONSFoot mounted.................................................................... 60Foot and flange mounted ................................................ 62Foot and face mounted.................................................... 64- MAINTENANCE / INSTALLATIONIdentification..................................................................... 70Identification plates and legend - frame size 80 to 132............ 70Identification plates and legend - frame size 160 to 355.......... 71Cross-sectional views and parts list .............................. 72<strong>FLSD</strong> 80 ................................................................................... 72<strong>FLSD</strong> 90 - 100 - 112................................................................. 74<strong>FLSD</strong> 132 ................................................................................. 76<strong>FLSD</strong> 160 - 180 - 200 - 225 ..................................................... 78<strong>FLSD</strong> 250 ................................................................................. 80<strong>FLSD</strong> 280 ................................................................................. 82<strong>FLSD</strong> 315 to 355 ...................................................................... 84Documentation - Manuals ............................................... 865

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>IndexPAGEPAGEAFNOR........................................................................ 10Altitude ........................................................................ 19Ambient temperature................................................... 19Approval ........................................................................ 9Area levels................................................................... 14Atmospheres at risk of explosion ................................ 14Balancing .................................................................... 44Bearing life .................................................................. 24Bearings ...................................................................... 24Cable gland ................................................................. 35Choice of equipment depending on the zone.............. 18Components ................................................................ 22Condensation .............................................................. 69Construction standards ............................................... 17Cos ϕ........................................................................... 12Cross-sectional views.................................................. 72Dimensions.................................................................. 60DIN/VDE...................................................................... 10Distinctive community mark........................................... 9Drain valves................................................................. 69Drip covers .................................................................. 68Dusty conditions .......................................................... 23Duty cycle.................................................................... 39Harsh environments..................................................... 23Heating......................................................................... 67Housing........................................................................ 22Humidity ....................................................................... 19Identification................................................................. 70Identification plates and legend.................................... 70<strong>IEC</strong> ............................................................................... 10Ignition temperature ..................................................... 15Increased safety........................................................... 16Indices of protection..................................................... 13Instruction manual........................................................ 88Jets of water................................................................. 13JIS................................................................................ 10Lubrication ................................................................... 25Maximum surface temperature .................................... 14Mechanical options ...................................................... 68MESG........................................................................... 14Mines............................................................................ 14Mounting arrangements ............................................... 21Earth terminals ............................................................ 38EC declaration of conformity ....................................... 88EC-type examination certificates................................... 9Electrical options ......................................................... 66End shields.................................................................. 22Explosible atmospheres .............................................. 14Explosive atmospheres ............................................... 14External finish.............................................................. 20Fan .............................................................................. 22Fan cover .................................................................... 22Flameproof enclosure.................................................. 16Flying leads ................................................................. 69Forced ventilation ........................................................ 69Frequency inverter ...................................................... 19Gas levels.................................................................... 14Grease......................................................................... 25Grease nipples ............................................................ 25NEC.............................................................................. 17NEMA........................................................................... 10Official accreditation laboratories................................... 9Parts list ....................................................................... 72Power supply terminals................................................ 38Quality............................................................................ 8Reaction to fire............................................................. 18Recommendations for storing and installing ................ 88Regreasing intervals .................................................... 25Resistance to fire ......................................................... 18Roller bearings............................................................. 69Rotor ............................................................................ 226

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>PAGEIndexSelection data.............................................................. 47Shot blasting................................................................ 20Sound .......................................................................... 42Space heaters ............................................................. 67Special finishes ........................................................... 23Standards .................................................................... 11Starting time ................................................................ 43Stator........................................................................... 22Surface industries........................................................ 14Temperature classes................................................... 14Terminal box................................................................ 22Thermal protection ...................................................... 66Tolerances................................................................... 12Types of protection...................................................... 16UTE ............................................................................. 10Vibration ...................................................................... 44Vibration sensor adaptations....................................... 68Wiring diagrams........................................................... 38Zones .......................................................................... 147

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>General informationA1 - Quality assuranceLEROY-SOMER's quality managementsystem is based on :- control of procedures right from theinitial sales offering until delivery to thecustomer, including design,manufacturing start-up and production.- a total quality policy based on makingcontinuous progress in improvingoperational procedures, involving alldepartments in the company in order togive customer satisfaction as regardsdelivery times, conformity and cost.- indicators used to monitor procedureperformance.- corrective actions and advancementswith tools such as FMECA, QFD,MAVP, MSP/MSQ and Hoshin typeimprovement workshops on flows,process re-engineering, plus LeanManufacturing and Lean Office.- annual surveys, opinion polls andregular visits to customers in order toascertain and detect their expectations.Personnel are trained and take part inthe analyses and the actions forcontinuously improving the procedures.LEROY-SOMER has entrusted the certification of its expertise to various international organisations.Certification is granted by independent professional auditors, and recognises the high standards of the company's qualityassurance procedures. All activities resulting in the final version of the machine have therefore received official ISO 9001:2000 certification from the DNV. Similarly, our environmental approach has enabled us to obtain ISO 14001: 2004 certification.Products for particular applications or those designed to operate in specific environments are also approved or certified by thefollowing organisations: CETIM, LCIE, DNV, ISSEP, INERIS, CTICM, UL, BSRIA, TUV, CCC, GOST, which check their technicalperformance against the various standards or recommendations.ISO 9001 : 20008

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>General informationA2 - Product approvalThe <strong>FLSD</strong> <strong>flameproof</strong> <strong>motors</strong> presented inthis catalogue conform to the national and/or international standards which govern theconstruction of this type of equipment.EC-type examination certificates are drawnup by notified bodies, in accordance withthe European Community CouncilDirective 94/9/EC known as ATEX.Approval is obtained when descriptivedocuments have been examined andvalidated, and tests performed. Theseinclude tests involving heating andexplosion of the equipment.EC-type examination certificates granted bythe bodies listed opposite are recognized byall EC countries.Approved equipment is authorized to carrythe mark or the distinctive communitymark .EC-type examination certificate acc. to ATEXType of motorIIA and IIBIIC<strong>FLSD</strong> 80 INERIS 01 ATEX 0001 X LCIE 94C6100*<strong>FLSD</strong> 90 - 100 INERIS 01 ATEX 0001 X INERIS 01 ATEX 0001 X<strong>FLSD</strong> 112 INERIS 01 ATEX 0001 X INERIS 01 ATEX 0001 X<strong>FLSD</strong> 132 INERIS 01 ATEX 0001 X INERIS 01 ATEX 0001 X<strong>FLSD</strong> 160 -180 INERIS 01 ATEX 0001 X INERIS 02 ATEX 0059 X<strong>FLSD</strong> 200 - 225 INERIS 01 ATEX 0001 X INERIS 02 ATEX 0059 X<strong>FLSD</strong> 250 INERIS 01 ATEX 0001 X –<strong>FLSD</strong> 280 INERIS 01 ATEX 0001 X –<strong>FLSD</strong> 315 ST INERIS 01 ATEX 0001 X –<strong>FLSD</strong> 315 M/L INERIS 01 ATEX 0001 X –<strong>FLSD</strong> 355 INERIS 01 ATEX 0001 X –Products certified under "the old approach" (Directivesprior to ATEX) can be used provided that they workcorrectly after 1 st July 2003.9

ORGANIZATION OF STANDARDS AUTHORITIES<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>General informationA3 - General standardizationInternational bodiesWorldwideGeneral standardizationISOInternational Standards OrganizationElectronics and ElectrotechnicalCertification<strong>IEC</strong>International Electrotechnical CommissionTCTechnicalCommitteesSCSubcommitteesWGWorkinggroupsTCTechnicalCommitteesSCSubcommitteesWGWorkinggroupsEuropeCENEuropean Committeefor StandardizationECISSEuropean Committee for Iron and SteelStandardsTCTechnical CommitteesCENELECEuropean Committee forElectrotechnical StandardizationTCTechnicalCommitteesSCSubcommitteesAHGAd hocgroupsCountry Initials NameAUSTRALIA SAA Standards Association of AustraliaBELGIUM IBN Institut Belge de NormalisationCIS (ex-USSR) GOST Gosudarstvenne Komitet StandartovDENMARK DS Dansk StandardisieringsraadFINLAND SFS Suomen StandardisoimisliittoFRANCE AFNOR including UTE Association Française de Normalisationincluding: Union Technique de l'ÉlectricitéGERMANY DIN/VDE Verband Deutscher ElektrotechnikerITALY CEI Comitato Electtrotechnico ItalianoJAPAN JIS Japanese Industrial StandardNETHERLANDS NNI Nederlands Normalisatie - InstituutNORWAY NFS Norges StandardisieringsforbundSAUDI ARABIA SASO Saudi Arabian Standards OrganizationSPAIN UNE Una Norma EspañolaSWEDEN SIS Standardisieringskommissionen I SverigeSWITZERLAND SEV or ASE Schweizerischer Elektrotechnischer VereinUNITED KINGDOM BSI British Standards InstitutionUSA ANSI including NEMA American National Standards Instituteincluding: National Electrical Manufacturers10

List of standards quoted in this document<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>General informationA3 - General standardizationReference International standards<strong>FLSD</strong> <strong>motors</strong> conform to allstandards mentioned in this catalogue<strong>IEC</strong> 60034-1 EN 60034-1 Electrical rotating machines: ratings and operating characteristics<strong>IEC</strong> 60034-5 EN 60034-5 Electrical rotating machines: classification of degrees of protection provided by casings of rotating machines.<strong>IEC</strong> 60034-6 EN 60034-6 Electrical rotating machines (except traction): cooling methods<strong>IEC</strong> 60034-7 EN 60034-7 Electrical rotating machines (except traction): symbols for mounting positions and assembly layouts<strong>IEC</strong> 60034-8Electrical rotating machines: terminal markings and direction of rotation<strong>IEC</strong> 60034-9 EN 60034-9 Electrical rotating machines: noise limits<strong>IEC</strong> 60034-12 EN 60034-12 Starting characteristics for single-speed 3-phase cage <strong>induction</strong> <strong>motors</strong> for supply voltages less than or equal to 660V.<strong>IEC</strong> 60034-14 EN 60034-14 Electrical rotating machines: mechanical vibrations of certain machines with a frame size above or equal to 56 mm.Measurement, evaluation and limits of vibrational intensity.<strong>IEC</strong> 60038<strong>IEC</strong> 60072-1<strong>IEC</strong> 60085<strong>IEC</strong> standard voltagesDimensions and power series for electrical rotating machines: designation of casings between 56 and 400 andflanges between 55 and 1080.Evaluation and thermal classification of electrical insulation.<strong>IEC</strong> 60529 EN 60529 Degrees of protection provided by enclosures.<strong>IEC</strong> 60721-2-1<strong>IEC</strong> 60892Classification of natural environment conditions. Temperature and humidity.Effects of an imbalance in the voltage system on the characteristics of three-phase squirrel-cage <strong>induction</strong> <strong>motors</strong>.<strong>IEC</strong> 61000-2-2 EN 61000-2-2 Electromagnetic compatibility (EMC): environment<strong>IEC</strong> guide 106ISO 281Guidelines on the specification of environmental conditions for the determination of operating characteristics of equipmentBearings - Basic dynamic loadings and nominal bearing lifeISO 1680 EN ISO 1680 Acoustics - Test code for measuring airborne noise emitted by electrical rotating machines: a method for establishing an expertopinion for free field conditions over a reflective surfaceISO 8821Mechanical vibration - Balancing. Conventions on shaft keys and related partsEN 60529Degree of protection provided by the electrical housing against extreme mechanical impacts.CEI 60079-0 EN 50014 Electrical equipment for explosive atmospheres: General regulationsCEI 60079-1 EN 50018 Electrical equipment for explosive atmospheres: <strong>flameproof</strong> casings "d"CEI 60079-7 EN 50019 Electrical equipment for explosive atmospheres: increased safety "e"EN 50281-1-1Electrical apparatus for use in the presence of combustible dust11

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>General informationA4 - Tolerances on main performance parametersTolerances on electromechanical characteristics<strong>IEC</strong> 60034-1 specifies standard tolerances for electromechanical characteristics.ParametersTolerancesEfficiency⎧⎨⎩machines P ≤ 50 kWmachines P > 50 kW– 15% (1 – η)– 10% (1 – η)Cos ϕ – 1/6 (1 – cos ϕ)(min 0.02 - max 0.07)Slip⎧⎨⎩machines P < 1 kWmachines P ≥ 1 kW± 30%± 20%Locked rotor torque– 15%, + 25% of rated torqueStarting current + 20%Run-up torque-15% of rated torqueBreakdown torque-10% of rated torque> 1.6 M NMoment of inertia ± 10%Noise+ 3 dB (A)Vibration+ 10% of the guaranteed classNote: <strong>IEC</strong> 60034-1 does not specify tolerances for current- the tolerance is ± 10% in NEMA-MG1Tolerances and adjustmentsThe standard tolerances shown below are applicable to the drawing dimensions given in ourcatalogues. They fully comply with <strong>IEC</strong> standard 60072-1.CharacteristicsTolerancesFrame size H ≤ 250> 280Diameter ∅ of shaft extension:- 11 to 28 mm- 32 to 48 mm- 55 mm and over0, — 0.5 mm0, — 1 mmDiameter N of flange spigot j6 up to FF 500,js6 for FF 600 and overKey widthh9j6k6m6E/2➀ Eccentricityof shaft in flanged <strong>motors</strong>Width of drive shaft keyway(normal keying)Key depth- square section- rectangular section➀ Eccentricity of shaft in flanged <strong>motors</strong> (standard class)- diameter > 10 up to 18 mm- diameter > 18 up to 30 mm- diameter > 30 up to 50 mm- diameter > 50 up to 80 mm- diameter > 80 up to 120 mm➁ Concentricity of spigot diameter and➂ perpendicularity of mating surface of flange in relation to shaft(standard class)Flange (FF) or Faceplate (FT):- F 55 to F 115- F 130 to F 265- FF 300 to FF 500- FF 600 to FF 740- FF 940 to FF 1080N9h9h110.035 mm0.040 mm0.050 mm0.060 mm0.070 mm0.08 mm0.10 mm0.125 mm0.16 mm0.20 mm1010➁Concentricity➂ Perpendicularity of matingsurface of flange in relation to shaft12

First number :protection against solid objectsIP01<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>General informationA5 - Definition of "Index of Protection" (IP/IK)Indices of protection of electrical equipment enclosuresmechanical protectionTests Definition IP Tests Definition IK Tests DefinitionNo protection 0 No protection 00 No protection∅ 50 mmProtected againstsolid objects ofover 50 mm(eg : accidentalhand contact)Second number :protection against liquids1Protected againstvertically drippingwater(condensation)<strong>FLSD</strong> <strong>motors</strong> are IP 55/ IK 08as standard150 gImpact energy :0110 cm 0.15 J2∅ 12 mmProtected againstsolid objects ofover 12 mm(eg : finger)215°Protected againstwater drippingup to 15° fromthe vertical200 gImpact energy :0210 cm 0.20 J3∅ 2.5 mmProtected againstsolid objects ofover 2.5 mm(eg : tools, wire)360°Protected againstrain falling at upto 60° fromthe vertical03250 g15 cmImpact energy :0.37 J4∅ 1 mmProtected againstsolid objects ofover 1 mm(eg : small tools,thin wire)4Protected againstwater splashesfrom all directions04250 g20 cmImpact energy :0.50 J5Protected againstdust ( no depositsof harmful material)5Protected againstjets of water fromall directions05350 g20 cmImpact energy :0.70 J6Totally protectedagainst any dustpenetration6Protected againstjets of watercomparable toheavy seas06250 g40 cmImpact energy :1 J70,15 m1 mProtégé contre leseffets de l’immersionentre 0,15 et 1 m070.5 kg40 cmImpact energy :2 JExample:IP 55 machine8 ..m. . mProtected againstthe effects ofimmersion to depthsof between 0.15and 1 m081.25 kg40 cmImpact energy :5 JIP :Index of protection5. : Machine protected against dust and accidental contact.Test result: no dust enters in harmful quantities, no risk of direct contactwith rotating parts. The test will last for 2 hours.092.5 kg40 cmImpact energy :10 J.5 : Machine protected against jets of water from all directions from hoses at 3 m distancewith a flow rate of 12.5 l/min at 0.3 bar.The test will last for 3 minutes. Test result: no damage from water projected onto themachine.105 kg40 cmImpact energy :20 J13

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>Special informationB1 - Definition of atmospheres and zonesB1.1 - ATMOSPHERES AT RISKOF EXPLOSIONThis includes all explosive and explosibleconditions, the explosion character beingpermanent or potential.Explosive atmospheres:An explosive atmosphere is an atmospherewhere a mixture of air and inflammablesubstances is to be found (in gas form,vapours, fog or mist) in such proportionsthat excessive temperature, arcs or sparkscause it to explode. The danger ispermanent.Explosible atmospheres:An explosible atmosphere is an atmospherewhich may become explosive due to theparticular local conditions. The danger ispotential.B1.2 - DEFINITION OF ZONES ATRISK OF EXPLOSIONThe international standard EN 60079-10defines the danger zones according to the riskof encountering an explosive atmosphereas shown in the diagram opposite:Zone 0: location where an explosivegaseous atmosphere is permanentlypresent for long periods.Zone 1: location where an explosivegaseous atmosphere is likely to developduring normal operation.Zone 2: location where an explosivegaseous atmosphere is not likely to formduring normal operation, and where sucha development, should it occur, only lastsfor a short period of time.Note: Each country has similar andcomplementary publications givinginstructions on the classification ofdangerous locations.012Note: The zone is classified under the responsibility of the manager of the company where theequipment is installed.B1.3 - EXPLOSION GROUPCLASSIFICATIONB1.3.1 - Area levelsThe areas presenting explosion risks aredivided into 2 groups:- Group I: Gas-prone mines.- Group II: Areas other than gas-prone mines(surface industries).This catalogue only concerns equipmentin group II.B1.3.2 - Gas levels- Group I: only applies to mine gas(methane in mines).- Group II: The gases present are classifiedin 3 subdivisions A, B and C.A B CLiLiLiThe A, B, C classification is according to theMESG (Maximum Experimental Safe Gap)which characterises the ability of a gas notto propagate ignition through a standardjoint. The risks following an explosionincrease from subdivision A tosubdivision C.Therefore, equipment certified for use in thepresence of a type C gas can also be usedin the presence of a type A or B gas.B1.4 - TEMPERATURE CLASSESThe temperature class is based on themaximum temperature rise in the equipmentand on the ambient operating temperature.The maximum surface temperature of anelectric device must always be lower thanthe ignition temperature of the mix of gasesor vapour in which it will be used.In order to be able to select various devicesaccording to their surface temperature, sixtemperature classes have been created.Temperature class T1 T2 T3 T4 T5 T6Ignition temperatureMax. surface temperaturepermitted on the equipment> 450 °C > 300 °C > 200 °C > 135 °C > 100 °C > 85 °C450 °C 300 °C 200 °C 135 °C 100 °C 85 °C14

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>Special informationB2 - Classification of common gases (indicative values)GasIgnitiontemperature °CTemperature classof equipmentExplosiongroupAcetic acid 464 T1 IIAAcetic anhydride 316 T2 IIAAcetone 465 T1 IIAAcetylene 305 T2 IICAmmonia solution 630 T1 IIAAmyl acetate 380 T2 IIABenzene (pure) 498 T1 IIAButane n 365 T2 IIAButanol n 343 T2 IIACarbon disulphide 95 T6 IICCarbon monoxide 605 T1 IIBCyclohexanon 420 T2 IIADichlorethylene 460 T1 IIADiesel oil DIN 51601/04.78 220 to 300 T3 IIAEthanal 140 T4 IIAEthane 472 T2 - T1 IIAEthyl acetate 427 T2 IIAEthyl alcohol 425 T2 IIA - IIBEthyl chloride 510 T1 IIAEthylene 425 T2 IIBEthylene glycol 235 T3 IIBEthylene oxide 440 T2 IIBEthylic ether 180 T4 IIBFuel EL DIN 51 603 section 1/12.81 220 to 300 T3 IIAFuel L DIN 51 603 section 2/10.76 220 to 300 T3 IIAFuels M and S DIN 51 603 section 2/10.76 220 to 300 T3 IIAHexane n 225 T3 IIAHydrogen 560 T1 IICHydrosulphuric acid 270 T3 IIBKerosene (or gas oil n°1) 220 to 300 T3 IIAMethane 537 T1 IIAMethanol 385 T2 IIAMethylene chloride 625 T1 IIANaphtalene 520 T1 IIAOils for <strong>motors</strong> with boiling point < 135 °C 220 to 300 T3 IIAOleic acid 360 T2 IIBPhenol 595 T1 IIAPropane 450 T2 IIAPropylene alcohol 405 T2 IIBSpecial oils for <strong>motors</strong> with boiling point > 135 °C 220 to 300 T3 IIATetraline (tetrahydronaphtalene) 425 T2 IIBToluene 482 T1 IIATown gas 560 T1 IIB15

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>Special informationB3 - Definition of equipmentB3.1 - TYPES OF PROTECTIONEuropean standards define, according tothe selected type of protection, constructionrules for electrical equipment which can beused in explosible conditions.These protection methods each form aspecific standard in addition to the EN50014 standard (general rules) and areindicated by a lower case letter.These are:- d: Flameproof enclosure- e: Increased safety- p: Pressurized enclosure- q: Powder filling- o: Oil immersion- i: Fail safe- m: EncapsulatingB3.1.1 - Electric <strong>motors</strong> protectedby "d" <strong>flameproof</strong> enclosure (EN50014 & EN 50018)They must satisfy, among others, thefollowing requirements:- Resist an internal explosion of the air/gasmixture without damage to or permanentdistortion of the enclosure.- Ensure that the ignition inside theenclosure cannot be transmitted to theambient explosive atmosphere.- Present a surface temperature lower thanthe ignition temperature of the gas.These three conditions require:- Very robust construction of the enclosure.- Minimum joint lengths and reduced gapsso that explosion of the air/gas mixture thatis present inside the enclosure is nottransmitted to the ambient explosibleatmosphere (end shield/housing recesses,shaft bodies, etc).- Limited temperature rise, taking intoaccount unfavourable operating conditions(voltage limits) ensuring, depending on theambient temperature, a surface temperaturethat is lower than the temperature classrequired by the type of gas present.B3.1.2 - Electric <strong>motors</strong> protectedby "e" increased safety enclosure(EN 50014 & EN 50019)The type "e" protection method concernsequipment which does not produce arcs,sparks or hot spots during normal operation.This excludes in particular all rotatingmachines with a commutator.This requires, amongst others, the followingdesign features:- Special precautions to avoid theproduction of arcs and sparks: air distances,and minimum creepage distances betweenitems which are powered up and, withregard to earths, absence of mechanicalfriction, insulation, minimum distances inventilation systems, special materials forventilation fans, etc.- Temperature at all points in the motorlower than the ignition temperature of thegas. This temperature must include a periodwith the rotor locked as defined in standardEN 50019.B3.1.3 - "n" non-sparking electric<strong>motors</strong> (EN 50014 & EN 50021)The type "n" protection method concernsequipment which generates no sparks, arcs,or hot spots, which operates in anexceptionally explosible atmosphere.▲ Flameproof motor - "d" terminal box▲ Flameproof motor - "e" terminal box16

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>Special informationB3.2 - CONSTRUCTION STANDARDSThe European standards (EN) drawn up by the various member countries of CENELEC, areapplicable in those countries as national standards.Their contents are identical in all countries.They have been published as national standards as shown in the table below:CountryGeneral rulesB3 - Definition of equipmentProtection type"d"Protection type"e"Germany DIN EN 50014VDE 0170/0171 T.1DIN EN 50018VDE 0170/0171 T.5DIN EN 50019VDE 0170/0171 T.6Austria EN 50014 EN 50018 EN 50019France NF EN 50014 NF EN 50018 NF EN 50019Great Britain BS 5501: Part 1 BS 5501: Part 5 BS 5501: Part 6Internat. (CENELEC) EN 50014 EN 50018 EN 50019B3.2.1 - Comparison of USA/European standardsThe installation regulations which apply in the USA are those specified in the NEC (NationalElectrical Code).There is no mutual recognition between NEC and EN standards.However, American firms in Europe or the Middle East often refer to the NEC, and it istherefore important to be able to translate:NECCENELECClass I Gas Group/Category IIClass II Dust Group/Category IIClass III Fibre No specific standardDivision (DIV) I Zone 0, 1 or 21Division (DIV) II Zone 2 or 22Group A Acetylene II CGroup B Hydrogen II CGroup CGroup DII BII AMotors which have been granted ATEX certification by INERIS cannot be used in the USA andCanada (please consult us for a design study).17

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>Special informationB4 - Installation rules for surface industriesB4.1 - REGULATION RELATINGTO ZONES AT RISK OFEXPLOSION CAUSED BY GASAND VAPOURSIn zones at risk of explosion, electricalinstallations must be reduced to what isessential to the operating needs.Equipment, <strong>motors</strong>, ducting, necessarycommunication devices must, as far aspossible, be placed outside the dangerzones.European Directive ATEX 94/9/EC,concerning electrical installations of plantclassified as being likely to present risks ofexplosion, requires in particular that theworker in an establishment:- Defines the zones where explosiveatmospheres may appear.- Selects electrical equipment suitablefor the previously defined zones.- Checks the conditions of installation,operation and maintenance of thisequipment.The standard EN 60079-10 can be usedto determine dangerous regions.B4.2 - CHOICE OF EQUIPMENTDEPENDING ON THE ZONEAlthough coordinated construction codesexist, there is no coordinated regulation forthe choice of equipment according to thezone (0, 1, 2) where it is installed, eventhough there is an EN 60079-14recommendation.Nevertheless it can be said that:Zone 0:The entire installation must be built with failsafe category “ia”. Only control ormeasurement equipment can be installedthere.Zone 1:All electrical equipment used in zone 1 mustbe “safe”, in other words it must conform tostandard NFC 23.514 (equivalent to EN50014).This equipment should be installed inaccordance with the current rules andregulations. If "d" <strong>flameproof</strong> equipment isauthorized for all countries, "e" increasedsafety equipment may be either totally orpartially accepted.In particular:- France, Germany, Holland = totallyaccepted- Belgium: partially (mains box but not<strong>motors</strong>)Zone 2:The equipment which can be used in zone 2must be equipment that satisfies one of thetwo following conditions:- Meets the rules for zone 1 equipment- Conforms with the construction rules of arecognized standard for industrial electricalequipment which, during normal operation,does not generate arcs, sparks or hotsurfaces which may cause ignition or anexplosion. It can for instance conform to theEnglish standard BS 5000 part 16 or to <strong>IEC</strong>79.15. In this case, the equipment can beaccompanied by a document issued by anofficial laboratory, or by a declaration ofconformity from the manufacturer.In all cases it is necessary to takeaccount of the particular specificationsand the internal safety rules for eachindustry in each country.B4.3 - INSTALLATION TECH-NOLOGIESFor installing electrical <strong>motors</strong> protected by"d" <strong>flameproof</strong> enclosures in zones at risk ofexplosion, there are three types ofconnection.1. Direct entry of cables into the "d"<strong>flameproof</strong> enclosure via cable inlets of anapproved type.2. Indirect entry of cables via an "e"increased safety box.3. Direct entry of cables into the "d"<strong>flameproof</strong> enclosure via tubes of anapproved type ("conduit" system mainlyused in the United States).B4.4 - THE CABLES AND THEIRMETHOD OF INSTALLATIONWhen selecting a type of cable to be used inexplosible zones the following must betaken into account:- Its area of use and environment (heat,humidity, corrosive environment, mechanicalshocks).- Its type of use.- Its method of installation.The passage of an electric current in a cablecauses temperature rise due to the Jouleeffect. This phenomenon must be taken intoaccount in explosible zones: in normaloperation the maximum permissible currentmust be limited to 85% of the acceptableintensity in the zones where there is nodanger of explosion (according to Europeanharmonization document HD 384).In all cases there must be constantmonitoring that the maximum temperatureof the cable remains below the ignitiontemperature of the gas.The behaviour of burning cables is definedby the two following parameters (accordingto European harmonization document HD405):* Reaction to fire:Ability to form a fuel for the fire and thus tocontribute to the development of the fire.There are 3 classes- C1 = cable which does not cause fireto spread- C2 = cable which does not causeflames to spread- C3 = ordinary cable* Resistance to fire:Ability to continue operation in spite of thefire, for a certain period.There are 2 classes:- CR1 = cable performing its function in afire for at least a certain time (if acable is CR1 type, it is also at leastC2 type)- CR2 = ordinary cableIn some countries, the use of cables typeC2 is required for explosible zones. Themost common are discussed in standards:- NFC 32-321 = unshielded rigid cable (wiremanufacturer reference U 1000 RO2V)- NFC 32-111 = shielded rigid cable (wiremanufacturer reference U1000RGPFV)18

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>Special informationB5 - Operating conditionsB5.1 - NORMAL OPERATINGCONDITIONSa/According to <strong>IEC</strong> 60034-1, <strong>motors</strong> canoperate in the following normal conditions:• ambient temperature within the range - 16and + 40 °Caltitude less than 1000 m• atmospheric pressure: 1050 hPa (mbar)Standard EN 50014 § 4.2 concerningelectrical equipment in an explosibleatmosphere extends the range of ambienttemperatures from - 20 to +40 °C asstandard. In this case, no additional markingis necessary on the certified equipment.Temperatures outside this range may beconsidered when the equipment is certified.An additional mark must therefore beadded. These extensions involve specialconsultation.b/ <strong>FLSD</strong> <strong>motors</strong> are designed to operate inatmospheres where the relative humiditycan reach 95% at 40 °C.B5.2 - POWER CORRECTIONThe power of our <strong>motors</strong> is given forcontinuous duty (S1) at nominal voltage andfrequency, at up to 1000 m altitude and at amaximum ambient temperature of 40 °C asstandard.• Correction as a function of the altitudeFor the different altitude values, apply acorrection coefficient to the rated power asshown in the graph below.Correction coeff.10.950.90.850.80.751000 2000 3000 4000Altitude (m)• Motor used with FREQUENCYINVERTERThe certification of <strong>FLSD</strong> <strong>motors</strong> makesthem suitable for use with frequencyinverters, as long as the maximumpermissible surface temperature of themotor (temperature class indicated on themotor) is not exceeded.For this reason, the <strong>motors</strong> must be fittedwith thermal winding probes for frame sizes80 to 355 and a DE end shield probe forframe sizes 160 to 355.Inverters of a type not designed foroperation in an explosible zone must beplaced in a non-explosible zone.In all cases, a preliminary consultation isdesirable. In fact, control of the motor by afrequency inverter generally requires, inview of the special applications, derating ofthe motor power. This in particularcompensates for the additional lossescaused by the voltage or current harmonicsat the inverter output, and the problems ofcooling at low speeds (sometimes requiringthe addition of a <strong>flameproof</strong> forcedventilation unit whose operation is governedby the general power supply). The speeddetection system must be certified foroperation in explosible zones.B5.3 - SEVERE ENVIRONMENTSome operating conditions require specialfinishes for the environment: very dusty,humid, or harsh atmospheres.The essential criteria for anti-corrosionprotection apply to stainless steelcomponents meeting the requirements ofthe ATEX Directive (screws and bolts, plates,cover), metal cable glands, protection ofworking parts (stator and rotor), specialfinishes.B5.4 - HEATING WHENSTATIONARYMachines which are subject to prolongedstops in particularly humid conditions areaffected by high levels of internalcondensation.Heating the motor internally during standstillperiods prevents condensation. This isachieved by supplying single-phase power(220 - 240V) to space heaters (fitted onrequest) which are switched on when themotor is stopped and cold (characteristicsp. 67) and switched off when the motor isrunning.19

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>Special informationLEROY-SOMER <strong>motors</strong> are protected with a range of surface finishes.The surfaces receive appropriate special treatments, as shown below.Preparation of surfacesB6 - External finishStandard <strong>FLSD</strong> <strong>motors</strong> conform toSystem IIaSURFACE PARTS TREATMENTCast ironSteelAll cast iron elements:housing for all the range,end shields and terminal boxes up to frame size 280Terminal box accessoriesend shields and terminal boxes from frame size 315Covers- SA 2.5 shot blasting- Application of primer (25 to 30 μm)or a coat of polyvinyl 20 μmPhosphatization + PrimerElectrostatic painting or Epoxy powderPainting systemsPRODUCTS ATMOSPHERE SYSTEM DESCRIPTION OF SYSTEMSModerately corrosive 2 : humidand outdoors (temperate climate)IIa1 base coat Epoxy 30/40 μm1 coat polyurethane finish 20/30 μmLEROY-SOMER<strong>motors</strong>Corrosive 2 : coastal, very humid(tropical climate)IIIa1 base coat Epoxy 30/40 μm1 intermediate coat Epoxy 30/40 μm1 coat polyurethane finish 20/30 μmSpecial conditionsSystem IVband special(consult us)1 base coat 20/30 μm2 intermediate coats Epoxy 35/40 μm for each one1 coat Epoxy finish 35/40 μm1. The polyvinyl butyral undercoat acts as a primer and base coat from frame size 160.2. An atmosphere is said to be CORROSIVE when components are attacked by oxygen.It is said to be HARSH when components are attacked by bases, acids or salts.The painting systems have been tested on steel plate in saline mist according to standard ISO 9227 (5% Na Cl at 6

Mountings and positions (<strong>IEC</strong> standard 60034-7)<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>ConstructionC1 - Mounting arrangementsIM 1001 (IM B3)- Horizontal shaft- Feet on floorIM 1071 (IM B8)- Horizontal shaft- Feet on topFoot mounted <strong>motors</strong>IM 1051 (IM B6)- Horizontal shaft- Wall mounted with feet onLHS when viewed from DEIM 1011 (IM V5)*- Vertical shaft facing down- Feet on wallIM 1061 (IM B7)- Horizontal shaft- Wall mounted with feet onRHS when viewed from DEIM 1031 (IM V6)- Vertical shaft facing up- Feet on wallIM 3001 (IM B5)- Horizontal shaftIM 2001 (IM B35)- Horizontal shaft- Feet on floor(FF) flange mounted <strong>motors</strong>• all frame sizes(except IM 3001, which is limited to frame size 225)IM 3011 (IM V1)*- Vertical shaft facing downIM 2011 (IM V15)*- Vertical shaft facing down- Feet on wallIM 3031 (IM V3)- Vertical shaft facing upIM 2031 (IM V36)- Vertical shaft facing up- Feet on wallIM 3601 (IM B14)- Horizontal shaftIM 2101 (IM B34)- Horizontal shaft- Feet on floor(FT) face mounted <strong>motors</strong>• all frame sizes ≤ 132 mmAll positions are allowedIM 3611 (IM V18)*- Vertical shaft facing downIM 2111 (IM V58)*- Vertical shaft facing down- Feet on wallIM 3631 (IM V19)- Vertical shaft facing upIM 2131 (IM V69)- Vertical shaft facing up- Feet on wall* All positions with shaft end facing down and outside require the addition of a drip cover up to frame size 225 (for larger <strong>motors</strong>, on request).Frame sizeMounting positionsIM 1001 IM 1051 IM 1061 IM 1071 IM 1011 IM 1031 IM 3001 IM 3011 IM 3031 IM 2001 IM 2011 IM 203180 to 200 ● ● ● ● ● ● ● ● ● ● ● ●225 and 250 ● ● ● ● ● ● ❍ ● ● ● ● ●280 and 315 ● ❍ ❍ ❍ ❍ ❍ ❍ ● ● ● ● ❍355 ● ❍ ❍ ❍ ❍ ❍ ❏ ● ❍ ● ● ❍● : possible positions❏: positions not available❍ : please consult Leroy-Somer specifying the coupling method and the axial and radial loads if applicable21

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>ConstructionC2 - ComponentsC2.1 - DESCRIPTION OF STANDARD <strong>FLSD</strong> EEx d IIB T4 CAST IRON MOTORSComponent Materials Remarks1Finned housing Cast iron - with integral feet (except frame size 80), or without feet• 4, 6 or 8 fixing holes for foot mounting• lifting rings- external earth terminal2StatorInsulated low-carbon magnetic steellaminationsInsulated electroplated copper- low carbon content guarantees long-term lamination pack stability- semi-enclosed slots- class F insulation3456RotorInsulated low-carbon magnetic steellaminationsAluminium or copperShaft Steel - for frame size ≤ 132:• tapped shaft end• closed keyway- for frame size ≥ 160:• tapped shaft end• open keywayEnd shields Cast iron or steel - Cast iron for frame sizes ≤ 280- Steel for frame sizes ≥ 315- squirrel cage with inclined cage bars- rotor cage pressure die-cast in aluminium (or alloy for special applications) orsoldered in copper- heat shrink fit to shaft or keyed to shaft- rotor dynamically balanced to class N - half keyBearings and lubrication - type ZZ "greased for life" up to frame size 132- regreasable types from 160 upwards- DE bearing locked on frame size 80- NDE bearing preloaded from 90 to 280 preloaded at DE from size 315 upwards7Labyrinth sealLipsealsPlastic or steelSynthetic rubber- lipseal at drive end and non drive end for frame sizes up to 225 inclusive and 280- labyrinth seal at drive end and non drive end for frame sizes ≥ 250 (except 280)8FanComposite material up to frame size225 inclusive,- 2 directions of rotation: straight blades9Fan cover Pressed steel - fitted with a drip cover for operation in vertical position, outside,shaft end facing down for frame sizes 80 to 225. On request for larger sizes.10Terminal box Cast iron for frame sizes ≤ 280Steel for frame sizes ≥ 315- type “d” in standard version- fitted with a <strong>flameproof</strong> cable gland(cable Ø must be specified at time of ordering, p. 36)- can be placed in any of 4 positions- internal earth terminal- terminal block or current bushing102473685 1922

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>ConstructionC2 - ComponentsC2.2 - OTHER VERSIONS : <strong>FLSD</strong>E EEx de IIB CAST IRON MOTORSThese <strong>motors</strong> have a type "d" <strong>flameproof</strong> casing and a type "e" increased safety terminal box.Enclosure in the main box ( between the power and the auxiliaries).Terminal box Cast iron - type "e" increased safety- type "d" separation between motor casing and type "e" terminal box- type "e" safety terminal block for frame sizes ≤ 132 and type "e" current bushing forlarger sizesC2.3 - OTHER VERSIONS : <strong>FLSD</strong> EEx d IIC and <strong>FLSD</strong>E EEx de IIC CAST IRON MOTORS (for FRAME SIZE ≤ 280)Terminal box Cast iron - special machining in order to comply with the Maximal Experimental Safe Gap(MESG) for group IIC (see p. 14)These <strong>motors</strong> require special consultation.C2.4 - SPECIAL FINISHESCertain application conditions require special finishes suitable for the environment (on request)- IP 6.: very dusty conditions:dust protection identical to that on LSPX, FLSPX <strong>motors</strong> and LSPX FAP <strong>motors</strong> (<strong>motors</strong> for dusty explosive atmospheres)according to standard EN 50281-1-1.- IP .6: jets of water (excluding heavy seas):waterproof protection available for frame sizes 90 to 355. Prior consultation with Leroy-Somer is necessary.- extremely harsh environments (industry, chemical, refineries...):Corrobloc finish,3a paint system,Stainless Steel Screws,Brass bloc (option),Stainless Steel cover (option).▲ Flameproof motor - Type "d" terminal box▲ Flameproof motor - Type "e" terminal box23

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>ConstructionC3 - Bearings and lubricationC3.1 - BEARINGS AND BEARINGLIFEDefinitionsLoad ratings- Basic static load C o :This is the load for which permanentdeformation at point of contact between abearing race and the ball (or roller) with theheaviest load reaches 0.01% of thediameter of the ball (or roller).- Basic dynamic load C:This is the load (constant in intensity anddirection) for which the nominal lifetime ofthe bearing will reach 1 millionrevolutions.The static load rating C o and dynamic loadrating C are obtained for each bearing byfollowing the method in ISO 281.LifetimeThe lifetime of a bearing is the number ofrevolutions (or number of operating hours ata constant speed) that the bearing canaccomplish before the first signs of fatigue(spalling) begin to appear on a ring, ball orroller.- Nominal lifetime L10hAccording to the ISO recommendations, thenominal lifetime is the length of timecompleted or exceeded by 90% ofapparently identical bearings operatingunder the conditions specified by themanufacturer.Note: The majority of bearings last muchlonger than the nominal lifetime; theaverage length of time achieved orexceeded by 50% of bearings is around 5times longer than the nominal lifetime.Determination of nominal lifetimeConstant load and speed of rotationThe nominal lifetime of a bearing expressedin operating hours L 10h , the basic dynamicload C expressed in daN and the appliedloads (radial load F r and axial load F a ) arerelated by the following equation:The formulae that give Equivalent DynamicLoad (values of factors X and Y) for differenttypes of bearing may be obtained from theirrespective manufacturers.Variable load and speed of rotationFor bearings with periodically variable loadand speed, the nominal lifetime isestablished using the equation:L 10h = 1000000----------------------60 ⋅ N mSpeed NNm: average speed of rotationN m =NmLoad PPm⋅N1P1⋅ ( ) pC-------P mN2P2100 %N3P3N4q1 % q2 % q3 % q4 %P4q1 % q2 % q3 % q4 %qN 1 q1 --------- + N 2100 2 --------- + …( min – 1 )100N m : average equivalent dynamic load⋅TimeTimeSituations and data differing from theseconditions will lead to either a reduction oran increase in lifetime compared to thenominal lifetime.Corrected nominal lifetimeIf the ISO recommendations (DIN ISO 281)are used, improvements to bearing steel,manufacturing processes and the effects ofoperating conditions may be integrated inthe nominal lifetime calculation.The theoretical pre-fatigue lifetime Lnah isthus calculated using the formula:L nah = a 1 a 2 a 3 L 10hwith:a 1 : failure probability factora 2 : factor for thecharacteristics and tempering of the steel.a 3 : factor for the operating conditions(lubricant quality, temperature, speed ofrotation, etc).Under normal operating conditions for<strong>FLSD</strong> <strong>motors</strong>, the corrected nominallifetime, calculated with a failureprobability factor a1 = 1 (L 10ah ), is longerthan the nominal lifetime L 10h .⋅ ( ) pL 10h = 1000000 C---------------------- ---60 ⋅ N Pwhere N = speed of rotation (min-1)P (P = X F r + Y F a ): equivalent dynamicload (F r , F a , P in daN)p: an index which depends on the type ofcontact between the races and balls (orrollers)p = 3 for ball bearingsp = 10/3 for roller bearings1⁄ p N 1qP m = P ⎛ 1 ⎝------ ⎞ 1 1N m⎠---- P ⁄ p N q⎛ 2100 2 ⎝------ ⎞ 21⁄ p ⋅ ⋅ + ⋅ ⋅---- + …( daN)N m⎠ 100with q 1 , q 2 , etc as a %Nominal lifetime L 10h is applicable tobearings made of bearing steel and normaloperating conditions (lubricating filmpresent, no pollution, correctly fitted, etc).24

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>ConstructionC3 - Bearings and lubricationC3.2 - LUBRICATION OFBEARINGS▼ Grease life L 10h in 000’s of hours, for frames sizes < 132.T amb (°C)C3.2.1 - Permanently greasedbearingsFor <strong>motors</strong> frame size ≤ 132, the type andsize of the bearings make for long greaselife and therefore lubrication for the lifetimeof the machine.The grease life L 10h according to speed ofrotation and ambient temperature is shownon the chart opposite.605040302010N = 750 min -1N = 1000 min -1N = 1500 min -1N = 3000 min -105 10 15 20 25Life L 10h in 000's of hours30C3.2.2 - Bearings with greasenipplesMotors of frame size ≥ 160 have greasenipples. The following table indicates thetype of ball bearing, the quantity of greaseand the regreasing intervals according tothe type of motor, in an ambienttemperature of 25 °C.For vertical shaft machines used in anambient temperature of 25 °C, theregreasing intervals will be approximately80% of the values stated.Motors operating in an ambient temperatureof 40 °C need more frequent lubrication.The regreasing intervals will be around 50%of the values stated (in all cases, complywith the requirements on the motornameplates).Grease references: see instructions onnameplate.Type of motor* For 6313QuantityBearingsRegreasing intervals in hoursof greaseN.D.E. D.E. cm 3 3000 min -1 1500 min -1 1000 min -1 750 min -1<strong>FLSD</strong> 160 -180 6310 6310 15 4 600 11 000 18 000 24 000<strong>FLSD</strong> 200 6312 6312 20 3 600 9 700 16 000 22 000<strong>FLSD</strong> 225* (6312) 6313 23 3 200 9 000 15 000 21 000<strong>FLSD</strong> 250 6314 6314 26 2 800 8 300 14 000 20 000<strong>FLSD</strong> 280 6317 6317 37 1 700 - - -<strong>FLSD</strong> 280 6318 6318 40 - 6 200 11 000 16 000<strong>FLSD</strong> 315 S/M/L 6317 6317 37 1 700 - - -<strong>FLSD</strong> 315 S/M/L 6320 6320 50 - 5 400 10 000 14 500<strong>FLSD</strong> 355 6317 6317 37 1 700 - - -<strong>FLSD</strong> 355 6322 6322 60 - 4 500 9 000 13 500C3.3 - GREASE LIFEThe lifetime of a lubricating grease dependson:- the characteristics of the grease (type ofsoap and base oil, etc)- service stress (type and size of bearing,speed of rotation, operating temperature,etc)- contamination25

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>ConstructionC3 - Bearings and lubricationC3.4 - TYPES OF BEARING AND STANDARD BEARING ASSEMBLIESHorizontal shaftVertical shaftShaft facing downShaft facing upFlange mounted and/orfoot mounted <strong>motors</strong>standard mountingThe DE bearing is:- locked at DE for frame 90 to 112- locked for 80 and from 132 to315 STThe NDE bearing is lockedfor frames 315 M to 355.The DE bearing is:- locked at DE for frame 90 to 112- locked for 80 and from 132 to315 STThe NDE bearing is lockedfor frames 315 M to 355.The DE bearing is:- locked at DE for frame 90 to 112- locked for 80 and from 132 to315 STThe NDE bearing is lockedfor frames 315 M to 355.on request DE bearing locked for frames ≤ 112 DE bearing locked for frames ≤ 112 DE bearing locked for frames ≤ 112Important: When ordering, state correct mounting type and position (see section C1).MotorStandard mountingFrame/TypeLEROY-SOMERdesignationNo. of polesNon drive endbearing(N.D.E.)Drive end bearing(D.E.)80 L <strong>FLSD</strong> 80 L 2 ; 4 ; 6 ; 8 6004 ZZ 6005 ZZ90 S/L <strong>FLSD</strong> 90 S/L 2 ; 4 ; 6 ; 8 6205 ZZ C3 6305 ZZ C3100 L <strong>FLSD</strong> 100 L 2 ; 4 ; 6 ; 8 6305 ZZ C3 6306 ZZ C3112 M <strong>FLSD</strong> 112 M 2 ; 4 ; 6 ; 8 6306 ZZ C3 6306 ZZ C3132 S/M <strong>FLSD</strong> 132 S/M 2 ; 4 ; 6 ; 8 6308 ZZ C3 6308 ZZ C3160 M/L <strong>FLSD</strong> 160 M/L 2 ; 4 ; 6 ; 8 6310 C3 6310 C3180 M/L <strong>FLSD</strong> 180 M/L 2 ; 4 ; 6 ; 8 6310 C3 6310 C3200 L <strong>FLSD</strong> 200 L 2 ; 4 ; 6 ; 8 6312 C3 6312 C3225 S/M <strong>FLSD</strong> 225 S/M 2 ; 4 ; 6 ; 8 6312 C3 6313 C3250 M <strong>FLSD</strong> 250 M 2 ; 4 ; 6 ; 8 6314 C3 6314 C3280 S <strong>FLSD</strong> 280 S 2 6317 C3 6317 C3280 S <strong>FLSD</strong> 280 S 4 ; 6 ; 8 6318 C3 6318 C3280 M <strong>FLSD</strong> 280 M 2 6317 C3 6317 C3280 M <strong>FLSD</strong> 280 M 4 ; 6 ; 8 6318 C3 6318 C3315 S/M <strong>FLSD</strong> 315 S/M 2 6317 C3 6317 C3315 S/M <strong>FLSD</strong> 315 S/M 4 ; 6 ; 8 6320 C3 6320 C3315 L <strong>FLSD</strong> 315 L (A,B) 2 6317 C3 6317 C3315 L <strong>FLSD</strong> 315 L (A,B) 4 ; 6 ; 8 6320 C3 6320 C3355 L <strong>FLSD</strong> 355 L (A,B,C,D) 2 6317 C3 6317 C3355 L <strong>FLSD</strong> 355 L (A,B,C,D) 4 ; 6 ; 8 6322 C3 6322 C3Assembly diagram referenceFoot mounted<strong>motors</strong>12223444567777777777Flange mounted(or foot and flange)<strong>motors</strong>12223444567777777777Bearing assemblies with roller bearings are available from frame sizes 132 to 355.26

C3.4.1 - Bearing assembly diagrams<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>ConstructionC3 - Bearings and lubrication1 2DENDEDENDE3 4DENDEDENDE5 6DE NDE DE NDE7DENDE27

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>ConstructionC3 - Bearings and lubricationC3.4.2 - Permissible axial load (in daN) on main shaft extension for standard bearing assemblyHorizontal motorNominal bearing life L 10h :25,000 hoursMotor2 polesN = 3000 min -14 polesN = 1500 min -16 polesN = 1000 min -18 polesN = 750 min -1FramesizeTypeIM B3 / B6IM B7 / B8IM B5 / B35IM B14 / B34IM B3 / B6IM B7 / B8IM B5 / B35IM B14 / B34IM B3 / B6IM B7 / B8IM B5 / B35IM B14 / B34IM B3 / B6IM B7 / B8IM B5 / B35IM B14 / B34IM B3 / B6IM B7 / B8IM B5 / B35IM B14 / B34IM B3 / B6IM B7 / B8IM B5 / B35IM B14 / B34IM B3 / B6IM B7 / B8IM B5 / B35IM B14 / B34IM B3 / B6IM B7 / B8IM B5 / B35IM B14 / B3480 <strong>FLSD</strong> 80 L 41 41 53 53 63 63 65 6590 <strong>FLSD</strong> 90 S 52 (81)* 69 (99)* 82 (110)* 91 (120)*90 <strong>FLSD</strong> 90 L 52 (81)* 69 (99)* 82 (110)* 91 (120)*100 <strong>FLSD</strong> 100 L 66 (101)* 87 (122)* 103 (138)* 114 (150)*112 <strong>FLSD</strong> 112 M 64 (103)* 85 (124)* 101 (140)* 112 (150)*132 <strong>FLSD</strong> 132 S 118 167 154 203 181 230 201 250132 <strong>FLSD</strong> 132 M - - 155 203 181 230 201 250160 <strong>FLSD</strong> 160 M 160 268 216 324 256 364 286 395160 <strong>FLSD</strong> 160 L 160 268 216 324 256 364 286 395180 <strong>FLSD</strong> 180 M 160 268 216 324 - - - -180 <strong>FLSD</strong> 180 L - - 216 324 256 364 286 395200 <strong>FLSD</strong> 200 L 230 338 303 411 357 465 396 504225 <strong>FLSD</strong> 225 S - - 353 461 - - 458 566225 <strong>FLSD</strong> 225 M 269 377 353 461 413 521 458 566250 <strong>FLSD</strong> 250 M 334 414 460 540 559 639 638 718280 <strong>FLSD</strong> 280 S 358 518 526 686 642 802 713 873280 <strong>FLSD</strong> 280 M 505 345 494 654 595 755 685 805315 <strong>FLSD</strong> 315 S/M 486 326 746 546 905 705 963 763315 <strong>FLSD</strong> 315 LA 504 344 728 528 886 686 940 740315 <strong>FLSD</strong> 315 LB 487 327 733 533 847 647 890 690355 <strong>FLSD</strong> 355 LA 453 293 788 587 934 694 1006 770355 <strong>FLSD</strong> 355 LB 448 288 771 531 892 652 945 705355 <strong>FLSD</strong> 355 LC 443 285 751 512 - - - -355 <strong>FLSD</strong> 355 LD 440 280 736 496 805 565 871 631( )* The axial loads in brackets are the permissible axial loads for locked DE bearings (non-standard assembly, special order).28

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>ConstructionC3 - Bearings and lubricationC3.4.2 - Permissible axial load (in daN) on main shaft extension for standard bearing assemblyVertical motorShaft facing downNominal bearing life L 10h :25,000 hoursMotor2 polesN = 3000 min -14 polesN = 1500 min -16 polesN = 1000 min -18 polesN = 750 min -1FramesizeTypeIM V5IM V1 / V15IM V18 / V58..IM V5IM V1 / V15IM V18 / V69..IM V5IM V1 / V15IM V18 / V69..IM V5IM V1 / V15IM V18 / V69..IM V5IM V1 / V15IM V18 / V69..IM V5IM V1 / V15IM V18 / V69..IM V5IM V1 / V15IM V18 / V69..IM V5IM V1 / V15IM V18 / V69..80 <strong>FLSD</strong> 80 L 38 44 50 57 59 68 60 6990 <strong>FLSD</strong> 90 S 48 (85)* 64 (104)* 76 (117)* 85 (126)*90 <strong>FLSD</strong> 90 L 48 (86)* 63 (105)* 75 (117)* 84 (126)*100 <strong>FLSD</strong> 100 L 60 (106)* 80 (130)* 95 (146)* 106 (157)*112 <strong>FLSD</strong> 112 M 53 (113)* 73 (136)* 89 (152)* 100 (163)*132 <strong>FLSD</strong> 132 S 101 183 133 224 156 255 184 267132 <strong>FLSD</strong> 132 M - - 131 227 156 255 180 271160 <strong>FLSD</strong> 160 M 133 295 184 355 222 400 251 428160 <strong>FLSD</strong> 160 L 128 300 177 363 214 406 247 433180 <strong>FLSD</strong> 180 M 121 307 171 368 - - - -180 <strong>FLSD</strong> 180 L - - 166 373 203 417 236 443200 <strong>FLSD</strong> 200 L 168 400 238 477 281 540 311 590225 <strong>FLSD</strong> 225 S - - 275 538 - - 369 655225 <strong>FLSD</strong> 225 M 195 450 265 548 319 615 357 667250 <strong>FLSD</strong> 250 M 268 481 376 627 460 740 538 620280 <strong>FLSD</strong> 280 S 424 493 552 727 676 831 726 941280 <strong>FLSD</strong> 280 M 400 500 504 734 616 824 639 926315 <strong>FLSD</strong> 315 S/M 361 545 582 861 764 976 800 1084315 <strong>FLSD</strong> 315 LA 344 572 546 876 726 988 756 1090315 <strong>FLSD</strong> 315 LB 306 596 514 909 644 1018 680 1100355 <strong>FLSD</strong> 355 LA 244 648 512 1050 684 1175 720 1340355 <strong>FLSD</strong> 355 LB 222 667 475 1067 605 1199 618 1367355 <strong>FLSD</strong> 355 LC 195 692 425 1081 - - - -355 <strong>FLSD</strong> 355 LD 175 707 391 1107 432 1259 494 1397( )* The axial loads in brackets are the permissible axial loads for locked DE bearings (non-standard assembly, special order).29

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>ConstructionC3 - Bearings and lubricationC3.4.2 - Permissible axial load (in daN) on main shaft extension for standard bearing assemblyVertical motorShaft facing upNominal bearing life L 10h :25,000 hoursMotor2 polesN = 3000 min -14 polesN = 1500 min -16 polesN = 1000 min -18 polesN = 750 min -1FramesizeTypeIM V6IM V3 / V36IM V19 / V69..IM V6IM V3 / V36IM V19 / V69..IM V6IM V3 / V36IM V19 / V69..IM V6IM V3 / V36IM V19 / V69..IM V6IM V3 / V36IM V19 / V69..IM V6IM V3 / V36IM V19 / V69..IM V6IM V3 / V36IM V19 / V69..IM V6IM V3 / V36IM V19 / V69..80 <strong>FLSD</strong> 80 L 38 44 50 57 59 68 60 6990 <strong>FLSD</strong> 90 S (77)* 56 (93)* 75 (105)* 87 (115)* 9790 <strong>FLSD</strong> 90 L (77)* 56 (93)* 75 (105)* 88 (114)* 97100 <strong>FLSD</strong> 100 L (95)* 71 (115)* 94 (130)* 110 (142)* 122112 <strong>FLSD</strong> 112 M (92)* 74 (112)* 97 (128)* 112 (140)* 123132 <strong>FLSD</strong> 132 S 150 134 183 175 205 206 233 218132 <strong>FLSD</strong> 132 M - - 180 177 205 206 230 222160 <strong>FLSD</strong> 160 M 240 187 292 247 330 290 360 320160 <strong>FLSD</strong> 160 L 236 192 285 255 322 300 355 325180 <strong>FLSD</strong> 180 M 229 200 280 260 - - - -180 <strong>FLSD</strong> 180 L - - 275 265 310 310 344 335200 <strong>FLSD</strong> 200 L 277 286 346 370 390 432 420 481225 <strong>FLSD</strong> 225 S - - 383 430 - - 477 547225 <strong>FLSD</strong> 225 M 303 343 373 440 427 507 466 560250 <strong>FLSD</strong> 250 M 348 400 456 547 540 660 618 740280 <strong>FLSD</strong> 280 S 424 493 552 727 676 831 726 941280 <strong>FLSD</strong> 280 M 401 502 504 735 616 824 639 926315 <strong>FLSD</strong> 315 S/M 361 545 582 861 764 976 800 1084315 <strong>FLSD</strong> 315 LA 344 572 546 876 726 988 756 1091315 <strong>FLSD</strong> 315 LB 306 596 514 909 644 1018 681 1098355 : prior consultation( )* The axial loads in brackets are the permissible axial loads for locked DE bearings (non-standard assembly, special order).30

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>ConstructionC3 - Bearings and lubricationC3.4.3 - Permissible radial load onmain shaft extensionIn pulley and belt couplings, the drive shaftcarrying the pulley is subjected to a radialforce Fpr applied at a distance X (mm) fromthe shoulder of the shaft extension (lengthE).abab● Radial force applied todrive shaft extension: FprThe radial force Fpr expressed in daNapplied to the shaft extension is found bythe formula.DDPFpr = 1.91 10 6 N ⋅ k-------------- ± PD ⋅ PN Nwith:P N = rated motor power (kW)D = external diameter of the drive pulley (mm)N N = rated speed of the motor (min -1 )k = factor depending on the type oftransmissionP P = weight of the pulley (daN)The weight of the pulley is positive when itacts in the same direction as the tensionforce in the belt (and negative when it actsin the opposite direction).Range of values for factor k(*)- toothed belts .............................. k = 1 to 1.5- V-belts ........................................ k = 2 to 2.5- flat belts• with tensioner .......................... k = 2.5 to 3• without tensioner ................... k = 3 to 4(*) A more accurate figure for factor k can beobtained from the transmission suppliers.● Permission radial force on the driveshaft extensionThe charts on the following pages indicate,for each type of motor, the radial force FR ata distance X permissible on the drive endshaft extension, for a bearing life L 10h of25,000 hours.Note: For frame sizes ≥ 315 M, the selectioncharts are applicable for a motor installedwith the shaft horizontal.● Change in bearing life depending onthe radial load factorFor a radial load Fpr (Fpr ≠ F R ), applied atdistance X, the bearing life L 10h changes, ata first approximation, in the ratio k R , (k R =Fpr / F R ) as shown in the chart opposite, forstandard assemblies.If the load factor k R is greater than 1.05, youshould consulter our technical department,stating mounting position and direction offorce before opting for a special assembly.{xEx = a +wherex ≤ EF prb2▼ Change in bearing life L 10h depending on the radial load factor k R for standardassemblies.k R1.21.11.00.90.80.70.60.50.40.30.2If K R > 1.05consult Leroy-Somer{xEx = a +wherex ≤ EF prb20 10 20 25 30 40 L 10hin 000'sof hours31

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>ConstructionC3 - Bearings and lubricationC3.4.4 - Standard assemblyPermissible radial load on main shaft extension with a bearing life L 10h of 25,000 hours.FR(daN)908070605040 N = 750 min -130N = 1000 min -1N = 1500 min -120100<strong>FLSD</strong> 800 10 20 30 40 50x (mm)FR(daN)1801501209060300N = 750 min -1N = 1000 min -1N = 1500 min -1N = 3000 min -1<strong>FLSD</strong> 900 10 20 30 40 50x (mm)FR(daN)250<strong>FLSD</strong> 100FR(daN)250<strong>FLSD</strong> 112FR(daN)360<strong>FLSD</strong> 13220020030015010050N = 750 min -1N = 1000 min -1N = 1500 min -1N = 3000 min -115010050N = 750 min -1N = 1000 min -1N = 1500 min -1N = 3000 min -124018012060N = 750 min -1N = 1000 min -1N = 1500 min -1N = 3000 min -100 15 30 45 60x (mm)0N = 3000 min -1 0 20 40 60 800 15 30 45 60x (mm)0x (mm)FR(daN)500<strong>FLSD</strong> 160FR(daN)500<strong>FLSD</strong> 180400400300300200100N = 750 min -1N = 1000 min -1N = 1500 min -1N = 3000 min -1200100N = 750 min -1N = 1000 min -1N = 1500 min -1N = 3000 min -100 50 100 150x (mm)00 50 100 150x (mm)32

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>ConstructionC3 - Bearings and lubricationC3.4.4 - Standard assemblyPermissible radial load on main shaft extension with a bearing life L 10h of 25,000 hours.FR(daN)720<strong>FLSD</strong> 200FR(daN)750<strong>FLSD</strong> 225600625480500360240120N = 750 min -1N = 1000 min -1N = 1500 min -1375250125N = 750 min -1N = 1000 min -1N = 1500 min -1N = 3000 min -10N = 3000 min -1 0 50 100 150N = 3000 min -1 N = 3000 min -13005004500 50 100 150x (mm)x (mm)FRFRFR(daN) <strong>FLSD</strong> 250 M(daN) <strong>FLSD</strong> 280 S(daN)90080011001000950850700900N = 750 min -1N = 750 min -1750600800N = 1000 min -1N = 1000 min -1650 N = 1500 min -1500700 N = 1500 min -1400N = 750 min -1N = 1000 min -1600550N = 1500 min -1N = 3000 min -10 40 80 120 160 0 40 80 120 160 0 40 80x (mm)x (mm)x (mm)0<strong>FLSD</strong> 280 M120160FR(daN)1300<strong>FLSD</strong> 315 S/M1100N = 750 min -1900700N = 1500 min -1N = 1000 min -1500N = 3000 min -10 40 80 120x (mm)16020033

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>ConstructionC3 - Bearings and lubricationC3.4.4 - Standard assemblyPermissible radial load on main shaft extension with a bearing life L 10h of 25,000 hours.FR(daN)1300<strong>FLSD</strong> 315 LAN = 750 min -1FR(daN)1200<strong>FLSD</strong> 315 LBN = 750 min -111001000N = 1000 min -1900N = 1500 min -1800N = 1500 min -1N = 3000 min -17006005000 40 80 120 160x (mm)2004000 40 80 120 160x (mm)200FR(daN)1400<strong>FLSD</strong> 355 LAFR(daN)1300<strong>FLSD</strong> 355 LBFR(daN)1000<strong>FLSD</strong> 355 LC - LD12001000800N = 750 min -1 N = 1000 min -1N = 1500 min -11100900700N = 750 min -1 N = 1000 min -1N = 1500 min -1900800700600N = 1000 min -1N = 1500 min -1N = 3000 min -1 N = 750 min -16005005004000 40 80 120 160x (mm)200N = 3000 min -1 0 40 80 120 160N = 3000 min -1 0 40 80 120 160N = 3000 min -1 N = 1000 min -1 240300240 200 240x (mm)400x (mm)20034

<strong>FLSD</strong> <strong>flameproof</strong><strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong>ConstructionC4 - Mains connectionC4.1 - TERMINAL BOX ANDCABLE GLAND POSITIONSPlaced as standard on the top of the motor,the terminal box has IP 55 protection and isfitted with a cable gland (see table in C4.3).The standard position of the cable gland ison the right, seen from the drive end(position A1) but , owing to the symmetricalconstruction of the box, it can usually beplaced in any of the 4 directions (see tablebelow).▼ Positions of the terminal box inrelation to the drive end(motor in IM 1001 position)DAStandardpositionB▼ Positions of the cable gland in relationto the drive end3421Standardpositionas supplied(can be oriented)Terminal box position A B D<strong>FLSD</strong> 80 to 280 ● - -<strong>FLSD</strong> 315* to 355 ● ❍ ❍●: standard ❍: ask for quotation - : not available* <strong>FLSD</strong> 315 = position B or D, the terminal box with cable glands facing downward exceeds the plan of motor feet.▲ Type "d" terminal boxCable gland position 1 2 3 4Foot mounted motor<strong>FLSD</strong> 80 to 355 ● ● ● ●FT face mounted motor<strong>FLSD</strong> 80 to 112 ● ❍ ● ●FF flange mounted motor<strong>FLSD</strong> 80 to 250 ● ❍ ● ●<strong>FLSD</strong> 280 to 355 ● - ● ●● : standard❍ : ask for quotation● : possible by simply turning round the terminal box*- : not available▲ Type "e" terminal box* Important: Take the necessary precautions when dismantling and re-assembling the terminal box, in orderto maintain the <strong>flameproof</strong> properties of the equipment. This is the responsibility of the person carryingout the operation.35