B45 B60 BV208DA Instructions - Gardner Bender

B45 B60 BV208DA Instructions - Gardner Bender

B45 B60 BV208DA Instructions - Gardner Bender

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

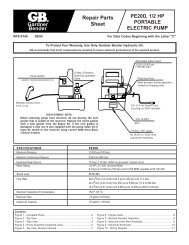

VI. Product DescriptionGB/JetLine ® Blowers and Blo-Vac systems aredesigned to provide a convenient means of installing pullline in a “sealed” conduit. “Sealed” conduit for thispurpose is considered EMT conduit with compressiontype couplings, rigid conduit with threaded joints, or PVCconduit with adhesive bonded joints.Blo-Vac SystemsGB/JetLine ® Blo-Vac Systems: <strong>BV208DA</strong> Super-UltraBlo-Vac provides blowing or vacuuming capabilitiesfor conduit fishing of 1 ⁄2” through 6”. These systemsprovide a higher output pressure for more difficult runs.The water lift capabilities of the Blo-Vac is the samefor blowing or vacuuming. See Table 2 for specifications.Conduit with set screw type couplings does noteffectively seal joints and substantial air or vacuum lossoccurs making it difficult to maintain pressure or vacuumto place a line in the conduit.Blower SystemsGB/JetLine ® supplies two blower systems; the<strong>B45</strong> Bak-Pak (for fishing from 1 ⁄2” through 2 1 ⁄2” tradesize conduit) and the <strong>B60</strong> Super Blower for heavy dutywork in conduit from 2 1 ⁄2” through 6”. FIGS. 2 and 3.<strong>B45</strong> Bak-PakPower UnitVacuumInletRecoveryCompartmentBlowerOutletThe <strong>B45</strong> Bak-Pakconduit fishing kit isequipped with a lightweight 1261 (Fig. 2)Power Unit, three foothose, shoulder strap,power saver linepackages, foam linecarriers, inflatables andaccessories for fishingconduit from 1 ⁄2” through2 1 ⁄2”. Bulk pull line is notincluded with the kit.<strong>B60</strong> Super BlowerThe <strong>B60</strong> Super Blowerwas designed for usein long undergroundsingle bore conduit from2 1 ⁄2” through 6”. TheB3000 Power Unit mustremain above ground forsafety reasons, and the2 1 ⁄2” diameter x 25 ft.long hose and seal-offare used in the manhole.The portable triple motorpower unit provides ahigh volume of air toblow a line in large boreconduit whether aboveground or below ground.1261 BlowerFIG. 2B3000 Super BlowerFIG. 3Tool StorageCompartmentBlo-VacFIG. 4Each Blo-Vac system is cart mounted for easytransporting around the job site. Each Blo-Vac unithas three compartments which are easily separated.The top section is the power unit, the center section isthe recovery compartment, and the bottom section isstorage for accessories. See Fig. 4. The power unitand the recovery compartment may be unlatched fromthe tool storage compartment and used as a portableblower vacuum system. All Blo-Vac systems areequipped with a 1 1 ⁄2” diameter x 8 ft. long hose andseal-offs to fit 1 ⁄2” through 6” conduit. Optional 15 ftmodel 125615, available.The <strong>BV208DA</strong> Super Ultra Blo-Vac has a powerfulthree-stage motor fan section. The recovery capacity is4.5 gallons expandable to 9 gallons by using the toolstorage compartment above the recovery compartmentafter removing the false bottom. Housings are made ofhigh impact polypropylene.5

E. Tag-Along Line PackagesThe Tag-Along line package must be used with a linecarrier (foam or inflatable) in 1 1 ⁄4” or larger conduit. Theincreased package diameter and length prevents thepackage from passing freely through or around bends inconduit less than 1 1 ⁄4”. Once attached to the line carrier,the Tag-Along line package function and operation issimilar to that of the Power Saver package. Breakingstrengths are 22 lb. and 50 lb. depending on theparticular Tag-Along package.F. PL Series Pull LineJetLine ® linear stranded PL series pull lines are designedspecifically for conduit fishing. These lines are made ofstrong polyolefin plastic that will not rust, rot or mildew.The coreless wound roll of knot free pull line makescenter dispensing from the carton a convenient featurewhen feeding the pull line directly into the conduitthrough the seal-off.Power Saver Line PackagesFIG. 6Table 4FIG. 8Tag-Along Line PackagesCat. No. Length Ft. Strength Lb.LP2206T 400’ 22LP2208T 600’ 22LP2207T 800’ 22Dispensing CartonDispensing BucketThe PL Series are oval in shape and tend to flatten out inbends. The flattened edges reduce the abrasive andcutting effect in PVC conduit.PL102 Pull Line - The 6500 ft. roll of 190 lb. breakingstrength pull line is fiberlated polyolefin line (approx.1⁄8 in. in diameter.Bulk Nylon LineJetLine bulk nylon line is fedinto the conduit through theseal-off feed through port.However, unlike the PowerSaver and Tag-Alongpackage, bulk line packagesremain at the conduit entrance.Line is pulled into the conduitby one of the JetLine ® linecarriers. Bulk nylon line issupplied in 22 lb., 50 lb. and100 lb. breaking strengths.Table 5Bulk Nylon LineFIG. 7Cat. No. Length (Ft.) Strength (Lbs.)LP1701 1000’ 100LP1702 2000’ 50LP1703 1400’ 22LP1707* 1350’ 100LP1722 2200’ 90* Wound on cardboard tube, not center dispensing.7PL232 Pull Line - The 6500 ft. roll of 200 lb. breakingstrength pull line is oval in shape (approx. 3 ⁄32 x 5 ⁄32 in.)will pass through the feed through port of all JetLine ®seal-offs.PL235 Pull Line - The 2200 ft. roll of 500 lb. breakingstrength pull line is oval in shape (approx. 1 ⁄8 x 5 ⁄16 in.)will feed through the port of Catalog No. B26 largeDial-A-Line seal-off body.Table 6PL-series Pull LineCat. No. Length (Ft.) Strength (Lbs.)PL231 1000’ 100PL102 6500’ 190PL232 6500’ 200PL235 2200’ 500Conduit Measuring TapeJetLine ® TT31 True Tape and ST40 Super TrueTape provide anaccurate means ofmeasuring the lengthof conduit runsalready in place. Bothare marked in 1 ft.increments.Conduit Measuring TapeFIG. 9

When measuring for wire length, measure from terminalto terminal, not from end of conduit. See table on roll ofmeasuring tape for allowances to be made for 90° bends,45° offsets, and panel boxes.G. Seal-OffsTable 7Conduit Measuring TapeCat. No. Description LengthTT31 True Tape 3000 ft. rollTT36 True Tape onCarrying Dispenser 3000 ft. rollST40 Super True Tape 2750 ft. rollThe GB/JetLine ® seal-offs are the final connectionbetween the blower or Blo-Vac hose and the conduit.Seal-offs attach to the JV07 or B26 Dial-A-Line body.The tapered seal-off cone (five sizes to fit 1 ⁄2” through 6”conduit) must be held firmly in the conduit when blowingor vacuuming line in conduit.JV08 Short Seal-OffThe JV08 Seal-Off isused in close quarterssuch as 2 x 4 electricalboxes, etc. It may beused on 1 ⁄2” through1 1 ⁄4” conduit.JV09 Long Seal-OffThe JV09 Seal-Off issimilar to the JV08,except for length, and isused to reach conduit indeep electrical boxes.JV12 Seal-OffJV08 Short Seal-OffFIG. 11JV09 Long Seal-OffFIG. 12The JV12 Seal-Off fits conduit sizes 1 1 ⁄4” through 2 1 ⁄2”.JV07 Dial-A-Line BodyThe small JV07 Dial-A-Line body is used in conjunctionwith the BV12 Hose Adapter, accepts the JV08 ShortSeal-Off, JV09 Long Seal-Off or the JV12 Seal-Off. Theperforated dial plate on the JV07 is adjusted to feed pullline up to 1 ⁄8” diameter or for feeding TT31 True Tape.Close off the feed port when Power Saveror Tag-Along line packages are used or when vacuuming.JV12 Seal-OffFIG. 13B26 Dial-A-Line BodyDial-A-Line Seal-Off Bodyand Hose AdapterFIG. 10The B26 is a large seal-off bodythat can be coupled directly toeither the 1 1 ⁄2” or 2 1 ⁄2” hoseassembly. It is used with theBV23 and BV24 seal-offs. The dialplate has a small hole for feedingpull line up to 1 ⁄8” diameter. Thelarge hole is for larger pull lineand rope up to 1 ⁄2” diameter.The slot is for feeding TT31True Tape or the feed portmay be closed offwhen using a Tag-Alongline package withline carrier orwhen vacuuming.B26 Dial-A-LineSeal-Off BodyFIG. 148

BV23 and BV24 Seal-OffThe larger internal diameter of BV23 and BV24 seal-offsallows more efficient flow of air when used with highvolume blowers and Blo-Vac systems. The BV23 andBV24 seal-offs are used in 1 1 ⁄4” through 2 1 ⁄2” and 2 1 ⁄2”through 6” conduit respectively.the conduit diameter and pass over local obstructionsthat would stop a foam line carrier.In large conduit 4”, 5” and 6”, the Inflatables ® may lieagainst the conduit wall. It may be necessary to point theseal-off nozzle toward the inflatable sleeve to achieveinitial inflation. This is accomplished by tilting the seal-offnozzle in the conduit entrance.When vacuuming an inflatable in the conduit it may benecessary to fluff it out and shake it to achieve inflation.BV23 Short Seal-Off BV24 Short Seal-OffFIG. 15 FIG 16H. Line CarriersThe line carrier is the movable “piston” that supplies theforce necessary to pull the line through the conduit whenpropelled by the blower or Blo-Vac system. They areconstructed of durable material and is reusable.FIG 18The Inflatables ® Line CarrierTable 9The Inflatables® Line CarriersFoam Line CarriersGB/JetLine ® foam linecarriers aremanufactured in 12 sizesfor use in conduit 1 ⁄2”through 6”. The foam linecarrier, as it travelsthrough the conduit, willclean out water and loosedebris providing the head Foam Line Carriersof water is not greaterFIG. 17than the maximum waterlift of the blower or Blo-Vac power unit. Sizes for 1 1 ⁄4”through 6” conduit are provided with a pulling eye on oneend and a hook on the other end. The hook provides aconvenient means of attaching the Tag-Along linepackage. If pull line is used, it should be attached to thepulling eye.Table 8Foam Line CarriersCat. No. Conduit Size Cat. No. Conduit SizeFC1 1⁄2” FC7 2 1 ⁄2”FC2 3⁄4” FC8 3”FC3 1” FC9 3 1 ⁄2”FC4 1 1 ⁄4” FC10 4”FC5 1 1 ⁄2” FC11 5”FC6 2” FC12 6”The Inflatables ® Line CarrierThe Inflatables ® line carrier has less friction in theconduit and is faster running than the foam line carrier.The flexible nature of the line carrier allows it to inflate to9Catalog No.Conduit SizeF125 3⁄4”, 1” and 1 1 ⁄4”F250 1 1 ⁄2”, 2” and 2 1 ⁄2”F400 3”, 3 1 ⁄2” and 4”F600 5” and 6”Plastic Line CarriersThe GB/JetLine ® slotteddouble skirted plastic linecarriers were developedfor the Blo-Vac conduitfishing systems for use inlong, single boreunderground ducts. Thelow friction properties of Missile Line Carrierthe plastic makes it a fastFIG 19running line carrier. If theline carrier encounters a blockage where it cannot getthrough, the slotted skirt allows the line carrier to bepulled out past joints or steps in the duct. A hard tug onthe pull line will cause the petals to turn inside outallowing for easy withdrawal.Table 10Plastic Line CarriersCat. No. Conduit Size Cat. No. Conduit SizeM2000 2” M4000 4”M2500 21⁄2” M5000 5”M3000 3” M6000 6”M3500 3 1 ⁄2”

I. Blowing or Vacuuming Through ConduitSelect the Power Saver line package for size andlength of line to fit the conduit. It is recommended thatyou flex the package back and forth two or three timesto loosen it. This will make the line easier to dispense.Blowing a line in the conduit1. Insert the hose in the blower side of the Blo-Vacpower unit.2. Insert the BV12 hose adapter in the other end ofthe hose. Screw the handle end of the JV07Dial-A-Line body into the hose adapter. Selecteither the JV08 or JV09 seal-off and screw it intothe JV07. FIGS. 20, 21 and 224. Insert the line packagein the conduit — foamtip first.5. Return to the other endof the conduit andpower unit.6. Hold the seal-off conein the conduit and turnon the power unit andvacuum the linepackage throughthe conduit.Tag-Along Line PackageConduitPower SaverLine PackageJV08 Seal-OffJV07 Dial-A-Line BodyFIG. 22JV08 Seal-OffJV07 Dial-A-Line BodyBV12 HoseAdapterTag-Along line packages perform the same functionas Power Saver line packages except they are usedin 1 1 ⁄4” diameter and larger conduit. Tag-Alongpackage must be used with a line carrier to supply thepulling force.Select the Tag-Along line package and a line carriereither foam or inflatable that fits the conduit diameter andproceed as follows:FIG. 203. Pull out approximatelytwo feet of line andhold on to trailing end.4. Insert the line packagein the conduit — foamtip first.5. Hold the seal-off conefirmly in the conduitentrance and turn onthe blower. Blow theline package throughthe conduit.6. It is recommendedthat the ends of theline be tied off, toprevent it from beingaccidentally pulled intothe conduit.Vacuuming a line in the conduitHose AssemblyConduitPower SaverLine PackageJV08 Seal-OffJV07Dial-A-LineBodyFIG. 211. Insert the hose in the vacuum side on the Blo-Vacpower unit.2. Assemble the hose and seal-off as in Item 2 above.3. At the far end of the conduit run, pull outapproximately two feet of line and tie off the trailingend of the line.10If a foam line carrier is selected—1. Attach the Tag-Alongline package plastic eyeto hook. Pull outapproximately two feetof line. Tie off the endsof the line to prevent itfrom being accidentallypulled into the conduit.2. Insert the foam linecarrier and Tag-Alongpackage in the conduit.3. Select the seal-off thatbest fits the conduit —JV07 Dial-A-Line bodywith the JV12 seal-off orthe B26 Dial-A-Linebody with the BV23 orBV24 seal-off.4. Hold the seal-off rubbercone firmly in theconduit and turn on thepower unit. The run timewill be longer than that12568 HoseAssemblyFoam LineCarrierTag-AlongBV23Seal-OffTrailing Endof LineB26 Dial-A-Line BodyFIG. 23for the Power Saver line package because of thelarger conduit and greater volume of air required.However, the run time in 3” and 4” conduit200 to 300 feet long should be complete in10 to 15 seconds.

Vacuuming Pull Line in the Conduit1. Insert the hose in the vacuum port.2. Select the JV07 small Dial-A-Line body thataccepts the JV08, JV09 or JV12 Seal-off for conduitsizes 1 ⁄2” through 2 1 ⁄2” or the B26 Large Dial-A-Line body that accepts the BV23 or BV24 Seal-offfor conduit sizes 1 1 ⁄4” through 6”.3. Connect the hose to the Dial-A-Line body.4. Place the pull line at the far end of the conduit.5. Select the appropriate line carrier and tie the pull linesecurely to the line carrier.6. Insert the line carrier in the conduit and turn on thepower unit.VIII. MaintenanceB26 Dial-A-Line BodyBV24 Seal-Off12568 Hose AssemblyInflatableVacuuming Line in Conduitwith the Inflatables®ConduitPullLineVacuuming Dirt and Water — Each Blo-Vac comeswith a cloth filter bag that must be used when vacuumingdirt and water. Use as follows:The Blowers and Blo-Vac systems should require verylittle maintenance. If the unit should require service, seeinstructions below.Blower overheating occurs when attempting to blow linein blocked conduit or a duct filled with water having ahead greater than the water lift capability of the blower.See Table 1.The 1261 and B3000 Blowers have an automatic thermaloverload switch built into the motor. If overheatingoccurs, the switch will turn the motor off. After a cooldownperiod of 15 to 30 minutes, the motor willautomatically re-set. The motor can be restarted.Blo-Vac power units are equipped with a perforatedfilter screen, located on the under side of the motorcompartment. Occasionally the screen becomes cloggedwith lint and dust and it should be cleaned to maintainmaximum air flow.Size Conduit1/2”3/4”1”1 1/4”1 1/2”2”2 1/2”3”3 1/2”4”5”6”Blower Application1. Release the latches securing the top and centertogether.2. Remove the filter bag from the bottom tool storagesection. Slide the filter bag onto the intake canisterlocated on the bottom of the motor. The filter bagprevents dust from entering the motor. Dust and dirtwill damage the motor and cause premature failure.3. After use, clean the filter bag by shaking off theexcess dirt and store the clean bag in the lowercompartment.4. The Blo-Vac is equipped with a ball float toprevent water from entering the motor. If the ballfloat seals the motor inlet, the motor will sounddifferent from usual. Immediately turn the unit off.Empty the recovery section and check the inletscreen for lint and dirt. Clean and reassemble theBlo-Vac sections.Blo-Vac Application1/2”3/4”<strong>BV208DA</strong>1”1 1/4”1 1/2”<strong>B45</strong>2”<strong>B60</strong>2 1/2”3”3 1/2”4”5”Distance6”0 200 400 600 800 1000 1200 0 200 400 600 800 1000 1200REPAIR AND SERVICE INSTRUCTIONS: For repair service and parts contact your nearest GB ELECTRICAL Service Center. The GBELECTRICAL Service Center will provide complete and prompt service on all GB ELECTRICAL products.Size ConduitPARTS AND SERVICE: For quality workmanship andgenuine GB ELECTRICAL parts, select an AuthorizedGB Service Center for your repair needs. Only repairsperformed by an Authorized Service Center displayingthe official GB Authorized sign are backed with fullfactory warranty. Contact GB Electrical (414)352-4160for the name of the nearest GB AuthorizedService Center.WARRANTY: GB ELECTRICAL, INC. warrants itsproduct against defects in workmanship and materialsfor 1 year from date of delivery to user. Chain is notwarranted. Warranty does not cover ordinary wearand tear, abuse, misuse, overloading, altered productsor use of improper fluid.WARRANTY RETURN PROCEDURE: When questionof warranty claim arises, send the unit to the nearest GBAuthorized Service Center for inspection, transportationprepaid. Furnish evidence of purchase date. If the claimcomes under the terms of our warranty the AuthorizedService Center will REPAIR OR REPLACE PARTSAFFECTED and return the unit prepaid.<strong>Gardner</strong>a unit of Tools and Supplies<strong>Bender</strong> 6101 N. Baker Road, Milwaukee, WI 53209 • Phone: (414) 352-4160 • FAX (414) 352-2377 ZRPS-0134 12/98