TN-S/P Performance Curves - barmex

TN-S/P Performance Curves - barmex

TN-S/P Performance Curves - barmex

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

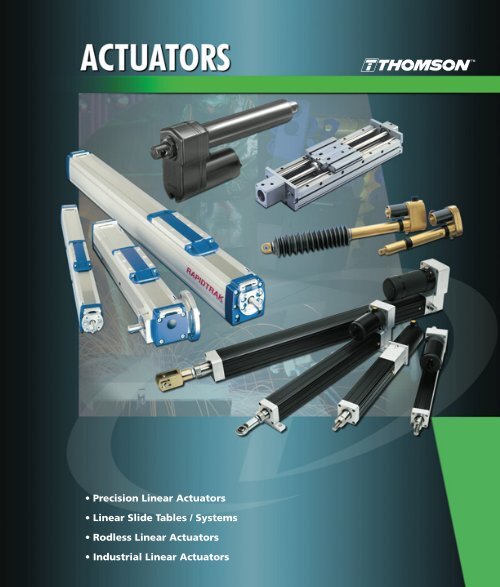

• Precision Linear Actuators<br />

• Linear Slide Tables / Systems<br />

• Rodless Linear Actuators<br />

• Industrial Linear Actuators

Mechanical and Electro-Mechanical<br />

Product Solutions by Danaher Motion<br />

Danaher Motion engineers, manufactures and markets a select<br />

combination of the world’s top brands of mechanical and<br />

electro-mechanical products. Our principle brands and products<br />

include:<br />

• THOMSON industrial, precision and rodless actuators, linear<br />

slide tables and systems, ball and lead screws, linear bearings<br />

and guides, precision balls, molded products, shafting and<br />

integrated solutions<br />

• THOMSON BSA lead screws and precision miniature<br />

ball screws<br />

• MICRON gearheads<br />

• DELTRAN PT electromagnetic friction and wrap spring<br />

clutches and brakes<br />

• SUPERIOR ELECTRIC stepper and servo motors and controls<br />

• SECO AC and DC variable speed drives<br />

Designed to help increase productivity and improve performance,<br />

our products are incorporated into new equipment designs as<br />

well as machines already in service. From semiconductor<br />

assembly, packaging, robotics and industrial automation to<br />

medical, fitness and mobile off-highway equipment, our<br />

mechanical and electro-mechanical products bring flexibility,<br />

precision, efficiency, and reliability to a wide variety of industries.<br />

Beyond our world-class product designs, one of our greatest<br />

strengths is our commitment to the Danaher Business System<br />

(DBS), which is comprised of a unique set of robust, repeatable<br />

processes that help us constantly improve the operational<br />

efficiency of our factories. Based upon the time-tested methods<br />

of Kaizen, the DBS is a team-based mindset that continuously<br />

and aggressively eliminates waste in every facet of our business<br />

operations. Furthermore, the DBS focuses the entire organization<br />

on breakthrough objectives that culminate in maintainable,<br />

results-oriented business processes, which, in turn, create<br />

advantages for our customers in the areas of quality, delivery<br />

and performance.<br />

At Danaher Motion, we bring together best-in-class products,<br />

unsurpassed customization expertise, and innovative solutions to<br />

significantly improve and revolutionize the way things move. We<br />

are the experts in motion control. In short, Danaher Motion offers<br />

more choices, more application expertise and more integrated<br />

solutions than anyone else in the market.<br />

Website: www.DanaherLinear.com

*<br />

ACTUATORS<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

1

Table of Contents<br />

Precision Linear Actuators<br />

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2<br />

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3<br />

Application Analysis Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6<br />

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9<br />

Design Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10<br />

Cross Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11<br />

<strong>TN</strong> Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13<br />

TC2 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-43<br />

TC3 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-71<br />

TC4 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-99<br />

TC5 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-117<br />

Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-139<br />

Linear Actuator Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-153<br />

Engineering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-165<br />

Linear Slide Tables/Systems<br />

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2<br />

Application Analysis Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-6<br />

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7<br />

How To Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8<br />

Custom Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-11<br />

Ball Screw and Lead Screw Driven Linear Slide Tables . . . . . . . . . . .B-13<br />

Microstage* MS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-14<br />

SuperSlide* 2RB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-16<br />

AccuSlide* 2HB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-18<br />

SuperSlide* 2DB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-20<br />

SuperSlide* 2EB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-22<br />

Belt Driven Linear Slide Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-25<br />

SuperSlide* 2RE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-26<br />

AccuSlide* 2HE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-28<br />

Linear Guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-31<br />

End Support 1BA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-32<br />

End Support 1NA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-34<br />

Continuous Support 1CA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-36<br />

Continuous Support 1PA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-38<br />

FluoroNyliner 1VA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-40<br />

Side Mounted 1DA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-42<br />

Dual Shaft Rail* 2DA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-44<br />

Twin Shaft Web* 2CA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-46<br />

Ball Screw Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-48<br />

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-51<br />

Motor Reference/Control Options . . . . . . . . . . . . . . . . . . . . . . . . . . B-66<br />

Engineering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-67<br />

2<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

Phone: 1-800-554-8466<br />

Website: www.linearactuators.com<br />

Rodless Actuators<br />

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2<br />

Product Selection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4<br />

Application Analysis Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6<br />

Rapidtrak Rodless Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8<br />

Turbo Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-35<br />

Movopart CB, Movo Z, ZB, Movo Z, Z2 . . . . . . . . . . . . . . . . . . . . . .C-41<br />

LoadMaster 80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-54<br />

Motor Reference/Control Options . . . . . . . . . . . . . . . . . . . . . . . . . .C-59<br />

Industrial Linear Actuators<br />

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-2<br />

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-3<br />

Product Selection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-4<br />

Application Analysis Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-6<br />

Electrak E050 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-8<br />

Electrak Q050 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-10<br />

Electrak E150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-12<br />

Electrak 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-14<br />

Electrak 1 Long Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-16<br />

Electrak 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-18<br />

Electrak 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-20<br />

Electrak 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-22<br />

Electrak 100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-24<br />

Electrak 205 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-26<br />

<strong>Performance</strong> Pak Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-29<br />

Repair Parts/Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-40<br />

T90 Special Purpose Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-41<br />

T130 Special Purpose Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . .D-42<br />

Movoact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-43<br />

Rotary Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-45<br />

Actuator Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-47<br />

Design Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-56<br />

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-58<br />

*

Phone: 1-800-554-8466<br />

Website: www.linearactuators.com<br />

T Series<br />

Microstage*<br />

Rapidtrak*<br />

Electrak 10<br />

PRECISION LINEAR ACTUATORS ($1000 - $5000)<br />

Simpler, cleaner, more precise, more controllable, cost-effective alternative to<br />

hydraulic and pneumatic positioning technology. Market applications include<br />

general industrial, semiconductor, packaging, scientific, printing and converting.<br />

Complete systems including actuator, motors, and controls are available.<br />

LINEAR SLIDE TABLES / SYSTEMS ($600 - $6000)<br />

Pre-assembled, ready to install stages providing low friction, smooth, accurate<br />

motion for a wide range of moment or normal loading configurations. Market<br />

applications include factory automation, medical, packaging, machine tool,<br />

semiconductor, printing, automotive assembly, aerospace and food processing.<br />

Slide tables are available as customizable linear guides to multiaxis, turnkey<br />

systems complete with motors, drives, controls and electromechanical accessories.<br />

RODLESS ACTUATORS ($800 - $12,500)<br />

Long travel, high speed, and high moment loading differentiates our rodless<br />

actuators from other mechanical transmissions. Market applications include X-Y<br />

tables, packaging, factory automation, scientific, and printing and converting.<br />

Complete systems including actuator ,motors, and controls can be provided.<br />

INDUSTRIAL LINEAR ACTUATORS ($110 - $900)<br />

Simpler, cleaner, more cost-effective alternative to hydraulic and pneumatic<br />

positioning technology. Market applications include agriculture, lawn & turf, marine,<br />

patient handling, ergonomic workstations, recreational vehicles, commercial floor<br />

machines, driveway and farm swing gates. Available in DC for battery operation, or<br />

115 & 220 AC for internal AC applications.<br />

*<br />

Product Overview<br />

The actuators included in this catalog represent the standard sizes and basic performance characteristics. Some of the options available include longer stroke lengths, higher loads, different mounting<br />

styles, CE or Marine duty ratings, anti-rotation of the extension tube, no cover tube, manual override and different voltage motors. If you don’t find the actuator to meet your needs in the catalog, call an<br />

applications engineer at 1-800-554-8466.<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

Key Features<br />

• Applications-range from extend/retract to<br />

high precision<br />

• Available with servo/stepper motor &<br />

drive packages for precise positioning or<br />

brush DC motor & drive packages for<br />

extend/retract course positioning<br />

• Max thrust to 5620 lb<br />

• Strokes to 60”<br />

• Speeds up to 51”/sec<br />

• IP 65 rating<br />

• Repeatability to 0.0005”<br />

• Clevis, trunnion, foot, and flange mounting<br />

Key Features<br />

• Applications-typically on factory machinery<br />

where accurate, smooth linear positioning is<br />

required<br />

• Available with servo/stepper motor & drive<br />

packages<br />

• Max thrust to 3100 lb<br />

• Strokes to 120”<br />

• Loads from 5 - 2000 lb<br />

• Repeatability to 0.0002”<br />

Key Features<br />

• Applications-where long travel and high speed<br />

are required<br />

• Available with servo/stepper motor & drive<br />

packages for precise positioning or brush DC<br />

motor & drive packages for course positioning<br />

• Max thrust to 1100 lb<br />

• Speeds up to 200”/sec<br />

• Loads from 6000 lb<br />

• Repeatability to 0.004”<br />

Key Features<br />

• Applications-extend/retract actuation<br />

(electro-mechanical replacement of hydraulic<br />

or pneumatic cylinder applications)<br />

• Available with AC or DC motor & drive<br />

packages for course positioning using<br />

available limit switch or clutch options<br />

• Max thrust to 1500 lb<br />

• Strokes to 36”<br />

• Speeds up to 2”/sec<br />

• Weatherproof (DC) - oily, damp, dirty (AC)<br />

• Clevis to clevis and trunnion mounting<br />

3<br />

LINEAR ACTUATORS TABLES/ SYSTEMS LINEAR ACTUATORS LINEAR ACTUATORS

Notes<br />

4<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

Phone: 1-800-554-8466<br />

Website: www.linearactuators.com<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

_____________________________________________________________________________<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

*

*<br />

Precision Linear Actuators<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

A-1

Overview<br />

A Precision Linear Actuator is preferred when:<br />

• Positioning an externally guided and supported load<br />

• Moving a load that pivots<br />

• There is a high concentration of airborne contaminants<br />

(rodless actuators are inherently less well protected)<br />

• Replacing a hydraulic or pneumatic cylinder with an<br />

electro-mechanical solution<br />

Danaher Motion offers two high performance Precision Linear<br />

Actuator Series:<br />

<strong>TN</strong> - The <strong>TN</strong> proven design has found its way into thousands of<br />

applications throughout the world. Regardless of the<br />

environment or requirement, we have likely solved your<br />

application with a standard or modified <strong>TN</strong> actuator.<br />

The <strong>TN</strong> combines durability and ease-of use to the largest<br />

selection of factory engineered options available today.<br />

TC - The TC series is our highest performance line of precision<br />

linear actuators. Designed for the most demanding applications,<br />

the TC series is ideal when the maximum available performance<br />

and longest cycle life are required. Precision rolled ball screws<br />

provide smooth motion, accurate positioning, and quiet<br />

operation.<br />

A-2<br />

Features & Benefits:<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

Phone: 1-800-554-8466<br />

Website: www.linearactuators.com<br />

TC Series<br />

• Highest <strong>Performance</strong><br />

• Precision rolled ball screws for smoothness and accuracy<br />

• Robust: designed for the highest loads and longest life possible<br />

• Environmentally sealed (IP54/optional IP65)<br />

• Metric dimensions ISO6431<br />

• Acme screw versions available<br />

<strong>TN</strong> Series<br />

• Smallest package<br />

• Most flexible: largest selection of factory-engineered options in the industry<br />

• English NFPA dimensions<br />

• Improved durability<br />

• Acme screw versions available<br />

*

Phone: 1-800-554-8466<br />

Website: www.linearactuators.com<br />

Quick Reference Guide<br />

*<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

Product Selection<br />

Nom Lead Screw Dia. 0.625" 0.625" 16mm 16mm 20mm 20mm 25mm 32mm<br />

Type of Screw Acme Ball Acme Ball Acme Ball Ball Ball<br />

Dimension Std. English Metric Metric Metric Metric<br />

NFPA Std. ISO6431 Std. ISO6431 Std. ISO6431 Std. ISO6431 Std.<br />

Motor Options 24VDC 24VDC<br />

Stepper Stepper Stepper Stepper Stepper<br />

Servo Servo Servo Servo Servo<br />

Max. Thrust (w/ Servo) 2670 N 3600 N 7200 N 12000 N 25000 N<br />

(note dimension std) (600 lbs) (810 lbs) (1620 lbs) (2700 lbs) (5620 lbs)<br />

Std. Stroke Lengths 2,4,6,8,10,12,16.5 in. 50,100,150,200,250 50,100,150,200,250 50,100,150,200,250 50,100,150,200,250<br />

300,450,600,750mm 300,450,600,750,1000mm 300,450,600,750 300,450,600,750<br />

1000,1250,1500mm 1000,1250,1500mm<br />

Max. Velocity (w/ Servo) .30 m/s .76 m/s .20 m/s 1.28 m/s .20 m/s 1.28 m/s 1.33 m/s 1.33 m/s<br />

(12 in/s) (30 in/s) (8 in/s) (50.5 in/s) (8 in/s) (50.5 in/s) (52.5 in/s) (52.5 in/s)<br />

Repeatability +/- .013 mm +/- .013 mm +/- .013 mm +/- .013 mm +/- .013 mm<br />

(+/- .0005 in) (+/- .0005 in) (+/- .0005 in) (+/- .0005 in) (+/- .0005 in)<br />

Backlash .400 mm .380mm .400 mm .250 mm .400 mm .250 mm .250 mm .300 mm<br />

(.016 in) (.015 in) (.016 in) (.010 in) (.016 in) (.010 in) (.010 in) (.012 in)<br />

Max. Rated Duty Cycle 100% 100% 100% 100% 100%<br />

(load, speed dependent)<br />

Limit Switches optional optional optional optional optional<br />

Std. Operating 32 to 140F -30 to +70C -30 to +70C -30 to +70C -30 to +70C<br />

Temperature Range (0 to 60C) (-22 to 158F) (-22 to 158F) (-22 to 158F) (-22 to 158F)<br />

Moisture/ Contaminants Humid, but Not IP54 Std. IP54 Std. IP54 Std. IP54 Std.<br />

Direct Contact IP65 Opt. IP65 Opt. IP65 Opt. IP65 Opt.<br />

Std. Control DC D2403 D2403<br />

Opt. Control DC D2502B D2502B<br />

<strong>TN</strong> TC2 TC3<br />

TC4<br />

TC5<br />

Std. Control Stepper SmartStep SmartStep SmartStep SmartStep SmartStep<br />

Std. Control Servo, single axis B8961 B8961 B8961 B8961 B896<br />

Std. Control Servo, dual axis B8962 B8962 B8962 B8962 B8962<br />

Catalog Page No. A-13 A-43 A-71 A-99 A-116<br />

A-3

Product Selection<br />

Precision Linear Actuator Selection Checklist<br />

A-4<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

Phone: 1-800-554-8466<br />

Website: www.linearactuators.com<br />

The following details the recommended step-by-step process of selecting an electric cylinder model which best matches your application requirements.<br />

1) Complete Application Analysis Worksheet<br />

(see page A-6)<br />

Effort and accuracy invested here can be<br />

directly proportional to the success of your<br />

applications. We encourage you to invest<br />

heavily in this critical and early phase of<br />

your applications development.<br />

2) Maximum Thrust Required<br />

Determine thrust requirement for your application, then adjust with safety factor for selected motor technology. (See Engineering Section)<br />

Formula: Max Thrust = F applied + F gravity + F accel + F friction<br />

Sample Calculation:<br />

50 + 30 + 1 + 5 = 86 lbs thrust (required by application)<br />

Product Selection Worksheet<br />

For selection assistance, fax to your local Danaher Motion Distributor<br />

Prepared By Prepared For<br />

Name<br />

Name<br />

Company<br />

Company<br />

Phone<br />

Phone<br />

Fax<br />

Fax<br />

E-Mail<br />

E-Mail<br />

Address<br />

Address<br />

User’s primary business<br />

Type of machine product to be used on<br />

Current user? Yes No<br />

Project Time Frame<br />

Volume Requirements<br />

Proposal Next 12 months:<br />

Build prototype Year 2:<br />

In production Year 3:<br />

1<br />

Action Required<br />

Demo<br />

Price quotation<br />

Recommend product Call me to discuss<br />

Please include drawings, comments or<br />

additional information on separate pages.<br />

Adjust the required thrust to ensure appropriate safety margin. Multiply by the appropriate safety factor, from the table shown:<br />

Thrust Safety Factor<br />

Motor Type Safety Factor<br />

Brushed DC Servo Motor 1.20 (20%)<br />

Step Motors 1.30 (30%)<br />

Brushless Servo Motors 1.20 (20%)<br />

Sample Calculation:<br />

86 x 1.20 = 103.2 lbs thrust (required for selection of brushless servo)<br />

3) Duty Cycle<br />

Determine the operating Duty Cycle, over a maximum ten-minute time interval. The thrust available from a given actuator is higher when<br />

thrust duration is less than continuous. (See Engineering Section)<br />

Formula: Duty Cycle = ON time ÷ TOTAL time<br />

Sample Calculation:<br />

REPEATED MOTION: 30 seconds ON, 15 seconds DWELL, then repeat.<br />

DUTY CYCLE = 30 seconds ON ÷ 45 seconds TOTAL CYCLE TIME = 66% Duty Cycle<br />

4) Peak Speed Requirement (see Engineering Section)<br />

Calculate the peak speed required to complete the desired motion profile.<br />

Formula: Trapezoidal Move Profile (peak speed = 1.5 times average speed)<br />

Sample Calculation:<br />

Desired Motion: Move 10 inches in 2.0 seconds.<br />

Peak Speed Requirement: 10 inches ÷ 2.0 seconds x 1.5 = 7.5 inches per second<br />

5) Select Cylinder Family and Motor/Drive Technology<br />

Review the introductory section of the specific cylinder family (<strong>TN</strong>, TC2, TC3, TC4, TC5.). You will find that each family of<br />

actuators is subdivided by motor technology (e.g. TC2-D (DC Motor), TC2-S (Step Motor), TC2-B (Servo)). Refer to the chart at the bottom<br />

of pages A-14.<br />

(rails, etc)<br />

Motion Profile<br />

Motor Type Preferred<br />

Graph your most demanding cycle, include accel/decel, velocity and dwell times.<br />

Servo Stepper<br />

You may also want to indicate load variations and I/O changes during the cycle.<br />

Label axes with proper scale and units.<br />

Other<br />

Speed ( )<br />

Axes of Motion<br />

Single Multiple #<br />

Synchronized<br />

Interface<br />

Host PLC Computer<br />

Analog I/O RS232<br />

Digital I/ O Control<br />

Other<br />

Operator<br />

( )<br />

Time<br />

Keypad/ LCD Display<br />

or<br />

Pushbuttons<br />

Distance<br />

Potentiometer /Joystick<br />

Thumbwheels<br />

Supply Voltage<br />

110 AC 220 AC<br />

Other<br />

Control Method<br />

Feedback Required<br />

Programmable External Control Signal<br />

Encoder Linear Potentiometer<br />

Manual Jog<br />

Digital (Step & Direction)<br />

Analog Velocity<br />

Other<br />

Analog Torque<br />

Analog Position<br />

Limit Switches<br />

Input Functions<br />

Description of Application<br />

Output Functions<br />

*

Phone: 1-800-554-8466<br />

Website: www.linearactuators.com<br />

Precision Linear Actuator Selection Checklist<br />

6) Select Speed-Thrust Curve<br />

Search through the performance curves to select an actuator which can<br />

provide both the speed and thrust calculated above.<br />

You might want to narrow your search using one of the following criteria:<br />

Control Features • Price Range • Motor Technology<br />

*<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

Product Selection<br />

7) Stroke Length<br />

Select the stroke length required for your application. Add extra travel at each end for placement of end-of-travel position sensors.<br />

The following formula can be used as a guideline for determining the appropriate added distance.<br />

a) Operating Stroke Distance<br />

Start with the required operating stroke distance. If you need to move 18 inches back and forth in a repeated cycle, then this distance<br />

is 18 inches.<br />

b) Increase Stroke Length for End-of-travel Position Sensors<br />

Include a short ‘over-travel distance’ to prevent hard-stopping when an end-of-travel sensor is triggered.<br />

Use this formula to calculate how much additional stroke is required in your application:<br />

1. Stopping Distance: X = m v2 ÷ (2F)<br />

Where: X = deceleration distance (inches)<br />

m = mass of payload (lbf/386)<br />

v = velocity before deceleration (inches per second)<br />

F = force available to decelerate, from performance curve (lbf)<br />

2. Add twice the X value to your required motion distance.<br />

High Speed Example: You require 18” actual travel. Payload = 100 lb. Max Speed = 30 in/sec. The actuator model you have selected<br />

shows 80 lb peak thrust capacity. The equation above predicts stopping distance (X) is 1.46 inches. This safety area is needed at each<br />

end-of-travel, ~3 inches (two times 1.46 inches) is added to 18”, so you need to order an actuator with a stroke of 21” or greater.<br />

NOTE: When utilizing a pivot mounting option (MP2 or MT4) in conjunction with a pivot rod end (FS2 or FC2) it is recommended that<br />

the cylinder be extended to only 90-95% of its fully extended length. This increases the system’s rigidity and extends the life of the guide<br />

bearings and rod seal.<br />

8) Critical Speed, Column Loading Limits<br />

Verify that the speed and thrust performance are not limited by the stroke length of your actuator. Compare the Critical Speed and<br />

Column Loading limits shown on the chart at the bottom of the page where you found your performance curve. Many shorter stroke<br />

actuators are not limited, which makes the entire performance curve available. See the Engineering Section for more information.<br />

9) Proceed to How To Order Section<br />

The motor, transmission ratio, and stroke have now been selected. Next, continue with the selection of mounting and other required<br />

options as directed in the Ordering section for your selected motor type (see chart below).<br />

Precision Linear Actuator Type Catalog Page No.<br />

<strong>TN</strong> A-13<br />

TC2 A-43<br />

TC3 A-71<br />

TC4 A-99<br />

TC5 A-117<br />

Speed<br />

mm/s in/s<br />

381 15<br />

305 12<br />

229 9<br />

152 6<br />

76 3<br />

0<br />

0<br />

X<br />

70<br />

311<br />

100% 60% 30%<br />

140<br />

623<br />

Thrust<br />

210<br />

934<br />

280<br />

1245<br />

350 lbs<br />

1557 N<br />

A-5

Application Analysis Worksheet<br />

Prepared By Prepared For<br />

Name<br />

Company<br />

Phone<br />

Fax<br />

E-Mail<br />

Address<br />

User’s primary business<br />

Type of machine product to be used on<br />

Current user? Yes No<br />

Project Time Frame<br />

A-6<br />

Name<br />

Company<br />

Phone<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

Fax<br />

Address<br />

Proposal Next 12 months:<br />

Build prototype Year 2:<br />

In production Year 3:<br />

Action Required<br />

Demo<br />

Recommend product<br />

Price quotation<br />

Call me to discuss<br />

Please include drawings, comments or<br />

additional information on separate pages.<br />

Volume Requirements<br />

1<br />

Phone: 1-800-554-8466<br />

Website: www.linearactuators.com<br />

For selection assistance, fax fax to your to your local local Danaher Danaher Motion Motion Distributor Distributor or Danaher Motion at 1-800-445-0329<br />

E-Mail<br />

*

Phone: 1-800-554-8466<br />

Website: www.linearactuators.com<br />

Precision Linear Actuators Selection Data<br />

*<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

Application Analysis Worksheet<br />

(rails, etc)<br />

A-7

Application Analysis Worksheet<br />

Motion Control Data<br />

Graph your most demanding cycle, include accel/decel, velocity and dwell times.<br />

You may also want to indicate load variations and I/O changes during the cycle.<br />

Label axes with proper scale and units.<br />

Speed ( )<br />

Control Method<br />

Programmable<br />

Manual Jog<br />

Limit Switches<br />

Description of Application<br />

A-8<br />

External Control Signal<br />

Digital (Step & Direction)<br />

Analog Torque<br />

( )<br />

Time<br />

or<br />

Distance<br />

Analog Velocity<br />

Analog Position<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

Phone: 1-800-554-8466<br />

Website: www.linearactuators.com<br />

Axes of Motion<br />

Single Multiple #<br />

Synchronized<br />

Interface<br />

Host<br />

Servo<br />

Other<br />

Operator<br />

PLC Computer<br />

Analog I/O RS232<br />

Digital I/ O Control<br />

Other<br />

Keypad/ LCD Display<br />

Pushbuttons<br />

Potentiometer /Joystick<br />

Thumbwheels<br />

Supply Voltage<br />

110 AC<br />

Other<br />

Feedback Required<br />

Encoder Linear Potentiometer<br />

Other<br />

Input Functions<br />

Output Functions<br />

Stepper<br />

220 AC<br />

*

Phone: 1-800-554-8466<br />

Website: www.linearactuators.com<br />

Precision Linear Actuators<br />

To learn more about applying Precision Linear Actuators, refer to the Engineering section<br />

beginning on page A-165. There you will find more detail on topics like: Move Profile<br />

Calculations, Loading Limitations, Defining Precision, Environmental Consideration and much<br />

more including a glossary of common terms.<br />

Valve Control<br />

Backstop Adjust<br />

*<br />

Two-Axis Unloading<br />

Edge Guide Control<br />

Applications<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

Welding Head Control<br />

A B8961 Smart Drive (controller and servo drive in one), with application<br />

specific software features, is combined with an TC Precision Linear Actuator<br />

in welding applications. The Thomson solution provides total control over the<br />

amount and duration of applied force.<br />

A-9

Design Considerations<br />

A-10<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

Phone: 1-800-554-8466<br />

Website: www.linearactuators.com<br />

Actuators are direct descendants of hydraulic and pneumatic cylinders. Possessing many of the same unique design characteristics that made hydraulic<br />

and pneumatic cylinders popular, actuators benefit from a cleaner and simpler power transmission. Decades of electric cylinder research and<br />

development has provided machine designers with a flexible, simple and unique approach to solving rigid or pivoting linear motion applications.<br />

Fig. 1<br />

Non-Intrusive:<br />

Thrust rod can clear out of the way.<br />

Mounting Ideas: Have you seen it done this way?<br />

As in most aspects of design, a little creativity goes a long way when attaching a cylinder to a<br />

machine. Two general types of mounting styles are available, rigid and pivoting. Rigid mounting<br />

options (Figure 3 & 4) include side-tapped holes, front and rear flanges, side lugs and side angle<br />

brackets. These typically restrict motion to straight-line travel paths. Pivoting mounts (figure 5<br />

through 8) such as the clevis or trunnion allow the cylinder to move as a link in a dynamic<br />

assembly. There are many applications for this “arc-motion” – conveyor diverter gates, pivoting<br />

rollers, lid lifters for chemical chambers, “scissors clamps” and so on.<br />

Rigid Mounting<br />

Fig. 3a<br />

Fig. 3b Fig. 4<br />

Fig. 9<br />

Electrically Powered, Maintenance Free<br />

Fig. 2<br />

A primary advantage of all three<br />

technologies is the capability to extend into a work area during an<br />

operation and then retract to clear the area for subsequent operations<br />

(Figures 1 and 2). Rodless actuators, precision tables or linear motors do<br />

not share this ability. Another benefit of the rod-type design is that the motor and main body<br />

of the electric cylinder can be isolated from the work area. This is very useful when dealing<br />

with such hostile environments as vacuum, high temperature, or wash down applications.<br />

Pivoting Mounting<br />

Straight-Line Thrust Transmission<br />

Use all available Power<br />

Fig. 5 Fig. 6<br />

Fig. 7 Fig. 8<br />

When high thrust is required, rod type cylinders have the advantage over rodless<br />

actuators and tables since all the thrust-transmitting components are in-line.<br />

This provides the simplest and most efficient means of transmitting thrust to the<br />

load (Figure 10). In rodless cylinders the load is offset from the leadscrew or<br />

piston (Figure 9). Many designs are limited to less<br />

than 50% of the available thrust due to the<br />

Fig. 10<br />

mechanical limitations of the components between<br />

the load and the screw or piston.<br />

Today nearly all machines incorporate panel switches, sensors, lights, displays, PLCs or even complete PCs. Electric power is nearly always available on the machine.<br />

Compressed air or hydraulic pumps are not always available or desirable. Actuators are available with DC, stepper or brushless servo motors, so why not simplify the<br />

machine by using the same control for all the axes of motion? A multi-axis programmable motor control can give you command of both rotary and linear motion.<br />

Lastly, the maintenance-free design provides another strong reason to consider actuators in your next application.<br />

*

Phone: 1-800-554-8466<br />

Website: www.linearactuators.com<br />

Operation of an actuator is pretty basic. An electric motor – through either a timing<br />

belt, a gear drive or via in-line direct coupling – rotates a ball screw or acme screw,<br />

which translates the torque into force through the thrust tube.<br />

While the concept is straight forward, as illustrated by the cylinder cutaways on<br />

these pages, significant expertise and development has been invested in the<br />

specification and design of each component.<br />

Standard motor mounting<br />

configurations include<br />

parallel (as shown), and inline.<br />

Several NFPA style mounting<br />

configurations available,<br />

thus the actuator can be<br />

configured to adapt to a<br />

wide variety of mounting<br />

requirements. English<br />

and Metric.<br />

Aluminum extruded<br />

square body offers<br />

exceptional stiffness<br />

and strength.<br />

*<br />

Lubricated polyacetal acme drive<br />

nut provides low-friction, smooth<br />

operation and high resistance to<br />

shock loads.<br />

Alloy steel, heat treated ball nut<br />

on ball screw models.<br />

Improved, more durable<br />

metal guide bearing prevents<br />

thrust tube rotation, provides<br />

screw support and holds<br />

sensing magnets which trip<br />

actuator mounted switches.<br />

Cross Section<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

Long life bearing guides<br />

thrust tube.<br />

Improved, more durable<br />

metal guide bearing prevents<br />

thrust tube rotation, provides<br />

screw support and holds<br />

sensing magnets which trip<br />

actuator mounted switches.<br />

Internally-guided output tube<br />

cannot rotate: eliminates all<br />

torque onto the load.<br />

Mechanical non-jamming<br />

end-of-stroke cushion<br />

provides over-stroke<br />

protection. In conjunction<br />

with Thomson Controls,<br />

actuator power is<br />

automatically shut off.<br />

A-11

Worksheet<br />

NOTES:<br />

A-12<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

Phone: 1-800-554-8466<br />

Website: www.linearactuators.com<br />

*

*<br />

<strong>TN</strong> Series<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

A-13

<strong>TN</strong> Series<br />

Life<br />

Acme Screw Life: Usable life for an acme screw is defined as the length of<br />

travel completed before backlash (of leadscrew/nut) exceeds 0.020 inches<br />

[0.5 mm]. A travel life of 1 million inches under the maximum rated load can<br />

be used as a general approximation, however, since wear is directly<br />

dependent on application conditions (load, duty cycle, move profiles and<br />

environment) it is difficult to quantify an accurate travel life.<br />

A-14<br />

Overview<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

Phone: 1-800-554-8466<br />

Website: www.linearactuators.com<br />

<strong>TN</strong> Series actuators are available with three motor types to meet a<br />

variety of application requirements.<br />

• The <strong>TN</strong>-D family features a cost effective 24 VDC motor. When<br />

combined with D2400 control, the complete system provides<br />

simple extend–retract motion, positioning to pre-determined<br />

stopping locations, or positioning to an analog voltage command;<br />

all at the lowest installed cost.<br />

• The <strong>TN</strong>-S/P family is a step motor based linear actuator. These<br />

systems are selected for applications that require high load and<br />

duty cycle, in-position holding, open loop operation, repeatable<br />

positioning to 0.0005 inches [0.013 mm] and maintenance-free<br />

operation.<br />

• The <strong>TN</strong>-B Series actuators offer very high acceleration and duty<br />

cycle for the most demanding automated motion applications. The<br />

B8961 Servo Drive is designed to optimize the performance of the<br />

brushless servo motor.<br />

All <strong>TN</strong> Series actuators are available with several time-proven<br />

options to enhance operation in the industrial environment.<br />

Options include holding brakes, linear potentiometers or encoders<br />

for position feedback, dual rod-end bearings to increase side load<br />

and more. See the end of this section for more information.<br />

<strong>TN</strong>-D Series <strong>TN</strong>-S/P Series <strong>TN</strong>-B Series<br />

Motor Type 24 VDC Permanent Magnet 1.8˚ Hybrid Stepper Rare Earth Magnet Brushless Servo<br />

<strong>Performance</strong> <strong>Curves</strong> Page A-16 Page A-20 Page A-26<br />

Load Capacity lbs [N] 600 [2,670] 600 [2,670] 600 [2,670]<br />

No Load Speed in/s [mm/s] 24 [610] 25 [635] 30 [760]<br />

Repeatability in [mm] ±0.005 [.127] ± 0.0005 [.0127] ± 0.001 [.025]<br />

Compatible Controls Offered D2403, D2502B <br />

B8961, B8962<br />

*

Phone: 1-800-554-8466<br />

Website: www.linearactuators.com<br />

General Specifications<br />

System Backlash<br />

Thrust Tube<br />

0.015 inches [0.38 mm]<br />

Side Load Moment Consult factory.<br />

Rotation Does not rotate.<br />

Standard Travel Lengths 2, 4, 6, 8, 10, 12, and 16.5 (18–DB); custom stroke lengths available<br />

*<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

<strong>TN</strong> Series<br />

Construction Materials<br />

Bearing Housings Type 380 die cast aluminum, epoxy coated<br />

Cylinder Housing 6063 T-6 aluminum, hard-coated anodized and Teflon impregnated<br />

Thrust Tube 300 Series stainless steel, 1/8 hard, ground<br />

Wiper Seal<br />

Lead Screw<br />

Polyurethaneß<br />

Pitch Choices 2, 5 Ball; 5, 8 Acme<br />

Support Bearings Ball bearings<br />

Acme Screw; drive nut 0.625 inch diameter, carbon steel screw; lubricated polyacetal plastic (<strong>TN</strong>-D, <strong>TN</strong>-P) or bronze (<strong>TN</strong>-S, <strong>TN</strong>-B) nut<br />

Ball Screw; drive nut 0.625 inch diameter, carbon steel screw; alloy steel, heat-treated ball nut<br />

Weight (approximate, 2 inch stroke unit without options. Add 0.25 lbs [0.11 kg] per additional inch of stroke)<br />

<strong>TN</strong>-D Series<br />

<strong>TN</strong>-S/P Series<br />

7 lbs [3.2 kg]<br />

<strong>TN</strong>-P22 6 lbs [2.7 kg]<br />

<strong>TN</strong>-S32 9 lbs [4.1 kg]<br />

<strong>TN</strong>-B Series 6 lbs [2.7 kg]<br />

Environmental Operation (See the Options and Accessories section, page A-139.)<br />

Temperature Range 32° to 140°F, [0° to 60°C]<br />

-H high temperature option allows 32° to 160°F [0° to 70°C]<br />

-F sub-freezing temperature option allows –20° to 105°F [-29° to 40°C]<br />

Moisture Humid, but not direct moisture contact<br />

-W water resistant option allows some direct moisture contact<br />

Contaminants Non-corrosive, non-abrasive<br />

-PB protective boot option prevents moisture and dry contaminants<br />

from entering the cylinder through the wiper ring on the rod<br />

A-15

<strong>TN</strong>-D <strong>Performance</strong> <strong>Curves</strong><br />

High-Speed Ball screw Models<br />

Speed<br />

Speed<br />

Speed<br />

mm/s in/s<br />

610 24<br />

508 20<br />

406 16<br />

305 12<br />

203<br />

102<br />

<strong>Performance</strong> using D2400 Series Controls.<br />

Duty Cycle is percentage of actuator “on time” or movement over<br />

10 minute interval.<br />

Repeatability achievable with D2400 control. Reduce cylinder speed<br />

prior to final positioning.<br />

A-16<br />

8<br />

4<br />

mm/s in/s<br />

508 20<br />

406<br />

305<br />

203<br />

102<br />

60% 30%<br />

0<br />

0 10 20 30 40 50 lbs<br />

45 89 133<br />

Thrust<br />

178 222 N<br />

16<br />

12<br />

8<br />

4<br />

0<br />

0<br />

mm/s in/s<br />

356 14<br />

305 12<br />

254 10<br />

203<br />

152<br />

102<br />

51<br />

8<br />

6<br />

4<br />

2<br />

0<br />

0<br />

60% 30%<br />

<strong>TN</strong>-D-10-2B<br />

<strong>TN</strong>-D-10L-2B<br />

20<br />

89<br />

40<br />

178<br />

60<br />

267<br />

Thrust<br />

80<br />

356<br />

100<br />

445<br />

120 lbs<br />

534 N<br />

60% 30%<br />

<strong>TN</strong>-D-15-2B<br />

<strong>TN</strong>-D-20-2B<br />

20<br />

89<br />

40<br />

178<br />

60<br />

267<br />

Thrust<br />

80<br />

356<br />

100<br />

445<br />

120 lbs<br />

534 N<br />

2 thru 18-DB<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

2B<br />

30.0<br />

n/a<br />

Critical Speed (in/sec)<br />

Stroke (in)<br />

Column Load Limit (lb)<br />

Phone: 1-800-554-8466<br />

Website: www.linearactuators.com<br />

<strong>TN</strong>-D-10-2B: 1:1 Timing Belt, 2 rev/inch Ball screw<br />

<strong>TN</strong>-D-10L-2B: Inline Coupling, 2 rev/inch Ball screw<br />

Min. Backdrive Load 10 lbs 45 N<br />

Max. No-Load Accel. 180 in/s2 4572 mm/s2<br />

Repeatability ±0.010 in ±0.254 mm<br />

<strong>TN</strong>-D-15-2B: 1.5:1 Timing Belt, 2 rev/inch Ball screw<br />

Min. Backdrive Load 10 lbs 45 N<br />

Max. No-Load Accel. 150 in/s2 3810 mm/s2<br />

Repeatability ±0.010 in ±0.254 mm<br />

<strong>TN</strong>-D-20-2B: 2:1 Timing Belt, 2 rev/inch Ball screw<br />

Min. Backdrive Load 10 lbs 45 N<br />

Max. No-Load Accel. 150 in/s2 3810 mm/s2<br />

Repeatability ±0.010 in ±0.254 mm<br />

Consider leadscrew critical speed and column load limits when specifying longer lengths.<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

*

Phone: 1-800-554-8466<br />

Website: www.linearactuators.com<br />

Ball screw Models<br />

Speed<br />

Speed<br />

Speed<br />

Speed<br />

Speed<br />

mm/s in/s<br />

305 12<br />

254 10<br />

203 8<br />

152 6<br />

102 4<br />

51 2<br />

0<br />

0<br />

100% 60% 30%<br />

20<br />

89<br />

40 60<br />

178 267<br />

Thrust<br />

mm/s in/s<br />

203 8<br />

178 7<br />

152 6<br />

127 5<br />

102<br />

76<br />

4<br />

100%<br />

3<br />

60% 30%<br />

51 2<br />

25 1<br />

0<br />

0 20 40 60 80 100<br />

89 178 267 356<br />

Thrust<br />

445<br />

mm/s in/s<br />

152 6<br />

127<br />

102<br />

76<br />

51<br />

25<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

0<br />

100% 60%<br />

30%<br />

25<br />

111<br />

50<br />

222<br />

75 100 125<br />

334 445<br />

Thrust<br />

556<br />

mm/s in/s<br />

102 4.0<br />

89 3.5<br />

76 3.0<br />

64<br />

51<br />

2.5<br />

2.0<br />

100% 60%<br />

30%<br />

38 1.5<br />

25 1.0<br />

13 0.5<br />

0<br />

0 50 100 150 200<br />

222 445 667<br />

Thrust<br />

890<br />

0<br />

0<br />

300 400<br />

1335 1779<br />

Thrust<br />

*<br />

80<br />

356<br />

120<br />

534<br />

150<br />

667<br />

140<br />

623<br />

175<br />

778<br />

250<br />

1112<br />

mm/s in/s<br />

25 1.0<br />

20 0.8<br />

15 0.6<br />

100% 60%<br />

30%<br />

10 0.4<br />

5 0.2<br />

100<br />

445<br />

200<br />

890<br />

500<br />

2224<br />

600<br />

2669<br />

100 lbs<br />

445 N<br />

160 lbs<br />

712 N<br />

200 lbs<br />

890 N<br />

300 lbs<br />

1334 N<br />

700<br />

3114<br />

Consider leadscrew critical speed and column load limits when specifying longer lengths.<br />

2 thru 18-DB<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

lbs<br />

N<br />

5B<br />

15.0<br />

n/a<br />

Critical Speed (in/sec)<br />

Stroke (in)<br />

<strong>TN</strong>-D <strong>Performance</strong> <strong>Curves</strong><br />

<strong>TN</strong>-D-10-5B<br />

<strong>TN</strong>-D-10L-5B <strong>TN</strong>-D-10-5B: 1:1 Timing Belt, 5 rev/inch Ball screw<br />

<strong>TN</strong>-D-10L-5B: Inline Coupling, 5 rev/inch Ball screw<br />

<strong>TN</strong>-D-15-5B<br />

<strong>TN</strong>-D-20-5B<br />

<strong>TN</strong>-D-31-5B<br />

<strong>TN</strong>-D-120-5B<br />

<strong>Performance</strong> using D2400 Series Controls.<br />

Duty Cycle is percentage of actuator “on time” or movement over<br />

10 minute interval.<br />

Repeatability achievable with D2400 control. Reduce cylinder speed<br />

prior to final positioning.<br />

Min. Backdrive Load 10 lbs 45 N<br />

Max. No-Load Accel. 180 in/s2 4572 mm/s2<br />

Repeatability ±0.010 in ±0.254 mm<br />

<strong>TN</strong>-D-15-5B: 1.5:1 Timing Belt, 5 rev/inch Ball screw<br />

Min. Backdrive Load 20 lbs 89 N<br />

Max. No-Load Accel. 80 in/s2 2032 mm/s2<br />

Repeatability ±0.005 in ±0.127 mm<br />

<strong>TN</strong>-D-20-5B: 2:1 Timing Belt, 5 rev/inch Ball screw<br />

Min. Backdrive Load 20 lbs 89 N<br />

Max. No-Load Accel. 70 in/s2 1778 mm/s2<br />

Repeatability ±0.005 in ±0.127 mm<br />

<strong>TN</strong>-D-31-5B: 3.1:1 Helical Gear, 5 rev/inch Ball screw<br />

Min. Backdrive Load 20 lbs 89 N<br />

Max. No-Load Accel. 40 in/s2 1016 mm/s2<br />

Repeatability ±0.005 in ±0.127 mm<br />

<strong>TN</strong>-D-120-5B: 12:1 Helical Gear, 5 rev/inch Ball screw<br />

Min. Backdrive Load 20 lbs 89 N<br />

Max. No-Load Accel. 13 in/s2 330 mm/s2<br />

Repeatability ±0.005 in ±0.127 mm<br />

Column Load Limit (lb)<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

A-17

Speed<br />

Speed<br />

Speed<br />

Speed<br />

Speed<br />

<strong>TN</strong>-D <strong>Performance</strong> <strong>Curves</strong><br />

Acme Screw Models<br />

mm/s in/s<br />

305 12<br />

254<br />

203<br />

152<br />

102<br />

51<br />

A-18<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

0<br />

mm/s in/s<br />

178 7<br />

152<br />

127<br />

102<br />

76<br />

51<br />

25<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

0<br />

mm/s in/s<br />

178 7<br />

152<br />

127<br />

102<br />

76<br />

51<br />

25<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

0<br />

60% 30%<br />

10<br />

45<br />

20<br />

89<br />

30<br />

133<br />

40<br />

178<br />

Thrust<br />

50<br />

222<br />

60<br />

267<br />

70<br />

311<br />

80 lbs<br />

356 N<br />

60% 30%<br />

20<br />

89<br />

40<br />

178<br />

60<br />

267<br />

Thrust<br />

80<br />

356<br />

100<br />

445<br />

120 lbs<br />

534 N<br />

60% 30%<br />

20<br />

89<br />

40<br />

178<br />

60<br />

267<br />

Thrust<br />

80<br />

356<br />

100<br />

445<br />

120 lbs<br />

534 N<br />

mm/s in/s<br />

102 4.0<br />

89 3.5<br />

76 3.0<br />

64 2.5<br />

51<br />

38<br />

2.0<br />

1.5<br />

60% 30%<br />

25 1.0<br />

13 0.5<br />

0<br />

0 20<br />

89<br />

40<br />

178<br />

60<br />

267<br />

80<br />

356<br />

Thrust<br />

100<br />

445<br />

120<br />

534<br />

140<br />

623<br />

160 lbs<br />

712 N<br />

mm/s in/s<br />

25 1.0<br />

20 0.8<br />

15 0.6<br />

10 0.4<br />

5 0.2<br />

0<br />

0<br />

<strong>TN</strong>-D-10-5A and <strong>TN</strong>-D-10L-5A<br />

<strong>TN</strong>-D-15-5A<br />

<strong>TN</strong>-D-20-5A<br />

<strong>TN</strong>-D-31-5A<br />

<strong>TN</strong>-D-120-5A<br />

60% 30%<br />

150<br />

667<br />

300<br />

1335<br />

450<br />

2002<br />

600<br />

2669<br />

750 lbs<br />

3336 N<br />

Thrust<br />

<strong>Performance</strong> using D2400 Series Controls.<br />

Duty Cycle is percentage of actuator “on time” or movement over<br />

10 minute interval.<br />

Repeatability achievable with D2400 control. Reduce cylinder speed<br />

prior to final positioning.<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

Phone: 1-800-554-8466<br />

Website: www.linearactuators.com<br />

<strong>TN</strong>-D-10-5A: 1:1 Timing Belt, 5 rev/inch Acme Screw<br />

<strong>TN</strong>-D-10L-5A: 1:1 Inline Coupling, 5 rev/inch Acme Screw<br />

Min. Backdrive Load 100 lbs 445 N<br />

Max. No-Load Accel. 100 in/s2 2540 mm/s2<br />

Repeatability ±0.005 in ±0.127 mm<br />

<strong>TN</strong>-D-15-5A: 1.5:1 Timing Belt, 5 rev/inch Acme Screw<br />

Min. Backdrive Load 100 lbs 445 N<br />

Max. No-Load Accel. 80 in/s2 2032 mm/s2<br />

Repeatability ±0.005 in ±0.127 mm<br />

<strong>TN</strong>-D-20-5A: 2:1 Timing Belt, 5 rev/inch Acme Screw<br />

Min. Backdrive Load 100 lbs 445 N<br />

Max. No-Load Accel. 70 in/s2 1778 mm/s2<br />

Repeatability ±0.005 in ±0.127 mm<br />

<strong>TN</strong>-D-31-5A: 3.1:1 Helical Gear, 5 rev/inch Acme Screw<br />

Min. Backdrive Load 100 lbs 445 N<br />

Max. No-Load Accel. 40 in/s2 1016 mm/s2<br />

Repeatability ±0.005 in ±0.127 mm<br />

<strong>TN</strong>-D-120-5A: 12:1 Helical Gear, 5 rev/inch Acme Screw<br />

Min. Backdrive Load 100 lbs 445 N<br />

Max. No-Load Accel. 13 in/s2 330 mm/s2<br />

Repeatability ±0.005 in ±0.127 mm<br />

Consider leadscrew critical speed and column load limits when specifying longer lengths.<br />

5A<br />

15.0<br />

2 thru 12<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

n/a<br />

13.8 Critical Speed (in/sec)<br />

18-DB<br />

n/a<br />

Stroke (in)<br />

Column Load Limit (lb)<br />

*

Phone: 1-800-554-8466<br />

Website: www.linearactuators.com<br />

Acme Screw Models<br />

Speed<br />

Speed<br />

Speed<br />

Speed<br />

mm/s in/s<br />

254 10.0<br />

203<br />

152<br />

102<br />

51<br />

8.0<br />

6.0<br />

4.0<br />

2.0<br />

4<br />

3<br />

2<br />

1<br />

0<br />

0<br />

mm/s in/s<br />

127 5<br />

102<br />

76<br />

51<br />

25<br />

0<br />

0<br />

mm/s in/s<br />

127 5<br />

102<br />

76<br />

51<br />

25<br />

4<br />

3<br />

2<br />

1<br />

0<br />

0<br />

mm/s in/s<br />

64 2.5<br />

51 2.0<br />

38 1.5<br />

25 1.0<br />

13 0.5<br />

Speed<br />

0<br />

mm/s in/s<br />

25 1.0<br />

20 0.8<br />

15 0.6<br />

10 0.4<br />

5 0.2<br />

<strong>TN</strong>-D-10-8A and <strong>TN</strong>-D-10L-8A<br />

60% 30%<br />

10<br />

45<br />

20<br />

89<br />

30<br />

133<br />

Thrust<br />

40<br />

178<br />

50 lbs<br />

222 N<br />

60% 30%<br />

20 40 60 80 100 120 lbs<br />

89 178 267<br />

Thrust<br />

356 445 534 N<br />

60% 30%<br />

50 100 150 200 250 lbs<br />

222 445 667 890 1112 N<br />

Thrust<br />

50<br />

222<br />

<strong>TN</strong>-D-15-8A<br />

<strong>TN</strong>-D-20-8A<br />

<strong>TN</strong>-D-31-8A<br />

60% 30%<br />

100 150<br />

445 667<br />

Thrust<br />

<strong>TN</strong>-D-120-8A<br />

60% 30%<br />

*<br />

200<br />

890<br />

250 lbs<br />

1112 N<br />

0<br />

0 75<br />

334<br />

150<br />

667<br />

225<br />

1001<br />

300 375<br />

1335 1669<br />

450 525<br />

2002 2336<br />

600 lbs<br />

2669 N<br />

Thrust<br />

<strong>Performance</strong> using D2400 Series Controls.<br />

Duty Cycle is percentage of actuator “on time” or movement over<br />

10 minute interval.<br />

Repeatability achievable with D2400 control. Reduce cylinder speed<br />

prior to final positioning.<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

<strong>TN</strong>-D-10-8A: 1:1 Timing Belt, 8 rev/inch Acme Screw<br />

<strong>TN</strong>-D-10L-8A: 1:1 Inline Coupling, 8 rev/inch Acme Screw<br />

Min. Backdrive Load 600 lbs 2669 N<br />

Max. No-Load Accel. 60 in/s2 1524 mm/s2<br />

Repeatability ±0.005 in ±0.127 mm<br />

<strong>TN</strong>-D-15-8A: 1.5:1 Timing Belt, 8 rev/inch Acme Screw<br />

Min. Backdrive Load 600 lbs 2669 N<br />

Max. No-Load Accel. 50 in/s2 1270 mm/s2<br />

Repeatability ±0.005 in ±0.127 mm<br />

<strong>TN</strong>-D-20-8A: 2:1 Timing Belt, 8 rev/inch Acme Screw<br />

Min. Backdrive Load 600 lbs 2669 N<br />

Max. No-Load Accel. 40 in/s2 1016 mm/s2<br />

Repeatability ±0.005 in ±0.127 mm<br />

<strong>TN</strong>-D-31-8A: 3.1:1 Helical Gear, 8 rev/inch Acme Screw<br />

Min. Backdrive Load 600 lbs 2669 N<br />

Max. No-Load Accel. 25 in/s2 635 mm/s2<br />

Repeatability ±0.005 in ±0.127 mm<br />

<strong>TN</strong>-D-120-8A: 12:1 Helical Gear, 8 rev/inch Acme Screw<br />

Min. Backdrive Load 600 lbs 2669 N<br />

Max. No-Load Accel. 8 in/s2 203 mm/s2<br />

Repeatability ±0.005 in ±0.127 mm<br />

Consider leadscrew critical speed and column load limits when specifying longer lengths.<br />

8A<br />

9.4<br />

2 thru 18-DB<br />

n/a<br />

Critical Speed (in/sec)<br />

Stroke (in)<br />

<strong>TN</strong>-D <strong>Performance</strong> <strong>Curves</strong><br />

Column Load Limit (lb)<br />

A-19

Speed<br />

Speed<br />

Speed<br />

<strong>TN</strong>-S/P <strong>Performance</strong> <strong>Curves</strong><br />

Ball Screw Models<br />

Speed<br />

Speed<br />

mm/s in/s<br />

762 30<br />

635 25<br />

508 20<br />

381 15<br />

254 10<br />

127 5<br />

A-20<br />

100%<br />

V (120)<br />

T (240)<br />

0<br />

0 20 40 60 80 100 120<br />

89 178 267<br />

Thrust<br />

356 445 534<br />

©2003 Danaher Motion. Printed in the U.S.A. The specifications in this publication are believed to be accurate and reliable.<br />

However, it is the responsibility of the product user to determine the suitability of Thomson products for a specific application.<br />

While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.<br />

* Trademark of Danaher Motion. DANAHER MOTION is registered in the U.S. Patent and Trademark Office and in other countries.<br />

lbs<br />

N<br />

mm/s in/s<br />

457 18<br />

0<br />

0 180<br />

801<br />

Thrust<br />

lbs<br />

406 16<br />

356 14<br />

305 12<br />

254<br />

203<br />

10<br />

8<br />

V (120)<br />

T (240)<br />

152<br />

102<br />

6<br />

4<br />

100%<br />

51 2<br />

20<br />

89<br />

40<br />

178<br />

60<br />

267<br />

80<br />

356<br />

100<br />

445<br />

120<br />

534<br />

140<br />

623<br />

160<br />

712 N<br />

mm/s in/s<br />

356 14<br />

305 12<br />

254 10<br />

203 8<br />

152 6<br />

102 4<br />

51 2<br />

mm/s in/s<br />

635 25<br />

508<br />

381<br />

254<br />

127<br />

100%<br />

V (120)<br />

T (240)<br />

0<br />

0 50<br />

222<br />

100<br />

445<br />

150<br />

667<br />

200<br />

890<br />

250 lbs<br />

1112 N<br />

Thrust<br />

20<br />

15<br />

10<br />

5<br />

mm/s in/s<br />

762 30<br />

635 25<br />

508 20<br />

381 15<br />

254 10<br />

127 5<br />

<strong>TN</strong>-P22(T/V)-10-2B<br />

<strong>TN</strong>-P22(T/V)-10L-2B<br />

<strong>TN</strong>-P22(T/V)-15-2B<br />

<strong>TN</strong>-P22(T/V)-20-2B<br />

<strong>TN</strong>-S32(T/V)-10-2B<br />

<strong>TN</strong>-S32(T/V)-10L-2B<br />

60%<br />

100%<br />

0<br />

0 20 40 60 80 100<br />

89 178 267 356<br />

Thrust<br />

445<br />

V<br />

T<br />

120<br />

534<br />

<strong>TN</strong>-S32(T/V)-15-2B<br />

100%<br />

V (120)<br />

T (240)<br />

140<br />

623<br />

24"<br />

160 lbs<br />

712 N<br />

0<br />

0 20 40 60 80 100 120<br />

89 178 267<br />

Thrust<br />

356 445 534<br />