The KIC Group Product Catalog

The KIC Group Product Catalog

The KIC Group Product Catalog

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

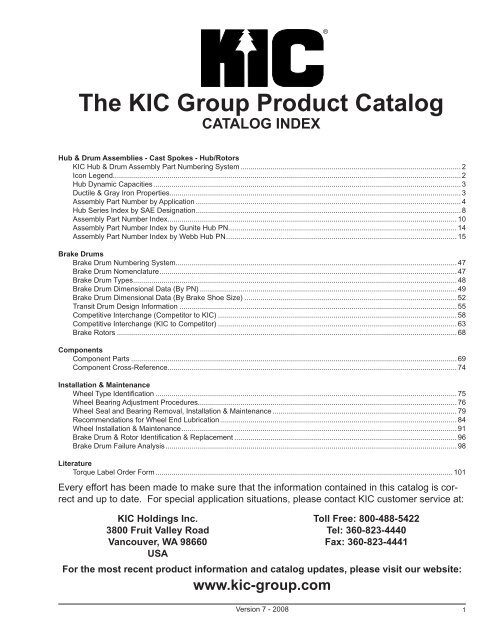

®<strong>The</strong> <strong>KIC</strong> <strong>Group</strong> <strong>Product</strong> <strong>Catalog</strong>CATALOG INDEXHub & Drum Assemblies - Cast Spokes - Hub/Rotors<strong>KIC</strong> Hub & Drum Assembly Part Numbering System............................................................................................................. 2Icon Legend............................................................................................................................................................................ 2Hub Dynamic Capacities........................................................................................................................................................ 3Ductile & Gray Iron Properties................................................................................................................................................ 3Assembly Part Number by Application.................................................................................................................................... 4Hub Series Index by SAE Designation................................................................................................................................... 8Assembly Part Number Index............................................................................................................................................... 10Assembly Part Number Index by Gunite Hub PN................................................................................................................. 14Assembly Part Number Index by Webb Hub PN.................................................................................................................. 15Brake DrumsBrake Drum Numbering System........................................................................................................................................... 47Brake Drum Nomenclature................................................................................................................................................... 47Brake Drum Types................................................................................................................................................................ 48Brake Drum Dimensional Data (By PN)................................................................................................................................ 49Brake Drum Dimensional Data (By Brake Shoe Size).......................................................................................................... 52Transit Drum Design Information.......................................................................................................................................... 55Competitive Interchange (Competitor to <strong>KIC</strong>)....................................................................................................................... 58Competitive Interchange (<strong>KIC</strong> to Competitor)....................................................................................................................... 63Brake Rotors......................................................................................................................................................................... 68ComponentsComponent Parts.................................................................................................................................................................. 69Component Cross-Reference............................................................................................................................................... 74Installation & MaintenanceWheel Type Identification...................................................................................................................................................... 75Wheel Bearing Adjustment Procedures................................................................................................................................ 76Wheel Seal and Bearing Removal, Installation & Maintenance............................................................................................ 79Recommendations for Wheel End Lubrication..................................................................................................................... 84Wheel Installation & Maintenance........................................................................................................................................ 91Brake Drum & Rotor Identification & Replacement............................................................................................................... 96Brake Drum Failure Analysis................................................................................................................................................ 98LiteratureTorque Label Order Form................................................................................................................................................... 101Every effort has been made to make sure that the information contained in this catalog is correctand up to date. For special application situations, please contact <strong>KIC</strong> customer service at:<strong>KIC</strong> Holdings Inc.3800 Fruit Valley RoadVancouver, WA 98660USAToll Free: 800-488-5422Tel: 360-823-4440Fax: 360-823-4441For the most recent product information and catalog updates, please visit our website:www.kic-group.comVersion 7 - 2008

<strong>KIC</strong> Hub & Drum Assembly Part Numbering SystemNotes: This catalog is divided into sections by axle spindle type. Each hub is listed by thehub casting (which determines bolt circle, bearing spacing etc.) Option codes are listed below.For options or configurations not listed here, please contact <strong>KIC</strong> Engineering or your local <strong>KIC</strong>distributor.<strong>KIC</strong> Hub & Drum Assembly Nomenclature0 0 1 0 0 1 2 5 L T NBearing CombinationNumber SAE Config. Outer Bearing Inner Bearing00 N HM220 HM2820002 FF/FG 3720 HM220 Hub Series003 FC/FD 3525 39520 0025004 P HM5840 HM5840005 FL 552A 6420 SUFFIX Description Application006 K30/A26 742 752 B Balanced Assembly (assemblies only) Disc/Spk007 A45 6535 772 D Disposable Shipping Nut Disc008 C-22/ROR Y3323 HM2820 F Fill Port with SAE Plug Disc/Spk009 L-Series 39520 47620 G Bearing Cones Included Disc/Spk00 R-Series 572 592A H Rim Clamps, Nuts & Spacer Band Spoke0 FC 25820 JM20700 K Rim Clamps & Nuts Only SpokePRT Part only - No Assemblies L Studs for Aluminum Wheels DiscSVC Hub Machined with Cups OnlyN Fasteners Installed (in Lieu of Shipping Nuts) DiscHUB Hub Machined with Cups & Studs (No Drum)R Recessed Shipping Nut DiscCST Casting OnlyT ABS Tone Ring Disc/SpkX Extra-Long Studs DiscZStemco ® Platinum Performance System TM BearingDisc/SpkCupsExample: 001-00125LTN“N Spindle Configuration, 00125 Series Hub Castingwith 4.79” M22 Studs, Tone Ring, 10 ea. 22mmFlange Nuts Installed, Assembled with Drum”Icon LegendAssembly is available with Stud Piloted (Ball Seat) mountingExample: 004-56807H“P Spindle Configuration, 56807 Series Spoke WheelCasting with Rim Clamps, Nuts & Spacer Band, Assembledwith DrumInterchange and competitors’ design information is based on the best information available at the time of publicationand is to be used as a guide only. Although every care has been taken in order to ensure the accuracy of theseinterchanges, <strong>KIC</strong> does not assume any liability for errors, changes, omissions or for harm resulting therefrom. Itis recommended that all parts be thoroughly checked for proper form, fit and function prior to installation and usageto determine interchangeability.Stemco, Platinum Performance System, are trademarks of STEMCO LPAssembly is available with Hub Piloted (Unimount) mountingCast Spoke Wheel AssemblyABS Ready (Machined for ABS tone ring)Assembly available with Balanced drum (20 in.oz. std.)Hub & Rotor Assembly

Hub Dynamic CapacitiesNOTE:Hub dynamic capacity is based on the weight-bearing capacity of the wheel bearings. Non-standard wheel offsets or specialapplications may affect the weight-bearing capacity of a hub.Please consult with <strong>KIC</strong> customer service and wheel supplier when using non-standard wheel offsets or with off-highway applicationsto determine total weight-bearing capacity of a hub.PrefixSAE Designation/Axle End TypeInner CupInner ConeOuter Bearing CupOuter BearingConeHub DynamicCapacity001 NHM218210HM218248HM212011HM21204912,500 lbs002 FF/FGHM212011HM212049372037827,300 lbs004 PHM518410HM518445HM518410HM51844512,500 lbs005 FL64206461A552A555S10,000 lbs006 K3074274075275915,000 lbs007 W (A45)7727876535658022,500 lbs008 C-22/RORY33213X33213HM218210HM21824812,500 lbs011 FCJM207010JM207049A25820258774,000 lbs<strong>KIC</strong> Hubs and cast-spoke wheels meet or exceed the following specificationsASTM A-536 (Grade 65-45-12)- Standard Specification for Ductile Iron CastingsASTM E-8- Methods of Tension Testing of Metallic MaterialsSAE J434 (Grade 64-45-12) - Automotive Ductile (Nodular) Iron Castings<strong>KIC</strong> standard brake drums meet or exceed the following specifications:ASTM A-159 (Grade G3500b) - Standard Specification for Automotive Gray Cast IronSAE J431 (G11H20b) - Automotive Gray Iron Castings<strong>KIC</strong> 6xxxx brake drums meet or exceed the following specifications:ASTM A-159 (Grade G3000b) - Standard Specification for Automotive Gray Cast IronSAE J431 (G11H18b) - Automotive Gray Iron Castings<strong>KIC</strong> material property testing is governed by:ASTM A-48 - Standard Tensile Specifications for Gray Iron CastingsASTM E-8 - Standard Test Methods for Tension TestingASTM E-10 - Hardness Testing ProcedureASTM A-247- Microstructure Evaluation ProcedureDuctile & Gray Iron Properties

Assembly Part Number by ApplicationTrailer - Disc WheelAssembly PNAssembly DescriptionHub Casting DescriptionSAECodeInner CupInner ConeOuter CupOuterCone<strong>Catalog</strong>Page001-00077 Stud Pilot, BSF RH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204916001-00078 Stud Pilot, BSF LH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204916001-00085 JIS, 285mm B.C., M20 X 1.5 RH 16.5 x 7Ductile Iron 8 stud hub w/ 285mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204917001-00086 JIS, 285mm B.C., M20 X 1.5 LH 16.5 x 7Ductile Iron 8 stud hub w/ 285mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204917001-00103 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204916001-00103L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204916001-00104 Hub Pilot, M22 x 3.70 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204916001-00125 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-00125L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-00126 Stud Pilot, 3/4-16 RH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-00127 Stud Pilot, 3/4-16 LH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-00133 Hub Pilot, M22 x 3.94 Stud, 12.25 x 7.5 DrumDuctile Iron 8 stud hub w/ 275mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204922001-00133L Hub Pilot, M22 x 4.79 Stud, 12.25 x 7.5 DrumDuctile Iron 8 stud hub w/ 275mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204922001-00135 Hub Pilot, M22 x 3.94 Stud, 16.5 x 8-5/8 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-00135L Hub Pilot, M22 x 4.79 Stud, 16.5 x 8-5/8 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-00136 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7 DrumDuctile Iron 8 stud hub w/ 275mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204923001-00136L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7 DrumDuctile Iron 8 stud hub w/ 275mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204923001-00225 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7 XHD DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-00225L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7 XHD DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920

Assembly Part Number by ApplicationTrailer - Disc WheelAssembly PNAssembly DescriptionHub Casting DescriptionSAECodeInner CupInner ConeOuter CupOuterCone<strong>Catalog</strong>Page001-00226 Stud Pilot, 3/4-16 RH Stud, 16.5 x 7 XHD DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-00227 Stud Pilot, 3/4-16 LH Stud, 16.5 x 7 XHD DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-01000 Hub Pilot, M22 x 3.94 Stud, 16.5 x 5 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-01000L Hub Pilot, M22 x 4.79 Stud, 16.5 x 5 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-01001 Hub Pilot, M22 x 3.94 Stud, 16.5 x 8-5/8 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-01001L Hub Pilot, M22 x 4.79 Stud, 16.5 x 8-5/8 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-10061 Stud Pilot, 3/4-16 RH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses InboardDrum - Shoulder StudNHM218210HM218248HM212011HM21204918001-10062 Stud Pilot, 3/4-16 LH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses InboardDrum - Shoulder StudNHM218210HM218248HM212011HM21204918001-10511 Stud Pilot, 3/4-16 RH 12.25 x 7.5 DrumDuctile Iron 10 stud hub w/ 8.75 Dia. Bolt Circle. Uses InboardDrum - Shoulder StudNHM218210HM218248HM212011HM21204919001-10512 Stud Pilot, 3/4-16 LH 12.25 x 7.5 DrumDuctile Iron 10 stud hub w/ 8.75 Dia. Bolt Circle. Uses InboardDrum - Shoulder StudNHM218210HM218248HM212011HM21204919004-00130 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844534004-00130L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844534004-00131 Stud Pilot, 3/4-16 RH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844534004-00132 Stud Pilot, 3/4-16 LH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844534004-00143 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844535004-00143L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844535004-00145 Hub Pilot, M22 x 3.94 Stud, 12.25 x 7.5 DrumDuctile Iron 8 stud hub w/ 275mm Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844536004-00146 Hub Pilot, M22 x 3.94 Stud, 16.5 x 8-5/8 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844535004-00147 Hub Pilot, M22 x 3.94 Stud, 16.5 x 8-5/8 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844534

Assembly Part Number by ApplicationTrailer - Disc WheelAssembly PNAssembly DescriptionHub Casting DescriptionSAECodeInner CupInner ConeOuter CupOuterCone<strong>Catalog</strong>Page004-00148 Hub Pilot, M22 x 3.94 Stud, 16.5 x 8-5/8 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844535004-00148L Hub Pilot, M22 x 4.79 Stud, 16.5 x 8-5/8 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844535004-00150 Stud Pilot, 3/4-16 RH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844535004-00151 Stud Pilot, 3/4-16LH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844535004-40077 Stud Pilot, BSF RH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studPHM518410HM518445HM518410HM51844533004-40078 Stud Pilot, BSF LH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studPHM518410HM518445HM518410HM51844533004-40103 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studPHM518410HM518445HM518410HM51844532004-40103L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studPHM518410HM518445HM518410HM51844532006-02133 Hub Pilot, M22 x 3.94 Stud, 16.5 x 8-5/8 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studK30 74274075275939006-02133L Hub Pilot, M22 x 4.79 Stud, 16.5 x 8-5/8 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studK30 74274075275939006-02134 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studK30 74274075275940006-02134L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studK30 74274075275940006-02135 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studK30 74274075275939006-02135L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studK30 74274075275939006-02136 Stud Pilot, 3/4-16 RH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studK30 74274075275940006-02137 Stud Pilot, 3/4-16 LH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studK30 74274075275940

Assembly Part Number by ApplicationTrailer - Cast Spoke WheelAssembly PNAssembly DescriptionHub Casting DescriptionSAECodeInner CupInner ConeOuter CupOuter Cone<strong>Catalog</strong>Page001-70003 3-Spoke x 15 Wheel, 12.25 x 7.5 DrumDuctile Iron 3-spoke 15NHM218210HM218248HM212011HM21204925001-75207 5-Spoke x 20 16.5 x 7 Brake DrumDuctile Iron 5-spoke 20NHM218210HM218248HM212011HM21204926001-76207 6-Spoke x 20 16.5 x 7 Brake DrumDuctile Iron 6-spoke 20NHM218210HM218248HM212011HM21204927001-76227 6-Spoke x 22 16.5 x 7 Brake DrumDuctile Iron 6-spoke 22NHM218210HM218248HM212011HM21204928004-56807 6-spoke x 20 - 16.5 x 7 DrumDuctile Iron 6-spoke 20PHM518410HM518445HM518410HM51844537006-90716 6-Spoke x 20, K30, 16.5 x 7 DrumDuctile Iron 6-spoke 20K30 74274075275942006-90718 6-Spoke x 20, K30, 18 x 7 DrumDuctile Iron 6-spoke 20K30 74274075275942006-94016 6-Spoke x 24, K30, 16.5 x 7 DrumDuctile Iron 6-spoke 24K30 74274075275943006-94018 6-Spoke x 24, K30, 18 x 7 DrumDuctile Iron 6-spoke 24K30 74274075275943007-94518 6-Spoke x 24, A45 18 x 7 DrumDuctile Iron 6-spoke 24W (A45) 7727876535658044007-94520 6-Spoke x 24, A45 20x 8 DrumDuctile Iron 6-spoke 24W (A45) 7727876535658044Truck/Trailer - Steer AxleAssembly PNAssembly DescriptionHub Casting DescriptionSAECodeInner CupInner ConeOuter CupOuter Cone<strong>Catalog</strong>Page001-02540L Hub Pilot, M22 x 3.94 Stud, 16.5 x 6 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204924001-02540X Hub Pilot, M22 x 4.25 Stud, 16.5 x 6 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204924001-02541 Stud Pilot, 3/4-16 RH Stud, 16.5 x 6 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204924001-02542 Stud Pilot, 3/4-16 LH Stud, 16.5 x 6 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204924001-02545 Hub Pilot, M22 x 3.70 Stud, 16.5 x 5 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204924001-02545L Hub Pilot, M22 x 3.94 Stud, 16.5 x 5 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204924001-02547 Hub Pilot, M22 x 3.70 Stud, 16.5 x 7 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204924001-02547L Hub Pilot, M22 x 3.94 Stud, 16.5 x 7 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204924

Assembly Part Number by ApplicationTruck/Trailer - Steer AxleAssembly PNAssembly DescriptionHub Casting DescriptionSAECodeInner CupInner ConeOuter CupOuter Cone<strong>Catalog</strong>Page002-00137 Hub Pilot, M22 x 3.70 Stud, 15 x 4 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378229002-00137L Hub Pilot, M22 x 3.94 Stud, 15 x 4 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378229002-00138 Stud Pilot, 3/4-16 RH Stud, 15 x 4 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378229002-00139 Stud Pilot, 3/4-16 LH Stud, 15 x 4 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378229002-00140 BSN RH, 11.25 B.C. 15 x 4 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378230002-00141 BSN LH, 11.25 B.C. 15 x 4 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378230002-00142 Hub Pilot, M22 x 3.70 Stud, 16.5 x 5 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378229002-00142L Hub Pilot, M22 x 3.94 Stud, 16.5 x 5 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378229002-00200 Hub Pilot, M22 x 3.70 Stud, 15 x 4 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378231002-00200L Hub Pilot, M22 x 3.97 Stud, 15 x 4 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378231005-01005L Hub Pilot, M22 x 4.25 Stud, 16.5 x 6 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFL552A555S64206461A38011-04000L Hub Pilot M18 x 3.15 Stud, 12.80 x 4 Drum BalDuctile Iron 6 stud hub w/ 8.07 Dia Bolt Circle. Uses OutboardDrum - Clipped Head StudI80(FC)JM207010JM207049A258202587745011-04100 Hub Pilot M22 x 2.87 Studs, 15 RotorDuctile Iron 8 stud hub w/ 275mm Dia. Bolt Circle. Uses Rotor- Serrated studI80(FC)JM207010JM207049A258202587746Hub Series Index by SAE DesignationPrefixHub SeriesDescriptionSAECodeInner CupInner ConeOuter CupOuterCone<strong>Catalog</strong>Page001 1002 SeriesDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204916001 1004 SeriesDuctile Iron 8 stud hub w/ 285mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204917001 1006 SeriesDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses InboardDrum - Shoulder StudNHM218210HM218248HM212011HM21204918001 1051 SeriesDuctile Iron 10 stud hub w/ 8.75 Dia. Bolt Circle. Uses InboardDrum - Shoulder StudNHM218210HM218248HM212011HM21204919

Hub Series listed by SAE DesignationPrefixHub SeriesDescriptionSAECodeInner CupInner ConeOuter CupOuterCone<strong>Catalog</strong>Page001 125 SeriesDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001 2027 SeriesDuctile Iron 8 stud hub w/ 275mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204922001 2028 SeriesDuctile Iron 8 stud hub w/ 275mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204923001 2540 SeriesDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204924001 7000 SeriesDuctile Iron 3-spoke 15NHM218210HM218248HM212011HM21204925001 75207 SeriesDuctile Iron 5-spoke 20NHM218210HM218248HM212011HM21204926001 76207 SeriesDuctile Iron 6-spoke 20NHM218210HM218248HM212011HM21204927001 76227 SeriesDuctile Iron 6-spoke 22NHM218210HM218248HM212011HM21204928002 137 SeriesDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378229002 1521 SeriesDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378230002 200 SeriesDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378231004 40103 SeriesDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studPHM518410HM518445HM518410HM51844532004 40104 SeriesDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studPHM518410HM518445HM518410HM51844533004 40130 SeriesDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844534004 40143 SeriesDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844535004 40145 SeriesDuctile Iron 8 stud hub w/ 275mm Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844536004 56807 SeriesDuctile Iron 6-spoke 20PHM518410HM518445HM518410HM51844537005 1005 SeriesDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFL552A555S64206461A38006 2133 SeriesDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studK30 74274075275939006 2133 SeriesDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studK30 74274075275939006 2134 SeriesDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studK30 74274075275940

Hub Series Index by SAE DesignationPrefixHub SeriesDescriptionSAECodeInner CupInner ConeOuter CupOuterCone<strong>Catalog</strong>Page006 907 SeriesDuctile Iron 6-spoke 20K30 74274075275942006 940 SeriesDuctile Iron 6-spoke 24K30 74274075275943007 945 SeriesDuctile Iron 6-spoke 24W (A45) 7727876535658044011 4000 SeriesDuctile Iron 6 stud hub w/ 8.07 Dia Bolt Circle. Uses OutboardDrum - Clipped Head StudI80 (FC)JM207010JM207049A258202587745011 4100 SeriesDuctile Iron 8 stud hub w/ 275mm Dia. Bolt Circle. Uses Rotor- Serrated studI80 (FC)JM207010JM207049A258202587746Assembly Part Number IndexAssembly PNAssembly DescriptionHub Casting DescriptionSAECodeInner CupInner ConeOuter CupOuter Cone<strong>Catalog</strong>Page001-00077 Stud Pilot, BSF RH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204916001-00078 Stud Pilot, BSF LH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204916001-00085 JIS, 285mm B.C., M20 X 1.5 RH 16.5 x 7Ductile Iron 8 stud hub w/ 285mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204917001-00086 JIS, 285mm B.C., M20 X 1.5 LH 16.5 x 7Ductile Iron 8 stud hub w/ 285mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204917001-00103 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204916001-00103L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204916001-00104 Hub Pilot, M22 x 3.70 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204916001-00125 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-00125L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-00126 Stud Pilot, 3/4-16 RH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-00127 Stud Pilot, 3/4-16 LH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-00133 Hub Pilot, M22 x 3.94 Stud, 12.25 x 7.5 DrumDuctile Iron 8 stud hub w/ 275mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204922001-00133L Hub Pilot, M22 x 4.79 Stud, 12.25 x 7.5 DrumDuctile Iron 8 stud hub w/ 275mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM2120492210

Assembly Part Number IndexAssembly PNAssembly DescriptionHub Casting DescriptionSAECodeInner CupInner ConeOuter CupOuter Cone<strong>Catalog</strong>Page001-00135 Hub Pilot, M22 x 3.94 Stud, 16.5 x 8-5/8 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-00135L Hub Pilot, M22 x 4.79 Stud, 16.5 x 8-5/8 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-00136 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7 DrumDuctile Iron 8 stud hub w/ 275mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204923001-00136L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7 DrumDuctile Iron 8 stud hub w/ 275mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204923001-00225 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7 XHD DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-00225L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7 XHD DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-00226 Stud Pilot, 3/4-16 RH Stud, 16.5 x 7 XHD DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-00227 Stud Pilot, 3/4-16 LH Stud, 16.5 x 7 XHD DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-01000 Hub Pilot, M22 x 3.94 Stud, 16.5 x 5 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-01000L Hub Pilot, M22 x 4.79 Stud, 16.5 x 5 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-01001 Hub Pilot, M22 x 3.94 Stud, 16.5 x 8-5/8 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-01001L Hub Pilot, M22 x 4.79 Stud, 16.5 x 8-5/8 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204920001-02540L Hub Pilot, M22 x 3.94 Stud, 16.5 x 6 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204924001-02540X Hub Pilot, M22 x 4.25 Stud, 16.5 x 6 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204924001-02541 Stud Pilot, 3/4-16 RH Stud, 16.5 x 6 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204924001-02542 Stud Pilot, 3/4-16 LH Stud, 16.5 x 6 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204924001-02545 Hub Pilot, M22 x 3.70 Stud, 16.5 x 5 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204924001-02545L Hub Pilot, M22 x 3.94 Stud, 16.5 x 5 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204924001-02547 Hub Pilot, M22 x 3.70 Stud, 16.5 x 7 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM21204924001-02547L Hub Pilot, M22 x 3.94 Stud, 16.5 x 7 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studNHM218210HM218248HM212011HM2120492411

Assembly Part Number IndexAssembly PNAssembly DescriptionHub Casting DescriptionSAECodeInner CupInner ConeOuter CupOuter Cone<strong>Catalog</strong>Page001-10061 Stud Pilot, 3/4-16 RH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses InboardDrum - Shoulder StudNHM218210HM218248HM212011HM21204918001-10062 Stud Pilot, 3/4-16 LH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses InboardDrum - Shoulder StudNHM218210HM218248HM212011HM21204918001-10511 Stud Pilot, 3/4-16 RH 12.25 x 7.5 DrumDuctile Iron 10 stud hub w/ 8.75 Dia. Bolt Circle. Uses InboardDrum - Shoulder StudNHM218210HM218248HM212011HM21204919001-10512 Stud Pilot, 3/4-16 LH 12.25 x 7.5 DrumDuctile Iron 10 stud hub w/ 8.75 Dia. Bolt Circle. Uses InboardDrum - Shoulder StudNHM218210HM218248HM212011HM21204919001-70003 3-Spoke x 15 Wheel, 12.25 x 7.5 DrumDuctile Iron 3-spoke 15NHM218210HM218248HM212011HM21204925001-75207 5-Spoke x 20 16.5 x 7 Brake DrumDuctile Iron 5-spoke 20NHM218210HM218248HM212011HM21204926001-76207 6-Spoke x 20 16.5 x 7 Brake DrumDuctile Iron 6-spoke 20NHM218210HM218248HM212011HM21204927001-76227 6-Spoke x 22 16.5 x 7 Brake DrumDuctile Iron 6-spoke 22NHM218210HM218248HM212011HM21204928002-00137 Hub Pilot, M22 x 3.70 Stud, 15 x 4 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378229002-00137L Hub Pilot, M22 x 3.94 Stud, 15 x 4 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378229002-00138 Stud Pilot, 3/4-16 RH Stud, 15 x 4 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378229002-00139 Stud Pilot, 3/4-16 LH Stud, 15 x 4 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378229002-00140 BSN RH, 11.25 B.C. 15 x 4 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378230002-00141 BSN LH, 11.25 B.C. 15 x 4 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378230002-00142 Hub Pilot, M22 x 3.70 Stud, 16.5 x 5 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378229002-00142L Hub Pilot, M22 x 3.94 Stud, 16.5 x 5 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378229002-00200 Hub Pilot, M22 x 3.70 Stud, 15 x 4 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378231002-00200L Hub Pilot, M22 x 3.97 Stud, 15 x 4 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFF/FGHM212011HM2120493720378231004-00130 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844534004-00130L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844534004-00131 Stud Pilot, 3/4-16 RH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM5184453412

Assembly Part Number IndexAssembly PNAssembly DescriptionHub Casting DescriptionSAECodeInner CupInner ConeOuter CupOuter Cone<strong>Catalog</strong>Page004-00132 Stud Pilot, 3/4-16 LH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844534004-00143 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844535004-00143L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844535004-00145 Hub Pilot, M22 x 3.94 Stud, 12.25 x 7.5 DrumDuctile Iron 8 stud hub w/ 275mm Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844536004-00146 Hub Pilot, M22 x 3.94 Stud, 16.5 x 8-5/8 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844535004-00147 Hub Pilot, M22 x 3.94 Stud, 16.5 x 8-5/8 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844534004-00148 Hub Pilot, M22 x 3.94 Stud, 16.5 x 8-5/8 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844535004-00148L Hub Pilot, M22 x 4.79 Stud, 16.5 x 8-5/8 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844535004-00150 Stud Pilot, 3/4-16 RH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844535004-00151 Stud Pilot, 3/4-16LH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses Outboarddrum - Serrated studPHM518410HM518445HM518410HM51844535004-40077 Stud Pilot, BSF RH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studPHM518410HM518445HM518410HM51844533004-40078 Stud Pilot, BSF LH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studPHM518410HM518445HM518410HM51844533004-40103 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studPHM518410HM518445HM518410HM51844532004-40103L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studPHM518410HM518445HM518410HM51844532004-56807 6-spoke x 20 - 16.5 x 7 DrumDuctile Iron 6-spoke 20PHM518410HM518445HM518410HM51844537005-01005L Hub Pilot, M22 x 4.25 Stud, 16.5 x 6 Drum BalDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studFL552A555S64206461A38006-02133 Hub Pilot, M22 x 3.94 Stud, 16.5 x 8-5/8 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studK30 74274075275939006-02133L Hub Pilot, M22 x 4.79 Stud, 16.5 x 8-5/8 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studK30 74274075275939006-02134 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studK30 74274075275940006-02134L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studK30 7427407527594013

Assembly Part Number IndexAssembly PNAssembly DescriptionHub Casting DescriptionSAECodeInner CupInner ConeOuter CupOuter Cone<strong>Catalog</strong>Page006-02135 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studK30 74274075275939006-02135L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses OutboardDrum - Serrated studK30 74274075275939006-02136 Stud Pilot, 3/4-16 RH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studK30 74274075275940006-02137 Stud Pilot, 3/4-16 LH Stud, 16.5 x 7 DrumDuctile Iron 10 stud hub w/ 11.25 Dia. Bolt Circle. Uses OutboardDrum - Serrated studK30 74274075275940006-90716 6-Spoke x 20, K30, 16.5 x 7 DrumDuctile Iron 6-spoke 20K30 74274075275942006-90718 6-Spoke x 20, K30, 18 x 7 DrumDuctile Iron 6-spoke 20K30 74274075275942006-94016 6-Spoke x 24, K30, 16.5 x 7 DrumDuctile Iron 6-spoke 24K30 74274075275943006-94018 6-Spoke x 24, K30, 18 x 7 DrumDuctile Iron 6-spoke 24K30 74274075275943007-94518 6-Spoke x 24, A45 18 x 7 DrumDuctile Iron 6-spoke 24W(A45)7727876535658044007-94520 6-Spoke x 24, A45 20x 8 DrumDuctile Iron 6-spoke 24W(A45)7727876535658044011-04000L Hub Pilot M18 x 3.15 Stud, 12.80 x 4 Drum BalDuctile Iron 6 stud hub w/ 8.07 Dia Bolt Circle. Uses OutboardDrum - Clipped Head StudI80(FC)JM207010JM207049A258202587745011-04100 Hub Pilot M22 x 2.87 Studs, 15 RotorDuctile Iron 8 stud hub w/ 275mm Dia. Bolt Circle. Uses Rotor- Serrated studI80(FC)JM207010JM207049A258202587746Assembly Part Number Index by Gunite Hub PNGunite PN <strong>KIC</strong> PN DescriptionSAEDesignation<strong>Catalog</strong> Page5712-4 001-00125 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7” Drum N 205711-4 001-00125L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7” Drum N 205714RH3 001-00126 Stud Pilot, 3/4-16 RH Stud, 16.5 x 7” Drum N 205714LH3 001-00127 Stud Pilot, 3/4-16 LH Stud, 16.5 x 7” Drum N 205716-3 001-00136 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7” Drum N 235715-3 001-00136L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7” Drum N 23HF850K 001-02540L Hub Pilot, M22 x 3.94 Stud, 16.5 x 6” Drum Bal N 24HF850K 001-02545L Hub Pilot, M22 x 3.94 Stud, 16.5 x 5” Drum Bal N 245721-2 004-00130 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7” Drum P 345719RH2 004-00131 Stud Pilot, 3/4-16 RH Stud, 16.5 x 7” Drum P 345719LH2 004-00132 Stud Pilot, 3/4-16 LH Stud, 16.5 x 7” Drum P 345720-2 004-00143L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7” Drum P 355728 004-56807 6-spoke x 20” - 16.5 x 7” Drum P 37HF805K 005-01005L Hub Pilot, M22 x 4.25 Stud, 16.5 x 6” Drum Bal FL 3814

Assembly Part Number Index by Webb Hub PNWebb PN <strong>KIC</strong> PN DescriptionSAEDesignation<strong>Catalog</strong> Page10069BETL 001-10062 Stud Pilot, 3/4-16 LH Stud, 16.5 x 7” Drum N 1810069BETR 001-10061 Stud Pilot, 3/4-16 RH Stud, 16.5 x 7” Drum N 1810519CLML 001-10512 Stud Pilot, 3/4-16 LH 12.25” x 7.5” Drum N 1910519CLMR 001-10511 Stud Pilot, 3/4-16 RH 12.25” x 7.5” Drum N 1920231UQ3 001-00125 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7” Drum N 2020231UQ5 001-00125L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7” Drum N 2020231UQML 001-00127 Stud Pilot, 3/4-16 LH Stud, 16.5 x 7” Drum N 2020231UQMR 001-00126 Stud Pilot, 3/4-16 RH Stud, 16.5 x 7” Drum N 2020241GRML 001-00086 JIS, 285mm B.C., M20 X 1.5 LH 16.5 x 7” N 1720241GTMR 001-00085 JIS, 285mm B.C., M20 X 1.5 RH 16.5 x 7” N 1720271CW3 001-00133 Hub Pilot, M22 x 3.94 Stud, 12.25 x 7.5” Drum N 2220271CW5 001-00133L Hub Pilot, M22 x 4.79 Stud, 12.25 x 7.5” Drum N 2220281UF3 001-00136 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7” Drum N 2320281UF5 001-00136L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7” Drum N 2320331FJ3 001-00103 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7” Drum N 1620331FJ5 001-00103L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7” Drum N 1620331FJML 001-00078 Stud Pilot, BSF LH Stud, 16.5 x 7” Drum N 1620331FJMR 001-00077 Stud Pilot, BSF RH Stud, 16.5 x 7” Drum N 1622501XQ 011-04100 Hub Pilot M22 x 2.87 Studs, 15” Rotor I80 (FC) 4623231UQ3 004-00130 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7” Drum P 3423231UQ5 004-00130L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7” Drum P 3423231UQML 004-00132 Stud Pilot, 3/4-16 LH Stud, 16.5 x 7” Drum P 3423231UQMR 004-00131 Stud Pilot, 3/4-16 RH Stud, 16.5 x 7” Drum P 3423431JA5 004-00148L Hub Pilot, M22 x 4.79 Stud, 16.5 x 8-5/8” Drum P 3523431UQ3 004-00143 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7” Drum P 3523431UQ5 004-00143L Hub Pilot, M22 x 4.79 Stud, 16.5 x 7” Drum P 3524011UH4 006-02134 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7” Drum K30 4024311FJ3 006-02135 Hub Pilot, M22 x 3.94 Stud, 16.5 x 7” Drum K30 3924331FK3 006-02133 Hub Pilot, M22 x 3.94 Stud, 16.5 x 8-5/8” Drum K30 3925201RX1 002-00137 Hub Pilot, M22 x 3.70 Stud, 15 x 4” Drum Bal FF/FG 2925301KV3 005-01005L Hub Pilot, M22 x 4.25 Stud, 16.5 x 6” Drum Bal FL 3825401KN3 001-02545L Hub Pilot, M22 x 3.94 Stud, 16.5 x 5” Drum Bal N 2425401KV3 001-02540L Hub Pilot, M22 x 3.94 Stud, 16.5 x 6” Drum Bal N 2425401RK3 001-02547L Hub Pilot, M22 x 3.94 Stud, 16.5 x 7” Drum Bal N 245680ZHDH 004-56807 6-spoke x 20” - 16.5 x 7” Drum P 3770159CKH 001-70003 3-Spoke x 15” Wheel, 12.25 x 7.5” Drum N 2575209GCH 001-75207 5-Spoke x 20” 16.5 x 7” Brake Drum N 2676209GCH 001-76207 6-Spoke x 20” 16.5 x 7” Brake Drum N 2776229GCH 001-76227 6-Spoke x 22” 16.5 x 7” Brake Drum N 2815

1002 Series001 - N TYPEItemDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses Outboard Drum - Serrated studSAE Spindle Designation:Inner Bearing Cup:Inner Bearing Cone:Outer Bearing Cup:Outer Bearing Cone:Hub SpecificationsNHM218210HM218248HM212011HM212049Dimensions (in)A: Hub Overall Length 7.06B: Inner Cup to Mtg. Face 4.87C: Distance between cups 3.34D: Tone Ring Bore Dia 6.50E: Tone Ring Bore Depth 0.44J: Bolt Circle 335mm (13.19")K: Hubcap Hole Pattern/Thread 6 Holes 5/16"-18UNC, 5.50 Bolt CircleAssembly OptionsAssembly PNDescriptionLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGStud PNThread StandOutMCup to drumOCup Faceto Mtg. FaceAssyWeight001-00077Stud Pilot, BSF RH Stud, 16.5 x 7" Drum001-00078Stud Pilot, BSF LH Stud, 16.5 x 7" Drum001-00103Hub Pilot, M22 x 3.94 Stud, 16.5 x 7" Drum54250-01 PRT-0002116.50 7.44 11.25 10.59 7/8-11 2.32BSF LH54250-01 PRT-0002216.50 7.44 11.25 10.59 7/8-11 2.32BSF RH54250-01 PRT-0011716.50 7.44 11.25 10.59 M22 x 1.5 2.799.810.789.810.789.810.78177177177001-00103LHub Pilot, M22 x 4.79 Stud, 16.5 x 7" Drum54250-01 PRT-0011816.50 7.44 11.25 10.59 M22 x 1.5 3.649.810.78179001-00104Hub Pilot, M22 x 3.70 Stud, 16.5 x 7" Drum54250-01 PRT-0012116.50 7.44 11.25 10.59 M22 x 1.5 2.559.810.78177Option "T" - ABS RingsDescription Part Number Pitch Diameter100-Tooth Tone Ring PRT-032376.77NOTERefer to “Component Parts” section for fastenerinformation.16

1004 SeriesDuctile Iron 8 stud hub w/ 285mm Dia. Bolt Circle. Uses Outboard Drum - Serrated studSAE Spindle Designation: NInner Bearing Cup: HM218210Inner Bearing Cone: HM218248Outer Bearing Cup: HM212011Outer Bearing Cone: HM212049001 - N TYPEHub SpecificationsItemDimensions (in)A: Hub Overall Length 7.07B: Inner Cup to Mtg. Face 4.87C: Distance between cups 3.34D: Tone Ring Bore Dia 6.50E: Tone Ring Bore Depth 0.43J: Bolt Circle 285mm (11.22")K: Hubcap Hole Pattern/Thread 6 Holes 5/16"-18UNC, 5.50 Bolt CircleAssembly OptionsAssembly PNDescriptionLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGStud PNThread StandOutMCup to drumOCup Faceto Mtg. FaceAssyWeight001-00085JIS, 285mm B.C., M20 X 1.5 RH 16.5 x 7"001-00086JIS, 285mm B.C., M20 X 1.5 LH 16.5 x 7"54247-01 PRT-0002616.50 7.82 9.00 10.61 M20 x 1.5 2.28RH54247-01 PRT-0002516.50 7.82 9.00 10.61 M20 x 1.5 2.28LH9.820.799.820.79160160Option "T" - ABS RingsDescription Part Number Pitch Diameter100-Tooth Tone Ring PRT-032376.77NOTERefer to “Component Parts” section for fastenerinformation.17

1006 Series001 - N TYPEItemDuctile Iron 10 stud hub w/ 11.25" Dia. Bolt Circle. Uses Inboard Drum - Shoulder StudSAE Spindle Designation:Inner Bearing Cup:Inner Bearing Cone:Outer Bearing Cup:Outer Bearing Cone:Hub SpecificationsNHM218210HM218248HM212011HM212049Dimensions (in)A: Hub Overall Length 6.85B: Inner Cup to Mtg. Face 4.65C: Distance between cups 3.34D: Tone Ring Bore Dia 6.50E: Tone Ring Bore Depth 0.50J: Bolt Circle 11.25K: Hubcap Hole Pattern/Thread 6 Holes 5/16"-18UNC, 5.50 Bolt CircleAssembly OptionsAssembly PNDescriptionLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGStud PNThread StandOutMCup to drumOCup Faceto Mtg. FaceAssyWeight001-10061Stud Pilot, 3/4-16 RH Stud, 16.5 x 7" Drum52020-01 PRT-0087416.50 7.63 9.44 9.50 3/4-16 RH 1.356.893.50152001-10062Stud Pilot, 3/4-16 LH Stud, 16.5 x 7" Drum52020-01 PRT-0087516.50 7.63 9.44 9.50 3/4-16 LH 1.356.893.50152Option "T" - ABS RingsDescription Part Number Pitch Diameter100-Tooth Tone Ring PRT-032376.77NOTEUses PRT-00152 LocknutRefer to “Component Parts” section for fastenerinformation.18

1051 SeriesDuctile Iron 10 stud hub w/ 8.75" Dia. Bolt Circle. Uses Inboard Drum - Shoulder StudSAE Spindle Designation: NInner Bearing Cup: HM218210Inner Bearing Cone: HM218248Outer Bearing Cup: HM212011Outer Bearing Cone: HM212049001 - N TYPEHub SpecificationsItemDimensions (in)A: Hub Overall Length 7.06B: Inner Cup to Mtg. Face 4.87C: Distance between cups 3.34D: Tone Ring Bore Dia 6.50E: Tone Ring Bore Depth 0.44J: Bolt Circle 8.75K: Hubcap Hole Pattern/Thread 6 Holes 5/16"-18UNC, 5.50 Bolt CircleAssembly OptionsAssembly PNDescriptionLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGStud PNThread StandOutMCup to drumOCup Faceto Mtg. FaceAssyWeight001-10511Stud Pilot, 3/4-16 RH 12.25" x 7.5" Drum53039-01 PRT-0087412.25 8.31 7.13 10.47 3/4-16 RH 1.4010.560.78118001-10512Stud Pilot, 3/4-16 LH 12.25" x 7.5" Drum53039-01 PRT-0087512.25 8.31 7.13 10.47 3/4-16 LH 1.4010.560.78118Option "T" - ABS RingsDescription Part Number Pitch Diameter80-Tooth Tone Ring PRT-009816.77Note: Uses PRT-00152 LocknutNOTERefer to “Component Parts” section for fastenerinformation.19

125 Series001 - N TYPEItemDuctile Iron 10 stud hub w/ 11.25" Dia. Bolt Circle. Uses Outboard Drum - Serrated studSAE Spindle Designation:Inner Bearing Cup:Inner Bearing Cone:Outer Bearing Cup:Outer Bearing Cone:Hub SpecificationsNHM218210HM218248HM212011HM212049Dimensions (in)A: Hub Overall Length 7.09B: Inner Cup to Mtg. Face 4.87C: Distance between cups 3.34D: Tone Ring Bore Dia 6.50E: Tone Ring Bore Depth 0.44J: Bolt Circle 11.25K: Hubcap Hole Pattern/Thread 6 Holes 5/16"-18UNC, 5.50 Bolt CircleAssembly OptionsAssembly PNDescriptionLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGStud PNThread StandOutMCup to drumOCup Faceto Mtg. FaceAssyWeight001-00125Hub Pilot, M22 x 3.94 Stud, 16.5 x 7" Drum60001-018 PRT-0011716.50 7.56 8.78 10.62 M22 x 1.5 2.719.810.81162001-00125LHub Pilot, M22 x 4.79 Stud, 16.5 x 7" Drum60001-018 PRT-0011816.50 7.56 8.78 10.62 M22 x 1.5 3.569.810.81164001-00126Stud Pilot, 3/4-16 RH Stud, 16.5 x 7" Drum60001-018 PRT-0012016.50 7.56 8.78 10.62 3/4-16 RH 1.349.810.81160001-00127Stud Pilot, 3/4-16 LH Stud, 16.5 x 7" Drum60001-018 PRT-0011916.50 7.56 8.78 10.62 3/4-16 LH 1.349.810.81160001-00135 (See Note)Hub Pilot, M22 x 3.94 Stud, 16.5 x 8-5/8" Drum54727-01 PRT-0011716.50 9.63 8.78 12.39 M22 x 1.5 2.6511.590.80185001-00135L (See Note)Hub Pilot, M22 x 4.79 Stud, 16.5 x 8-5/8" Drum54727-01 PRT-0011816.50 9.63 8.78 12.39 M22 x 1.5 3.5011.590.80187001-00225Hub Pilot, M22 x 3.94 Stud, 16.5 x 7" XHD Drum54261-018 PRT-0011716.50 7.60 8.78 10.59 M22 x 1.5 2.659.790.80176001-00225LHub Pilot, M22 x 4.79 Stud, 16.5 x 7" XHD Drum54261-018 PRT-0011816.50 7.60 8.78 10.59 M22 x 1.5 3.509.790.80178001-00226Stud Pilot, 3/4-16 RH Stud, 16.5 x 7" XHD Drum54261-018 PRT-0012016.50 7.60 8.78 10.59 3/4-16 RH 1.599.790.80176001-00227Stud Pilot, 3/4-16 LH Stud, 16.5 x 7" XHD Drum54261-018 PRT-0011916.50 7.60 8.78 10.59 3/4-16 LH 1.599.790.80176001-01000Hub Pilot, M22 x 3.94 Stud, 16.5 x 5" Drum Bal54257-018 PRT-0011716.50 5.50 8.78 8.56 M22 x 1.5 2.697.790.77150001-01000LHub Pilot, M22 x 4.79 Stud, 16.5 x 5" Drum Bal54257-018 PRT-0011816.50 5.50 8.78 8.56 M22 x 1.5 3.547.790.7715220

125 SeriesAssembly OptionsAssembly PNDescription001-01001001-00125(See Note)Hub Pilot, M22 x 3.94 Stud, 16.5 x 7" DrumHub Pilot, M22 3.94 Stud, 16.5 8-5/8" Drum001-00125L001-01001L (See Note)Hub Pilot, M22 x 4.79 Stud, 16.5 x 7" DrumHub Pilot, M22 4.79 Stud, 16.5 8-5/8" Drum001-00126Stud Pilot, 3/4-16 RH Stud, 16.5 x 7" DrumOption "T" - ABS RingsLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGStud PNThread StandOut60001-01854229-01PRT-00117PRT-0011716.50 7.56 8.78 10.62 M22 x 1.516.50 9.00 8.78 11.39 M22 1.5 2.712.6560001-018 PRT-0011854229-01 PRT-0011816.50 7.56 8.78 10.62 M22 x 1.516.50 9.00 8.78 11.39 M22 1.53.563.5060001-018 PRT-0012016.50 7.56 8.78 10.62 3/4-16 RH 1.34MCup to drumOCup Faceto Mtg. Face10.519.810.810.909.8110.510.810.909.810.81AssyWeight162166164168160001 - N TYPEDescription 001-00127Part Number Pitch Diameter 60001-018 PRT-00119100-Tooth Stud Pilot, Tone 3/4-16 Ring LH Stud, 16.5 PRT-03237 x 7" Drum 16.50 6.77 7.56 8.78 10.62 3/4-16 LH 1.34001-00135 (See Note)54727-01 PRT-00117Hub Pilot, M22 x 3.94 Stud, 16.5 x 8-5/8" Drum 16.50 9.63 8.78 12.39 M22 x 1.5 2.659.810.8111.590.80160185001-00135L (See Note)Hub Pilot, M22 x 4.79 Stud, 16.5 x 8-5/8" Drum54727-01 PRT-0011816.50 9.63 8.78 12.39 M22 x 1.5 3.5011.590.80187001-00225Hub Pilot, M22 x 3.94 Stud, 16.5 x 7" XHD Drum54261-018 PRT-0011716.50 7.60 8.78 10.59 M22 x 1.5 2.659.790.80176001-00225LHub Pilot, M22 x 4.79 Stud, 16.5 x 7" XHD Drum54261-018 PRT-0011816.50 7.60 8.78 10.59 M22 x 1.5 3.509.790.80178001-00226Stud Pilot, 3/4-16 RH Stud, 16.5 x 7" XHD Drum54261-018 PRT-0012016.50 7.60 8.78 10.59 3/4-16 RH 1.59NOTE 001-0022754261-018 PRT-00119Stud Pilot, 3/4-16 LH Stud, 16.5 x 7" XHD Drum 16.50 7.60 8.78 10.59 3/4-16 LH 1.59001-00135 suitable for offset brake shoes001-0100054257-018 PRT-00117001-01001 suitable for centerline brake shoes.Hub Pilot, M22 x 3.94 Stud, 16.5 x 5" Drum Bal 16.50 5.50 8.78 8.56 M22 x 1.5 2.69Refer 001-01000L to “Component Parts” section for fastener 54257-018 PRT-00118information.Hub Pilot, M22 x 4.79 Stud, 16.5 x 5" Drum Bal 16.50 5.50 8.78 8.56 M22 x 1.5 3.549.790.809.790.807.790.777.790.7717617615015221

001 - N TYPE2027 SeriesItemDuctile Iron 8 stud hub w/ 275mm Dia. Bolt Circle. Uses Outboard Drum - Serrated studSAE Spindle Designation:Inner Bearing Cup:Inner Bearing Cone:Outer Bearing Cup:Outer Bearing Cone:Hub SpecificationsNHM218210HM218248HM212011HM212049Dimensions (in)A: Hub Overall Length 7.09B: Inner Cup to Mtg. Face 4.87C: Distance between cups 3.34D: Tone Ring Bore Dia 6.50E: Tone Ring Bore Depth 0.44J: Bolt Circle 275mm (10.83")K: Hubcap Hole Pattern/Thread 6 Holes 5/16"-18UNC, 5.50 Bolt CircleJIGOBCAEPNMDLAssembly OptionsAssembly PNDescriptionLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGStud PNThread StandOutMCup to drumOCup Faceto Mtg. FaceAssyWeight001-00133Hub Pilot, M22 x 3.94 Stud, 12.25 x 7.5" Drum54244-01 PRT-0011712.25 9.84 9.00 11.22 M22 x 1.5 2.6510.440.80127001-00133LHub Pilot, M22 x 4.79 Stud, 12.25 x 7.5" Drum54244-01 PRT-0011812.25 9.84 9.00 11.22 M22 x 1.5 3.5010.440.80129Option "T" - ABS RingsDescription Part Number Pitch Diameter80-Tooth Tone Ring PRT-009816.77NOTERefer to “Component Parts” section for fastenerinformation.22

2028 SeriesDuctile Iron 8 stud hub w/ 275mm Dia. Bolt Circle. Uses Outboard Drum - Serrated studSAE Spindle Designation: NInner Bearing Cup: HM218210Inner Bearing Cone: HM218248Outer Bearing Cup: HM212011Outer Bearing Cone: HM212049001 - N TYPEHub SpecificationsItemDimensions (in)A: Hub Overall Length 7.09B: Inner Cup to Mtg. Face 4.87C: Distance between cups 3.34D: Tone Ring Bore Dia 6.50E: Tone Ring Bore Depth 0.44J: Bolt Circle 275mm (10.83")K: Hubcap Hole Pattern/Thread 6 Holes 5/16"-18UNC, 5.50 Bolt CircleAssembly OptionsAssembly PNDescriptionLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGStud PNThread StandOutMCup to drumOCup Faceto Mtg. FaceAssyWeight001-00136Hub Pilot, M22 x 3.94 Stud, 16.5 x 7" Drum53033-30 PRT-0011716.50 7.63 9.00 10.63 M22 x 1.5 2.659.790.80158001-00136LHub Pilot, M22 x 4.79 Stud, 16.5 x 7" Drum53033-30 PRT-0011816.50 7.63 9.00 10.63 M22 x 1.5 3.509.790.80159Option "T" - ABS RingsDescription Part Number Pitch Diameter100-Tooth Tone Ring PRT-032376.77NOTERefer to “Component Parts” section for fastenerinformation.23

2540 Series001 - N TYPEItemDuctile Iron 10 stud hub w/ 11.25" Dia. Bolt Circle. Uses Outboard Drum - Serrated studSAE Spindle Designation: NInner Bearing Cup: HM218210Inner Bearing Cone: HM218248Outer Bearing Cup: HM212011Outer Bearing Cone: HM212049Hub SpecificationsDimensions (in)A: Hub Overall Length 7.22B: Inner Cup to Mtg. Face 5.04C: Distance between cups 3.34D: Tone Ring Bore Dia 6.50E: Tone Ring Bore Depth 1.14J: Bolt Circle 11.25K: Hubcap Hole Pattern/Thread 6 Holes 5/16"-18UNC, 5.50 Bolt CircleAssembly OptionsAssembly PNDescriptionLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGStud PNThread StandOutMCup to drumOCup Faceto Mtg. FaceAssyWeight001-02540LHub Pilot, M22 x 3.94 Stud, 16.5 x 6" Drum Bal54242-018 PRT-0011716.50 6.47 8.78 9.76 M22 x 1.5 2.364.745.02183001-02540XHub Pilot, M22 x 4.25 Stud, 16.5 x 6" Drum Bal54242-018 PRT-0012216.50 6.47 8.78 9.76 M22 x 1.5 2.654.745.02183001-02541Stud Pilot, 3/4-16 RH Stud, 16.5 x 6" Drum Bal54242-018 PRT-0129416.50 6.47 8.78 9.76 3/4-16 RH 1.524.745.02180001-02542Stud Pilot, 3/4-16 LH Stud, 16.5 x 6" Drum Bal54242-018 PRT-0129516.50 6.47 8.78 9.76 3/4-16 LH 1.524.745.02180001-02545Hub Pilot, M22 x 3.70 Stud, 16.5 x 5" Drum Bal54238-018 PRT-0012116.50 5.29 8.78 9.14 M22 x 1.5 2.124.254.88158001-02545LHub Pilot, M22 x 3.94 Stud, 16.5 x 5" Drum Bal54238-018 PRT-0011716.50 5.29 8.78 9.14 M22 x 1.5 2.364.254.88159001-02547Hub Pilot, M22 x 3.70 Stud, 16.5 x 7" Drum Bal60001-018 PRT-0012116.50 7.56 8.78 10.62 M22 x 1.5 2.235.704.92167001-02547LHub Pilot, M22 x 3.94 Stud, 16.5 x 7" Drum Bal60001-018 PRT-0011716.50 7.56 8.78 10.62 M22 x 1.5 2.475.704.92169Option "T" - ABS RingsDescription Part Number Pitch Diameter100-Tooth Tone Ring PRT-032376.77NOTERefer to “Component Parts” section for fastenerinformation.24

7000 SeriesItemSAE Spindle Designation:Inner Bearing Cup:Inner Bearing Cone:Outer Bearing Cup:Outer Bearing Cone:Spoke Wheel SpecificationsNHM218210HM218248HM212011HM212049Dimensions (in)A: Overall Length 6.97B: Inner Cup to Mtg. Face 4.87C: Distance between cups 3.34D: Tone Ring Bore Dia 6.38E: Tone Ring Bore Depth 0.45J: Bolt Circle 12.50F: Outside Dia 14.37Q: Cup to C/L Wheel track 1.67K: Hubcap Hole Pattern 6 Holes 5/16"-18UNC, 5.50 Bolt CircleDuctile Iron 3-spoke 15"001 - N TYPEAssembly OptionsAssembly PNDescription001-700033-Spoke x 15" Wheel, 12.25 x 7.5" DrumLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGRim Stud PNThread StandOut52743-11 PRT-0011412.25 7.89 8.50 8.88 ¾"-10 2.15MCup to drumOCup Faceto Mtg. Face10.71N/AAssyWeight163Option "T" - ABS RingsDescription Part Number Pitch Diameter80-Tooth Tone Ring PRT-009816.77Spoke Wheel Fasteners & PartsDescription Part Number Qty.Drum Bolt PN PRT-00143 6Locknut PN PRT-00144 6Rim Clamp PN PRT-00123 6Rim Stud PN PRT-00114 6Rim Nut PN PRT-00075 6Spacer PN PRT-04015NOTERefer to “Component Parts” section for fastenerinformation.25

75207 Series001 - N TYPEItemSAE Spindle Designation:Inner Bearing Cup:Inner Bearing Cone:Outer Bearing Cup:Outer Bearing Cone:Spoke Wheel SpecificationsNHM218210HM218248HM212011HM212049Dimensions (in)A: Overall Length 6.93B: Inner Cup to Mtg. Face 4.74C: Distance between cups 3.34D: Tone Ring Bore Dia 6.50E: Tone Ring Bore Depth 0.44J: Bolt Circle 17.5F: Outside Dia 19.37Q: Cup to C/L Wheel track 1.36K: Hubcap Hole Pattern 6 Holes 5/16"-18UNC, 5.50 Bolt CircleDuctile Iron 5-spoke 20"Assembly OptionsAssembly PNDescription001-752075-Spoke x 20" 16.5 x 7" Brake DrumLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGRim Stud PNThread StandOut52230-10 PRT-0011416.50 7.50 9.44 8.39 ¾"-10 2.16MCup to drumOCup Faceto Mtg. Face10.07N/AAssyWeight186Option "T" - ABS RingsDescription Part Number Pitch Diameter100-Tooth Tone Ring PRT-032376.77Spoke Wheel Fasteners & PartsDescription Part Number Qty.Drum Bolt PN PRT-00151 5Locknut PN PRT-00152 5Rim Clamp PN PRT-00123 5Rim Stud PN PRT-00114 5Rim Nut PN PRT-00075 5Spacer PN PRT-04020NOTERefer to “Component Parts” section for fastenerinformation.26

76207 SeriesItemSAE Spindle Designation:Inner Bearing Cup:Inner Bearing Cone:Outer Bearing Cup:Outer Bearing Cone:Spoke Wheel SpecificationsNHM218210HM218248HM212011HM212049Dimensions (in)A: Overall Length 6.93B: Inner Cup to Mtg. Face 4.74C: Distance between cups 3.34D: Tone Ring Bore Dia 6.50E: Tone Ring Bore Depth 0.44J: Bolt Circle 17.50F: Outside Dia 19.37Q: Cup to C/L Wheel track 1.36K: Hubcap Hole Pattern 6 Holes 5/16"-18UNC, 5.50 Bolt CircleDuctile Iron 6-spoke 20"001 - N TYPEAssembly OptionsAssembly PNDescription001-762076-Spoke x 20" 16.5 x 7" Brake DrumLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGRim Stud PNThread StandOut52230-10 PRT-0011416.50 7.50 9.44 8.39 ¾"-10 2.16MCup to drumOCup Faceto Mtg. Face10.07N/AAssyWeight199Option "T" - ABS RingsDescription Part Number Pitch Diameter100-Tooth Tone Ring PRT-032376.77Spoke Wheel Fasteners & PartsDescription Part Number Qty.Drum Bolt PN PRT-00151 6Locknut PN PRT-00152 6Rim Clamp PN PRT-00123 6Rim Stud PN PRT-00114 6Rim Nut PN PRT-00075 6Spacer PN PRT-04020NOTERefer to “Component Parts” section for fastenerinformation.27

76227 Series001 - N TYPEItemSAE Spindle Designation:Inner Bearing Cup:Inner Bearing Cone:Outer Bearing Cup:Outer Bearing Cone:Spoke Wheel SpecificationsNHM218210HM218248HM212011HM212049Dimensions (in)A: Overall Length 7.05B: Inner Cup to Mtg. Face 4.8C: Distance between cups 3.34D: Tone Ring Bore Dia 6.50E: Tone Ring Bore Depth 0.44J: Bolt Circle 19.52F: Outside Dia 21.38Q: Cup to C/L Wheel track 1.36K: Hubcap Hole Pattern 6 Holes 5/16"-18UNC, 5.50 Bolt CircleDuctile Iron 6-spoke 22"Assembly OptionsAssembly PNDescription001-762276-Spoke x 22" 16.5 x 7" Brake DrumLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGRim Stud PNThread StandOut52230-10 PRT-0011416.50 7.50 9.44 8.39 ¾"-10 2.16MCup to drumOCup Faceto Mtg. Face9.95N/AAssyWeight192Option "T" - ABS RingsDescription Part Number Pitch Diameter100-Tooth Tone Ring PRT-032376.77Spoke Wheel Fasteners & PartsDescription Part Number Qty.Drum Bolt PN PRT-00143 6Locknut PN PRT-00144 6Rim Clamp PN PRT-00123 6Rim Stud PN PRT-00114 6Rim Nut PN PRT-00075 6Spacer PN PRT-04022NOTERefer to “Component Parts” section for fastenerinformation.28

137 SeriesDuctile Iron 10 stud hub w/ 11.25" Dia. Bolt Circle. Uses Outboard Drum - Serrated studSAE Spindle Designation: FF/FGInner Bearing Cup: HM212011Inner Bearing Cone: HM212049Outer Bearing Cup: 3720Outer Bearing Cone: 3782Hub SpecificationsItemDimensions (in)A: Hub Overall Length 6.30B: Inner Cup to Mtg. Face 4.43C: Distance between cups 3.37D: Tone Ring Bore Dia 5.52E: Tone Ring Bore Depth 0.67J: Bolt Circle 11.25K: Hubcap Hole Pattern/Thread 6 holes 5/16"-18UNC. 4.50 Bolt Circle002 - FF/FG TYPEAssembly OptionsAssembly PNDescriptionLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGStud PNThread StandOutMCup to drumOCup Faceto Mtg. FaceAssyWeight002-00137Hub Pilot, M22 x 3.70 Stud, 15 x 4" Drum Bal54224-018 PRT-0012115.00 4.77 8.78 8.86 M22 x 1.5 2.363.175.69115002-00137LHub Pilot, M22 x 3.94 Stud, 15 x 4" Drum Bal54224-018 PRT-0011715.00 4.77 8.78 8.86 M22 x 1.5 2.613.175.69118002-00138Stud Pilot, 3/4-16 RH Stud, 15 x 4" Drum Bal54224-018 PRT-0129415.00 4.77 8.78 8.86 3/4-16 RH 1.783.175.69113002-00139Stud Pilot, 3/4-16 LH Stud, 15 x 4" Drum Bal54224-018 PRT-0129515.00 4.77 8.78 8.86 3/4-16 LH 1.783.175.69113002-00142Hub Pilot, M22 x 3.70 Stud, 16.5 x 5" Drum Bal54238-018 PRT-0012116.50 5.29 8.78 9.14 M22 x 1.5 2.363.455.69154002-00142LHub Pilot, M22 x 3.94 Stud, 16.5 x 5" Drum Bal54238-018 PRT-0011716.50 5.29 8.78 9.14 M22 x 1.5 2.613.455.69157002-00144Hub Pilot, M22 x 3.70 Stud, 15 x 4" Drum Bal54282-018 PRT-0012115.00 6.26 8.78 9.47 M22 x 1.5 2.363.175.69122002-00144LHub Pilot, M22 x 3.94 Stud, 15 x 4" Drum Bal54282-018 PRT-0011715.00 6.26 8.78 9.47 M22 x 1.5 2.363.175.69123Option "T" - ABS RingsDescription Part Number Pitch Diameter100-Tooth Tone Ring PRT-009256.46NOTERefer to “Component Parts” section for fastenerinformation.29

1521 SeriesDuctile Iron 10 stud hub w/ 11.25" Dia. Bolt Circle. Uses Outboard Drum - Serrated studSAE Spindle Designation: FF/FGInner Bearing Cup: HM212011Inner Bearing Cone: HM212049Outer Bearing Cup: 3720Outer Bearing Cone: 3782002 - FF/FG TYPEHub SpecificationsItemDimensions (in)A: Hub Overall Length 6.91B: Inner Cup to Mtg. Face 5.30C: Distance between cups 3.40D: Tone Ring Bore Dia 5.52E: Tone Ring Bore Depth 0.67J: Bolt Circle 11.25K: Hubcap Hole Pattern/Thread 6 holes 5/16"-18UNC, 5.50 Bolt CircleAssembly OptionsAssembly PNDescriptionLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGStud PNThread StandOutMCup to drumOCup Faceto Mtg. FaceAssyWeight002-00140BSN RH, 11.25" B.C. 15" x 4" Drum Bal002-00141BSN LH, 11.25" B.C. 15" x 4" Drum Bal54241-018 PRT-0062815.00 4.84 9.00 8.84 1-1/8-16 1.82RH54241-018 PRT-0062715.00 4.84 9.00 8.84 1-1/8-16 1.82LH2.925.922.925.92145145Option "T" - ABS RingsDescription Part Number Pitch Diameter100-Tooth Tone Ring PRT-009256.46NOTERefer to “Component Parts” section for fastenerinformation.30

200 SeriesDuctile Iron 10 stud hub w/ 11.25" Dia. Bolt Circle. Uses Outboard Drum - Serrated studSAE Spindle Designation: FF/FGInner Bearing Cup: HM212011Inner Bearing Cone: HM212049Outer Bearing Cup: 3720Outer Bearing Cone: 3782Hub SpecificationsItemDimensions (in)A: Hub Overall Length 6.25B: Inner Cup to Mtg. Face 5.95C: Distance between cups 3.37D: Tone Ring Bore Dia 5.52E: Tone Ring Bore Depth 0.67J: Bolt Circle 11.25K: Hubcap Hole Pattern/Thread 6 holes 5/16"-18UNC. 4.50 Bolt Circle002 - FF/FG TYPEAssembly OptionsAssembly PNDescriptionLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGStud PNThread StandOutMCup to drumOCup Faceto Mtg. FaceAssyWeight002-00200Hub Pilot, M22 x 3.70 Stud, 15 x 4" Drum Bal54224-018 PRT-0011715.00 4.77 8.78 8.86 M22 x 1.5 2.372.915.95111002-00200LHub Pilot, M22 x 3.97 Stud, 15 x 4" Drum Bal54224-018 PRT-0012215.00 4.77 8.78 8.86 M22 x 1.5 2.682.915.95111Option "T" - ABS RingsDescription Part Number Pitch Diameter100-Tooth Tone Ring PRT-009256.46NOTERefer to “Component Parts” section for fastenerinformation.31

40103 SeriesDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses Outboard Drum - Serrated studSAE Spindle Designation:Inner Bearing Cup:Inner Bearing Cone:Outer Bearing Cup:Outer Bearing Cone:PHM518410HM518445HM518410HM518445004 - P TYPEHub SpecificationsItemDimensions (in)A: Hub Overall Length 9.06B: Inner Cup to Mtg. Face 6.94C: Distance between cups 4.50D: Tone Ring Bore Dia 6.50E: Tone Ring Bore Depth 0.44J: Bolt Circle 335mm (13.19")K: Hubcap Hole Pattern/Thread 6.25 X 8 TPIThreadedAssembly OptionsAssembly PNDescriptionLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGStud PNThread StandOutMCup to drumOCup Faceto Mtg. FaceAssyWeight004-40103Hub Pilot, M22 x 3.94 Stud, 16.5 x 7" Drum54250-01 PRT-0011716.50 7.44 11.25 10.59 M22 x 1.5 2.658.801.79191004-40103LHub Pilot, M22 x 4.79 Stud, 16.5 x 7" Drum54250-01 PRT-0011816.50 7.44 11.25 10.59 M22 x 1.5 3.488.801.79193Option "T" - ABS RingsDescription Part Number Pitch Diameter100-Tooth Tone Ring PRT-032376.77NOTE004-00103 has been superseded by 004-40103Refer to “Component Parts” section for fastenerinformation.32

40104 SeriesDuctile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses Outboard Drum - Serrated studSAE Spindle Designation:Inner Bearing Cup:Inner Bearing Cone:Outer Bearing Cup:Outer Bearing Cone:PHM518410HM518445HM518410HM518445Hub SpecificationsItemDimensions (in)A: Hub Overall Length 9.06B: Inner Cup to Mtg. Face 6.94C: Distance between cups 4.50D: Tone Ring Bore Dia 6.50E: Tone Ring Bore Depth 0.44J: Bolt Circle 335mm (13.19")K: Hubcap Hole Pattern/Thread 6.25 X 8 TPIThreaded004 - P TYPEAssembly OptionsAssembly PNDescriptionLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGStud PNThread StandOutMCup to drumOCup Faceto Mtg. FaceAssyWeight004-40077Stud Pilot, BSF RH Stud, 16.5 x 7" Drum004-40078Stud Pilot, BSF LH Stud, 16.5 x 7" Drum54250-01 PRT-0002216.50 7.44 11.25 10.59 7/8-11 2.32BSF RH54250-01 PRT-0002116.50 7.44 11.25 10.59 7/8-11 2.32BSF LH8.801.798.801.79193193NOTERefer to “Component Parts” section for fastenerinformation.33

40130 SeriesDuctile Iron 10 stud hub w/ 11.25" Dia. Bolt Circle. Uses Outboard drum - Serrated studSAE Spindle Designation:Inner Bearing Cup:Inner Bearing Cone:Outer Bearing Cup:Outer Bearing Cone:PHM518410HM518445HM518410HM518445004 - P TYPEHub SpecificationsItemDimensions (in)A: Hub Overall Length 9.06B: Inner Cup to Mtg. Face 6.94C: Distance between cups 4.50D: Tone Ring Bore Dia 6.50E: Tone Ring Bore Depth 0.44J: Bolt Circle 11.25K: Hubcap Hole Pattern/Thread 6.25 X 8 TPIThreadedAssembly OptionsAssembly PNDescriptionLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGStud PNThread StandOutMCup to drumOCup Faceto Mtg. FaceAssyWeight004-00130Hub Pilot, M22 x 3.94 Stud, 16.5 x 7" Drum60001-018 PRT-0011716.50 7.56 8.78 10.62 M22 x 1.5 2.638.801.82172004-00130LHub Pilot, M22 x 4.79 Stud, 16.5 x 7" Drum60001-018 PRT-0011816.50 7.56 8.78 10.62 M22 x 1.5 3.508.801.82174004-00131Stud Pilot, 3/4-16 RH Stud, 16.5 x 7" Drum60001-018 PRT-0012016.50 7.56 8.78 10.62 3/4-16 RH 1.578.801.82169004-00132Stud Pilot, 3/4-16 LH Stud, 16.5 x 7" Drum60001-018 PRT-0011916.50 7.56 8.78 10.62 3/4-16 LH 1.578.801.82169004-00147Hub Pilot, M22 x 3.94 Stud, 16.5 x 8-5/8" Drum54727-01 PRT-0011716.50 9.63 8.78 12.39 M22 x 1.5 2.638.801.79192Option "T" - ABS RingsDescription Part Number Pitch Diameter100-Tooth Tone Ring PRT-032376.77NOTERefer to “Component Parts” section for fastenerinformation.34

40143 SeriesDuctile Iron 10 stud hub w/ 11.25" Dia. Bolt Circle. Uses Outboard drum - Serrated studSAE Spindle Designation:Inner Bearing Cup:Inner Bearing Cone:Outer Bearing Cup:Outer Bearing Cone:PHM518410HM518445HM518410HM518445Hub SpecificationsItemDimensions (in)A: Hub Overall Length 8.07B: Inner Cup to Mtg. Face 5.96C: Distance between cups 4.50D: Tone Ring Bore Dia 6.50E: Tone Ring Bore Depth 0.35J: Bolt Circle 11.25K: Hubcap Hole Pattern/Thread 6 Holes 5/16"-18UNC, 6.75 Bolt Circle004 - P TYPEAssembly OptionsAssembly PNDescriptionLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGStud PNThread StandOutMCup to drumOCup Faceto Mtg. FaceAssyWeight004-00143Hub Pilot, M22 x 3.94 Stud, 16.5 x 7" Drum60001-018 PRT-0011716.50 7.56 8.78 10.62 M22 x 1.5 2.498.811.81165004-00143LHub Pilot, M22 x 4.79 Stud, 16.5 x 7" Drum60001-018 PRT-0011816.50 7.56 8.78 10.62 M22 x 1.5 3.348.811.81167004-00146Hub Pilot, M22 x 3.94 Stud, 16.5 x 8-5/8" Drum54727-01 PRT-0011716.50 9.63 8.78 12.39 M22 x 1.5 2.5110.631.76189004-00148Hub Pilot, M22 x 3.94 Stud, 16.5 x 8-5/8" Drum54229-01 PRT-0011716.50 9.00 8.78 11.39 M22 x 1.5 2.519.631.76174004-00148LHub Pilot, M22 x 4.79 Stud, 16.5 x 8-5/8" Drum54229-01 PRT-0011816.50 9.00 8.78 11.39 M22 x 1.5 3.369.631.76174004-00150Stud Pilot, 3/4-16 RH Stud, 16.5 x 7" Drum53033-01 PRT-0012016.50 8.00 8.78 10.59 3/4-16 RH 2.518.831.76167004-00151Stud Pilot, 3/4-16LH Stud, 16.5 x 7" Drum53033-01 PRT-0011916.50 8.00 8.78 10.59 3/4-16 LH 2.518.831.76167Option "T" - ABS RingsDescription Part Number Pitch Diameter100-Tooth Tone Ring PRT-032376.77NOTERefer to “Component Parts” section for fastenerinformation.35

40145 SeriesDuctile Iron 8 stud hub w/ 275mm Dia. Bolt Circle. Uses Outboard drum - Serrated studSAE Spindle Designation:Inner Bearing Cup:Inner Bearing Cone:Outer Bearing Cup:Outer Bearing Cone:PHM518410HM518445HM518410HM518445004 - P TYPEHub SpecificationsItemDimensions (in)A: Hub Overall Length 9.06B: Inner Cup to Mtg. Face 6.94C: Distance between cups 4.50D: Tone Ring Bore Dia 6.50E: Tone Ring Bore Depth 0.44J: Bolt Circle 275mm (10.83")K: Hubcap Hole Pattern/Thread 6.25 X 8 TPIThreadedAssembly OptionsAssembly PNDescriptionLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGStud PNThread StandOutMCup to drumOCup Faceto Mtg. FaceAssyWeight004-00145Hub Pilot, M22 x 3.94 Stud, 12.25 x 7.5" Drum54244-01 PRT-0011712.25 9.84 9.00 11.22 M22 x 1.5 2.658.542.66141Option "T" - ABS RingsDescription Part Number Pitch Diameter80-Tooth Tone Ring PRT-009816.77NOTERefer to “Component Parts” section for fastenerinformation.36

56807 SeriesDuctile Iron 6-spoke 20"SAE Spindle Designation:Inner Bearing Cup:Inner Bearing Cone:Outer Bearing Cup:Outer Bearing Cone:PHM518410HM518445HM518410HM518445Spoke Wheel SpecificationsItemDimensions (in)A: Overall Length 9.06B: Inner Cup to Mtg. Face 6.93C: Distance between cups 4.50D: Tone Ring Bore Dia 6.50E: Tone Ring Bore Depth 0.44J: Bolt Circle 17.96F: Outside Dia 19.37Q: Cup to C/L Wheel track 2.59K: Hubcap Hole Pattern 6.25 X 8 TPIThreaded004 - P TYPEAssembly OptionsAssembly PNDescription004-568076-spoke x 20" - 16.5 x 7" DrumLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGRim Stud PNThread StandOut54249-01 PRT-0011416.50 7.49 9.50 8.74 ¾"-10 2.16MCup to drumOCup Faceto Mtg. Face8.80N/AAssyWeight215Option "T" - ABS RingsDescription Part Number Pitch Diameter100-Tooth Tone Ring PRT-032376.77Spoke Wheel Fasteners & PartsDescription Part Number Qty.Drum Bolt PN PRT-00143 6Locknut PN PRT-00144 6Rim Clamp PN PRT-00123 6Rim Stud PN PRT-00114 6Rim Nut PN PRT-00075 6Spacer PN PRT-04020NOTERefer to “Component Parts” section for fastenerinformation.37

005 - FL TYPE1005 SeriesItemDuctile Iron 10 stud hub w/ 11.25" Dia. Bolt Circle. Uses Outboard Drum - Serrated studSAE Spindle Designation: FLInner Bearing Cup: 552AInner Bearing Cone: 555SOuter Bearing Cup: 6420Outer Bearing Cone: 6461AHub SpecificationsDimensions (in)A: Hub Overall Length 7.56B: Inner Cup to Mtg. Face 5.32C: Distance between cups 3.07D: Tone Ring Bore Dia 6.50E: Tone Ring Bore Depth 0.49J: Bolt Circle 11.25K: Hubcap Hole Pattern/Thread 6 Holes 5/16"-18UNC, 5.50 Bolt CircleAssembly OptionsAssembly PNDescriptionLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGStud PNThread StandOutMCup to drumOCup Faceto Mtg. FaceAssyWeight005-01005LHub Pilot, M22 x 4.25 Stud, 16.5 x 6" Drum Bal54248-018 PRT-0012216.50 6.41 8.78 9.76 M22 x 1.5 2.404.864.90170Option "T" - ABS RingsDescription Part Number Pitch Diameter100-Tooth Tone Ring PRT-009356.92NOTERefer to “Component Parts” section for fastenerinformation.38

Ductile Iron 10 stud hub w/ 335mm Dia. Bolt Circle. Uses Outboard Drum - Serrated studSAE Spindle Designation: K30Inner Bearing Cup: 742Inner Bearing Cone: 740Outer Bearing Cup: 752Outer Bearing Cone: 759Hub Specifications2133 SeriesItemDimensions (in)A: Hub Overall Length 8.46B: Inner Cup to Mtg. Face 5.94C: Distance between cups 4.06D: Tone Ring Bore Dia N/AE: Tone Ring Bore Depth N/AJ: Bolt Circle 13.19K: Hubcap Hole Pattern/Thread 6 Holes 5/16"-18UNC., 6.75 BoltCircle005 - FL TYPEAssembly OptionsAssembly PNDescriptionLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGStud PNThread StandOutMCup to drumOCup Faceto Mtg. FaceAssyWeight006-02133Hub Pilot, M22 x 3.94 Stud, 16.5 x 8-5/8" Drum54251-01 PRT-0011716.50 9.15 11.25 12.37 M22 x 1.5 2.4010.641.73187006-02133LHub Pilot, M22 x 4.79 Stud, 16.5 x 8-5/8" Drum54251-01 PRT-0011816.50 9.15 11.25 12.37 M22 x 1.5 3.2610.641.18189006-02135Hub Pilot, M22 x 3.94 Stud, 16.5 x 7" Drum54250-01 PRT-0011716.50 7.44 11.25 10.59 M22 x 1.5 2.418.911.68186006-02135LHub Pilot, M22 x 4.79 Stud, 16.5 x 7" Drum54250-01 PRT-0011816.50 7.44 11.25 10.59 M22 x 1.5 3.268.911.68188NOTERefer to “Component Parts” section for fastenerinformation.39

2134 SeriesDuctile Iron 10 stud hub w/ 11.25" Dia. Bolt Circle. Uses Outboard Drum - Serrated studSAE Spindle Designation: K30Inner Bearing Cup: 742Inner Bearing Cone: 740Outer Bearing Cup: 752Outer Bearing Cone: 759ONMPHub SpecificationsItemDimensions (in)GA: Hub Overall Length 8.47B: Inner Cup to Mtg. Face 5.95C: Distance between cups 4.06D: Tone Ring Bore Dia N/AE: Tone Ring Bore Depth N/AJ: Bolt Circle 11.25K: Hubcap Hole Pattern/Thread 6 Holes 5/16"-18UNC., 6.75 BoltCircleJIKBCADL006 - K30 TYPEAssembly OptionsAssembly PNDescription006-02134Hub Pilot, M22 x 3.94 Stud, 16.5 x 7" DrumLBrakeFace DiaDrum Part NumberPBrakeWidthIHubPilotNOverallDepthGStud PNThread StandOut54261-01 PRT-0011816.50 7.60 8.78 10.59 M22 x 1.5 2.65MCup to drumOCup Faceto Mtg. Face8.991.60AssyWeight148006-02134LHub Pilot, M22 x 4.79" Stud, 16.5 x 7" Drum54261-01 PRT-0011816.50 7.60 8.78 10.59 M22 x 1.5 3.508.991.60150006-02136Stud Pilot, 3/4-16 RH Stud, 16.5 x 7" Drum54261-01 PRT-0012016.50 7.60 8.78 10.59 3/4-16 RH8.991.60148006-02137Stud Pilot, 3/4-16 LH Stud, 16.5 x 7" Drum54261-01 PRT-0011916.50 7.60 8.78 10.59 3/4-16 LH8.991.60148NOTERefer to “Component Parts” section for fastenerinformation.40

This Page Intentionally Left Blank41